While doing something else, I rediscovered the fact that common 5 gallon plastic bucket lids have an O-ring gasket that seals against the top of the bucket. Some seals are hollow tubes, some are solid rods:

The white O-ring has about the right consistency to serve as a quilting pin cap, along the lines of those 3D printed and silicone rubber filled cylinders. Although the rubber / plastic stuff isn’t quite as squishy as silicone snot, it holds the pin point firmly without much of a push.

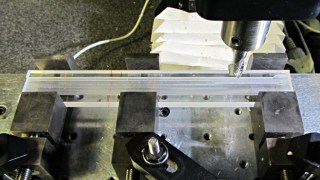

Chopping the O-ring into 10 mm sections produced another small box of prototypes:

Garden planting season remains in full effect, shoving all quilting projects to the back burner and delaying the evaluation phase of the project…