|

# Generator for rainbow block layered paper |

|

# Ed Nisley – KE4ZNU |

|

# 2025-08-03 cargo-culted from svg library examples |

|

|

|

import svg |

|

import math |

|

from argparse import ArgumentParser |

|

from random import randint, choice, seed |

|

from itertools import chain |

|

from pprint import pprint |

|

|

|

INCH = 25.4 |

|

X = 0 |

|

Y = 1 |

|

|

|

def as_mm(number): |

|

return repr(number) + "mm" |

|

|

|

parser = ArgumentParser() |

|

parser.add_argument('–layernum', type=int, default=0) |

|

parser.add_argument('–colors', type=int, default=16) |

|

parser.add_argument('–seed', type=int, default=1) |

|

parser.add_argument('–width', type=int, default=16) |

|

parser.add_argument('–height', type=int, default=16) |

|

parser.add_argument('–debug', default=False) |

|

args = parser.parse_args() |

|

|

|

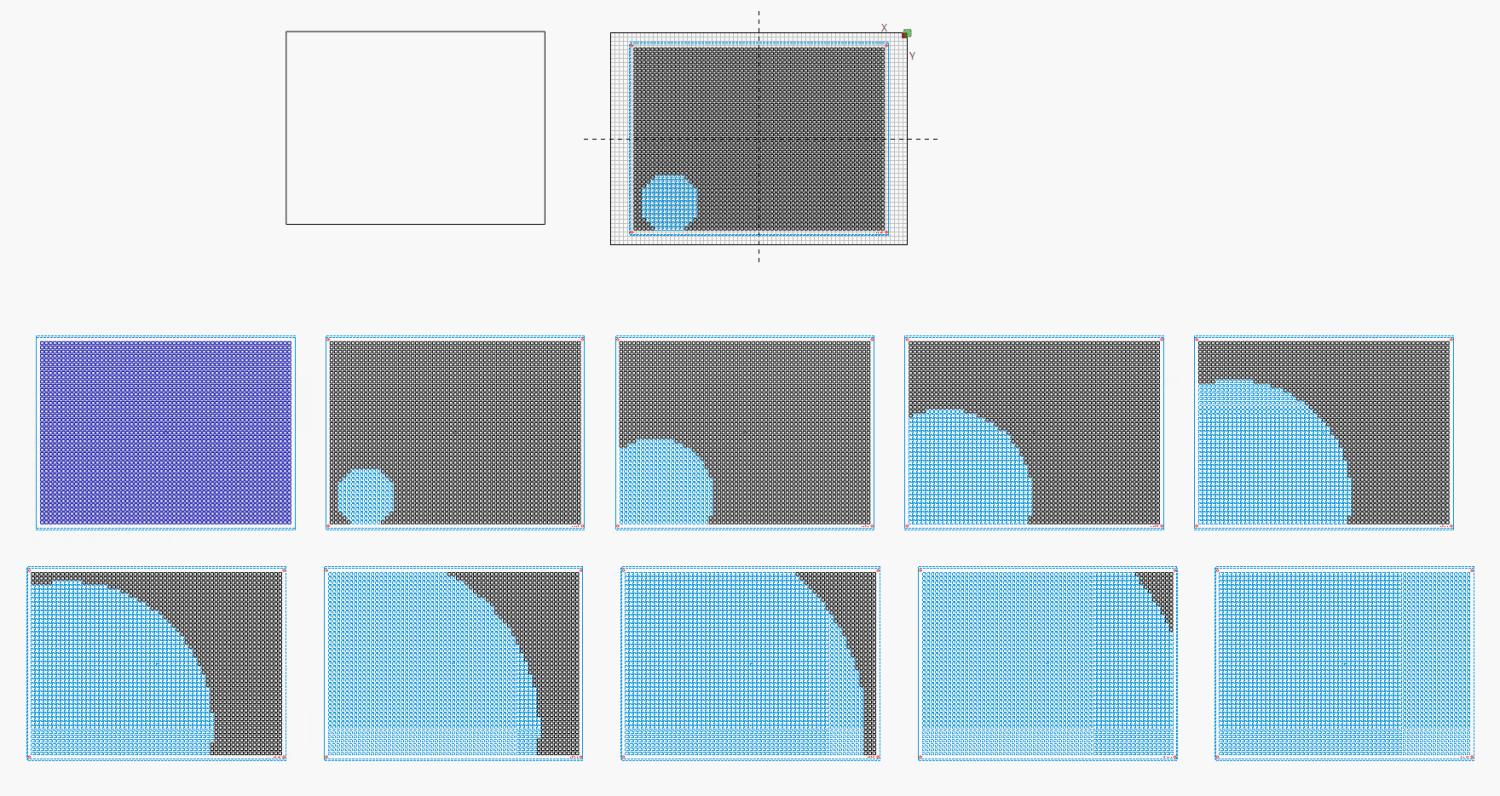

PageSize = (round(8.5*INCH,3), round(11.0*INCH,3)) |

|

|

|

SheetCenter = (PageSize[X]/2,PageSize[X]/2) # symmetric on Y! |

|

|

|

SheetSize = (200,200) # overall sheet |

|

|

|

AlignOC = (180,180) # alignment pins in corners |

|

AlignOD = 5.0 # … pin diameter |

|

|

|

MatrixOA = (170,170) # outer limit of cell matrix |

|

|

|

CellCut = "black" # C00 Black |

|

SheetCut = "red" # C02 Red |

|

HeavyCut = "rgb(255,128,0)" # C05 Orange black mask paper is harder |

|

HeavyCellCut = "rgb(0,0,160)" # C09 Dark Blue ditto |

|

Tooling = "rgb(12,150,217)" # T2 Tool |

|

|

|

DefStroke = "0.2mm" |

|

DefFill = "none" |

|

|

|

ThisLayer = args.layernum # determines which cells get cut |

|

Layers = args.colors # black mask = 0, color n = not perforated |

|

|

|

SashWidth = 1.5 # between adjacent cells |

|

|

|

CellSize = ((MatrixOA[X] – (args.width – 1)*SashWidth)/args.width, |

|

(MatrixOA[Y] – (args.height – 1)*SashWidth)/args.height) |

|

CellOC = (CellSize[X] + SashWidth,CellSize[Y] + SashWidth) |

|

|

|

if args.seed: |

|

seed(args.seed) |

|

|

|

#— accumulate tooling layout |

|

|

|

ToolEls = [] |

|

# mark center of sheet for drag-n-drop location |

|

ToolEls.append( |

|

svg.Circle( |

|

cx=SheetCenter[X], |

|

cy=SheetCenter[Y], |

|

r="2mm", |

|

stroke=Tooling, |

|

stroke_width=DefStroke, |

|

fill="none", |

|

) |

|

) |

|

# mark page perimeter for alignment check |

|

if False: |

|

ToolEls.append( |

|

svg.Rect( |

|

x=0, |

|

y=0, |

|

width=as_mm(PageSize[X]), |

|

height=as_mm(PageSize[Y]), |

|

stroke=Tooling, |

|

stroke_width=DefStroke, |

|

fill="none", |

|

) |

|

) |

|

# center huge box on matrix center |

|

if False: |

|

ToolEls.append( |

|

svg.Rect( |

|

x=as_mm(SheetCenter[X] – 2*SheetSize[X]/2), |

|

y=as_mm(SheetCenter[Y] – 2*SheetSize[Y]/2), |

|

width=as_mm(2*SheetSize[X]), |

|

height=as_mm(2*SheetSize[Y]), |

|

stroke=Tooling, |

|

stroke_width=DefStroke, |

|

fill="none", |

|

) |

|

) |

|

|

|

#— accumulate sheet cuts |

|

|

|

SheetEls = [] |

|

# cut perimeter |

|

SheetEls.append( |

|

svg.Rect( |

|

x=as_mm(SheetCenter[X] – SheetSize[X]/2), |

|

y=as_mm(SheetCenter[Y] – SheetSize[Y]/2), |

|

width=as_mm(SheetSize[X]), |

|

height=as_mm(SheetSize[Y]), |

|

stroke=SheetCut if ThisLayer > 0 else HeavyCut, |

|

stroke_width=DefStroke, |

|

fill="none", |

|

), |

|

) |

|

# cut layer ID holes except on mask layer |

|

if ThisLayer > 0: |

|

c = ((1,1)) |

|

h = f'{ThisLayer:0{Layers.bit_length()}b}' |

|

for i in range(Layers.bit_length()): |

|

SheetEls.append( |

|

svg.Circle( |

|

cx=as_mm(SheetCenter[X] + c[X]*AlignOC[X]/2 – (i + 2)*AlignOD), |

|

cy=as_mm(SheetCenter[Y] + c[Y]*AlignOC[Y]/2), |

|

r=AlignOD/4 if h[-(i + 1)] == '1' else AlignOD/8, |

|

stroke=SheetCut, |

|

stroke_width=DefStroke, |

|

fill="none", |

|

) |

|

) |

|

# cut alignment pin holes except on mask layer |

|

if ThisLayer > 0: |

|

for c in ((1,1),(-1,1),(-1,-1),(1,-1)): |

|

SheetEls.append( |

|

svg.Circle( |

|

cx=as_mm(SheetCenter[X] + c[X]*AlignOC[X]/2), |

|

cy=as_mm(SheetCenter[Y] + c[Y]*AlignOC[Y]/2), |

|

r=as_mm(AlignOD/2), |

|

stroke=SheetCut, |

|

stroke_width=DefStroke, |

|

fill="none", |

|

) |

|

) |

|

|

|

#— calculate matrix contents |

|

|

|

CenterPoint = (choice(range(args.width)),choice(range(args.height))) |

|

|

|

CellMatrix = [[math.hypot(x – CenterPoint[X],y – CenterPoint[Y]) |

|

for y in range(args.height)] |

|

for x in range(args.width)] |

|

|

|

dmax = max(list(chain.from_iterable(CellMatrix))) |

|

|

|

if args.debug: |

|

print(CenterPoint) |

|

print(dmax) |

|

pprint(CellMatrix) |

|

print() |

|

|

|

#— accumulate matrix cuts |

|

|

|

LayerThreshold = (ThisLayer/Layers)*dmax |

|

if args.debug: |

|

print(LayerThreshold) |

|

|

|

MatrixEls = [] |

|

for i in range(args.width): |

|

x =i*CellOC[X] |

|

for j in range(args.height): |

|

y = j*CellOC[Y] |

|

|

|

if args.debug: |

|

print(i) |

|

print(j) |

|

print(CellMatrix[i][j]) |

|

|

|

|

|

if ThisLayer == 0: # black mask |

|

s = HeavyCellCut |

|

elif LayerThreshold < CellMatrix[i][j]: # rest of sheets above color layer |

|

s = CellCut |

|

else: |

|

s = Tooling # at or below color layer |

|

|

|

MatrixEls.append( |

|

svg.Rect( |

|

x=as_mm(SheetCenter[X] – MatrixOA[X]/2 + x), |

|

y=as_mm(SheetCenter[Y] – MatrixOA[Y]/2 + y), |

|

width=as_mm(CellSize[X]), |

|

height=as_mm(CellSize[Y]), |

|

stroke=s, |

|

stroke_width=DefStroke, |

|

fill="none", |

|

) |

|

) |

|

|

|

#— assemble and blurt out the SVG file |

|

|

|

if not args.debug: |

|

canvas = svg.SVG( |

|

width=as_mm(PageSize[X]), |

|

height=as_mm(PageSize[Y]), |

|

elements=[ |

|

ToolEls, |

|

SheetEls, |

|

MatrixEls |

|

], |

|

) |

|

|

|

print(canvas) |