Well, it’s actually not “sensing”, but the demo code now sizes the graph to the paper size reported by the plotter, so you can plot on cheap and readily available A-size paper. The Vulcan Nerve Pinch that switches paper size on the fly is Enter+Size; I leave the DIP switches set for B-size sheets, because they’re more impressive and take longer to plot.

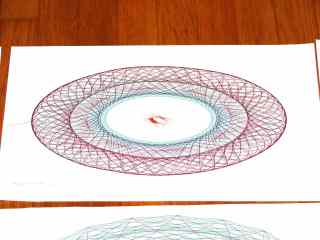

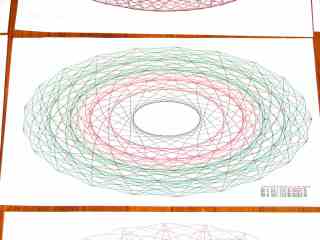

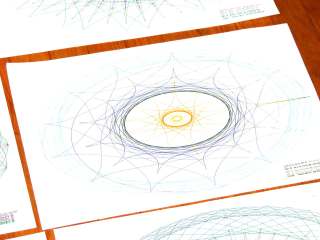

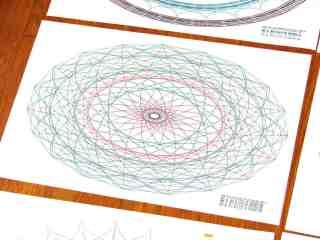

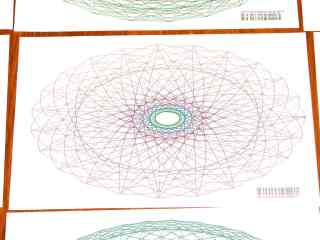

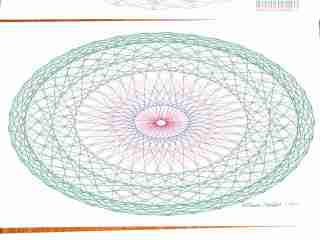

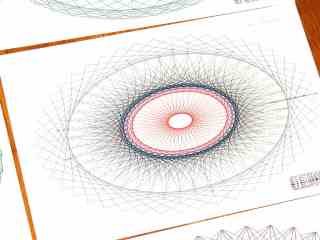

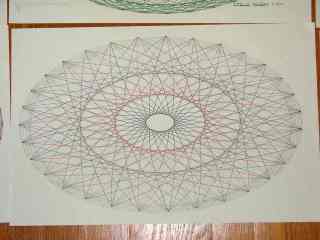

A collection of A-size plots:

The perspective foreshortening makes the sheets look square and the plots seem circular; they’re not.

The plots lie in rough time sequence from lower left to upper right, showing that I tweaked the n1 parameter to avoid the sort of tiny middle that gnawed a hole right through the center-bottom sheet. I also removed higher m parameter values, because more than 50-ish points doesn’t work well on smaller sheets.

I figured out how to use the Python ternary “operator” and tweaked the print formatting, but basically it’s a hack job through & through.

The Python source code, including the hacked Chiplotle routines that produce the SuperFormula:

from chiplotle import *

from math import *

from datetime import *

import random

def superformula_polar(a, b, m, n1, n2, n3, phi):

''' Computes the position of the point on a

superformula curve.

Superformula has first been proposed by Johan Gielis

and is a generalization of superellipse.

see: http://en.wikipedia.org/wiki/Superformula

Tweaked to return polar coordinates

'''

t1 = cos(m * phi / 4.0) / a

t1 = abs(t1)

t1 = pow(t1, n2)

t2 = sin(m * phi / 4.0) / b

t2 = abs(t2)

t2 = pow(t2, n3)

t3 = -1 / float(n1)

r = pow(t1 + t2, t3)

if abs(r) == 0:

return (0,0)

else:

# return (r * cos(phi), r * sin(phi))

return (r,phi)

def supershape(width, height, m, n1, n2, n3,

point_count=10*1000, percentage=1.0, a=1.0, b=1.0, travel=None):

'''Supershape, generated using the superformula first proposed

by Johan Gielis.

- `points_count` is the total number of points to compute.

- `travel` is the length of the outline drawn in radians.

3.1416 * 2 is a complete cycle.

'''

travel = travel or (10*2*pi)

## compute points...

phis = [i * travel / point_count

for i in range(1 + int(point_count * percentage))]

points = [superformula_polar(a, b, m, n1, n2, n3, x) for x in phis]

## scale and transpose...

path = [ ]

for r, a in points:

x = width * r * cos(a)

y = height * r * sin(a)

path.append(Coordinate(x, y))

return Path(path)

## RUN DEMO CODE

if __name__ == '__main__':

plt=instantiate_plotters()[0]

# plt.write('IN;')

if plt.margins.soft.width < 11000: # A=10365 B=16640

maxplotx = (plt.margins.soft.width / 2) - 100

maxploty = (plt.margins.soft.height / 2) - 150

legendx = maxplotx - 2600

legendy = -(maxploty - 650)

tscale = 0.45

numpens = 4

m_list = [n/10.0 for n in [11, 13, 17, 19, 23]]; # prime/10 = number of spikes

n1_list = [n/100.0 for n in range(55,75,1) + range(80,120,5) + range(120,200,10)] # ring-ness 0.1 to 2.0, higher is larger

else:

maxplotx = plt.margins.soft.width / 2

maxploty = plt.margins.soft.height / 2

legendx = maxplotx - 3000

legendy = -(maxploty - 700)

tscale = 0.45

numpens = 6

m_list = [n/10.0 for n in [11, 13, 17, 19, 23, 29, 31, 37, 41, 43, 47, 53, 59]]; # prime/10 = number of spikes

n1_list = [n/100.0 for n in range(15,75,1) + range(80,120,5) + range(120,200,10)] # ring-ness 0.1 to 2.0, higher is larger

print "Max: ({},{})".format(maxplotx,maxploty)

n2_list = [n/100.0 for n in range(10,50,1) + range(55,100,5) + range(110,200,10)] # spike-ness 0.1 to 2.0, lower is spiky

plt.write(chr(27) + '.H200:') # set hardware handshake block size

plt.set_origin_center()

plt.write(hpgl.SI(tscale*0.285,tscale*0.375)) # scale based on B size characters

plt.write(hpgl.VS(10)) # slow speed for those abrupt spikes

plt.select_pen(1) # standard loadout has pen 1 = black

plt.write(hpgl.PA([(legendx,legendy)]))

plt.write(hpgl.LB("Started " + str(datetime.today())))

m = random.choice(m_list)

pen = 1

for n1, n2 in zip(random.sample(n1_list,numpens),random.sample(n2_list,numpens)):

n3 = n2

print "{0} - m: {1:.1f}, n1: {2:.2f}, n2=n3: {3:.2f}".format(pen,m,n1,n2)

plt.select_pen(pen)

plt.write(hpgl.PA([(legendx, legendy - 100*pen)]))

plt.write(hpgl.LB("Pen {0}: m={1:.1f} n1={2:.2f} n2=n3={3:.2f}".format(pen,m,n1,n2)))

e = supershape(maxplotx, maxploty, m, n1, n2, n3)

plt.write(e)

pen = pen + 1 if (pen % numpens) else 1

plt.select_pen(1)

plt.write(hpgl.PA([(legendx, legendy - 100*(numpens + 1))]))

plt.write(hpgl.LB("Ended " + str(datetime.today())))

plt.select_pen(0)