This is the season for erecting the structures upon which the pole beans will climb:

They’re made from a dozen small trees and branches of larger trees harvested around the yard. They last for a few years, just long enough for the next crop to reach useful lengths.

We lash them together with fabric strips:

My knot hand is weak, but seems sufficient to the task.

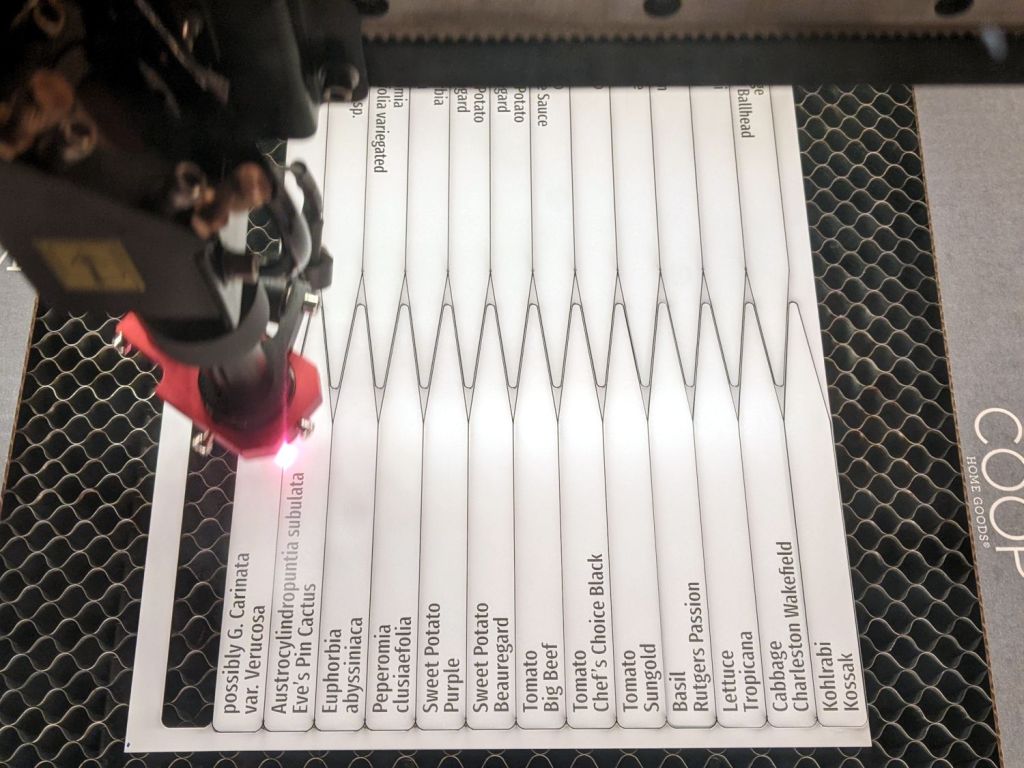

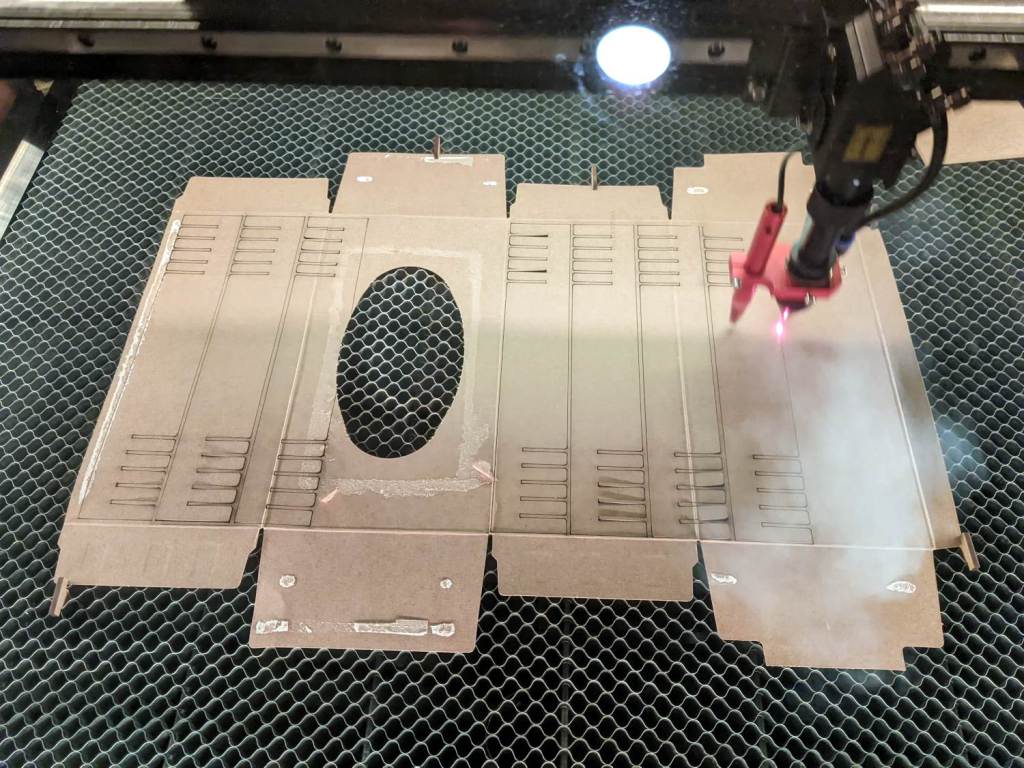

Mary formerly tore the strips from old jeans / pants / whatever, which required considerable effort, produced ragged edges, and filled the air with fabric dust. This year, I proposed an alternative:

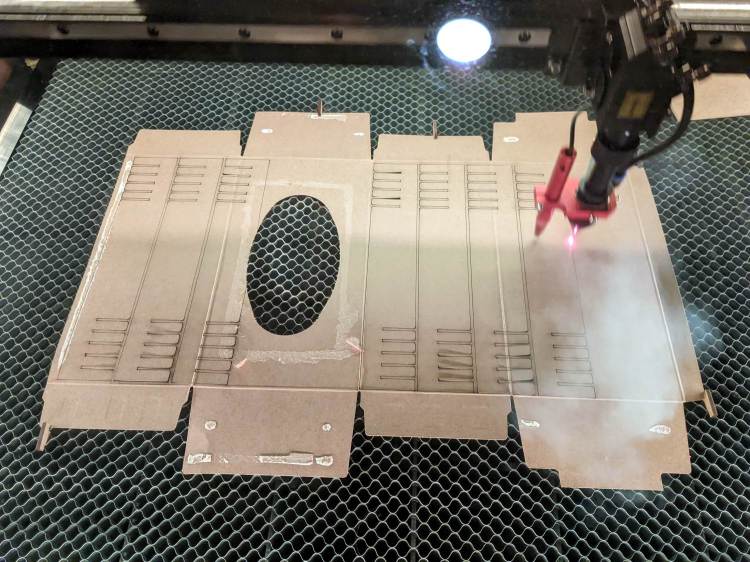

The weird thing in the middle is a reflection of an overhead can light in the laser cabinet’s polycarb lid.

From starting the LightBurn layout to presenting the strips for final inspection required the better part of ten minutes. I scissors-cut along the main seams to get single fabric layers, with everything above the crotch seam wadded off the platform to the left.

As with my shop raglets, the layout depends on LightBurn’s overhead camera view to align the cuts with the fabric on the platform:

It’d be easier to see with lighter fabric, but that’s what came to hand in the scrap box and the beans won’t care. We do not anticipate complaints about the odor of charred fabric when they reach the top of the poles, either.

The strips must align with the fabric’s grain to put the warp threads along their length, which makes the main side seam parallel to the X-axis. Even I can handle that layout!

Yes, the strips have rounded corners and, no, it doesn’t matter.