It seems 390/389 alkaline button cells can power the mini-lathe’s DROs for about a year:

Given that the replacement cells all come from the same batch, they’re aging on the shelf as well as in the DROs.

Once again, I replaced both of them.

The Smell of Molten Projects in the Morning

Ed Nisley's Blog: Shop notes, electronics, firmware, machinery, 3D printing, laser cuttery, and curiosities. Contents: 100% human thinking, 0% AI slop.

Mechanical widgetry

It seems 390/389 alkaline button cells can power the mini-lathe’s DROs for about a year:

Given that the replacement cells all come from the same batch, they’re aging on the shelf as well as in the DROs.

Once again, I replaced both of them.

Transferring the printers to a new “server” provided an opportunity to dump another king’s ransom of waste ink down the drain, whereupon the tank cracked under finger pressure:

The black smudge on the far side is an ink stain on adhesive left over from the hook-n-loop strip formerly holding it to the printer.

It looks to be an ordinary polypropylene tube, nothing fancy, and, after a decade, it really doesn’t owe me anything.

Scrounge a suitable bottle from one of the Big Boxes o’ Containers, run a bead of JB Weld Plasticbonder around the shoulder matching the discarded lid, jam on an original waste ink tank cap, and let the urethane goo cure while rotating slowly in the lathe to avoid unsightly dribbles:

The goo surely won’t bond to the polyethylene bottle, but it’s likely better than anything else in my inventory. We shall see.

Drill a hole for the hose, ignore the chips left inside the tank due to a sequence error, stick the original hook-n-loop tape in place, replace the drip-catcher rags, and install:

The red silicone tape encourages the cap to remain in place against the urethane adhesive. One fewer endcap = one less seal.

The cap need not be removable, as you just squeeze the tube slightly to squirt the aforementioned king’s ransom down the drain.

It ought to last until I finally scrap out the printer.

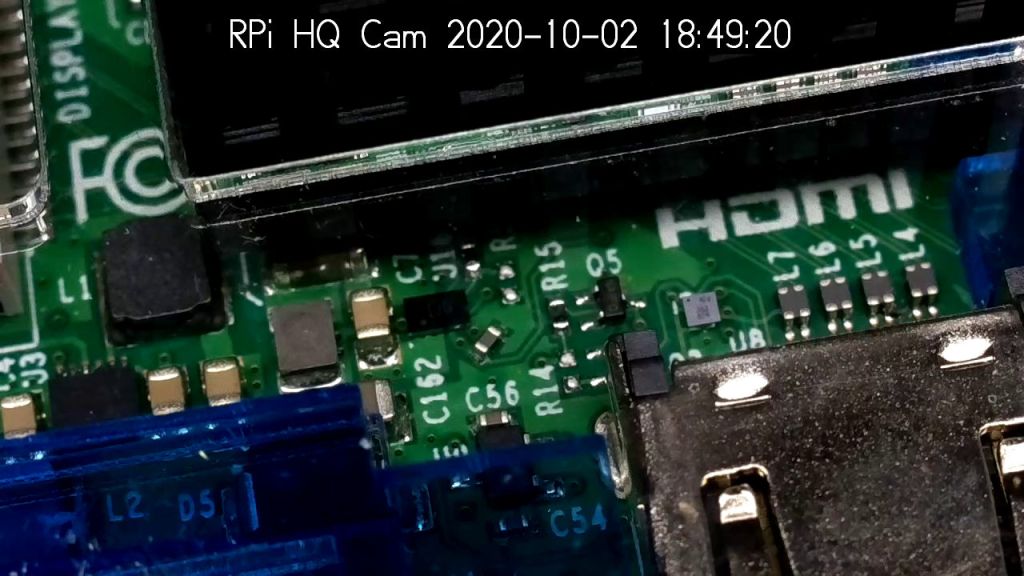

It Would Be Nice to turn the various Raspberry Pi camera boxen around here into more-or-less full-automatic IP streaming cameras, perhaps using RTSP, so as to avoid having to start everything manually, then restart the machinery after a trivial interruption. I naively thought video streaming was a solved problem, especially on an RPi, particularly with an Official RPi Camera, given the number of solutions found by casual searching with the obvious keywords.

As far as I can tell, however, all of the recommended setups fail in glorious / amusing / tragic ways. Some failures may be due to old configurations no longer applicable to new software, but I’m nowhere near expert experienced enough to figure out what’s broken and how to fix anything in particular.

Doing RTSP evidently requires the live555.com Streaming Media libraries & test suite. Compiling requires adding -DNO_SSL=1 to the COMPILE_OPTS line in the Makefile, then letting it bake it for a while.

The v4l2rtspserver code fetches & cleanly compiles its version of the live555 code, then emits various buffer overflow errors while streaming; the partial buffers clearly show how the compression works on small blocks in successive lines. Increasing various buffer sizes from 60 kB to 100 kB to 300 kB had little effect. This may have to do with the stream’s encoding / compression methods / bit rates, none of which seem amenable to random futzing.

Another straightforward configuration compiled fine, but VLC failed to actually show the stream, perhaps due to differences between the old version of Raspbian (“Stretch”) and the new version of Raspberry Pi OS (“Buster”).

Running the RPi camera through the Video4Linux2 interface to create a /dev/video0 device seems to work, but controlling the camera’s exposure (and suchlike) with v4l2_ctl behaves erratically. Obvious effects, like rotation & flipping, work fine, but not the fine details along the lines of auto exposure and color modes.

Attempting to fire raspivid through cvlc to produce an RTSP stream required installing VLC on a headless Raspberry Pi, plus enough co-requisite packages to outfit world+dog+kitchenSink. After all the huffing & puffing wound down, the recommended VLC parameters failed to produce an output stream. The VLC doc regarding streaming is, to me, impenetrable, so I have no idea how to improve the situation; I assume RTSP streaming is possible, just not by me.

Whenever any of those lashups produced any video whatsoever, the images suffered from tens-of-seconds latency, dropped frames, out-of-order video updates, and generally poor behavior. Some maladies certainly came from the aforementioned inappropriate encoding / compression methods / bit rates.

The least horrible alternative seems to be some variation on the original theme of using raspivid to directly create a tcp stream or firing raspivid into netcat to the same effect, then re-encoding it on a beefier PC as needed. I’m sure systemd can automagically restart raspivid (or, surely, a script with all the parameters) after it shuts down.

So far, this has been an … unsatisfactory … experience, but now I can close a dozen browser tabs.

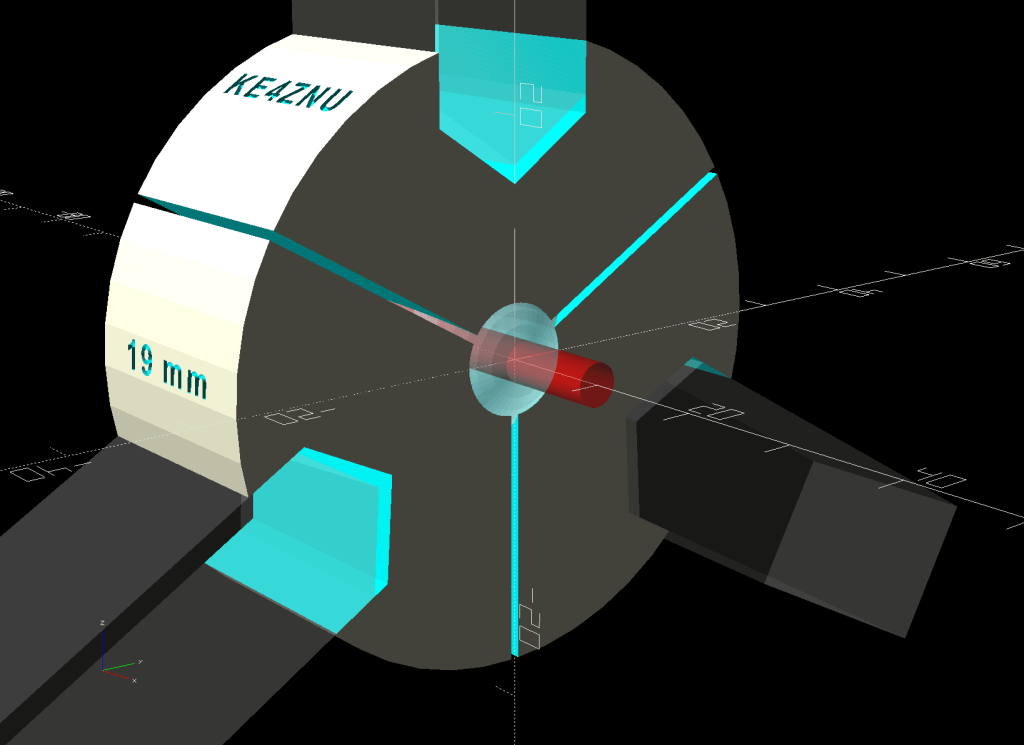

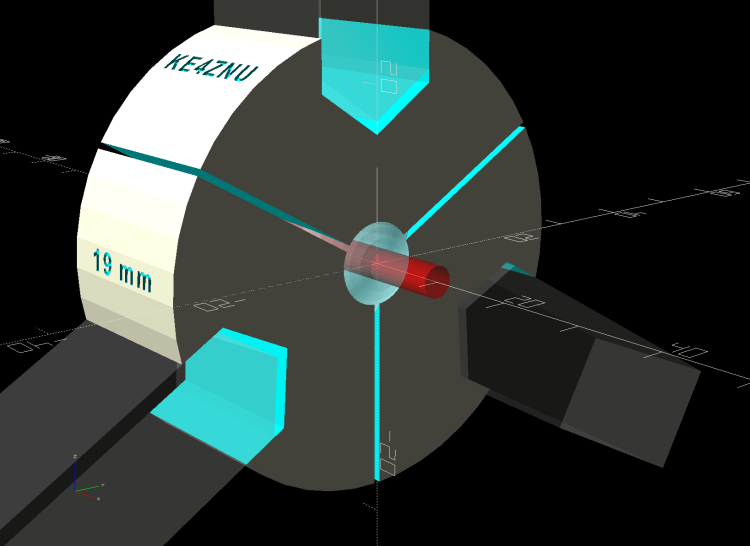

Despite successfully drilling holes in a few plastic balls, I wanted a somewhat less terrifying setup than this:

The stiffness of the bike helmet mirror mount suggested a similar clamp would have enough griptivity to immobilize the ball while cutting it in the lathe:

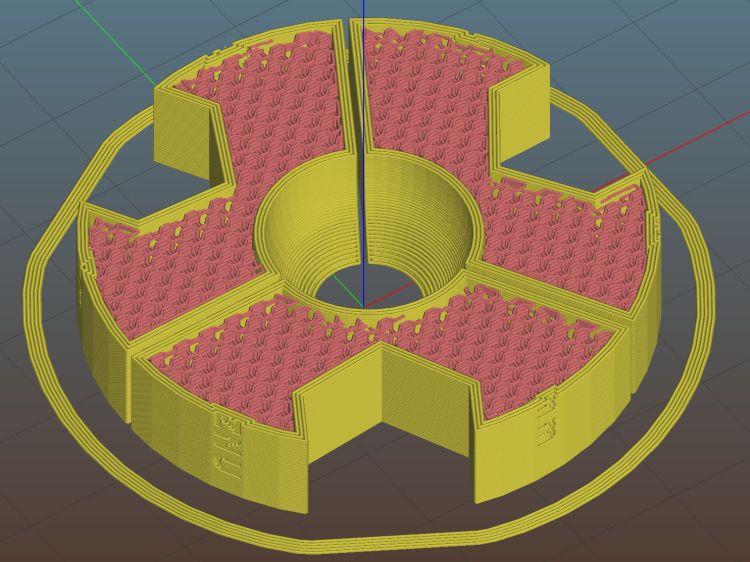

Building the clamp around the lathe’s three-jaw lathe chuck eliminates the need for screws / washers / inserts:

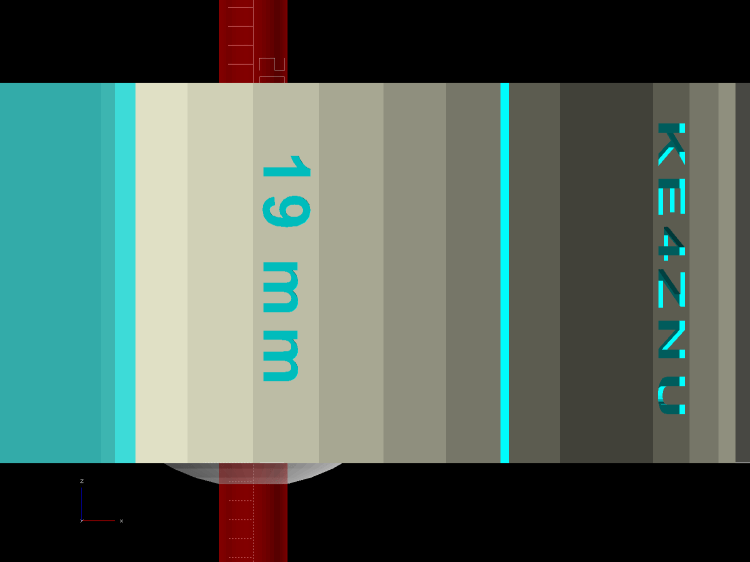

The Ah-ha! moment came when I realized the fixture can expose half of the ball’s diameter for drilling while clamping 87% of its diameter, because 0.5 = sin 30° and 0.87 = cos 30°:

That’s an orthogonal view showing 13% of the ball radius sticking out of the fixture; it’s 6% of the diameter.

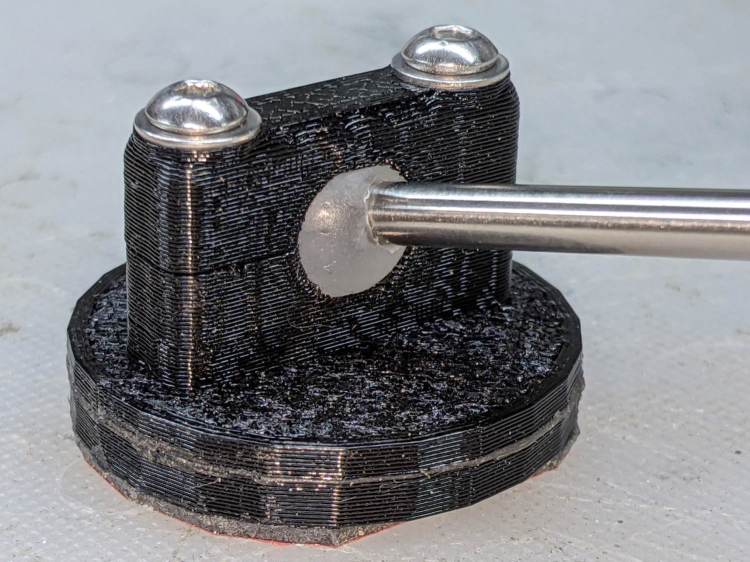

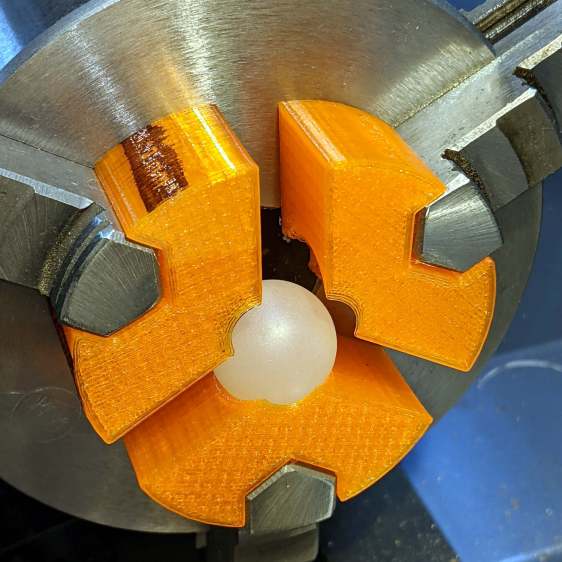

Which looks like this in real life:

The socket is offset toward the tailstock end of the clamp (on the right in the picture) to expose half its diameter flush with the surface perpendicular to the lathe axis. The other side necks down into a cylinder of the same diameter to clear the drill bit.

This works nicely until the ball diameter equals the chuck jaw’s 20 mm length, whereupon larger balls protrude into the chuck body’s spindle opening. Although I haven’t yet built one, the 25 mm balls in my Box o’ Bearings should fit, with exceedingly sissy cuts required for large holes.

The fixture doesn’t require support material, because the axial holes eliminate the worst of the overhang. Putting the tailstock side flat on the platform gives it the best-looking surface:

The kerf between the segments ensures the jaws can apply pressure to the ball, whereupon the usual crappy serrated 3D printed surface firmly grabs it.

The fixture is a slip fit on the chuck jaws:

Tightening the jaws shoves them all the way into the fixture’s slots and clamps the ball:

Overtightening the chuck will (probably) compress the ball around the drill, which will (best case) give you slightly oversize holes or (worst case) cause the ball to seize / melt around the drill bit, so sleaze up to the correct hole diameter maybe half a millimeter at a time:

That fixture exposes 9.5 mm = 19/2 of the ball. The drill makes a 6 mm hole to fit the telescoping shaft seen above.

Obviously, you must build a custom fixture for every ball diameter in your inventory, which is no big deal when you have a hands-off manufacturing process. Embossing the diameter into the fixture helps match them, although the scribbled Sharpie isn’t particularly elegant.

The OpenSCAD source code as a GitHub Gist:

| // Lathe Ball Drilling Fixture | |

| // Ed Nisley KE4ZNU 2020-11 | |

| /* [Layout options] */ | |

| Layout = "Build"; // [Build, Show, Body, Jaws] | |

| BallDia = 10.0; // [5.0:0.5:25.0] | |

| /* [Extrusion parameters] */ | |

| /* [Hidden] */ | |

| ThreadThick = 0.25; | |

| ThreadWidth = 0.40; | |

| HoleWindage = 0.2; | |

| function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); | |

| function IntegerLessMultiple(Size,Unit) = Unit * floor(Size / Unit); | |

| Protrusion = 0.1; // make holes end cleanly | |

| inch = 25.4; | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| //* [Basic dimensions] */ | |

| Chuck = [21.0,100.0,20.0]; // chuck bore, OD, jaw length | |

| Jaw = [Chuck[LENGTH],15.0,12.0]; // jaw free length, base width, first step radius | |

| JawInclAngle = 112; // < 120 degrees for clearance! | |

| JawAngle = JawInclAngle/2; // angle from radius | |

| WallThick = 5.0; // min wall thickness | |

| Kerf = 0.75; // space between clamp blocks | |

| ClampSides = 8*(2*3); | |

| ClampBore = BallDia/2; // clear bore through clamp | |

| ClampAngle = asin(ClampBore/BallDia); // angle from lathe axis to clamp front | |

| Plate = [ClampBore, | |

| BallDia + 2*WallThick + 2*Jaw.z, | |

| Jaw.x]; | |

| LegendDepth = 1*ThreadWidth; | |

| ShaftOD = 3.6; // sample shaft | |

| ShowGap = 1.5; | |

| //———————- | |

| // Chuck jaws | |

| // Real jaws have a concave radiused tip we simply ignore | |

| module ChuckJaws(l=Jaw.x,r=10) { | |

| for (a=[0:120:240]) | |

| rotate(a) | |

| linear_extrude(height=l) | |

| translate([r,0]) | |

| difference() { | |

| translate([Chuck[OD]/4,0]) | |

| square([Chuck[OD]/2,Jaw.y],center=true); | |

| for (i=[-1,1]) | |

| rotate(i*(90 – JawAngle)) | |

| translate([-Jaw.z/2,0]) | |

| square([Jaw.z,2*Jaw.y],center=true); | |

| } | |

| } | |

| //———————- | |

| // Clamp body | |

| module ClampBlocks() { | |

| difference() { | |

| cylinder(d=Plate[OD],h=Plate[LENGTH],$fn=ClampSides); // main disk | |

| translate([0,0,-Protrusion]) // central bore | |

| cylinder(d=ClampBore,h=2*Plate[LENGTH],$fn=ClampSides); | |

| for (a=[0:120:240]) // kerf slits | |

| rotate(60 + a) | |

| translate([Plate[OD]/2,0,Protrusion]) | |

| cube([Plate[OD],Kerf,2*Plate[LENGTH]],center=true); | |

| translate([0,0,BallDia/2 * cos(ClampAngle)]) // ball socket | |

| sphere(d=BallDia,$fn=ClampSides); | |

| for (a=[0:120:240]) { // legend | |

| rotate(4.5*360/ClampSides + a) | |

| translate([Plate[OD]/2 – LegendDepth,0,Plate[LENGTH]/2]) | |

| rotate([0,90,0]) | |

| linear_extrude(height=LegendDepth + Protrusion,convexity=10) | |

| mirror([0,0,0]) | |

| text(text=str(BallDia," mm"),size=2.5,spacing=1.20,font="Arial:style:Bold",halign="center",valign="center"); | |

| rotate(-4.5*360/ClampSides + a) | |

| translate([Plate[OD]/2 – LegendDepth,0,Plate[LENGTH]/2]) | |

| rotate([0,90,0]) | |

| linear_extrude(height=LegendDepth + Protrusion,convexity=10) | |

| mirror([0,0,0]) | |

| text(text="KE4ZNU",size=2.5,spacing=1.20,font="Arial:style:Bold",halign="center",valign="center"); | |

| } | |

| } | |

| } | |

| //———————- | |

| // Clamp with jaw cutouts | |

| module ClampBody() { | |

| difference() { | |

| ClampBlocks(); | |

| translate([0,0,-Protrusion]) | |

| ChuckJaws(l=Jaw.x + 2*Protrusion,r=BallDia/2 + WallThick); | |

| } | |

| } | |

| //———————- | |

| // Lash it together | |

| if (Layout == "Body") { | |

| ClampBlocks(); | |

| } | |

| if (Layout == "Jaws") { | |

| ChuckJaws(); | |

| } | |

| if (Layout == "Build") { | |

| ClampBody(); | |

| } | |

| if (Layout == "Show") { | |

| ClampBody(); | |

| color("ivory",0.2) | |

| ChuckJaws(r=BallDia/2 + WallThick + ShowGap); // move out for E-Z viewing | |

| color("red",0.4) | |

| translate([0,0,-Jaw.x/2]) | |

| cylinder(d=ShaftOD,h=2*Jaw.x,$fn=ClampSides,center=false); | |

| color("white",0.5) | |

| translate([0,0,BallDia/2 * cos(ClampAngle)]) // ball socket | |

| sphere(d=BallDia,$fn=ClampSides); | |

| } | |

The dimension doodles, including some notions that didn’t work:

My new bike helmet mirror mounts required poking a 3.6 mm hole through a 10 mm polypropylene ball:

Although how I did it worked, it wasn’t pretty.

I had a Micromark Spherical Object Drilling and Finishing Vise which was obviously intended for smaller holes in less challenging objects:

Given the angle between the two plates, I didn’t see any way to put a large hole though the center of the ball:

A scrap of wood aligned the two plates somewhat better:

With that as a hint, the Box o’ Brass Cutoffs disgorged a better spacer, although the original screw was just an itsy too short:

Grabbing the modified vise in a machinist’s vise got me most of the way toward the goal:

Polypropylene is grabby, so the drill stuck / rotated the ball inside the vise / made a mess:

A close look at the top picture shows the nasty ring around the hole (on the right side). The vise grips the ball between two holes punched in the metal plates, contacting it only at the right-angle (-ish) edges forming two rings, so there’s really not enough friction against the plastic to hold the ball in position and any slippage results in a gouge. Perhaps pearls / beads / jewelry behave differently?

Fortunately, I had a bag of 100 balls, so a few failures gave me enough of a clue to do what I should have done from the beginning:

That’s silicone tape wrapped around a ball grabbed in the lathe chuck, with a center drill in the tailstock. There’s barely enough traction between the ball and the chuck to get the job done, but it worked out well enough to build a few new mirrors:

There’s obviously a better way, although it took a few weeks to shake out the solid model …

Zenni ships their glasses in a snap-close case with a fuzzy insert on the bottom, but after you unpack the cleaning cloth and suchlike, the glasses rattle against the hard plastic top.

Make trial fit prototype from thin cardboard and trace it onto a sheet of craft foam:

The pen, much favored by quiltists, has a white ceramic lead that washes out of dark fabrics. You can find a corresponding dark-lead pen, but I can use an ordinary pencil.

Use different colors for different glasses:

Then walk ninja-style again.

Protip: slip an address label atop the foam so a nice person can reunite you with your glasses, should they slip out of your pocket in the unlikely event you sit down anywhere other than in your house.

A new set of glasses arrived from Zenni with one of the nose pads totally misaligned:

Definitely a QC escape.

Start by removing the tiny screw and the nose pad:

Apply a metal bending pliers (with the concave jaw around bottom of the socket), twist until it lines up properly, then reinstall the pad:

No big deal if you happen to have the pliers. Bonus: apply Parafilm to prevent scratching the lenses, OK?

For what it’s worth, the latest set of four spectacles with high-index (not polycarbonate) progressive lenses in metal frames cost a bit over $200 delivered. The last time around, two specs cost a bit more than half that.

I’m satisfied with Zenni and EyeBuyDirect (although Luxottica borged EBD and they now push spendy “brand name” frames), but you must be ready / willing / able to apply final tweakage to whatever arrives.

On the other paw, I’ve been repairing Mary’s collection of full-frontal retail glasses for quite a while, because she’s frustrated with making multiple trips to have The Nice Man repeatedly apply final tweakage.