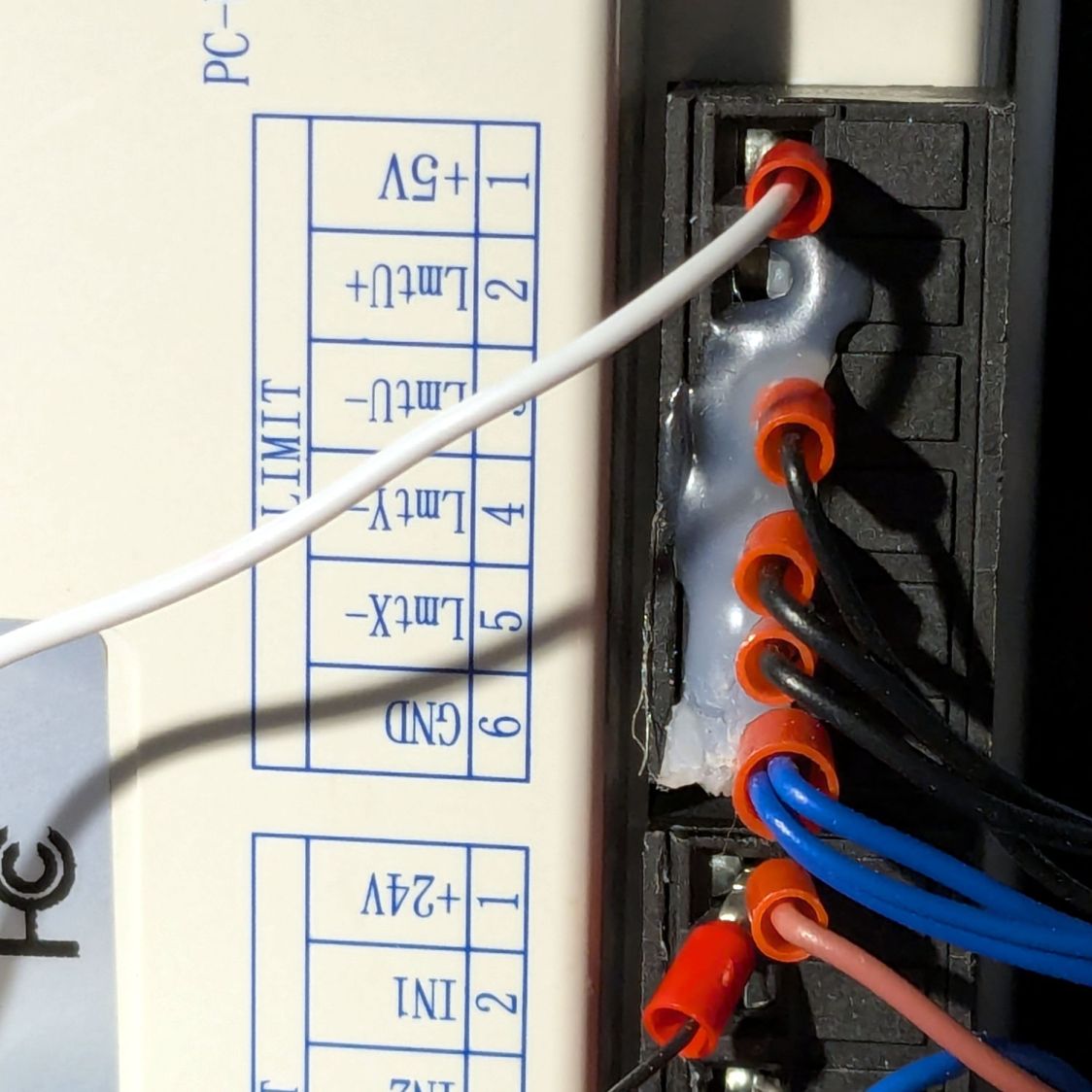

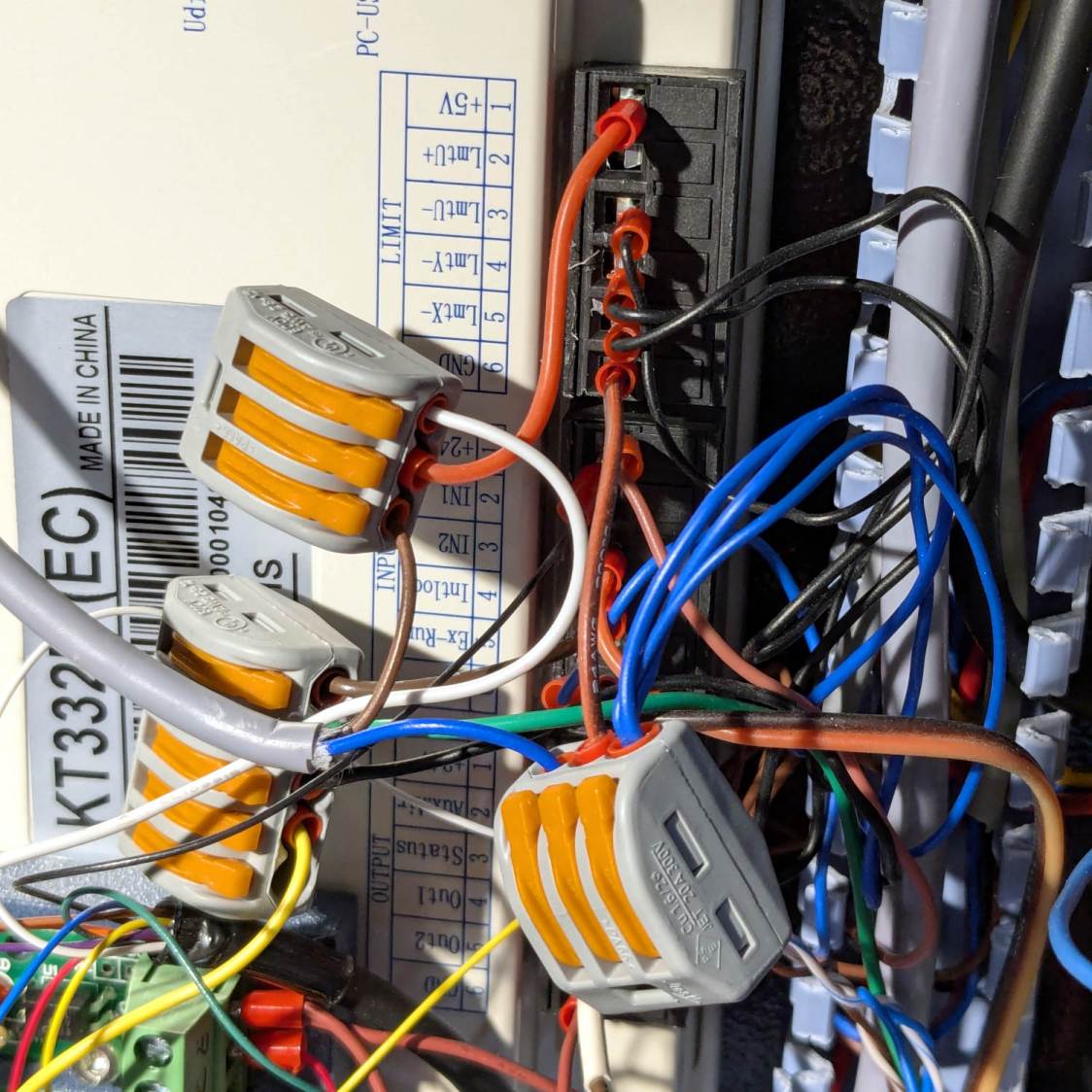

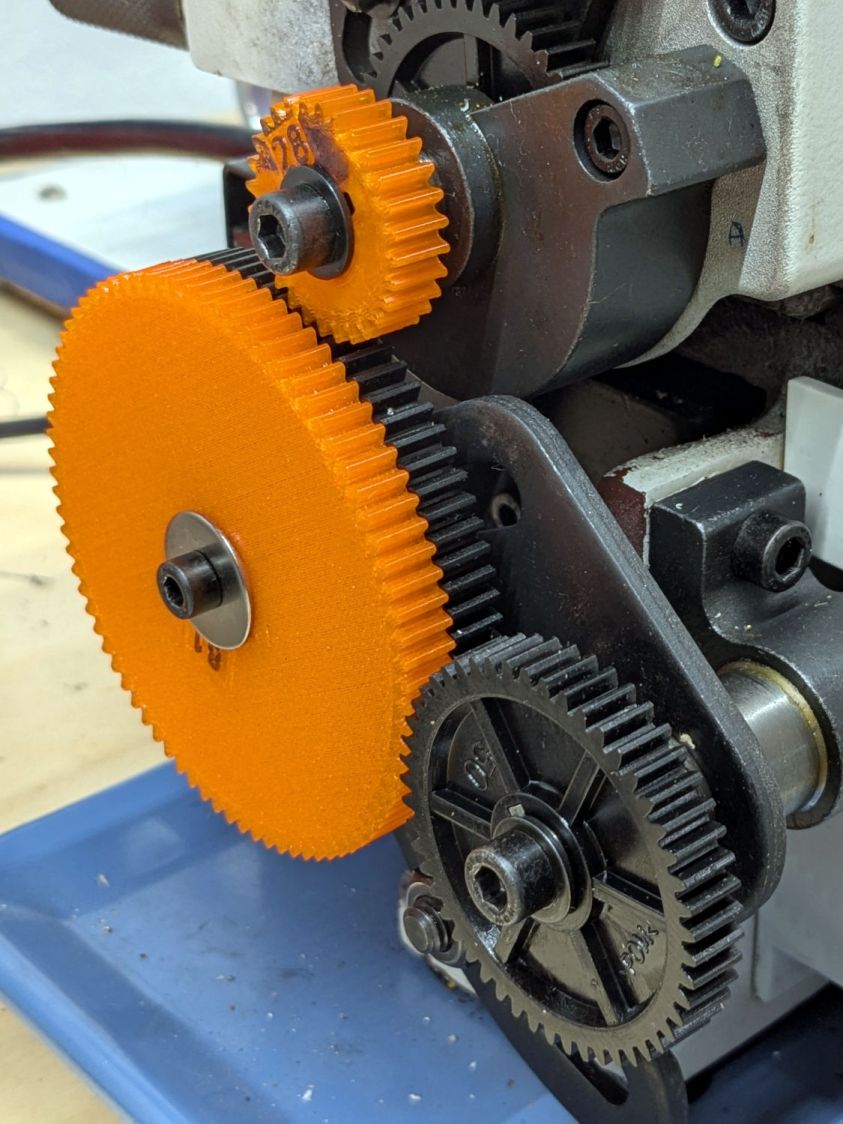

In the process of replacing the laser cutter’s OEM 24 V 6 A power supply with a 15 A supply, one of the two screws holding it in place remained stuck in the underlying sheet metal plate:

You can’t see either of the screws from that position, but they’re in the upper-left and lower-right corners. The offending screw is, of course, on the top, tucked between the top of the supply and the wire raceway. The bottom screw came out easily and I could maneuver the supply out of the way.

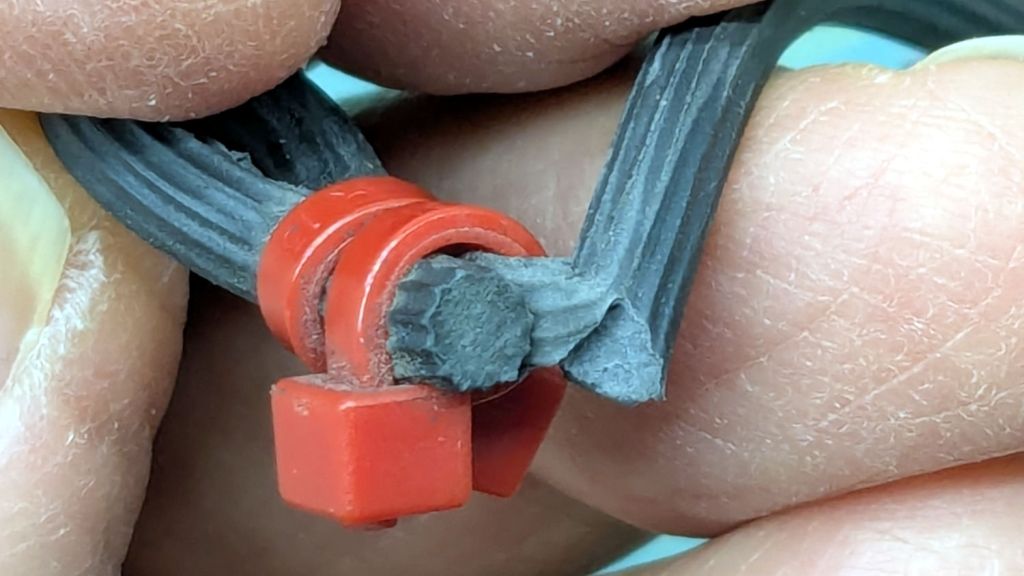

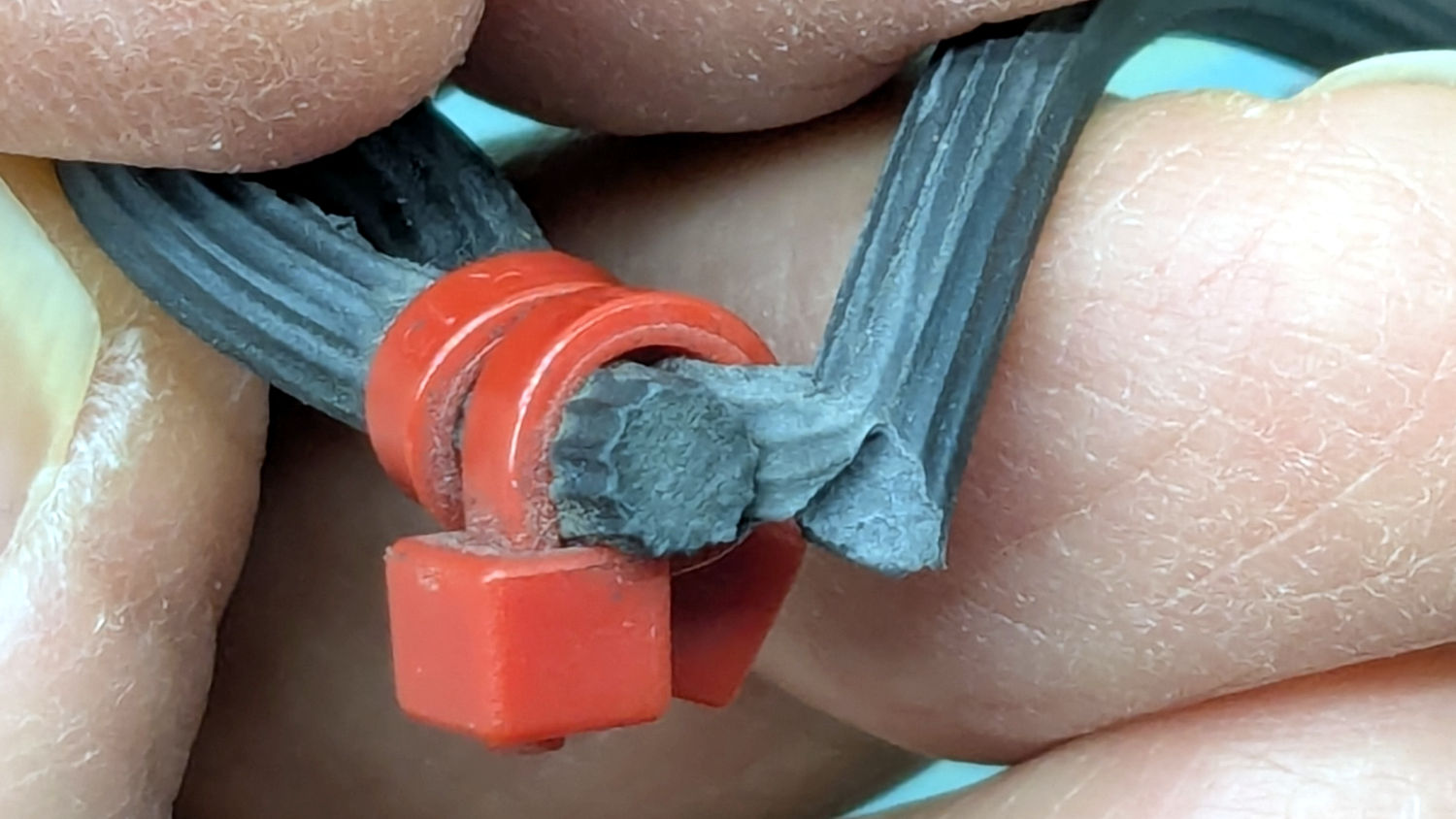

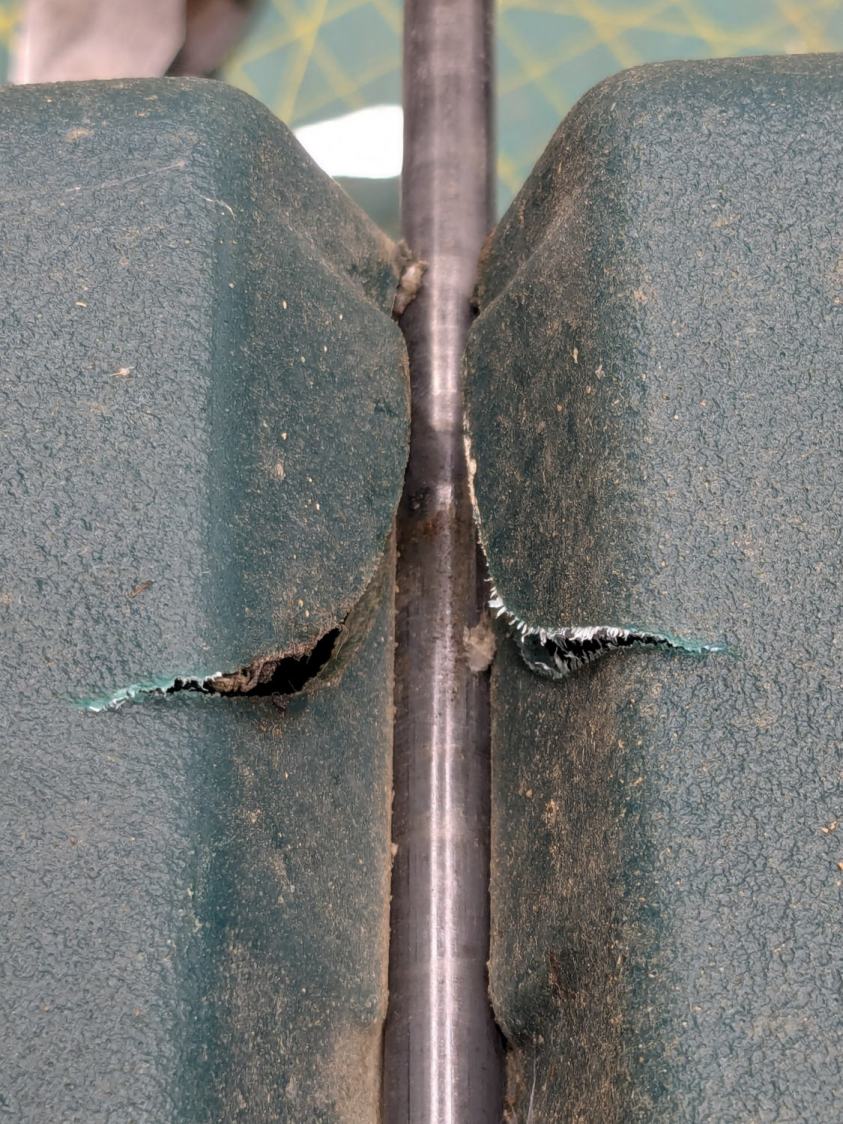

Vigorous persuasion involving a bent-nose pliers and muttering got the screw out and revealed the problem:

The reason why the screwdriver didn’t get much traction in the head also became obvious:

Folks on the LightBurn forum seem astonished when they discover their fresh-from-the-factory has loose screws, missing screws, and occasionally the wrong screws.

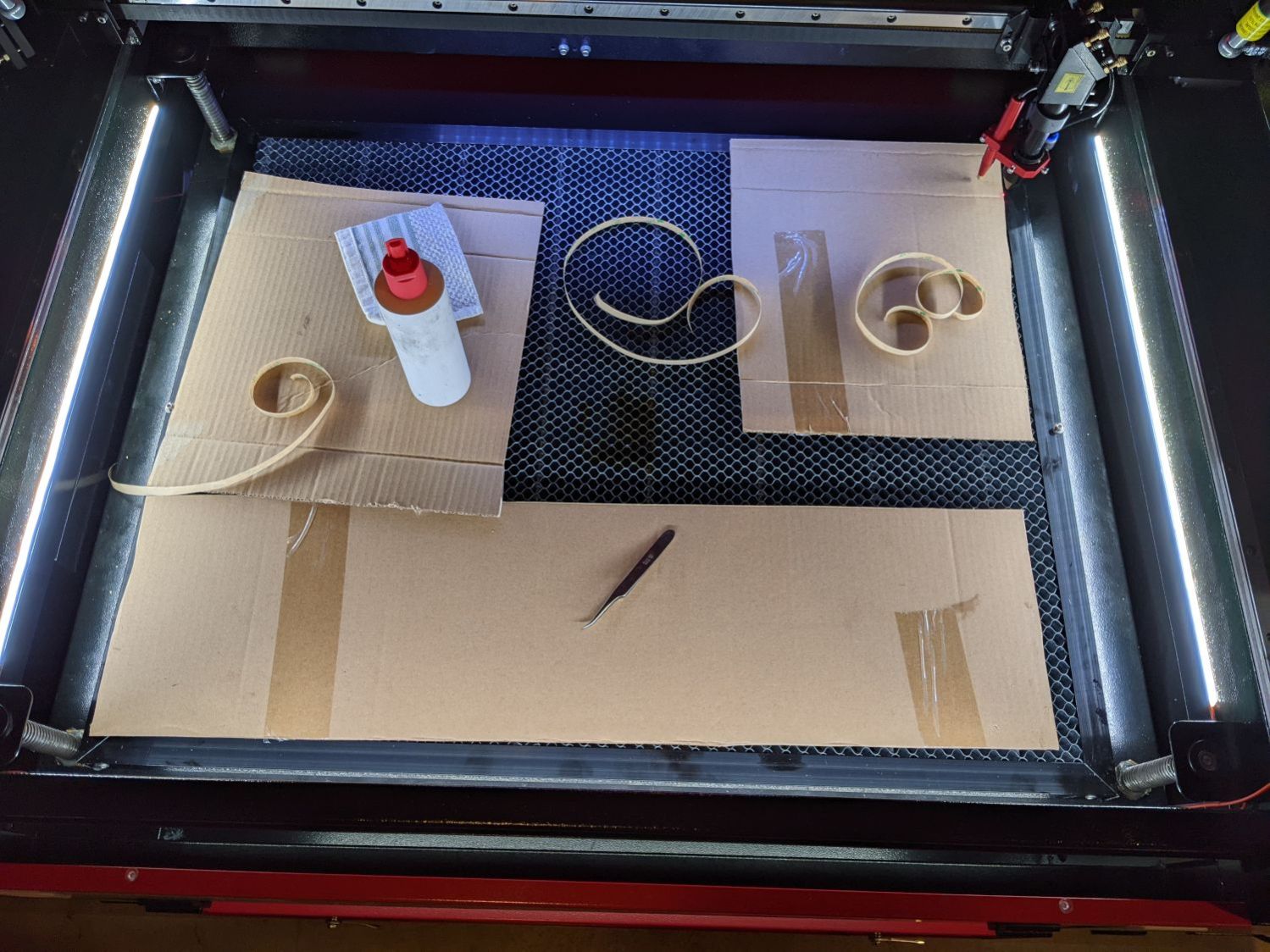

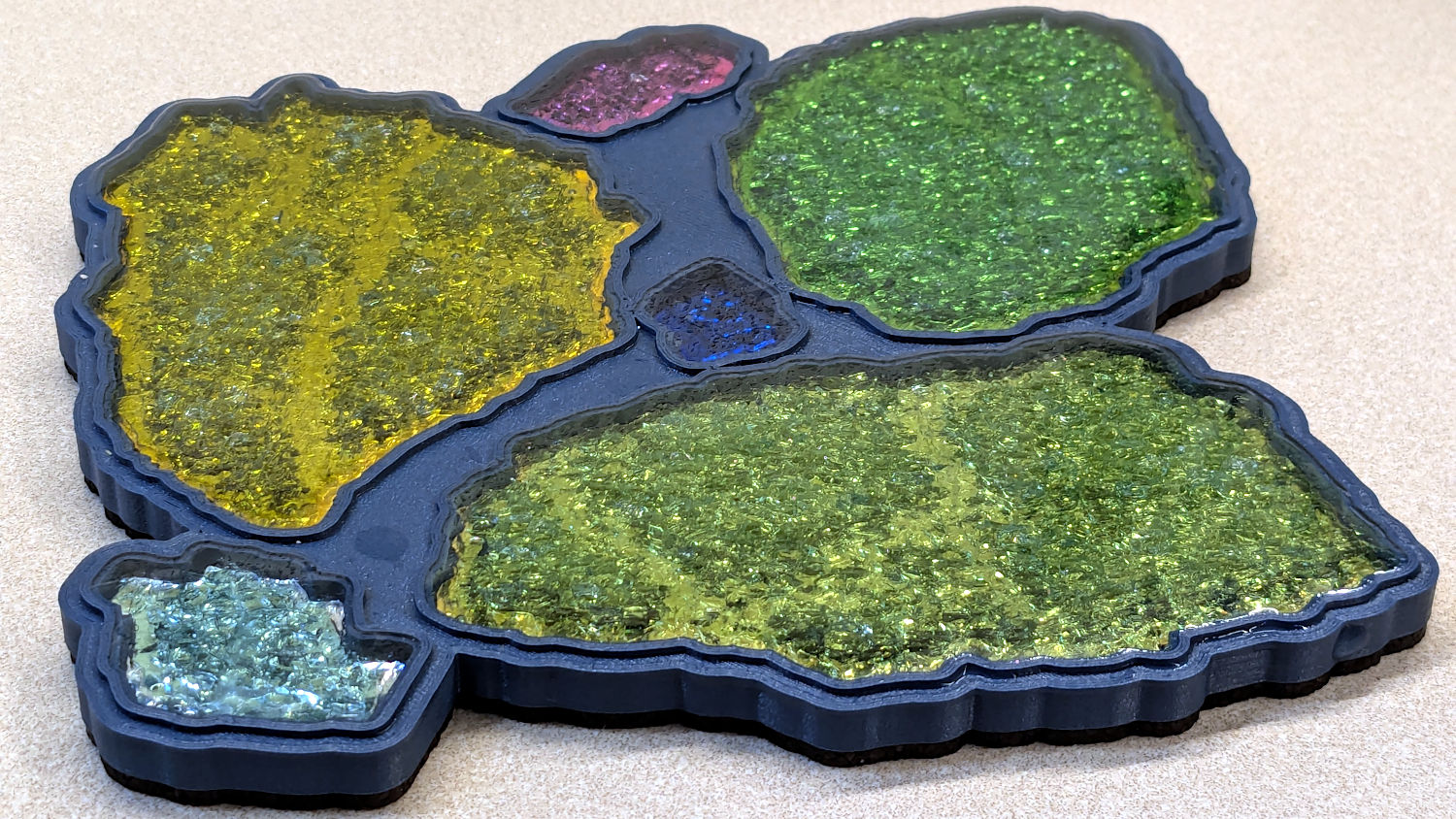

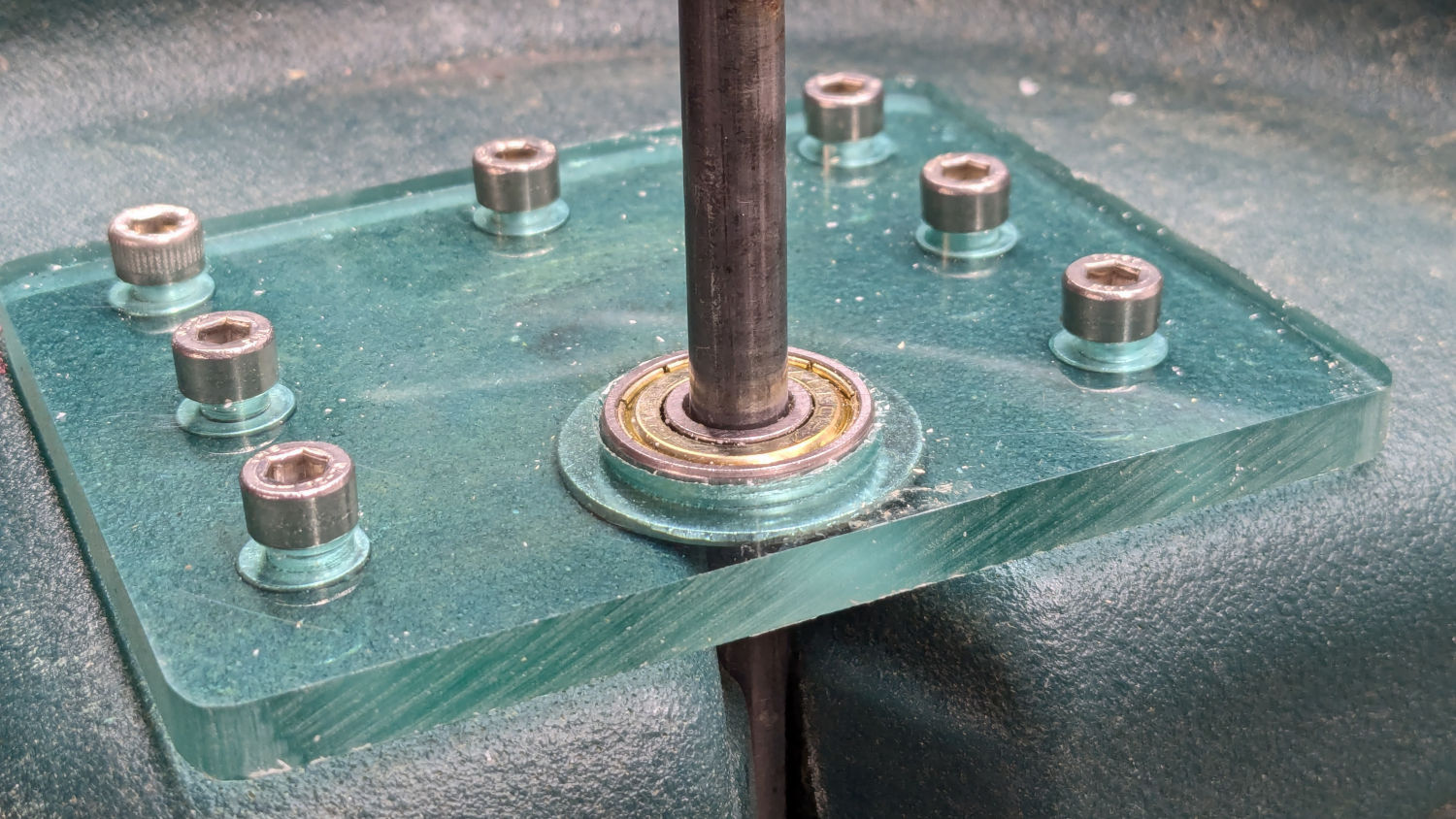

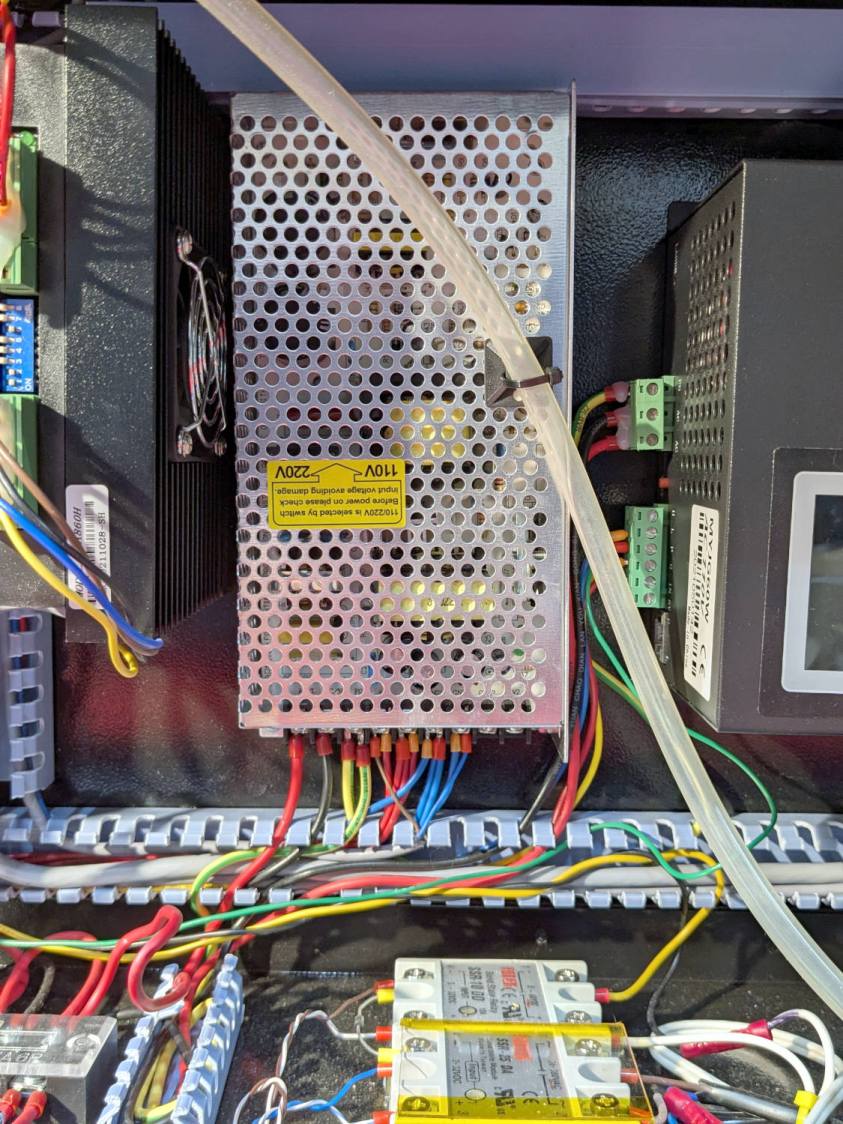

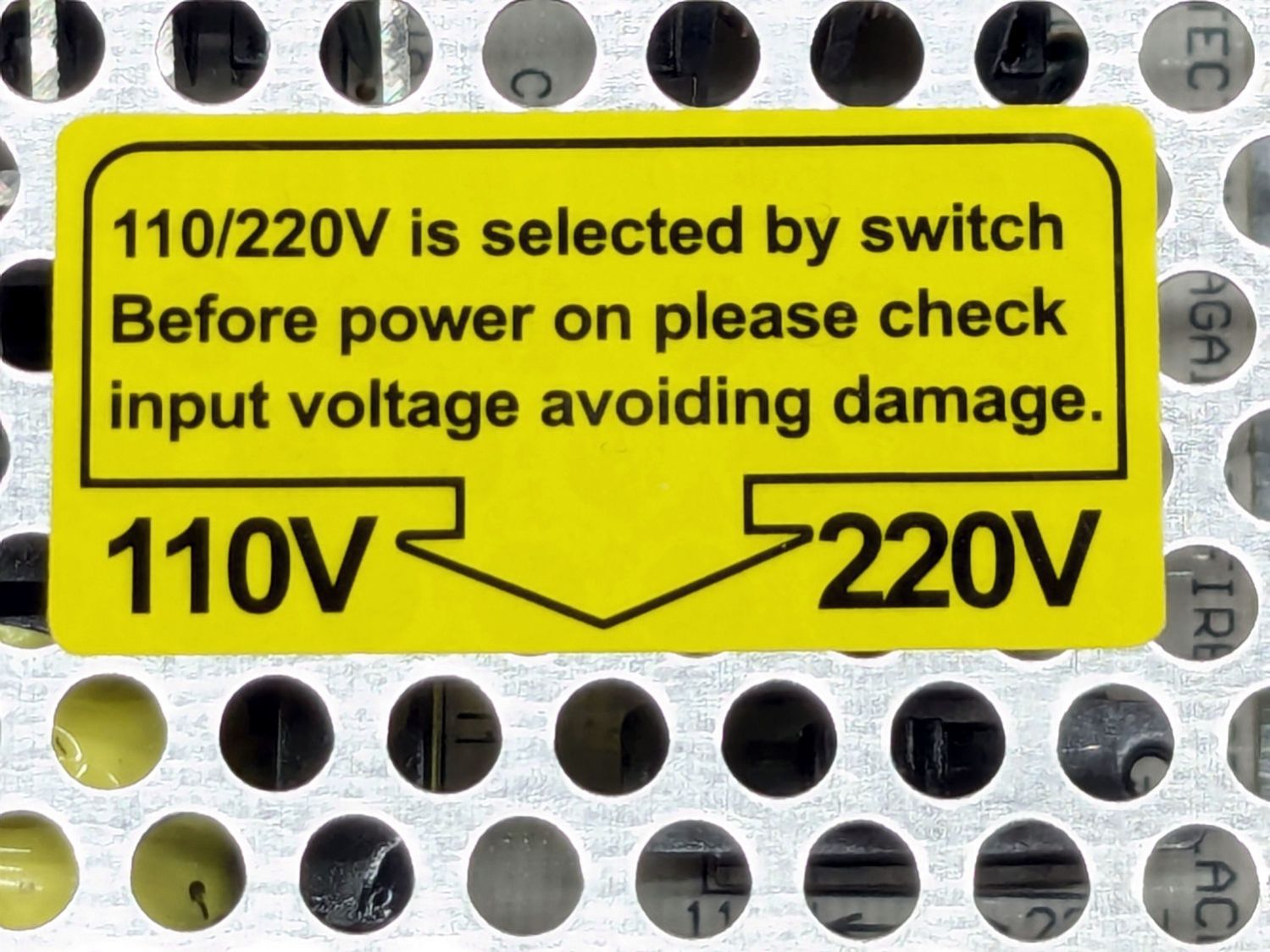

I always wondered where the switch pointed to by the conspicuous label might be:

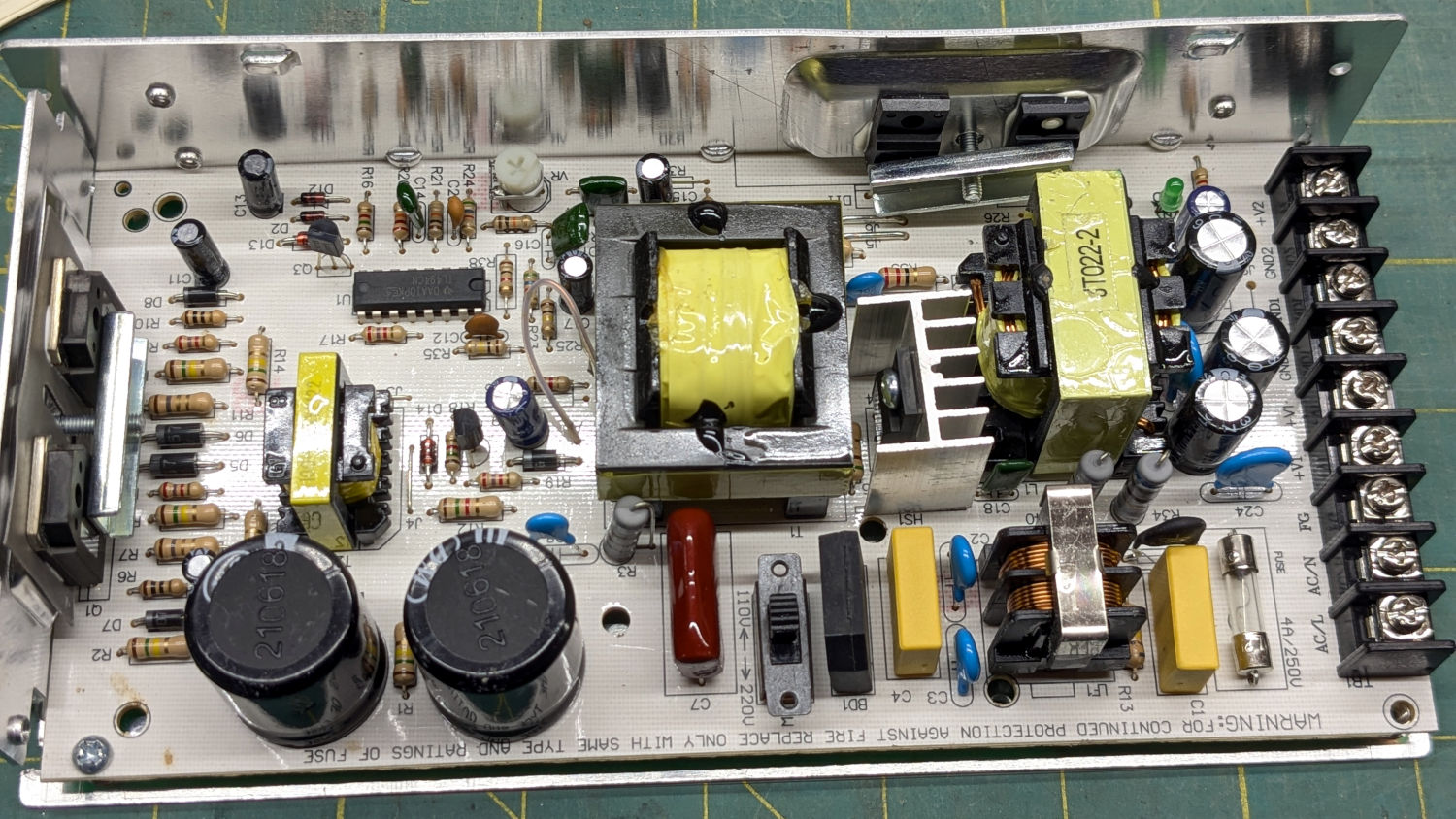

Unlike most supplies, it’s inside the case:

After you spot it, you can also find it just below the tip of the arrow in the previous picture. I suppose putting it inside the case prevents it from being inadvertently flipped, but somebody had to dismantle All. The. Supplies. to flip that switch for the USA-ian market.

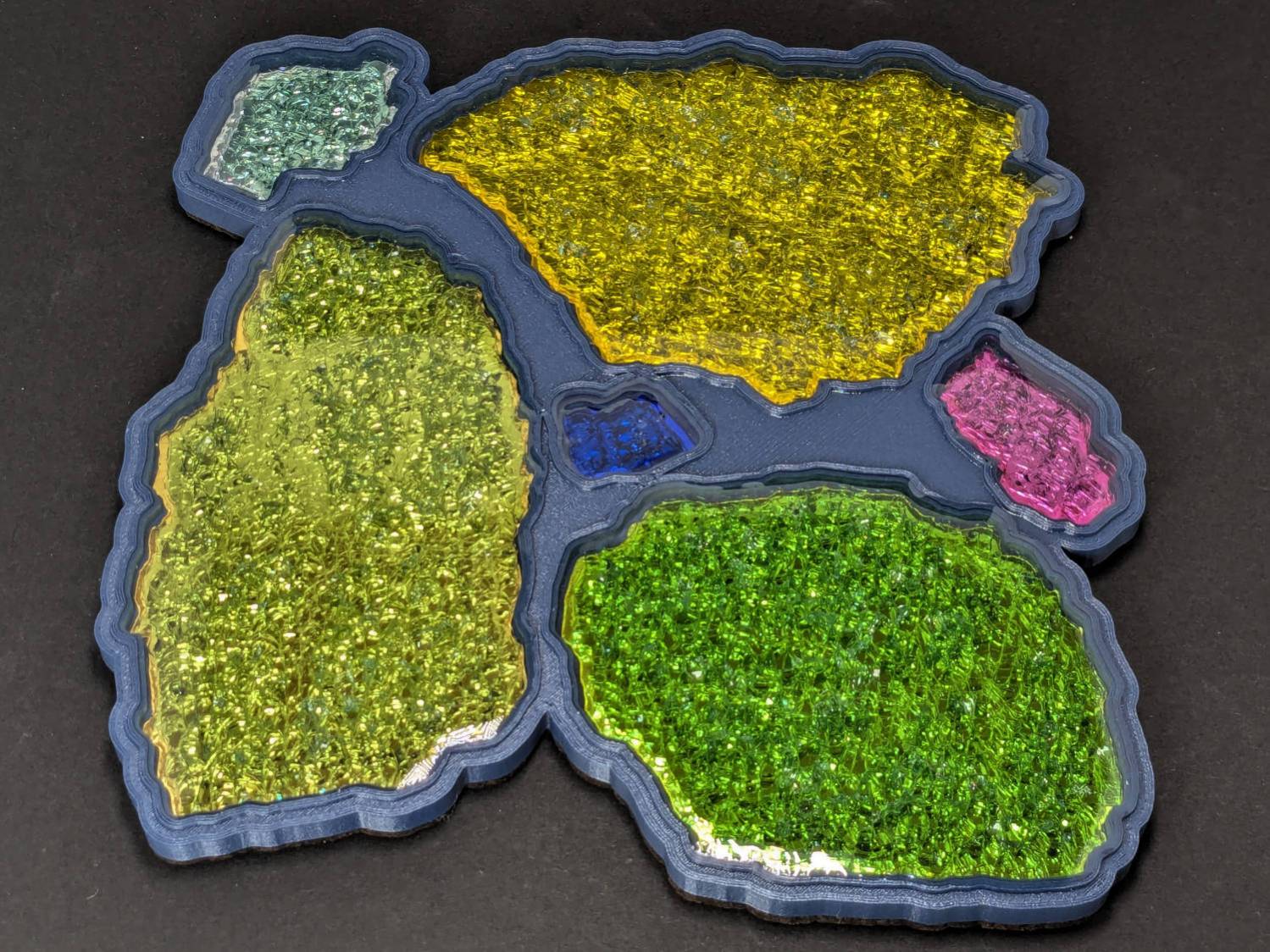

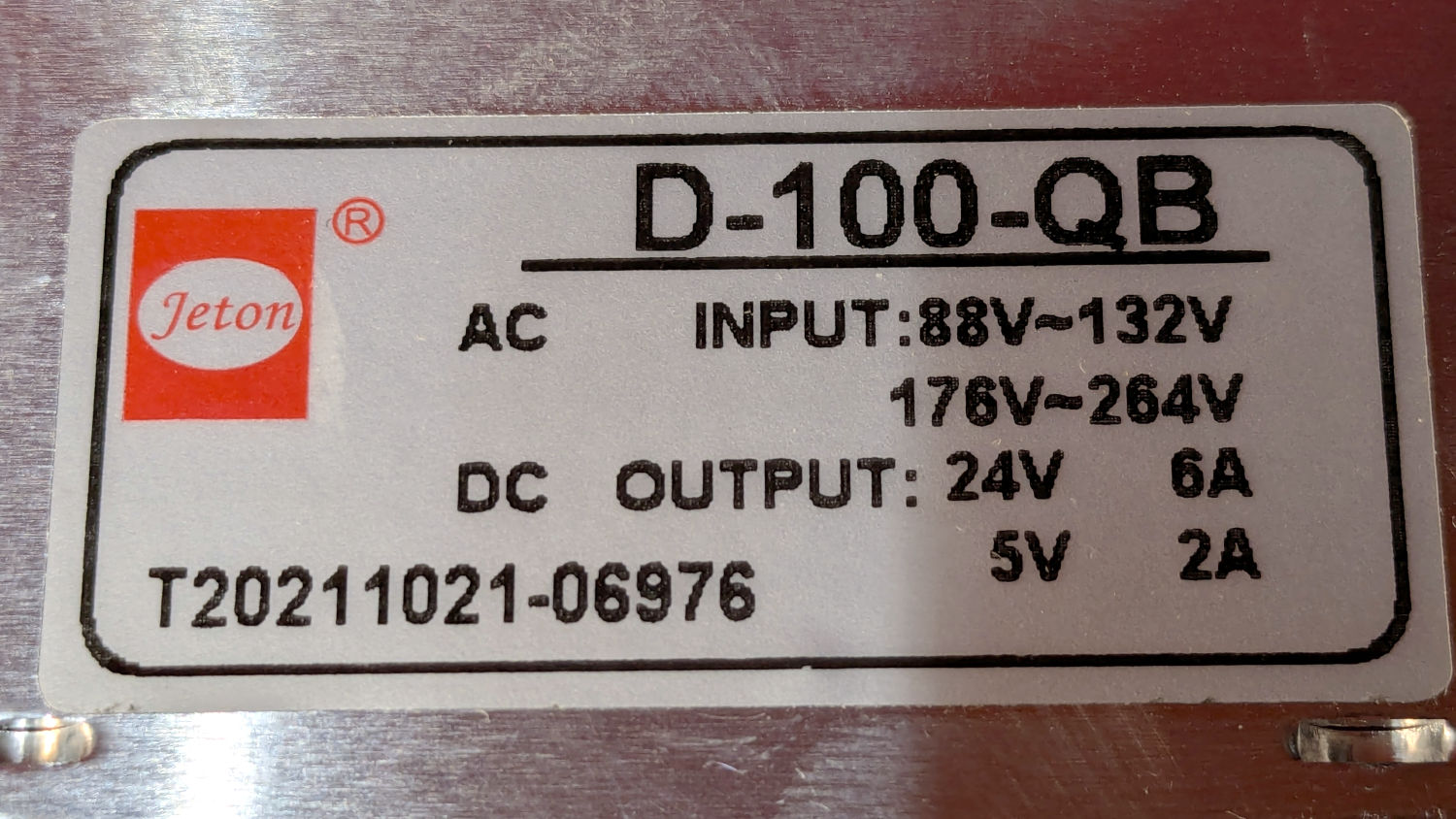

The dataplate also became visible:

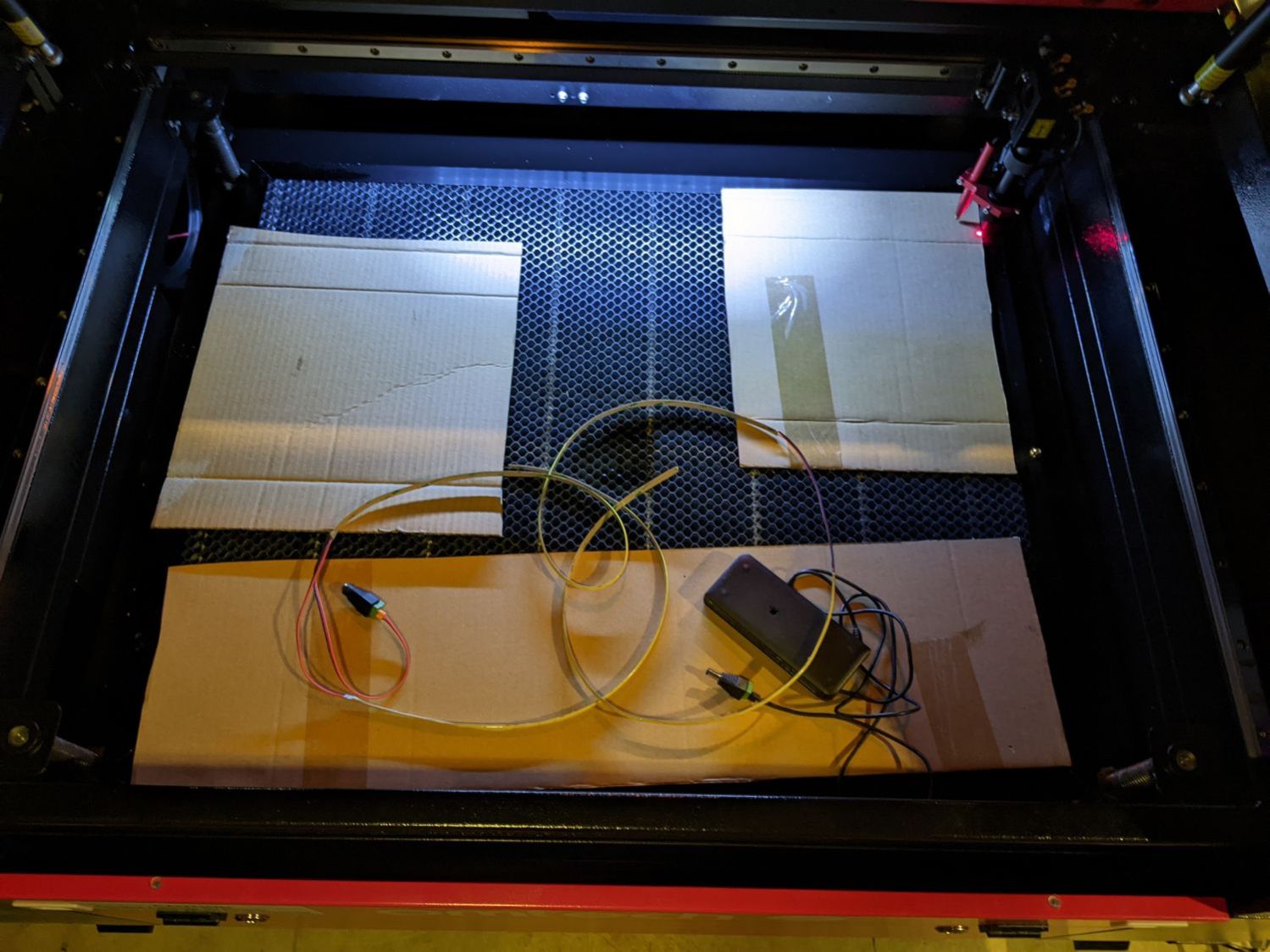

You’ll recall the 5 V 2 A output was dedicated to the red-dot pointer drawing about 20 mA.

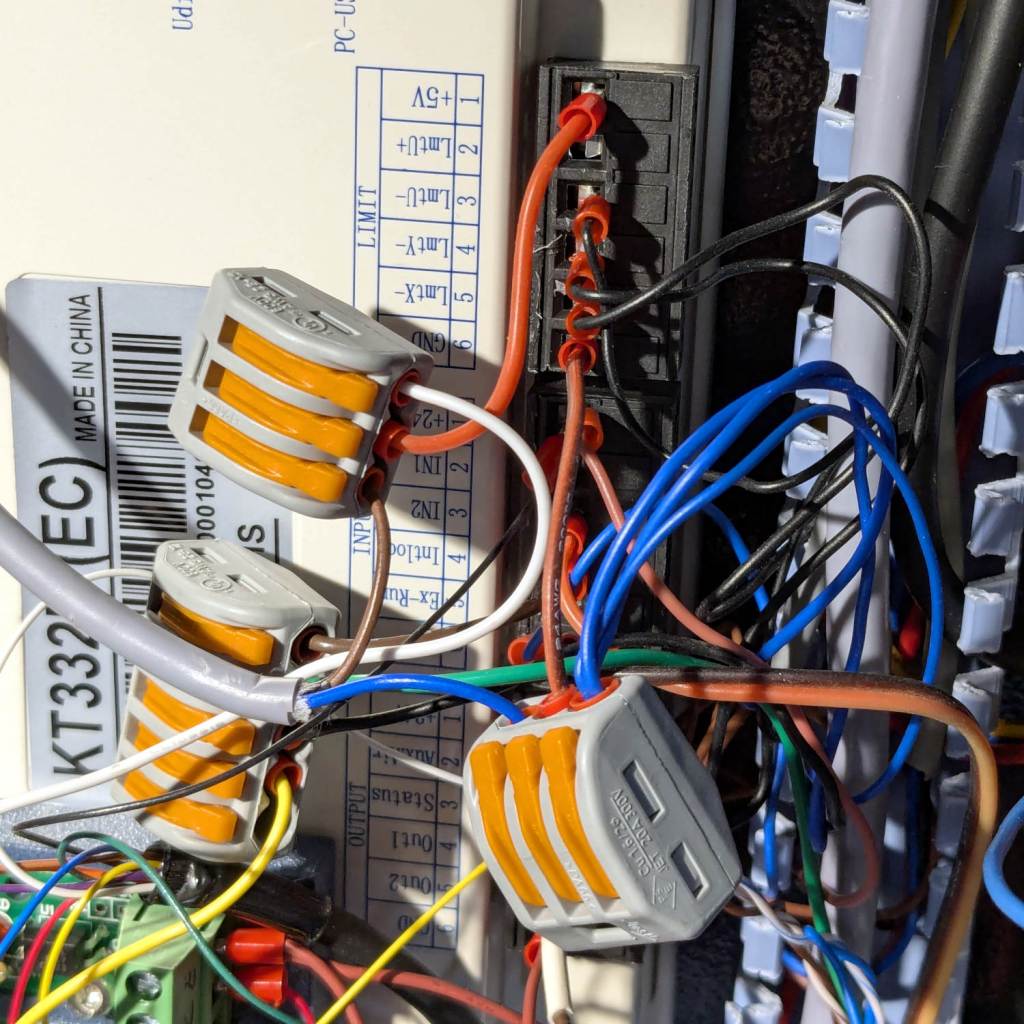

In contrast, the 24 V 6 A output handled:

- X axis stepper driver: 3.5 A peak

- Y axis stepper driver: 3.5 A peak

- U axis stepper driver: 5.1 A peak

- KT332N controller &c: 1 or 2 A

- Gantry LED strip: 0.25 A

The stepper drivers are set to drop the motor current by half when they’re idle, which means their load would be only around 6 A. That’s as delivered to the motor windings, with the power supply’s average current being lower by roughly the ratio between the motor’s rated voltage and the power supply voltage. The instantaneous peak current, however, is the sum of all those currents.

At some point I must measure all that, but for now I want to shoehorn a bigger supply in there to take care of the additional load of the rotary stepper driver, plus the existing platform lighting and improved electronics bay blower.