Although our Tour Easy recumbents use ordinary (*) V-brakes, their frame geometry doesn’t route the rear cable quite the way the brake designers expected. Mary’s Medium-Small frame always had its rear brake cable resting against the frame tube, where it bent slightly as she applied the brakes:

That’s looking up from under the rear wheel, with the bike on a workstand, and, yeah, it’s pretty grubby down there.

The squashed rubber boot suggests the brake arms are too close together, but that’s where they must be to hold the brake pads in the proper position, even with new pads and big spacer washers. As a result, the cable stop over on the right at the end of the noodle rests against the frame and dings the paint.

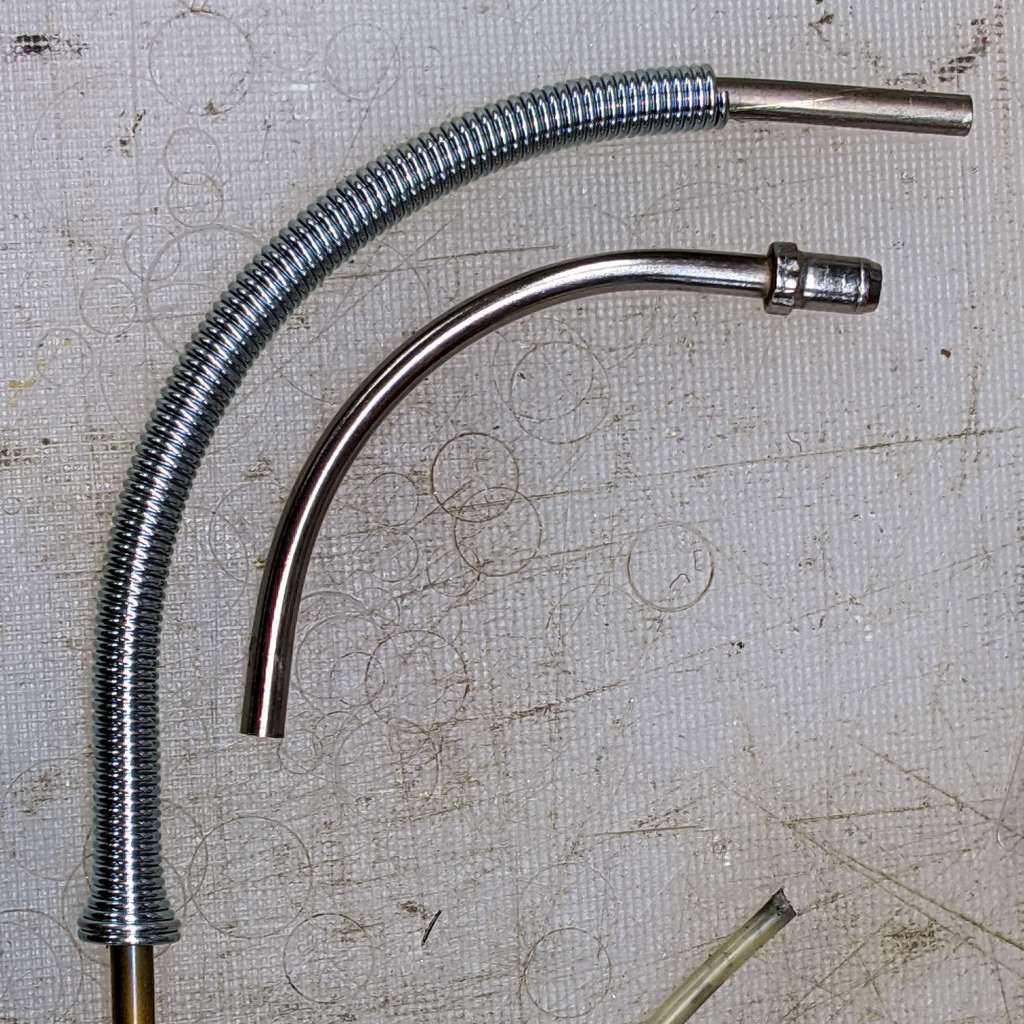

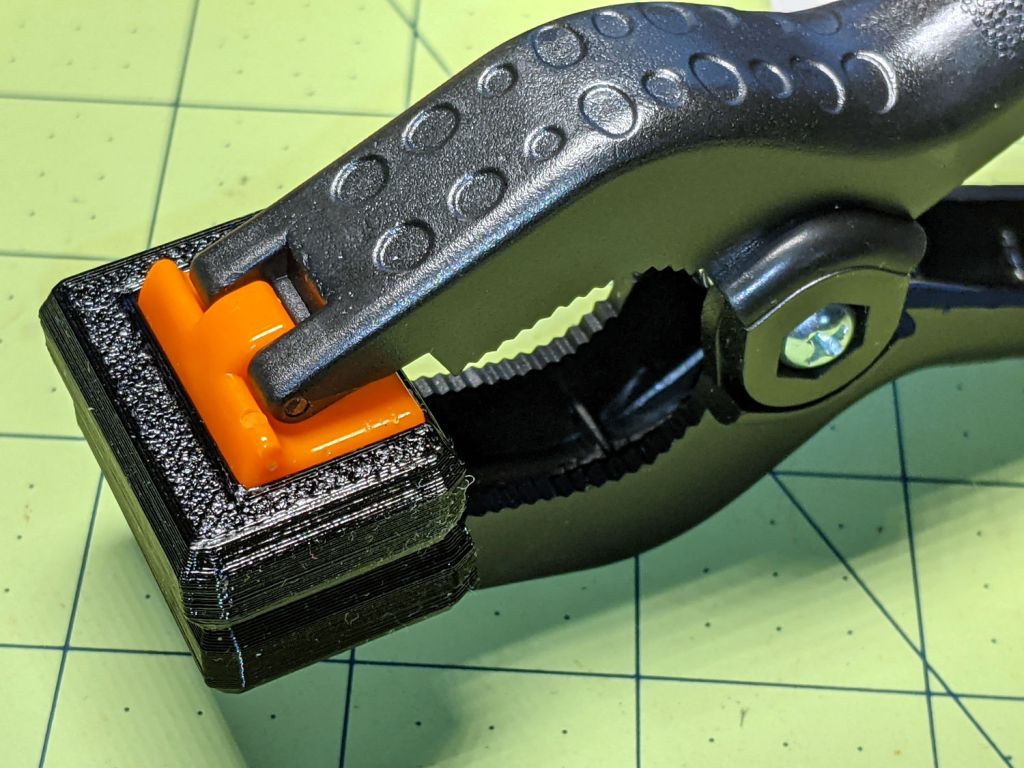

My first thought was to add some length to the end of the noodle inside the stirrup, so I made an adapter with the ID on the noodle end matching the OD on the fitting end:

Which worked poorly, because the noodle has a straight section leading up to the fitting inside the stirrup; any additional length pushes the noodle curve against the stirrup pivot and cants it out of line:

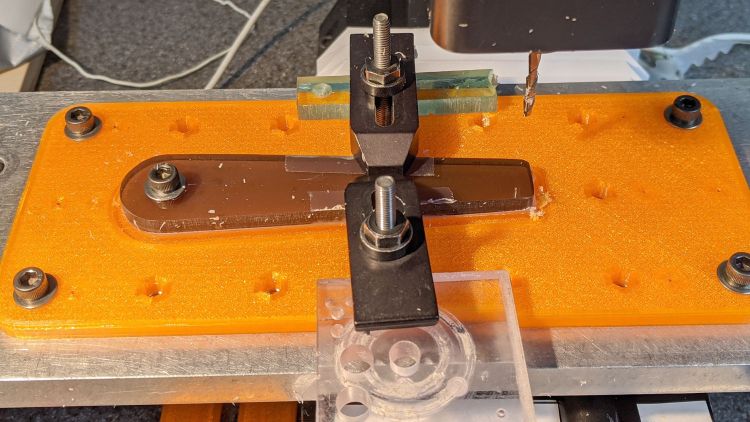

I’ve been avoiding the fallback plan of building a bigger noodle for years, but finally combined a foot of 3/32 inch brass tubing, a tube bender spring, and various large-diameter round-ish objects from the Basement Warehouse Wing:

I annealed the tube by running a torch along its length until the color changed to the obvious “I’m hot enough” copper color, then let it air-cool while I did something else. Brass work-hardens quickly and required two more annealings while finishing that smooth curve; as far as I know, brass doesn’t harden with the heat-and-quench cycle used for steel.

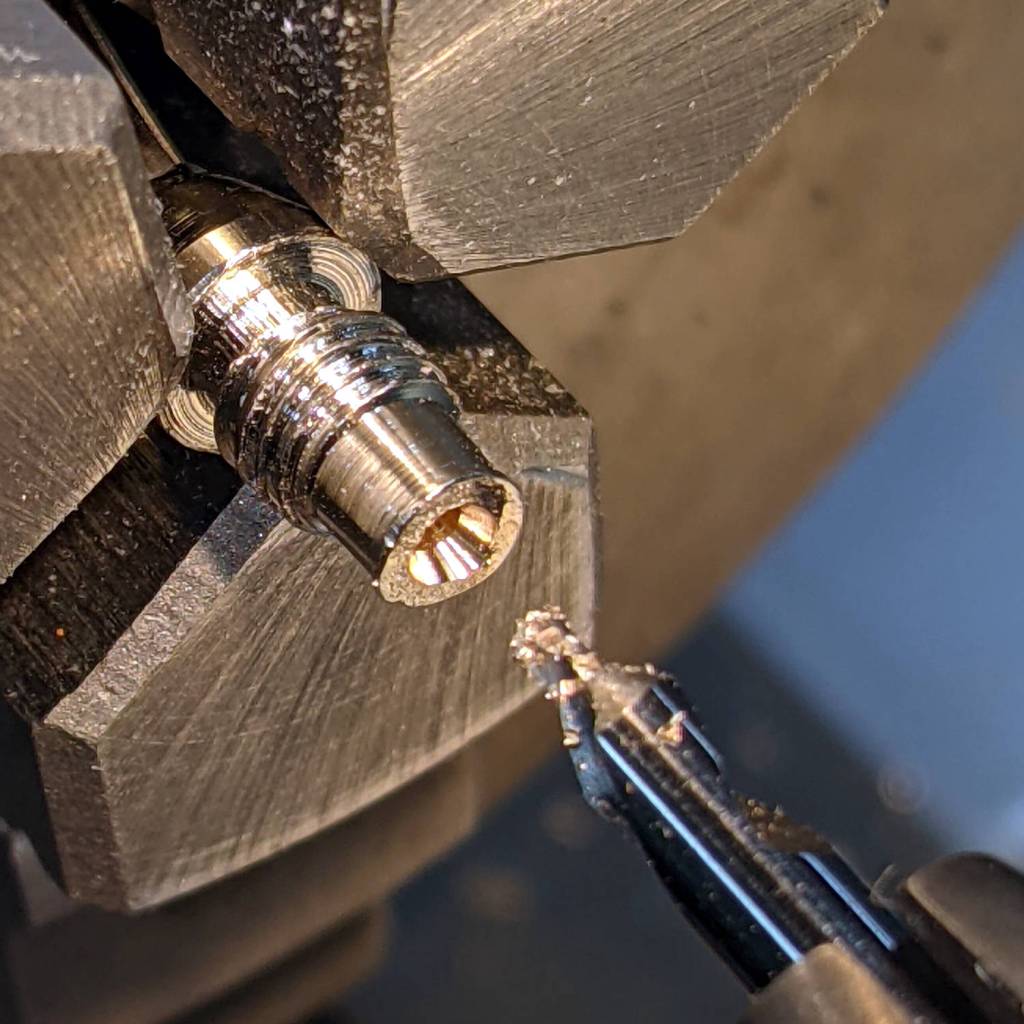

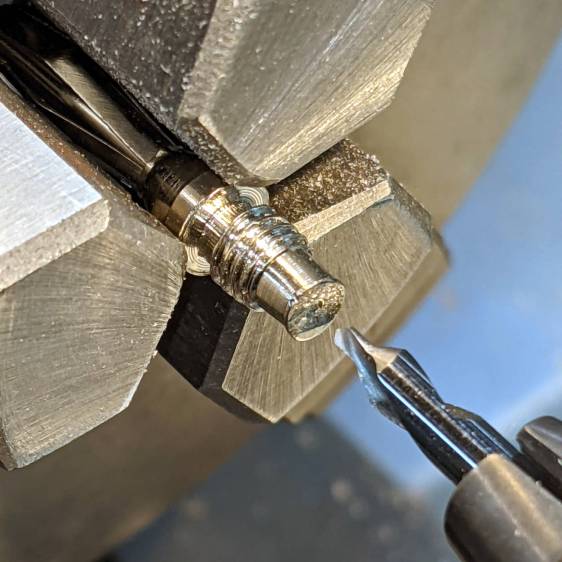

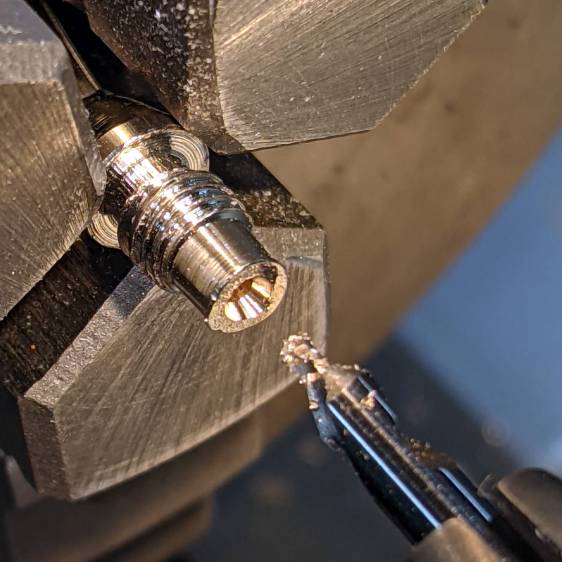

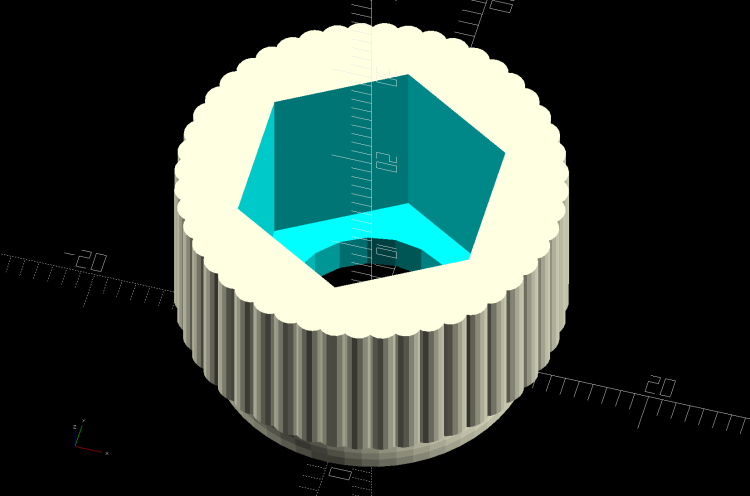

A little more lathe work produced a replacement fitting:

The hole is barely one diameter deep, but I think it’ll align the tube well enough for my simple needs. The failure will most likely involve having the cable chew through the inward side of the mis-aligned tube, which should become obvious in short order.

The fitting on the OEM noodle seems to be crimped in place, but I figure my version is unlikely to fall off in normal use:

Lined up thusly, you can see the reduced straight section behind my fitting and the much larger sweep out to the cable stop.

The OEM noodle had a (presumably) PTFE liner, so I adapted a length of PTFE brake cable liner by mashing the end with various conical objects until it kinda-sorta looked like the cable stop might capture the ragged flange:

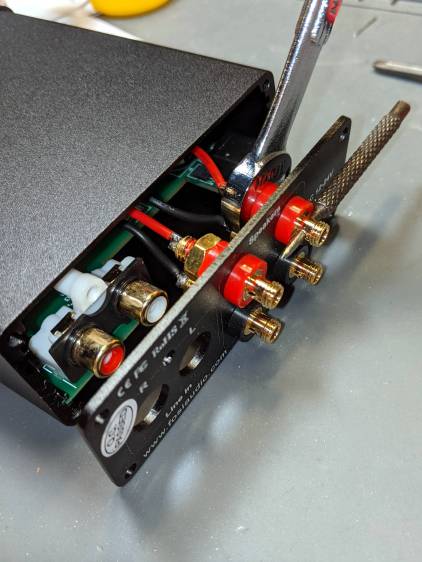

Reassembling in reverse order produces a comforting sight:

Despite appearances, the new noodle sits below the frame and well above the chain in normal use. In the most extreme small-small cross gearing position the chain barely clears it, but the takeup arm on the rear derailleur starts clattering enough to remind us not to do that.

Brass is certainly not as strong as stainless (?) steel, although I think it ended up in a reasonably hard condition after all the bending. I’m certain neither of us can squeeze the brake lever enough to come anywhere close to causing a problem.

Making a noodle was easier than I expected and, in a month or so, we’ll see how it behaves under actual riding conditions.

(*) “Ordinary” as of many decades ago, because the design dates back to the mid-70s, when Fast Freddy Markham broke 65 mph on a rather customized Easy Racers Gold Rush.