Back in the day, bathtubs had a porcelain coating over a cast-iron carcass, so embedding little magnets in shower curtains worked perfectly to keep the loose ends from billowing out of the tub. Surprisingly, even here in the future, with plastic bathtubs ruling the land, some shower curtains still have magnets. The mud-job tile walls of shower stall in the Black Bathroom have nary a trace of iron, but we though I could add ferrous targets for a new shower curtain, thusly:

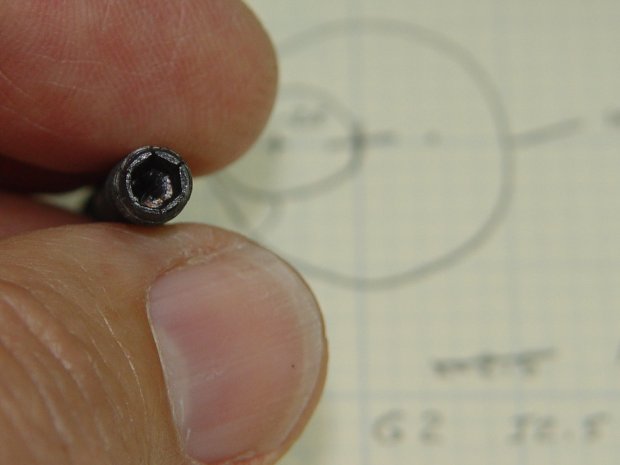

The magnet lives inside a heat-sealed disk, so it’s (more-or-less) isolated from the water. As you’d expect, it’s a cheap ceramic magnet, not a high-performance neodymium super magnet, with no more strength than absolutely necessary to work under the most ideal of conditions.

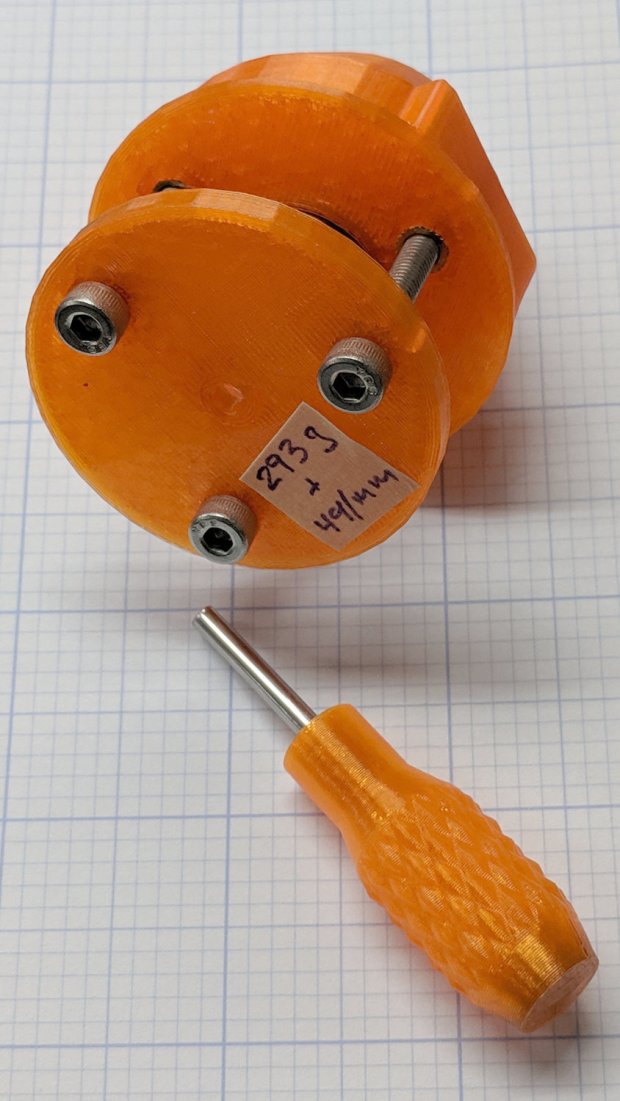

My anchors must also be waterproof, firmly attached, non-marking, easily removable, and no more ugly than absolutely necessary. The general idea is to slice the bottom from a pill bottle, entomb a thin steel disk in epoxy, and attach to the tile with a patch of outdoor-rated foam tape.

So, we begin …

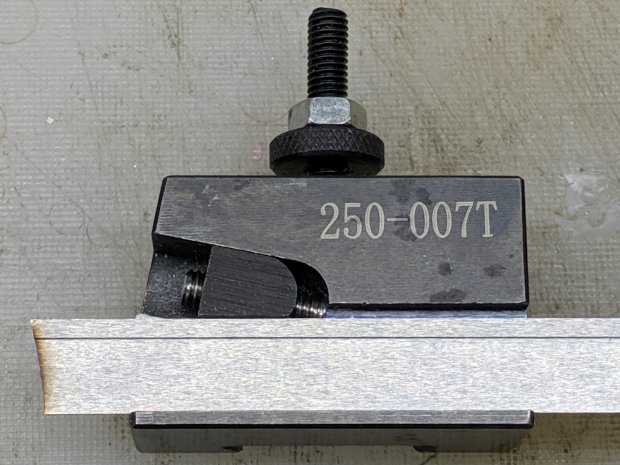

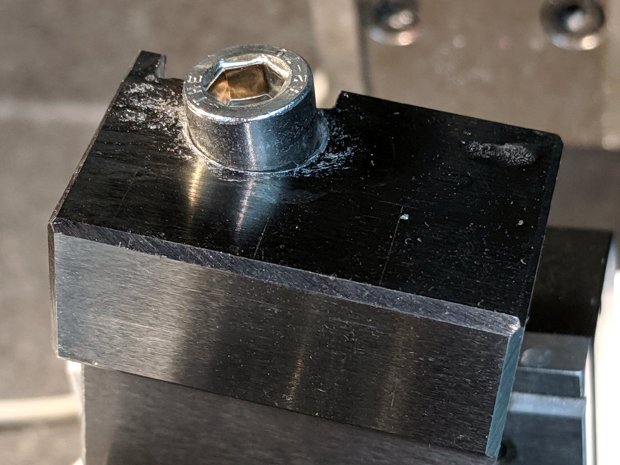

Cutting a narrow ring from a pill bottle requires a collet around the whole circumference, which started life as some sort of stout aluminum pole:

Bore out the inside, with a small step to locate the bottle:

Clean up the outside, just for pretty:

Slit the fixture to let it collapse around the bottle, then chuck up the first victim with support from a conveniently sized drill chuck in the tailstock:

I did a better job of cutting the second bottle to the proper length:

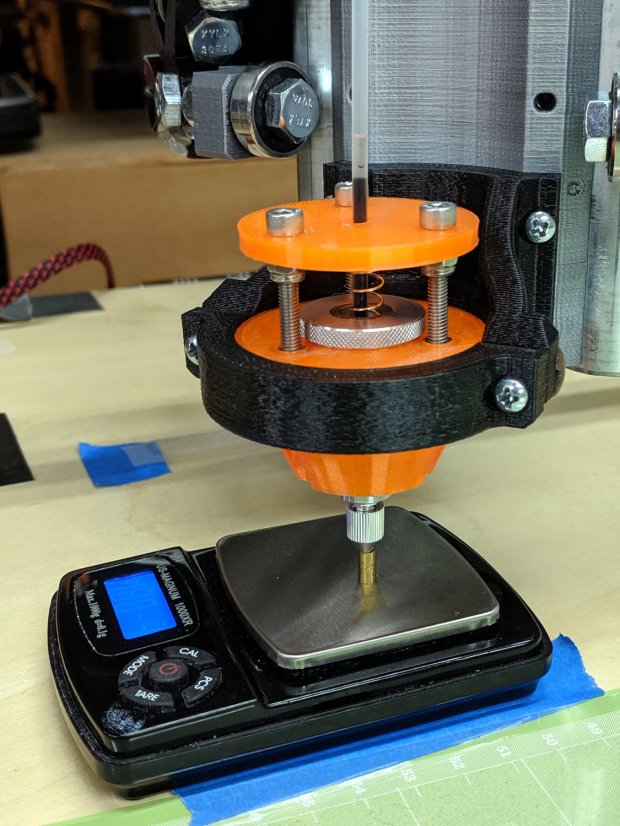

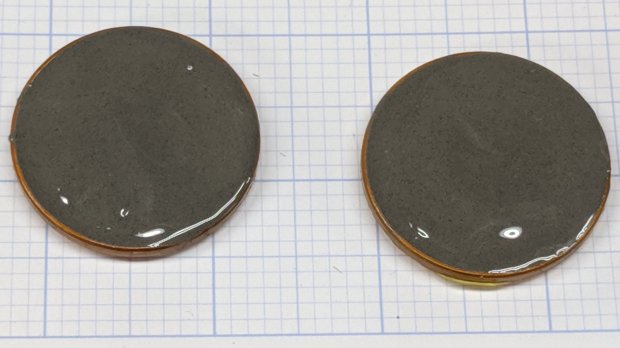

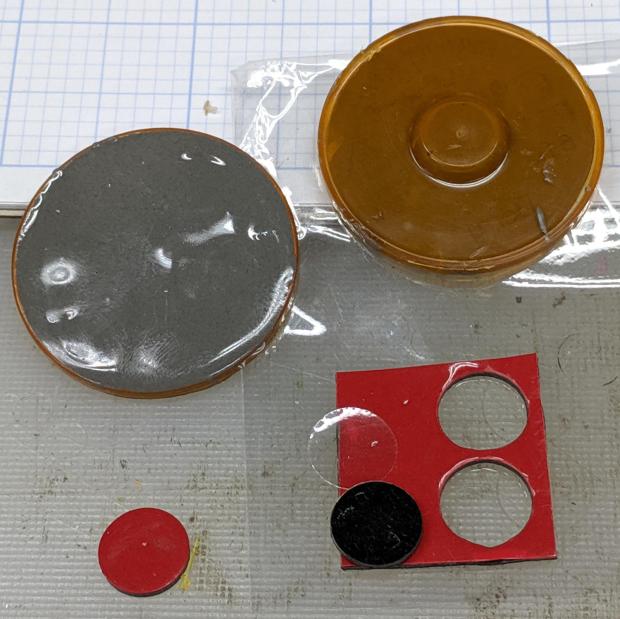

Nibble disks from sheet metal, half-fill the bottle bottoms with steel-filled (and, thus, magnetic!) JB Weld epoxy, insert disks, add sufficient epoxy to cover the evidence:

Fast-forward to the next day, punch out two disks of double-sided foam tape:

Affix, install, and it’s all good.

Actually, it’s not. The ceramic magnets are so weak they don’t hold the curtain nearly well enough to satisfy me. The next anchor iteration should have embedded neodymium magnets to attract the curtain’s crappy ceramic magnets, but this is Good Enough™ for now.