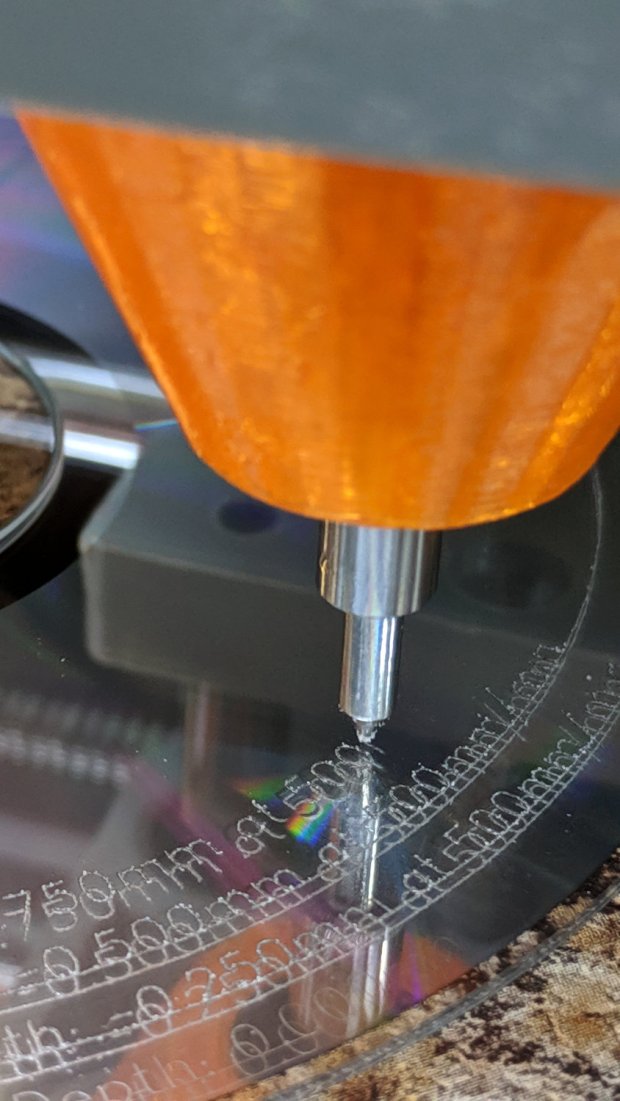

The smaller and more rigid CNC 3018-Pro should be able to engrave text faster than the larger and rather springy MPCNC, which could engrave text at about 50 mm/min. This test pattern pushes both cutting depth and engraving speed to absurd values:

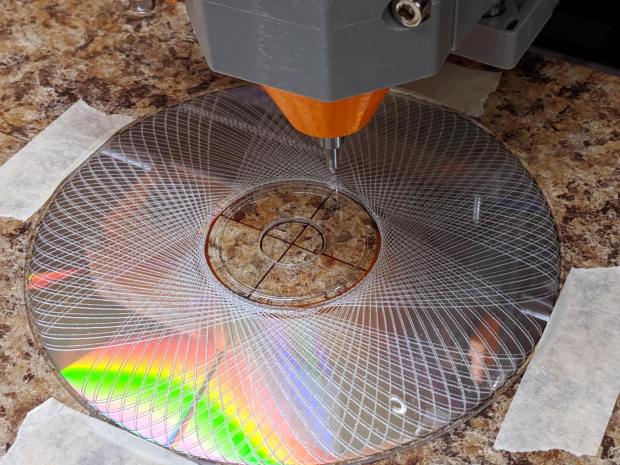

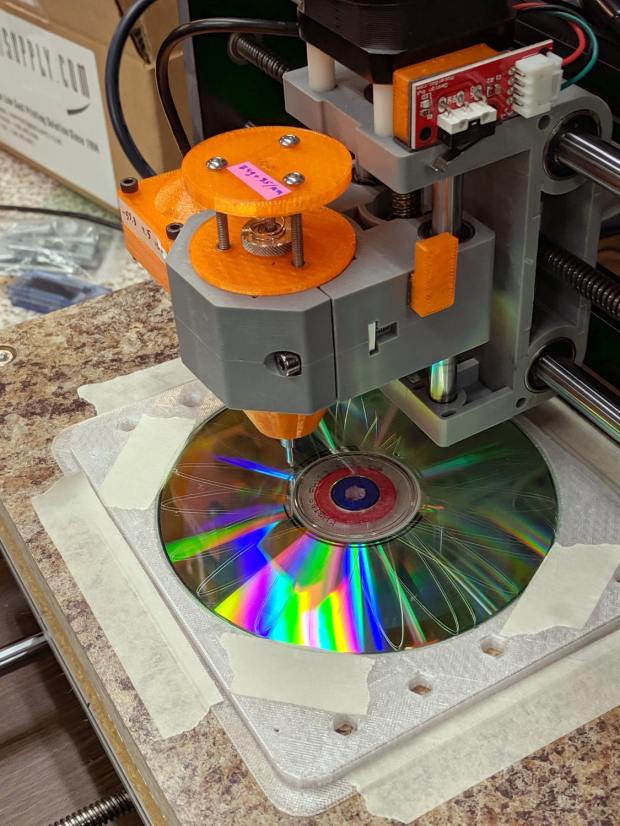

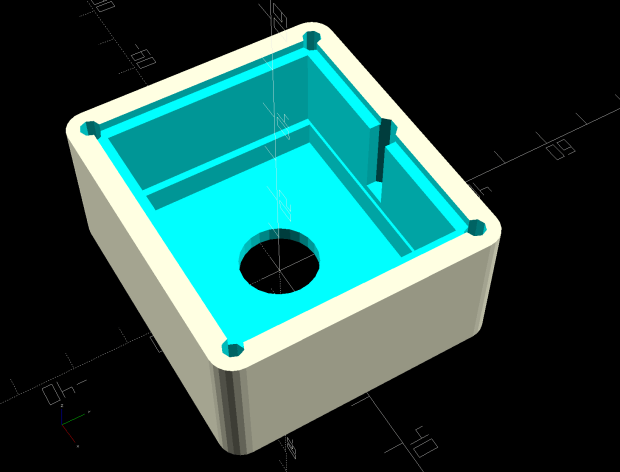

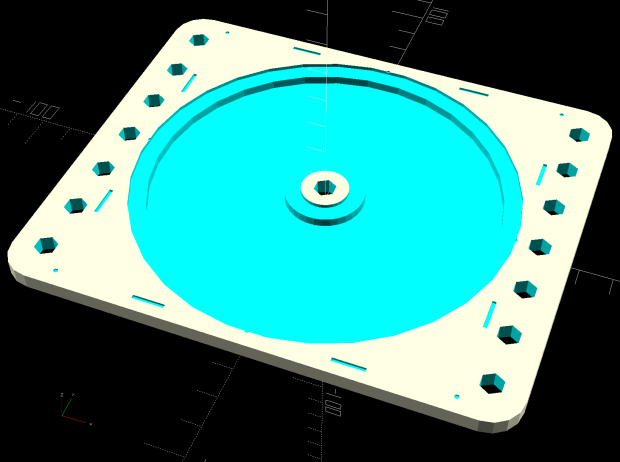

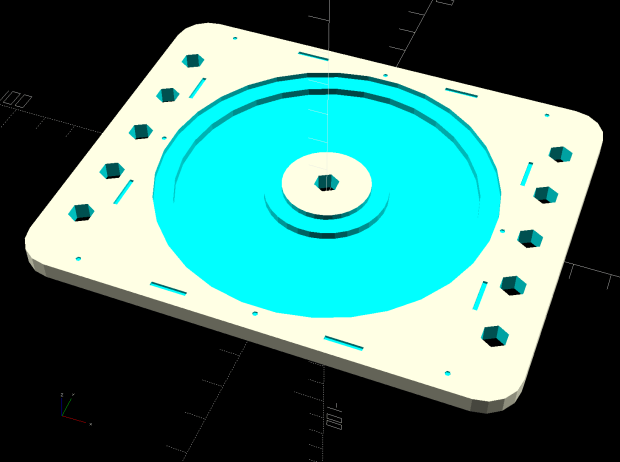

Compile the GCMC source to generate G-Code, lash a CD / DVD to the platform (masking tape works fine), touch off the XY coordinates in the center, touch off Z=0 on the surface, then see what happens:

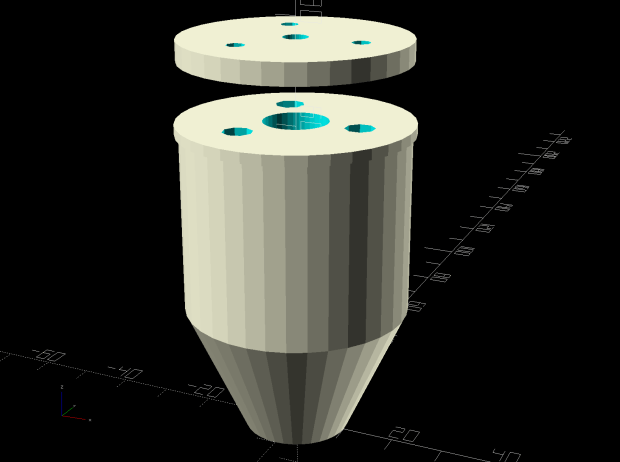

The “engraving depth” translates directly into the force applied to the diamond point, because the spring converts displacement into force. Knowing the Z depth, you can calculate or guesstimate the force.

Early results from the 3018 suggest it can engrave good-looking text about 20 times faster than the MPCNC:

You must trade off speed with accuracy on your very own machine, as your mileage will certainly differ!

The GCMC source code as a GitHub Gist:

| // Engraving test piece | |

| // Ed Nisley KE4ZNU – 2019-09 | |

| //—– | |

| // Command line parameters | |

| // -D OuterDia=number | |

| if (!isdefined("OuterDia")) { | |

| OuterDia = 120mm – 2mm; // CD = 120, 3.5 inch drive = 95 | |

| } | |

| OuterRad = OuterDia / 2.0; | |

| comment("Outer Diameter: ",OuterDia); | |

| comment(" Radius: ",OuterRad); | |

| //—– | |

| // Library routines | |

| include("tracepath.inc.gcmc"); | |

| include("engrave.inc.gcmc"); | |

| //—– | |

| // Bend text around an arc | |

| function ArcText(TextPath,Center,Radius,BaseAngle,Align) { | |

| PathLength = TextPath[-1].x; | |

| Circumf = 2*pi()*Radius; | |

| TextAngle = to_deg(360 * PathLength / Circumf); | |

| AlignAngle = BaseAngle + (Align == "Left" ? 0 : | |

| Align == "Center" ? -TextAngle / 2 : | |

| Align == "Right" ? -TextAngle : | |

| 0); | |

| ArcPath = {}; | |

| foreach(TextPath; pt) { | |

| if (!isundef(pt.x) && !isundef(pt.y) && isundef(pt.z)) { // XY motion, no Z | |

| r = Radius – pt.y; | |

| a = 360deg * (pt.x / Circumf) + AlignAngle; | |

| ArcPath += {[r*cos(a) + Center.x, r*sin(a) + Center.y,-]}; | |

| } | |

| elif (isundef(pt.x) && isundef(pt.y) && !isundef(pt.z)) { // no XY, Z up/down | |

| ArcPath += {pt}; | |

| } | |

| else { | |

| error("Point is not pure XY or pure Z: " + to_string(pt)); | |

| } | |

| } | |

| return ArcPath; | |

| } | |

| //—– | |

| // Set up for drawing | |

| SafeZ = 10.0mm; // above clamps and screws | |

| TravelZ = 1.0mm; // above workpiece | |

| PlotZ = -0.5mm; // tune for best results | |

| TextSpeed = 1000mm; // intricate detail | |

| DrawSpeed = 2000mm; // smooth curves | |

| TextFont = FONT_HSANS_1_RS; | |

| TextSize = [2.0mm,2.0mm]; | |

| TextLeading = 2*TextSize.y; // line spacing | |

| DiskCenter = [0mm,0mm]; // middle of the platter | |

| InnerDia = 40mm; | |

| InnerRad = InnerDia / 2.0; | |

| comment("Inner Diameter: ",InnerDia); | |

| comment(" Radius: ",InnerRad); | |

| NumRings = ceil((OuterRad – (InnerRad + TextLeading))/TextLeading); // number of rings to draw | |

| comment("Numer of rings: ",NumRings); | |

| if (1) { | |

| comment("Text Size begins"); | |

| feedrate(TextSpeed); | |

| ts = "Text size: " + to_string(TextSize); | |

| tp = scale(typeset(ts,TextFont),TextSize); | |

| tpa = ArcText(tp,DiskCenter,OuterRad,90deg,"Left"); | |

| engrave(tpa,TravelZ,PlotZ); | |

| } | |

| if (1) { | |

| comment("Depth variations begin"); | |

| TextRadius = OuterRad; | |

| pz = 0.0mm; | |

| repeat(NumRings ; i) { | |

| comment(" depth: " + to_string(pz)); | |

| feedrate(TextSpeed); | |

| ts = "Depth: " + to_string(pz) + " at " + to_string(TextSpeed) + "/min"; | |

| tp = scale(typeset(ts,TextFont),TextSize); | |

| tpa = ArcText(tp,DiskCenter,TextRadius,-5deg,"Right"); | |

| engrave(tpa,TravelZ,pz); | |

| feedrate(DrawSpeed); | |

| goto([0,-TextRadius,-]); | |

| move([-,-,pz]); | |

| arc_ccw([-TextRadius,0,-],-TextRadius); | |

| goto([-,-,TravelZ]); | |

| feedrate(TextSpeed); | |

| tp = scale(typeset("Rad: " + to_string(TextRadius),TextFont),TextSize); | |

| tpa = ArcText(tp,DiskCenter,TextRadius,180deg,"Right"); | |

| engrave(tpa,TravelZ,PlotZ); | |

| TextRadius -= TextLeading; | |

| pz -= 0.10mm; | |

| } | |

| } | |

| if (1) { | |

| comment("Feedrate variations begin"); | |

| TextRadius = OuterRad; | |

| ps = 250mm; | |

| repeat(NumRings ; i) { | |

| comment(" speed: " + to_string(ps) + "/min"); | |

| feedrate(ps); | |

| ts = "Speed: " + to_string(ps) + "/min at " + to_string(PlotZ); | |

| tp = scale(typeset(ts,TextFont),TextSize); | |

| tpa = ArcText(tp,DiskCenter,TextRadius,5deg,"Left"); | |

| engrave(tpa,TravelZ,PlotZ); | |

| TextRadius -= TextLeading; | |

| ps += 250mm; | |

| } | |

| } | |

| if (1) { | |

| comment("Off-center text arcs begin"); | |

| feedrate(TextSpeed); | |

| tc = [-40mm/sqrt(2),-40mm/sqrt(2)]; // center point | |

| r = 3mm; | |

| s = [0.5mm,0.5mm]; | |

| ts = "Radius: " + to_string(r) + " Size: " + to_string(s); | |

| tp = scale(typeset(ts,TextFont),s); | |

| tpa = ArcText(tp,tc,r,0deg,"Center"); | |

| engrave(tpa,TravelZ,PlotZ); | |

| r = 5mm; | |

| s = [1.0mm,1.0mm]; | |

| ts = "Radius: " + to_string(r) + " Size: " + to_string(s); | |

| tp = scale(typeset(ts,TextFont),s); | |

| tpa = ArcText(tp,tc,r,0deg,"Center"); | |

| engrave(tpa,TravelZ,PlotZ); | |

| r = 8mm; | |

| s = [1.5mm,1.5mm]; | |

| ts = "Radius: " + to_string(r) + " Size: " + to_string(s); | |

| tp = scale(typeset(ts,TextFont),s); | |

| tpa = ArcText(tp,tc,r,0deg,"Center"); | |

| engrave(tpa,TravelZ,PlotZ); | |

| r = 15mm; | |

| s = [3.0mm,3.0mm]; | |

| ts = "Radius: " + to_string(r) + " Size: " + to_string(s); | |

| tp = scale(typeset(ts,FONT_HSCRIPT_2),s); | |

| tpa = ArcText(tp,tc,r,0deg,"Center"); | |

| engrave(tpa,TravelZ,PlotZ); | |

| } | |

| if (1) { | |

| comment("Attribution begins"); | |

| feedrate(TextSpeed); | |

| tp = scale(typeset("Ed Nisley – KE4ZNU – softsolder.com",TextFont),TextSize); | |

| tpa = ArcText(tp,DiskCenter,15mm,0deg,"Center"); | |

| engrave(tpa,TravelZ,PlotZ); | |

| tp = scale(typeset("Engraving Test Disc",TextFont),TextSize); | |

| tpa = ArcText(tp,DiskCenter,15mm,180deg,"Center"); | |

| engrave(tpa,TravelZ,PlotZ); | |

| } | |

| goto([-,-,SafeZ]); | |

| goto([0mm,0mm,-]); | |

| comment("Done!"); |

| #!/bin/bash | |

| # Engraving test pattern generator | |

| # Ed Nisley KE4ZNU – 2019-08 | |

| Diameter='OuterDia=116mm' | |

| Flags='-P 3 –pedantic' | |

| # Set these to match your file layout | |

| LibPath='/opt/gcmc/library' | |

| Prolog='/mnt/bulkdata/Project Files/CNC 3018-Pro Router/Patterns/gcmc/prolog.gcmc' | |

| Epilog='/mnt/bulkdata/Project Files/CNC 3018-Pro Router/Patterns/gcmc/epilog.gcmc' | |

| Script='/mnt/bulkdata/Project Files/CNC 3018-Pro Router/Patterns/Engraving Test.gcmc' | |

| ts=$(date +%Y%m%d-%H%M%S) | |

| fn='TestPattern_'${ts}'.ngc' | |

| echo Output: $fn | |

| rm -f $fn | |

| echo "(File: "$fn")" > $fn | |

| /opt/gcmc/src/gcmc -D $Diameter $Flags \ | |

| –include "$LibPath" –prologue "$Prolog" –epilogue "$Epilog" \ | |

| "$Script" >> $fn | |