|

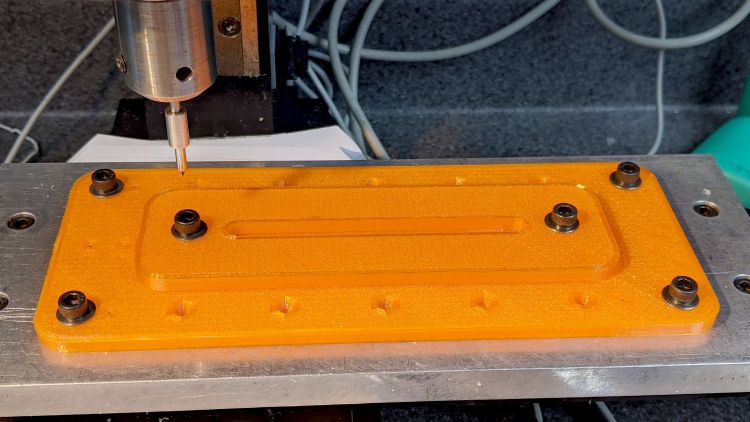

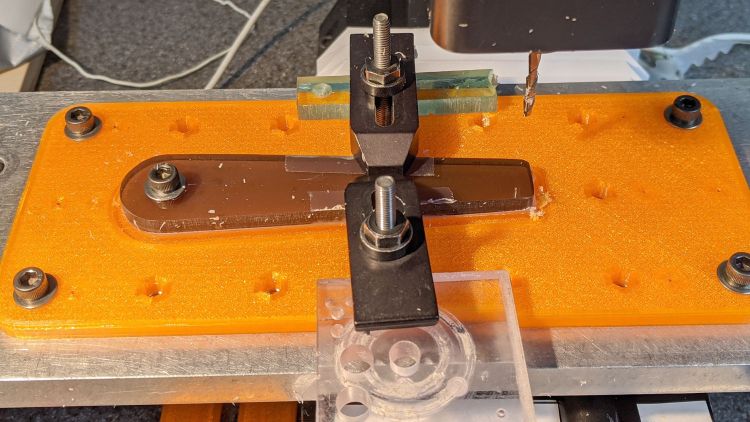

// Machining fixtures for Tek Circuit Computer cursor |

|

// Ed Nisley KE4ZNU Jan 2021 |

|

|

|

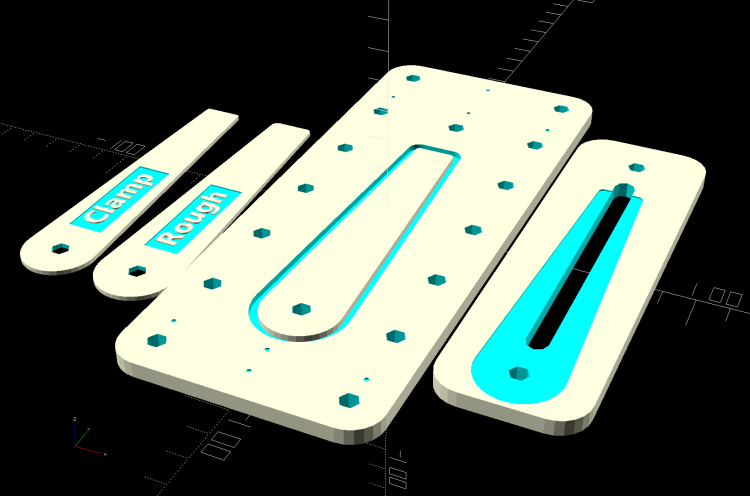

Layout = "Show"; // [Show, Build, Cursor, Clamp, Rough, Engrave] |

|

|

|

/* [Hidden] */ |

|

|

|

ThreadThick = 0.25; |

|

ThreadWidth = 0.40; |

|

|

|

HoleWindage = 0.2; |

|

|

|

Protrusion = 0.1; // make holes end cleanly |

|

|

|

inch = 25.4; |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

|

|

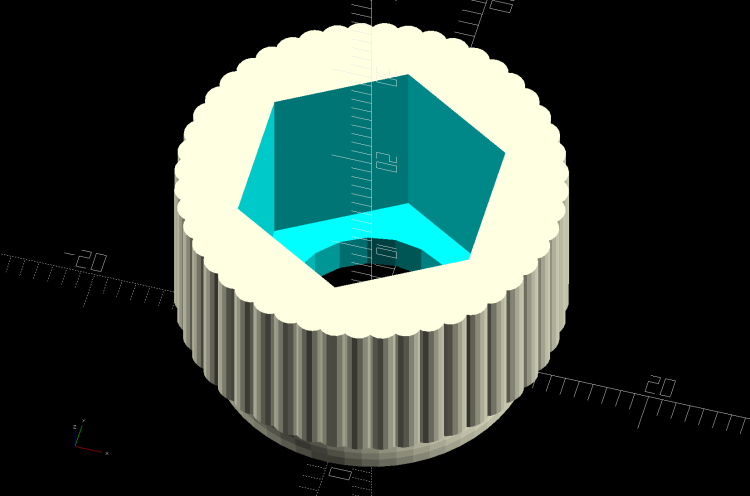

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

FixDia = Dia / cos(180/Sides); |

|

cylinder(d=(FixDia + HoleWindage),h=Height,$fn=Sides); |

|

} |

|

|

|

//———————- |

|

// Dimensions |

|

|

|

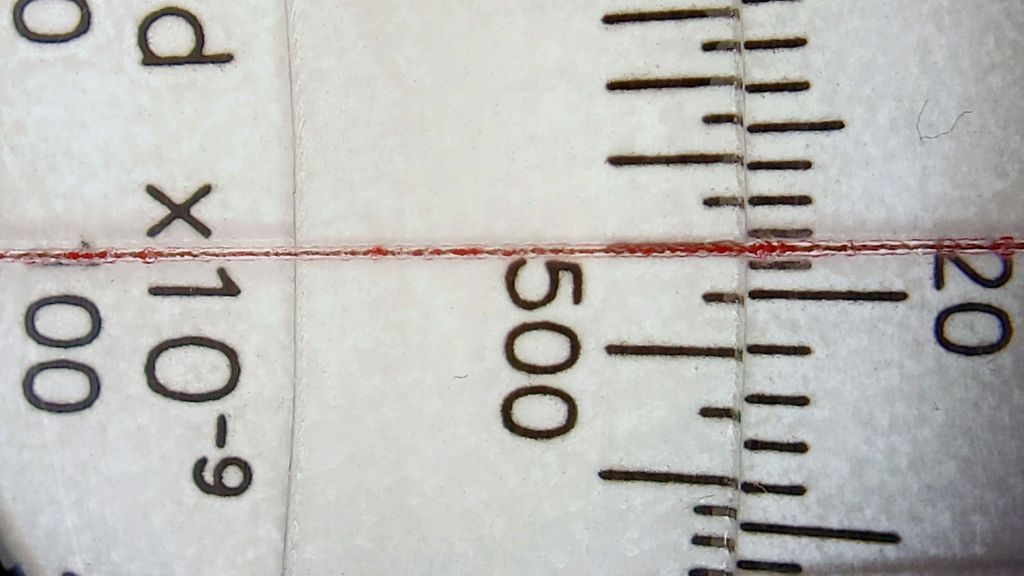

CursorHubOD = 1.0*inch; // original Tek CC was hard inch! |

|

CursorTipWidth = (9.0/16.0)*inch; |

|

CursorTipRadius = (1.0/16.0)*inch; |

|

|

|

CursorThick = 0.5; // plastic sheet thickness |

|

|

|

CutterOD = 3.175; // milling cutter dia |

|

CutterDepth = 2.0; // … depth of cut |

|

CutterLip = 0.5; // … clearance under edge |

|

|

|

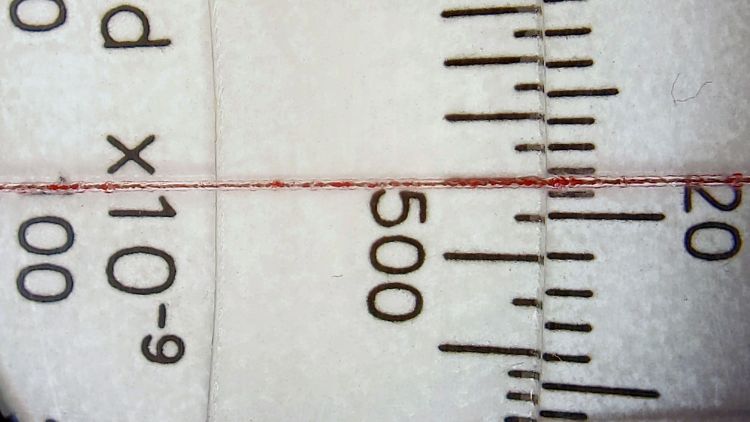

ScribeOD = 3.0; // diamond scribe shank |

|

|

|

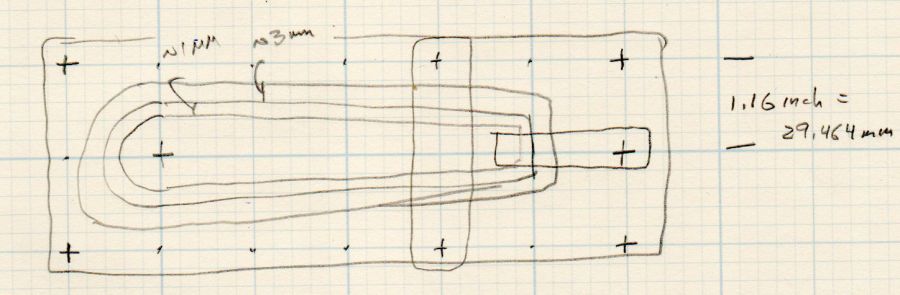

StudOC = [1.16*inch,1.16*inch]; // Sherline tooling plate grid |

|

StudClear = 5.0; // … screw clearance |

|

StudWasher = 11.0; // … washer OD |

|

|

|

CursorOffset = [-2*StudOC.x,0,0]; // hub center relative to fixture center |

|

|

|

// must have even multiples of stud spacing to put studs along centerlines |

|

BasePlateStuds = [6*StudOC.x,2*StudOC.y]; // fixture screws |

|

echo(str("Stud spacing: ",StudOC)); |

|

|

|

CornerRad = 10.0; // corner radius |

|

|

|

BasePlate = [2*StudWasher + BasePlateStuds.x,2*StudWasher + BasePlateStuds.y,5.0]; |

|

echo(str("Base Plate: ",BasePlate)); |

|

|

|

EngravePlate = [5*StudOC.x,1.5*StudOC.y,BasePlate.z]; |

|

echo(str("Engrave Plate: ",EngravePlate)); |

|

|

|

TemplateThick = 6*ThreadThick; |

|

LegendThick = 2*ThreadThick; |

|

|

|

Gap = 3.0; |

|

|

|

//———————- |

|

// Import SVG of cursor outline |

|

// Requires our hub OD to match reality |

|

// Hub center at origin |

|

|

|

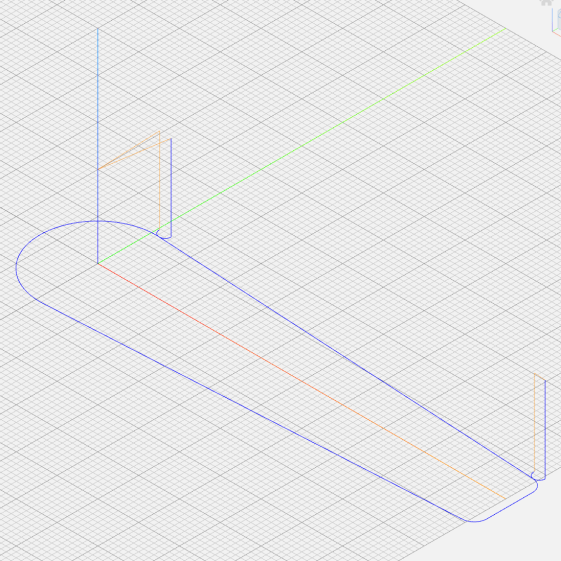

module CursorSVG(t=CursorThick,od=0) { |

|

|

|

hr = CursorHubOD/2; |

|

|

|

translate([-hr,-hr,0]) |

|

linear_extrude(height=t,convexity=3) |

|

offset(r=od/2) |

|

import(file="/mnt/bulkdata/Project Files/Tektronix Circuit Computer/Firmware/TekCC-Cursor-Mark.svg",center=false); |

|

|

|

} |

|

|

|

//———————- |

|

// Milling fixture for cursor blanks |

|

|

|

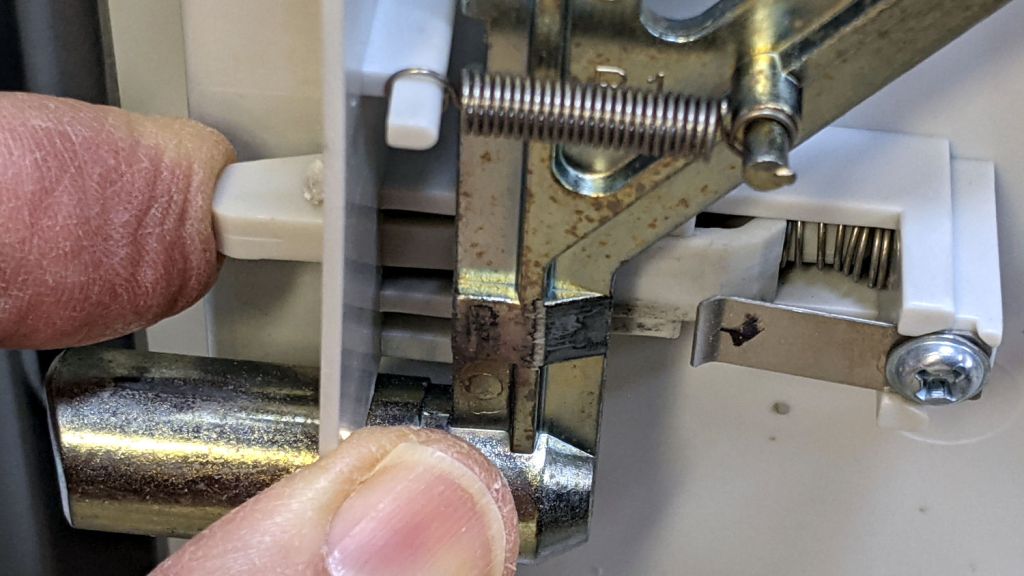

module Fixture() { |

|

|

|

difference() { |

|

hull() // basic plate shape |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*(BasePlate.x/2 – CornerRad),j*(BasePlate.y/2 – CornerRad),0]) |

|

cylinder(r=CornerRad,h=BasePlate.z,$fn=24); |

|

|

|

translate(CursorOffset + [0,0,BasePlate.z – CutterDepth]) |

|

difference() { |

|

CursorSVG(CutterDepth + Protrusion,1.5*CutterOD); |

|

CursorSVG(CutterDepth + Protrusion,-CutterLip); |

|

} |

|

|

|

translate(CursorOffset + [0,0,BasePlate.z – 2*ThreadThick]) { // alignment pips |

|

for (x=[-20.0,130.0], y=[-30.0,0.0,30.0]) |

|

translate([x,y,0]) |

|

cylinder(d=4*ThreadWidth,h=1,$fn=6); |

|

|

|

for (x=[-30.0,130.0,150.0]) |

|

translate([x,0,0]) |

|

cylinder(d=4*ThreadWidth,h=1,$fn=6); |

|

} |

|

|

|

for (i=[-1,1], j=[-1,1]) // mounting stud holes |

|

translate([i*BasePlateStuds.x/2,j*BasePlateStuds.y/2,-Protrusion]) |

|

rotate(180/6) |

|

PolyCyl(StudClear,BasePlate.z + 2*Protrusion,6); |

|

|

|

translate(CursorOffset + [0,0,-Protrusion]) // hub clamp hole |

|

rotate(180/6) |

|

PolyCyl(StudClear,BasePlate.z + 2*Protrusion,6); |

|

|

|

translate([2*StudOC.x,0,-Protrusion]) // tip clamp hole |

|

rotate(180/6) |

|

PolyCyl(StudClear,BasePlate.z + 2*Protrusion,6); |

|

|

|

for (i=[-2:2], j=[-1,1]) // side clamp holes |

|

translate([i*StudOC.x,j*StudOC.y,-Protrusion]) |

|

rotate(180/6) |

|

PolyCyl(StudClear,BasePlate.z + 2*Protrusion,6); |

|

|

|

} |

|

|

|

} |

|

|

|

//———————- |

|

// Show-n-Tell cursor |

|

|

|

module Cursor() { |

|

|

|

difference() { |

|

CursorSVG(CursorThick,0.0); |

|

translate([0,0,-Protrusion]) |

|

rotate(180/6) |

|

PolyCyl(StudClear,TemplateThick + 2*Protrusion,6); |

|

} |

|

} |

|

|

|

|

|

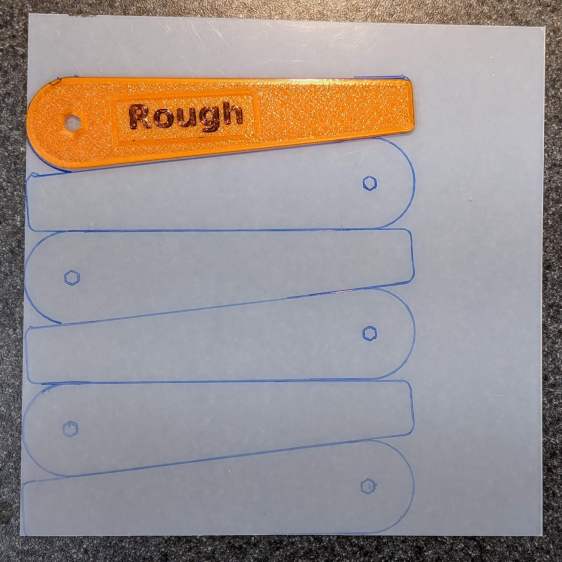

//———————- |

|

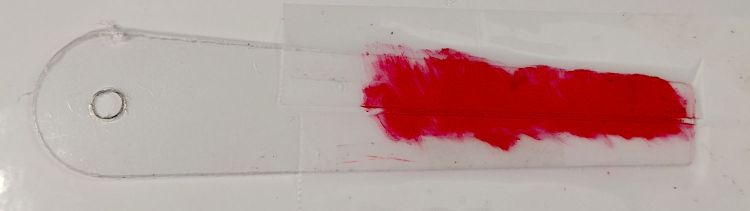

// Template for rough-cutting blanks |

|

|

|

module Rough() { |

|

|

|

bb = [40,12,LegendThick]; |

|

|

|

difference() { |

|

CursorSVG(TemplateThick,1.0); |

|

translate([0,0,-Protrusion]) |

|

rotate(180/6) |

|

PolyCyl(StudClear,TemplateThick + 2*Protrusion,6); |

|

|

|

difference() { |

|

translate([bb.x/2 + CursorHubOD/2,0,TemplateThick – bb.z/2 + Protrusion]) |

|

cube(bb + [0,0,Protrusion],center=true); |

|

translate([bb.x/2 + CursorHubOD/2,0,TemplateThick – bb.z]) |

|

linear_extrude(height=bb.z,convexity=10) |

|

text(text="Rough",size=7,spacing=1.00,font="DejaVu Sans:style:Bold",halign="center",valign="center"); |

|

} |

|

} |

|

} |

|

|

|

//———————- |

|

// Template for aluminium clamping plate |

|

|

|

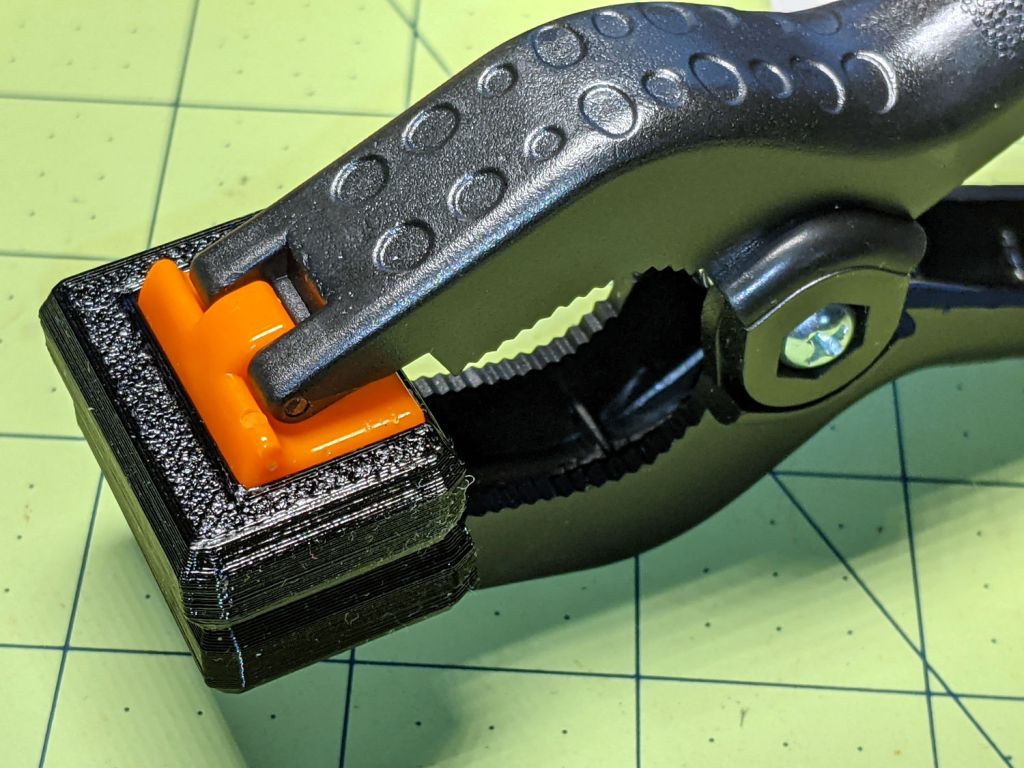

module Clamp() { |

|

|

|

bb = [40,12,LegendThick]; |

|

|

|

difference() { |

|

CursorSVG(TemplateThick,-1.0); |

|

translate([0,0,-Protrusion]) |

|

rotate(180/6) |

|

PolyCyl(StudClear,TemplateThick + 2*Protrusion,6); |

|

|

|

difference() { |

|

translate([bb.x/2 + CursorHubOD/2,0,TemplateThick – bb.z/2 + Protrusion]) |

|

cube(bb + [0,0,Protrusion],center=true); |

|

translate([bb.x/2 + CursorHubOD/2,0,TemplateThick – bb.z]) |

|

linear_extrude(height=bb.z,convexity=10) |

|

text(text="Clamp",size=7,spacing=1.00,font="DejaVu Sans:style:Bold",halign="center",valign="center"); |

|

} |

|

} |

|

} |

|

|

|

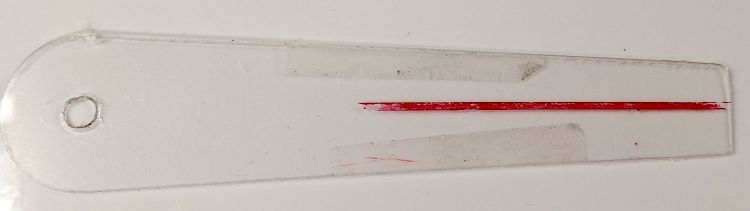

//———————- |

|

// Engraving clamp |

|

|

|

module Engrave() { |

|

|

|

difference() { |

|

|

|

hull() // clamp outline |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*(EngravePlate.x/2 – CornerRad),j*(EngravePlate.y/2 – CornerRad),0]) |

|

cylinder(r=CornerRad,h=EngravePlate.z,$fn=24); |

|

|

|

translate(CursorOffset + [0,0,-Protrusion]) |

|

CursorSVG(CursorThick + Protrusion,0.5); // pocket for blank cursor |

|

|

|

translate(CursorOffset + [0,0,-Protrusion]) |

|

rotate(180/6) |

|

PolyCyl(StudClear,EngravePlate.z + 2*Protrusion,6); |

|

|

|

translate([2*StudOC.x,0,-Protrusion]) |

|

rotate(180/6) |

|

PolyCyl(StudClear,EngravePlate.z + 2*Protrusion,6); |

|

|

|

hull() { |

|

for (i=[-1,1]) |

|

translate([i*1.5*StudOC.x,0,-Protrusion]) |

|

PolyCyl(2*ScribeOD,EngravePlate.z + 2*Protrusion,8); |

|

} |

|

} |

|

|

|

} |

|

|

|

|

|

//———————- |

|

// Build it |

|

|

|

if (Layout == "Cursor") { |

|

Cursor(); |

|

} |

|

|

|

if (Layout == "Clamp") { |

|

Clamp(); |

|

} |

|

|

|

if (Layout == "Rough") { |

|

Rough(); |

|

} |

|

|

|

if (Layout == "Engrave") { |

|

Engrave(); |

|

} |

|

|

|

if (Layout == "Show") { |

|

Fixture(); |

|

color("Green",0.3) |

|

translate(CursorOffset + [0,0,BasePlate.z + Protrusion]) |

|

Cursor(); |

|

|

|

color("Orange") |

|

translate(CursorOffset + [0,0,BasePlate.z + 10]) |

|

Rough(); |

|

|

|

|

|

color("Brown") |

|

translate(CursorOffset + [0,0,BasePlate.z + 20]) |

|

Clamp(); |

|

|

|

color("Gold") |

|

translate(0*CursorOffset + [0,0,BasePlate.z + 40]) |

|

Engrave(); |

|

|

|

} |

|

|

|

if (Layout == "Build"){ |

|

rotate(90) { |

|

Fixture(); |

|

translate([0,-((BasePlate.y + EngravePlate.y)/2 + Gap),EngravePlate.z]) |

|

rotate([180,0,0]) |

|

Engrave(); |

|

translate(CursorOffset + [0,(BasePlate.y + CursorHubOD)/2 + Gap,0]) |

|

Rough(); |

|

translate(CursorOffset + [0,(BasePlate.y + 3*CursorHubOD)/2 + 2*Gap,0]) |

|

Clamp(); |

|

} |

|

} |

|

|