|

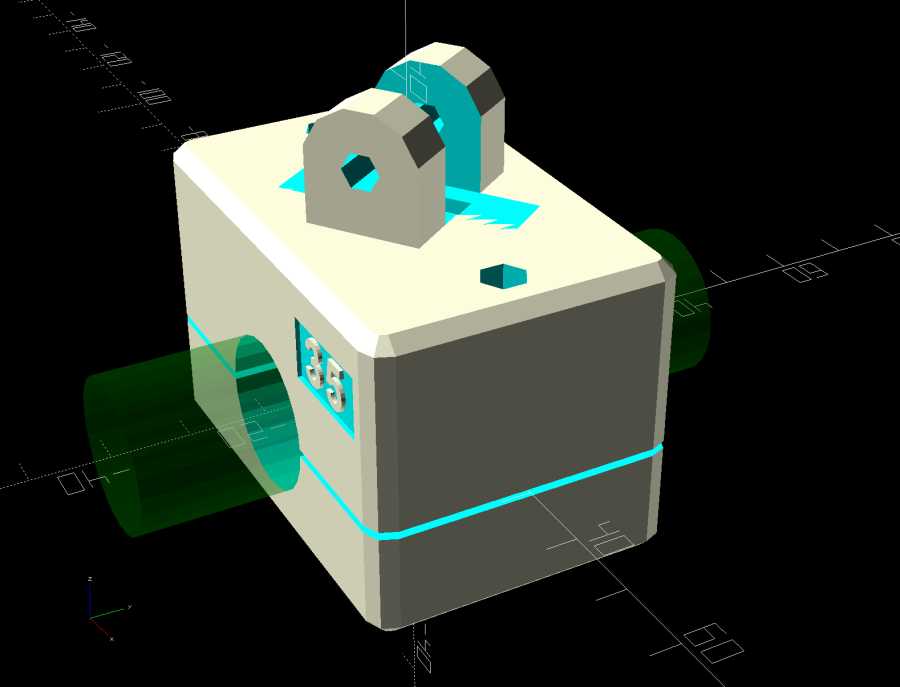

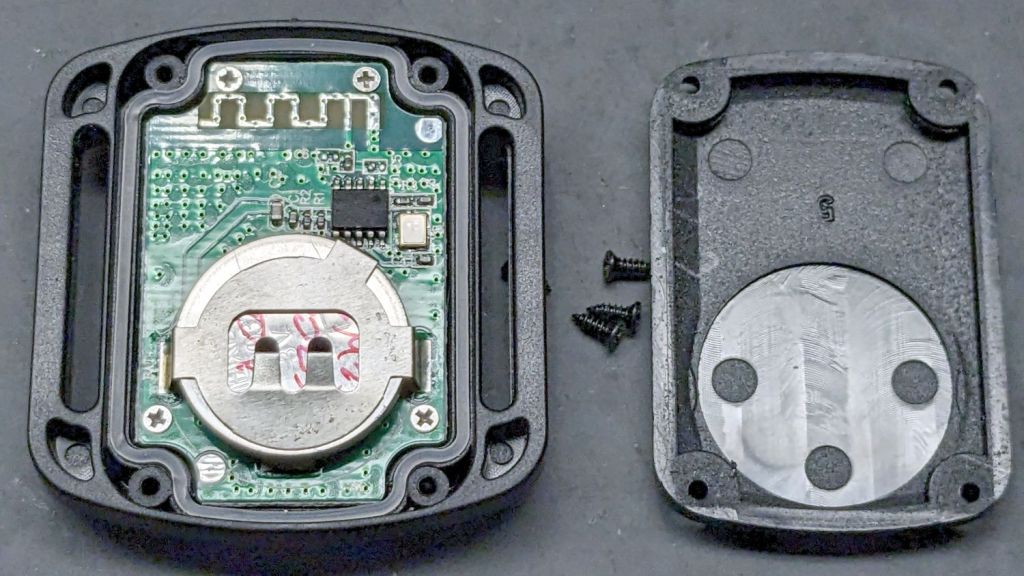

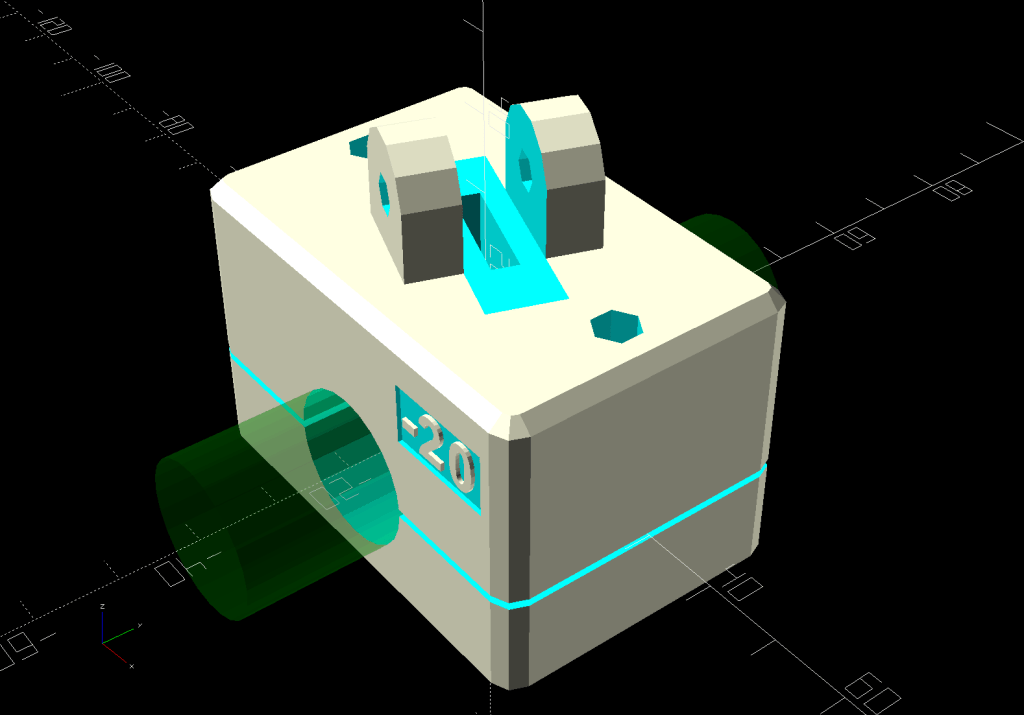

// SJCAM C100+ Camera Mount for Tour Easy seat back rail |

|

// Ed Nisley – KE4ZNU |

|

// 2023-04 |

|

|

|

/* [Layout Options] */ |

|

|

|

LookAngle = -20; // camera angle, looking backwards = 0° |

|

|

|

Layout = "Show"; // [Show,Build] |

|

|

|

|

|

/* [Hidden] */ |

|

|

|

ThreadWidth = 0.40; |

|

ThreadThick = 0.25; |

|

|

|

HoleWindage = 0.2; |

|

|

|

Protrusion = 0.1; |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

//—– |

|

// Dimensions |

|

|

|

ClampScrew = [5.0,10.0,40.0]; // ID=thread OD=washer LENGTH=total |

|

ClampInsert = [5.0,7.5,10.5]; // brass insert |

|

|

|

MountScrew = [5.0,10.0,23.0]; // ID=thread OD=washer LENGTH=under nut |

|

MountInsert = [5.0,7.5,10.5]; // ID=screw OD, OD=knurl dia |

|

|

|

EmbossDepth = 2*ThreadThick + Protrusion; // recess depth + Protrusion beyond surface |

|

|

|

DebossHeight = EmbossDepth; // text height + Protrusion into part |

|

|

|

RailOD = 20.0; // slightly elliptical in bent section |

|

RailSides = 2*3*4; |

|

|

|

ClampOA = [60.0,40.0,ClampScrew[LENGTH]]; // set clamp size to avoid weird screw spacing |

|

echo(ClampOA = ClampOA); |

|

|

|

ClampScrewOC = IntegerMultiple(ClampOA.x – ClampScrew[OD] – 10*ThreadWidth,1.0); |

|

echo(ClampScrewOC = ClampScrewOC); |

|

|

|

ClampOffset = 5.0; // in case we need more room on top |

|

|

|

ClampRadius = 3.0; |

|

ClampSides = 8; |

|

|

|

Kerf = 1.0; // slice through the middle |

|

|

|

// center mount blade, Z = depth into block |

|

MountBlade = [15.0 + 2*HoleWindage, |

|

3.0 + 2*HoleWindage, |

|

(ClampOA.z – RailOD + ClampOffset)/2 – 4*ThreadThick + Protrusion]; |

|

echo(MountBlade = MountBlade); |

|

|

|

MountRadius = MountBlade.x / 2; |

|

|

|

MountGap = 9.5; // camera mount gap around center blade |

|

|

|

MountOffset = [0,0,7.0]; // mount hole offset from block surface |

|

|

|

FadeColor = "Green"; |

|

FadeAlpha = 0.25; |

|

|

|

//—– |

|

// Useful routines |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

|

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

|

|

FixDia = Dia / cos(180/Sides); |

|

|

|

cylinder(r=(FixDia + HoleWindage)/2, |

|

h=Height, |

|

$fn=Sides); |

|

} |

|

|

|

|

|

//—– |

|

// Clamp |

|

// Grips seat frame rail |

|

// Origin at middle of seat rail, X rearward, Y parallel to seat frame rail |

|

// Block offset raises whole thing |

|

|

|

module Clamp() { |

|

|

|

difference() { |

|

translate([0,0,ClampOffset]) { |

|

difference() { |

|

union() { |

|

hull() // the main block |

|

for (i=[-1,1], j=[-1,1], k=[-1,1]) |

|

translate([i*(ClampOA.x – 2*ClampRadius)/2, |

|

j*(ClampOA.y – 2*ClampRadius)/2, |

|

k*(ClampOA.z – 2*ClampRadius)/2]) |

|

sphere(r=ClampRadius/cos(180/ClampSides),$fn=ClampSides); |

|

|

|

hull() // camera mount boss |

|

for (k=[0,1]) |

|

translate([0,0,k*(MountOffset.z) + ClampOA.z/2]) |

|

rotate([0,90,LookAngle + 90]) rotate(180/12) |

|

cylinder(r=MountRadius,h=MountScrew[LENGTH],center=true,$fn=12); |

|

|

|

} |

|

|

|

for (i=[-1,1]) // clamp inserts |

|

translate([i*ClampScrewOC/2,0,-(ClampOA.z/2 + Protrusion)]) |

|

rotate(180/6) |

|

PolyCyl(ClampInsert[OD],ClampInsert[LENGTH],6); |

|

|

|

for (i=[-1,1]) // clamp screw holes |

|

translate([i*ClampScrewOC/2,0,-ClampOA.z]) |

|

rotate(180/6) |

|

PolyCyl(ClampScrew[ID],2*ClampOA.z,6); |

|

|

|

translate([0,0,ClampOA.z/2 – (MountBlade.z/2 – Protrusion/2)]) // camera center blade |

|

rotate(LookAngle) |

|

cube(MountBlade,center=true); |

|

|

|

rotate(LookAngle + 90) // camera mount boss slot |

|

translate([0,0,ClampOA.z/2 + 2*MountRadius]) |

|

cube([MountGap,4*MountRadius,4*MountRadius],center=true); |

|

|

|

translate([0,0,ClampOA.z/2 + MountOffset.z]) // camera mount boss hole |

|

rotate([90,0,LookAngle]) |

|

cylinder(d=MountScrew[ID],h=4*MountGap,center=true,$fn=6); |

|

|

|

translate([0.3*ClampOA.x, // recess for LookAngle legend |

|

-(ClampOA.y/2 – (EmbossDepth – Protrusion)/2), |

|

ClampOA.z/4]) |

|

cube([15,EmbossDepth,8],center=true); |

|

|

|

translate([0,0,-ClampOA.z/2 + (EmbossDepth – Protrusion)/2]) // recess for ID legend |

|

cube([35,10,EmbossDepth],center=true); |

|

} |

|

|

|

translate([0.3*ClampOA.x, // LookAngle legend |

|

-ClampOA.y/2 + DebossHeight + Protrusion/2, |

|

ClampOA.z/4]) |

|

rotate([90,0,00]) |

|

linear_extrude(height=DebossHeight,convexity=20) |

|

text(text=str(LookAngle),size=6,spacing=1.20, |

|

font="Arial:style:Bold",halign="center",valign="center"); |

|

|

|

translate([0,0,-ClampOA.z/2]) // ID legend |

|

linear_extrude(height=DebossHeight,convexity=20) |

|

mirror([0,1,0]) |

|

text(text="KE4ZNU",size=5,spacing=1.20, |

|

font="Arial:style:Bold",halign="center",valign="center"); |

|

} |

|

|

|

cube([2*ClampOA.x,2*ClampOA.y,Kerf],center=true); // split across rail |

|

|

|

rotate([90,0,0]) // seat rail |

|

cylinder(d=RailOD,h=2*ClampOA.y,$fn=RailSides,center=true); |

|

|

|

} |

|

} |

|

|

|

//—– |

|

// Build things |

|

|

|

// Layouts for design & tweaking |

|

|

|

if (Layout == "Show") { |

|

Clamp(); |

|

color(FadeColor,FadeAlpha) |

|

rotate([90,0,0]) |

|

cylinder(d=RailOD,h=2*ClampOA.y,$fn=RailSides,center=true); |

|

} |

|

|

|

|

|

// Build layout |

|

|

|

if (Layout == "Build") { |

|

translate([0,0.7*ClampOA.y,0]) |

|

difference() { |

|

translate([0,0,-Kerf/2]) |

|

Clamp(); |

|

translate([0,0,-ClampOA.z]) |

|

cube(2*ClampOA,center=true); |

|

} |

|

translate([0,-0.7*ClampOA.y,-0]) |

|

difference() { |

|

translate([0,0,-Kerf/2]) |

|

rotate([0,180,0]) |

|

Clamp(); |

|

translate([0,0,-ClampOA.z]) |

|

cube(2*ClampOA,center=true); |

|

} |

|

} |