The upcycled Nissan fog lamp now has a desk stand:

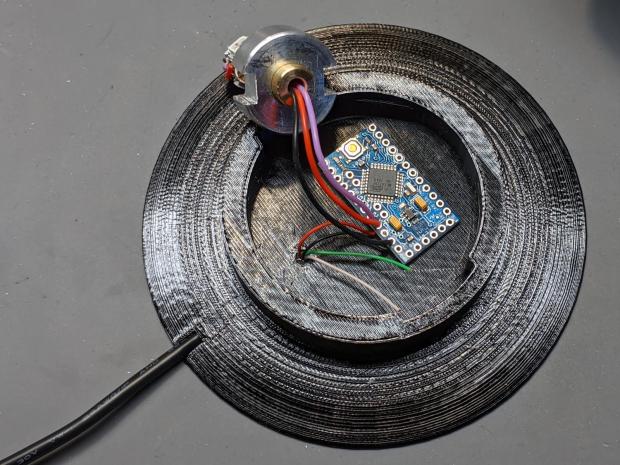

A knockoff Arduino Pro Mini atop a strip of foam tape drives the WS2812 RGB LEDs:

Next time, I’ll cut the wires another inch longer.

The firmware is a tidied-up version of the vacuum tube code, minus cruft, plus fixes, and generally better at doing what it does. The Pro Mini lacks a USB output, so this came from the same code running on a Nano:

14:44:04.169 -> Algorithmic Art

14:44:04.169 -> RGB WS2812

14:44:04.169 -> Ed Nisley - KE4ZNU - April 2020

14:44:04.169 -> Lamp test: flash full-on colors

14:44:04.169 -> color: 00ff0000

14:44:05.165 -> color: 0000ff00

14:44:06.160 -> color: 000000ff

14:44:07.155 -> color: 00ffffff

14:44:08.151 -> color: 00000000

14:44:09.180 -> Random seed: da98f7f6

14:44:09.180 -> Primes: 7 19 3

14:44:09.180 -> Super cycle length: 199500 steps

14:44:09.180 -> Inter-pixel phase: 1 deg = 26 steps

14:44:09.180 -> c: 0 Steps: 3500 Init: 1538 Phase: 2 deg PWM: 255

14:44:09.180 -> c: 1 Steps: 9500 Init: 7623 Phase: 0 deg PWM: 255

14:44:09.213 -> c: 2 Steps: 1500 Init: 1299 Phase: 6 deg PWM: 255

14:44:19.265 -> Color 2 steps 1500 at 15101 ms 50 TS 201

14:45:34.293 -> Color 2 steps 1500 at 90136 ms 50 TS 1701

14:45:43.085 -> Color 1 steps 9500 at 98940 ms 50 TS 1877

14:45:47.332 -> Color 0 steps 3500 at 103192 ms 50 TS 1962

14:46:49.324 -> Color 2 steps 1500 at 165170 ms 50 TS 3201

… much snippage …

17:26:52.896 -> Color 2 steps 1500 at 9769584 ms 50 TS 195201

17:28:07.926 -> Color 2 steps 1500 at 9844618 ms 50 TS 196701

17:29:11.000 -> Color 0 steps 3500 at 9907697 ms 50 TS 197962

17:29:22.974 -> Color 2 steps 1500 at 9919653 ms 50 TS 198201

17:30:27.941 -> Supercycle end, setting new color values

17:30:27.941 -> Primes: 17 7 3

17:30:27.941 -> Super cycle length: 178500 steps

17:30:27.941 -> Inter-pixel phase: 1 deg = 23 steps

17:30:27.941 -> c: 0 Steps: 8500 Init: 5415 Phase: 0 deg PWM: 255

17:30:27.974 -> c: 1 Steps: 3500 Init: 3131 Phase: 2 deg PWM: 255

17:30:27.974 -> c: 2 Steps: 1500 Init: 420 Phase: 5 deg PWM: 255

17:30:46.394 -> Color 1 steps 3500 at 10003091 ms 50 TS 369

17:31:21.964 -> Color 2 steps 1500 at 10038658 ms 50 TS 1080 The “Super cycle length” is the number of 50 ms steps until the colors start repeating, something over an hour in that sample. When the code reaches the end of the supercycle, it picks another set of three prime numbers, reinitializes the color settings, and away it goes.

The fog light looks pretty in action:

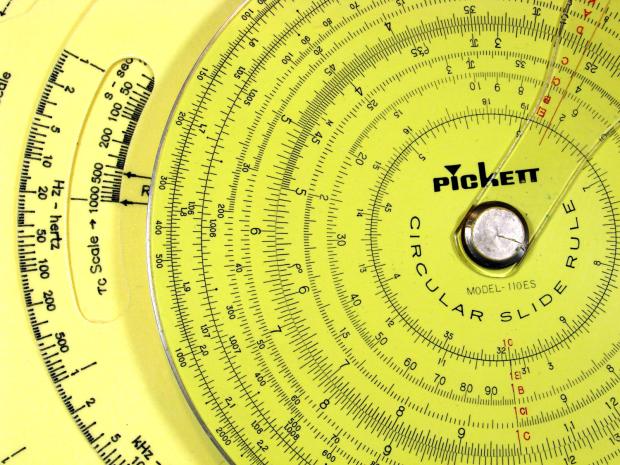

The four LEDs don’t produce the same light pattern as the halogen filament and they’re distinctly visible when you squint against the glare:

The shadow on the right comes from the larger hood support strut, the shadow on the left is the narrower strut, and the two other gaps show the beam angle gaps between the LEDs.

You’ll see plenty of residual sandpaper scratches on the lens: my surface (re)finishing hand is weak.

The LED beamwidth is so broad the “bulb” position inside the reflector doesn’t make much difference, particularly as it must, at most, wash a wall and ceiling at close range:

All in all, a much-needed dose of Quality Shop Time.

The Arduino source code as a GitHub Gist:

| // Neopixel Algorithmic Art | |

| // W2812 RGB Neopixel version | |

| // Ed Nisley – KE4ZNU | |

| #include <Adafruit_NeoPixel.h> | |

| #include <Entropy.h> | |

| //———- | |

| // Pin assignments | |

| const byte PIN_NEO = A3; // DO – data out to first Neopixel | |

| const byte PIN_HEARTBEAT = 13; // DO – Arduino LED | |

| #define PIN_MORSE 12 | |

| //———- | |

| // Constants | |

| // number of pixels | |

| #define PIXELS 4 | |

| // lag between adjacent pixels in degrees of slowest period | |

| #define PIXELPHASE 1 | |

| // update LEDs only this many ms apart (minus loop() overhead) | |

| #define UPDATEINTERVAL 50ul | |

| #define UPDATEMS (UPDATEINTERVAL – 0ul) | |

| // number of steps per cycle, before applying prime factors | |

| #define RESOLUTION 500 | |

| //———- | |

| // Globals | |

| Adafruit_NeoPixel strip = Adafruit_NeoPixel(PIXELS, PIN_NEO, NEO_GRB + NEO_KHZ800); | |

| uint32_t FullWhite = strip.Color(255,255,255); | |

| uint32_t FullOff = strip.Color(0,0,0); | |

| uint32_t MorseColor; | |

| struct pixcolor_t { | |

| unsigned int Prime; | |

| unsigned int NumSteps; | |

| unsigned int Step; | |

| float StepSize; | |

| float Phase; | |

| byte MaxPWM; | |

| }; | |

| unsigned long int TotalSteps; | |

| unsigned long int SuperCycleSteps; | |

| byte PrimeList[] = {3,5,7,11,13,17,19,29}; // small primes = faster changes | |

| // colors in each LED and their count | |

| enum pixcolors {RED, GREEN, BLUE, PIXELSIZE}; | |

| struct pixcolor_t Pixel[PIXELSIZE]; // all the data for each pixel color intensity | |

| uint32_t UniColor; | |

| unsigned long int MillisNow; | |

| unsigned long int MillisThen; | |

| //– Select three unique primes for the color generator function | |

| // Then compute all the step parameters based on those values | |

| void SetColorGenerators(void) { | |

| Pixel[RED].Prime = PrimeList[random(sizeof(PrimeList))]; | |

| do { | |

| Pixel[GREEN].Prime = PrimeList[random(sizeof(PrimeList))]; | |

| } while (Pixel[RED].Prime == Pixel[GREEN].Prime); | |

| do { | |

| Pixel[BLUE].Prime = PrimeList[random(sizeof(PrimeList))]; | |

| } while (Pixel[BLUE].Prime == Pixel[RED].Prime || | |

| Pixel[BLUE].Prime == Pixel[GREEN].Prime); | |

| if (false) { | |

| Pixel[RED].Prime = 1; | |

| Pixel[GREEN].Prime = 3; | |

| Pixel[BLUE].Prime = 5; | |

| } | |

| printf("Primes: %d %d %d\r\n",Pixel[RED].Prime,Pixel[GREEN].Prime,Pixel[BLUE].Prime); | |

| TotalSteps = 0; | |

| SuperCycleSteps = RESOLUTION; | |

| for (byte c = 0; c < PIXELSIZE; c++) { | |

| SuperCycleSteps *= Pixel[c].Prime; | |

| } | |

| printf(" Super cycle length: %lu steps\r\n",SuperCycleSteps); | |

| Pixel[RED].MaxPWM = 255; | |

| Pixel[GREEN].MaxPWM = 255; | |

| Pixel[BLUE].MaxPWM = 255; | |

| unsigned int PhaseSteps = (unsigned int) ((PIXELPHASE / 360.0) * | |

| RESOLUTION * (unsigned int) max(max(Pixel[RED].Prime,Pixel[GREEN].Prime),Pixel[BLUE].Prime)); | |

| printf("Inter-pixel phase: %d deg = %d steps\r\n",(int)PIXELPHASE,PhaseSteps); | |

| for (byte c = 0; c < PIXELSIZE; c++) { | |

| Pixel[c].NumSteps = RESOLUTION * Pixel[c].Prime; // steps per cycle | |

| Pixel[c].StepSize = TWO_PI / Pixel[c].NumSteps; // radians per step | |

| Pixel[c].Step = random(Pixel[c].NumSteps); // current step | |

| Pixel[c].Phase = PhaseSteps * Pixel[c].StepSize; // phase in radians for this color | |

| printf(" c: %d Steps: %5d Init: %5d Phase: %3d deg",c,Pixel[c].NumSteps,Pixel[c].Step,(int)(Pixel[c].Phase * 360.0 / TWO_PI)); | |

| printf(" PWM: %d\r\n",Pixel[c].MaxPWM); | |

| } | |

| } | |

| //– Helper routine for printf() | |

| int s_putc(char c, FILE *t) { | |

| Serial.write(c); | |

| } | |

| //—————— | |

| // Set the mood | |

| void setup() { | |

| pinMode(PIN_HEARTBEAT,OUTPUT); | |

| digitalWrite(PIN_HEARTBEAT,LOW); // show we arrived | |

| Serial.begin(57600); | |

| fdevopen(&s_putc,0); // set up serial output for printf() | |

| printf("Algorithmic Art\r\n RGB WS2812\r\nEd Nisley – KE4ZNU – April 2020\r\n"); | |

| Entropy.initialize(); // start up entropy collector | |

| // set up pixels | |

| strip.begin(); | |

| strip.show(); | |

| // lamp test: a brilliant white flash | |

| printf("Lamp test: flash full-on colors\r\n"); | |

| uint32_t FullRGB = strip.Color(255,255,255); | |

| uint32_t FullR = strip.Color(255,0,0); | |

| uint32_t FullG = strip.Color(0,255,0); | |

| uint32_t FullB = strip.Color(0,0,255); | |

| uint32_t FullOff = strip.Color(0,0,0); | |

| uint32_t TestColors[] = {FullR,FullG,FullB,FullRGB,FullOff}; | |

| for (byte i = 0; i < sizeof(TestColors)/sizeof(uint32_t) ; i++) { | |

| printf(" color: %08lx\r\n",TestColors[i]); | |

| for (int p=0; p < strip.numPixels(); p++) { | |

| strip.setPixelColor(p,TestColors[i]); | |

| } | |

| strip.show(); | |

| delay(1000); | |

| } | |

| // get an actual random number | |

| uint32_t rn = Entropy.random(); | |

| printf("Random seed: %08lx\r\n",rn); | |

| randomSeed(rn); | |

| // set up the color generators | |

| SetColorGenerators(); | |

| MillisNow = MillisThen = millis(); | |

| } | |

| //—————— | |

| // Run the mood | |

| void loop() { | |

| MillisNow = millis(); | |

| if ((MillisNow – MillisThen) >= UPDATEMS) { // time for another step? | |

| digitalWrite(PIN_HEARTBEAT,HIGH); | |

| TotalSteps++; | |

| strip.show(); // send out precomputed colors | |

| for (byte c = 0; c < PIXELSIZE; c++) { // compute next increment for each color | |

| if (++Pixel[c].Step >= Pixel[c].NumSteps) { | |

| Pixel[c].Step = 0; | |

| printf("Color %-5d steps %-5d at %-8ld ms %-8ld TS %-8lu\r\n", | |

| c,Pixel[c].NumSteps,MillisNow,(MillisNow – MillisThen),TotalSteps); | |

| } | |

| } | |

| // If all cycles have completed, reset the color generators | |

| if (TotalSteps >= SuperCycleSteps) { | |

| printf("Supercycle end, setting new color values\r\n"); | |

| SetColorGenerators(); | |

| } | |

| for (int p = 0; p < strip.numPixels(); p++) { // for each pixel | |

| byte Value[PIXELSIZE]; | |

| for (byte c=0; c < PIXELSIZE; c++) { // compute new colors | |

| Value[c] = (Pixel[c].MaxPWM / 2.0) * (1.0 + sin(Pixel[c].Step * Pixel[c].StepSize – p*Pixel[c].Phase)); | |

| } | |

| UniColor = strip.Color(Value[RED],Value[GREEN],Value[BLUE]); | |

| strip.setPixelColor(p,UniColor); | |

| } | |

| MillisThen = MillisNow; | |

| digitalWrite(PIN_HEARTBEAT,LOW); | |

| } | |

| } |