|

// CNC 3018-Pro Probe Camera mount for anonymous USB camera |

|

// Ed Nisley KE4ZNU – August 2019 |

|

|

|

Layout = "Show"; // [Show, Build, Ball, Clamp, Bracket, Mount] |

|

|

|

//——- |

|

//- Extrusion parameters must match reality! |

|

// Print with 2 shells |

|

|

|

/* [Hidden] */ |

|

|

|

ThreadThick = 0.25; |

|

ThreadWidth = 0.40; |

|

|

|

HoleWindage = 0.2; |

|

|

|

Protrusion = 0.1; // make holes end cleanly |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

|

|

inch = 25.4; |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

//——- |

|

// Dimensions |

|

|

|

//– Camera |

|

|

|

PCBThick = 1.2; |

|

PCBDia = 25.0; |

|

|

|

KeySize = [28.0,8.5,IntegerMultiple(PCBThick,ThreadThick)]; |

|

KeyOffset = [0.0,2.0,0.0]; |

|

|

|

KeyRadius = IntegerMultiple(sqrt(pow(KeySize.y – KeyOffset.y,2) + pow(KeySize.x/2,2)),0.01); |

|

echo(str("Key radius: ",KeyRadius)); |

|

|

|

Lens = [14.0,18.0,25.0]; |

|

|

|

BallID = PCBDia; |

|

BallOD = IntegerMultiple(2*KeyRadius,5.0); |

|

echo(str("Ball OD: ",BallOD)); |

|

|

|

WallThick = 3.0; |

|

|

|

CableOD = 3.75; |

|

|

|

NumPins = 3; |

|

Pin = [1.75,1.8,5.0]; |

|

|

|

Screw = [ |

|

3.0,6.8,25.0 // M3 ID=thread, OD=washer, LENGTH=below head |

|

]; |

|

|

|

RoundRadius = IntegerMultiple(Screw[OD]/2,1.0); // corner rounding |

|

|

|

ClampSize = [BallOD + 2*WallThick,BallOD + 2*WallThick,20.0]; |

|

echo(str("Clamp: ",ClampSize)); |

|

|

|

MountSize = [5.0,BallOD,25.0]; |

|

MountClearance = 1.0; // distance between clamp and mount |

|

|

|

Kerf = 2*ThreadThick; |

|

|

|

ScrewOC = [ClampSize.x – 2*RoundRadius,ClampSize.y – 2*RoundRadius]; |

|

echo(str("Screw OC: ",ScrewOC)); |

|

|

|

Insert = [ // brass insert: body, knurl,length |

|

3.9,4.9,8.0 |

|

]; |

|

UseInsert = false; |

|

|

|

NumSides = 12*4; |

|

|

|

//——- |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

FixDia = Dia / cos(180/Sides); |

|

cylinder(r=(FixDia + HoleWindage)/2, |

|

h=Height, |

|

$fn=Sides); |

|

} |

|

|

|

|

|

//——- |

|

// Components |

|

|

|

module CamBall(Section="Both") { |

|

|

|

Offset = (Section == "Both") ? 0 : |

|

(Section == "Upper") ? BallOD/2 : |

|

(Section == "Lower") ? -BallOD/2 : |

|

0; |

|

|

|

render(convexity=4) |

|

intersection(convexity = 3) { |

|

difference() { |

|

sphere(d=BallOD,$fn=NumSides); |

|

|

|

sphere(d=BallID,$fn=NumSides); // interior |

|

|

|

PolyCyl(CableOD,2*BallOD,8); // cable & lens holes |

|

translate([0,0,-Lens[LENGTH]]) |

|

PolyCyl(Lens[OD],Lens[LENGTH],NumSides); |

|

|

|

translate([0,0,-PCBThick]) |

|

PolyCyl(PCBDia,PCBThick,NumSides); |

|

|

|

translate(KeyOffset + [0,-KeySize.y/2,-PCBThick/2]) // PCB key |

|

cube(KeySize,center=true); |

|

|

|

for (i=[0:NumPins – 1]) |

|

rotate(i*360/NumPins) |

|

translate([0,-(BallID + BallOD)/4,-Pin[LENGTH]/2]) |

|

PolyCyl(Pin[OD],Pin[LENGTH],6); |

|

} |

|

translate([0,0,Offset]) |

|

cube([BallOD,BallOD,BallOD] + 2*[Protrusion,Protrusion,0],center=true); |

|

} |

|

} |

|

|

|

module Clamp(Section="Both") { |

|

|

|

Offset = (Section == "Both") ? 0 : |

|

(Section == "Upper") ? ClampSize.z/2 : |

|

(Section == "Lower") ? -ClampSize.z/2 : |

|

0; |

|

|

|

render(convexity=4) |

|

intersection() { |

|

difference() { |

|

hull() |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*ScrewOC.x/2,j*ScrewOC.y/2,0]) |

|

cylinder(r=RoundRadius,h=ClampSize.z,$fn=NumSides,center=true); |

|

|

|

sphere(d=BallOD + 2*HoleWindage,$fn=NumSides); // space around camera ball |

|

|

|

for (i=[-1,1], j=[-1,1]) // screws |

|

translate([i*ScrewOC.x/2,j*ScrewOC.y/2,-ClampSize.z]) |

|

PolyCyl(Screw[ID],2*ClampSize.z,6); |

|

|

|

if (UseInsert) |

|

for (i=[-1,1], j=[-1,1]) // inserts |

|

translate([i*ScrewOC.x/2,j*ScrewOC.y/2,-(ClampSize.z/2 + Protrusion)]) |

|

PolyCyl(Insert[OD],Insert[LENGTH] + Protrusion,8); |

|

|

|

cube([2*ClampSize.x,2*ClampSize.y,Kerf],center=true); // clamping gap |

|

|

|

} |

|

translate([0,0,Offset]) |

|

cube([ClampSize.x,ClampSize.y,ClampSize.z] + 2*[Protrusion,Protrusion,0],center=true); |

|

|

|

} |

|

} |

|

|

|

module Bracket() { |

|

|

|

translate([ClampSize.x/2 + MountSize.x/2 + MountClearance,0,MountSize.z/2 – ClampSize.z/2]) |

|

cube(MountSize,center=true); |

|

|

|

translate([ClampSize.x/2 + MountClearance/2,0,-(ClampSize.z + Kerf)/4]) |

|

cube([MountClearance + 2*Protrusion,MountSize.y,(ClampSize.z – Kerf)/2],center=true); |

|

|

|

} |

|

|

|

|

|

module Mount() { |

|

|

|

union() { |

|

Clamp("Lower"); |

|

Bracket(); |

|

} |

|

|

|

} |

|

|

|

|

|

|

|

//——- |

|

// Build it! |

|

|

|

if (Layout == "Ball") |

|

CamBall(); |

|

|

|

if (Layout == "Clamp") |

|

Clamp(); |

|

|

|

if (Layout == "Bracket") |

|

Bracket(); |

|

|

|

if (Layout == "Mount") |

|

Mount(); |

|

|

|

if (Layout == "Show") { |

|

difference() { |

|

union() { |

|

color("Purple") |

|

Clamp("Upper"); |

|

Mount(); |

|

color("LimeGreen") |

|

CamBall(); |

|

} |

|

rotate([0,0,45]) |

|

translate([-ClampSize.x,0,0]) |

|

cube(2*ClampSize,center=true); |

|

} |

|

} |

|

|

|

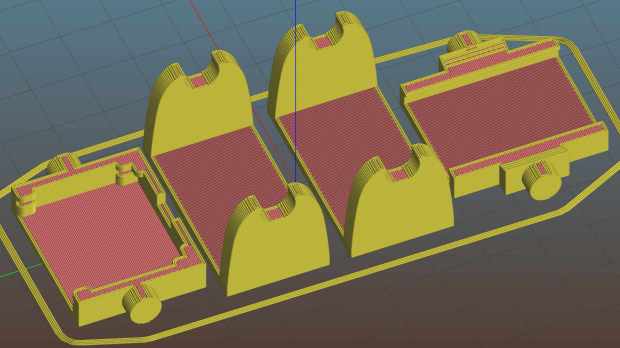

if (Layout == "Build") { |

|

Gap = 0.6; |

|

translate([-Gap*BallOD,Gap*BallOD,0]) |

|

CamBall("Upper"); |

|

|

|

translate([-Gap*BallOD,-Gap*BallOD,0]) |

|

rotate([0,180,0]) |

|

CamBall("Lower"); |

|

|

|

translate([Gap*ClampSize.x,-Gap*ClampSize.y,ClampSize.z/2]) |

|

rotate([0,180,0]) |

|

Clamp("Upper"); |

|

|

|

translate([Gap*ClampSize.x,Gap*ClampSize.y,ClampSize.z/2]) { |

|

rotate(180) |

|

Mount(); |

|

} |

|

} |