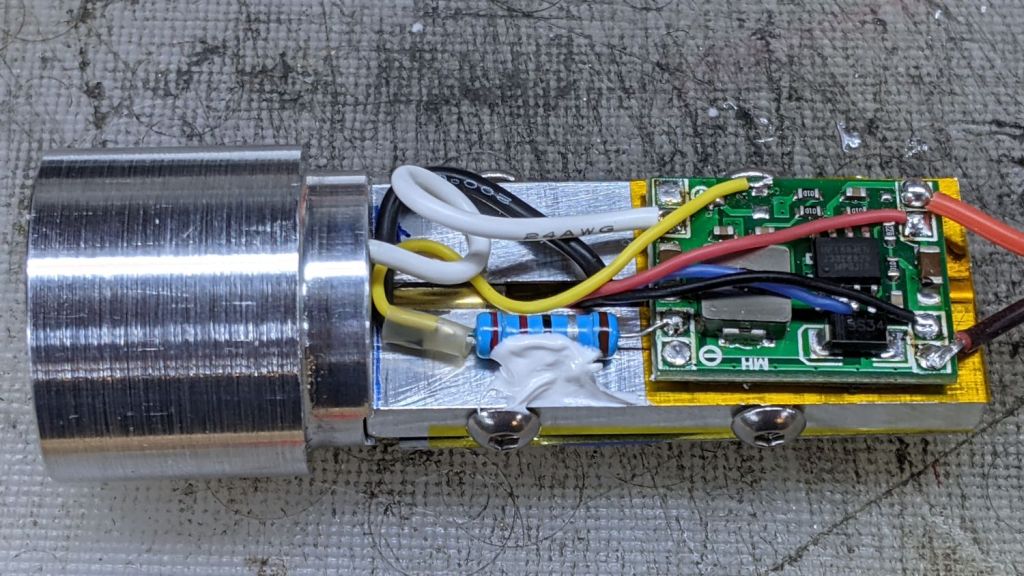

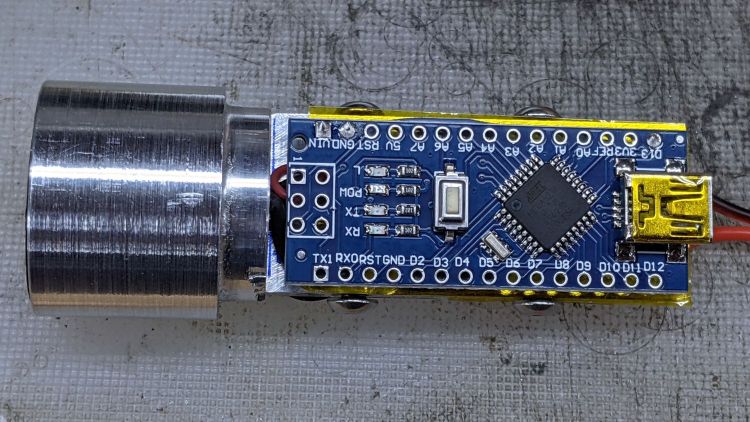

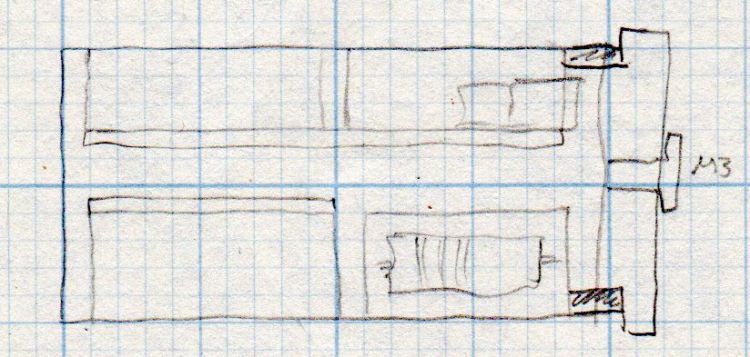

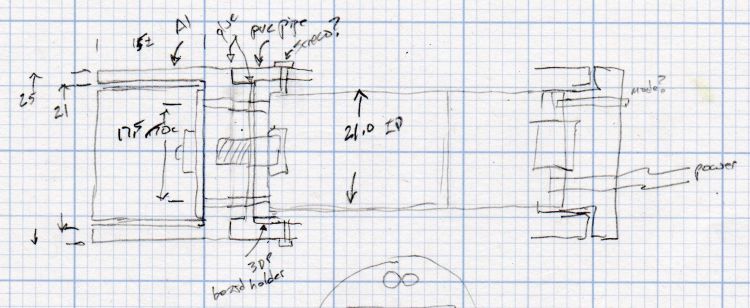

My initial doodles suggested an end cap with an opening for the Arduino’s USB port and something for the power cable from the Bafang controller:

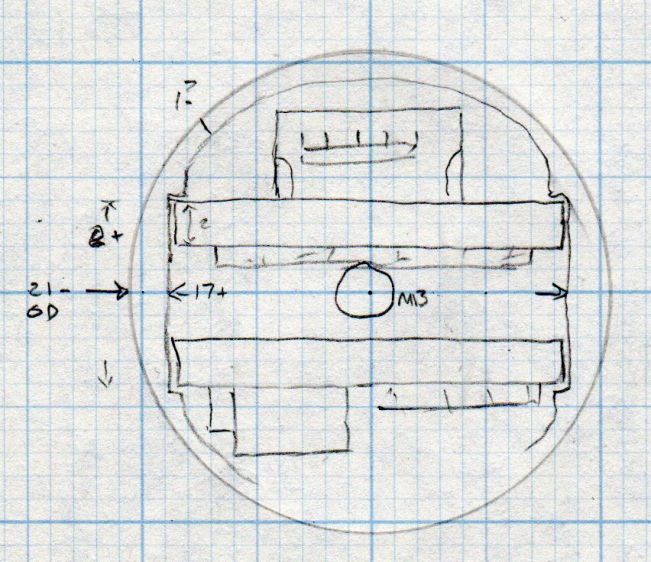

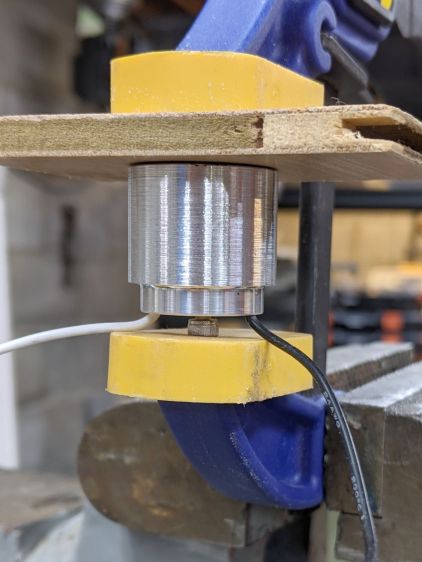

Common sense finally broke out and I made a simple disk cover held in place with an M3 screw:

Unfortunately, I cut the PVC shell flush with the USB port, which meant the cap couldn’t have a little shoulder to stabilize it on the shell. Maybe next time?

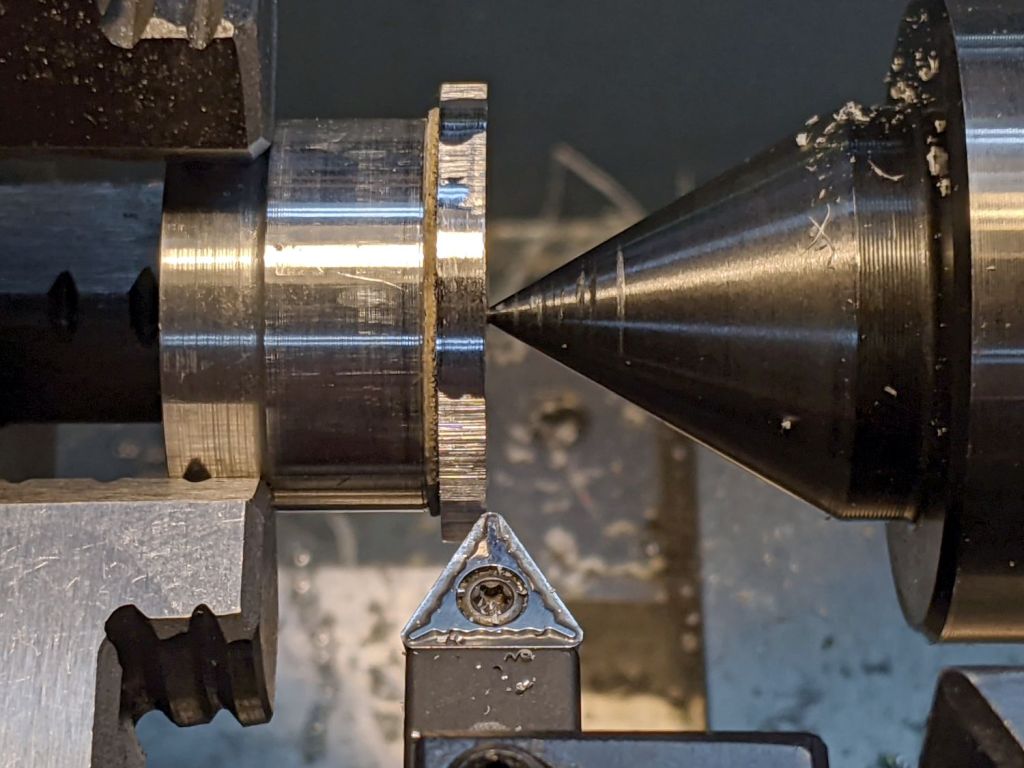

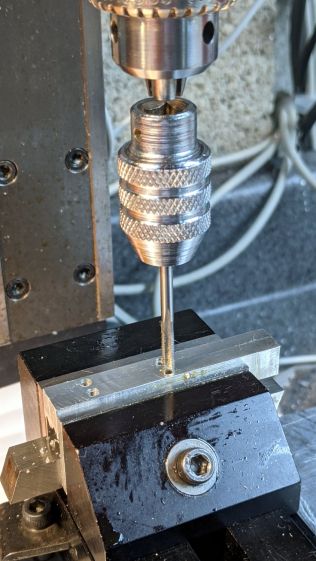

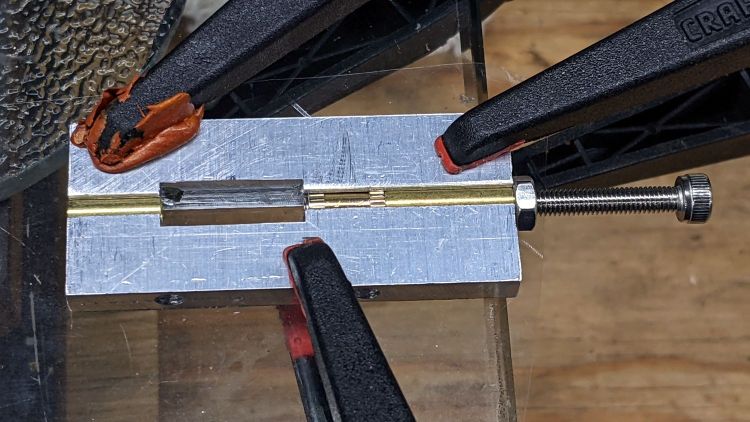

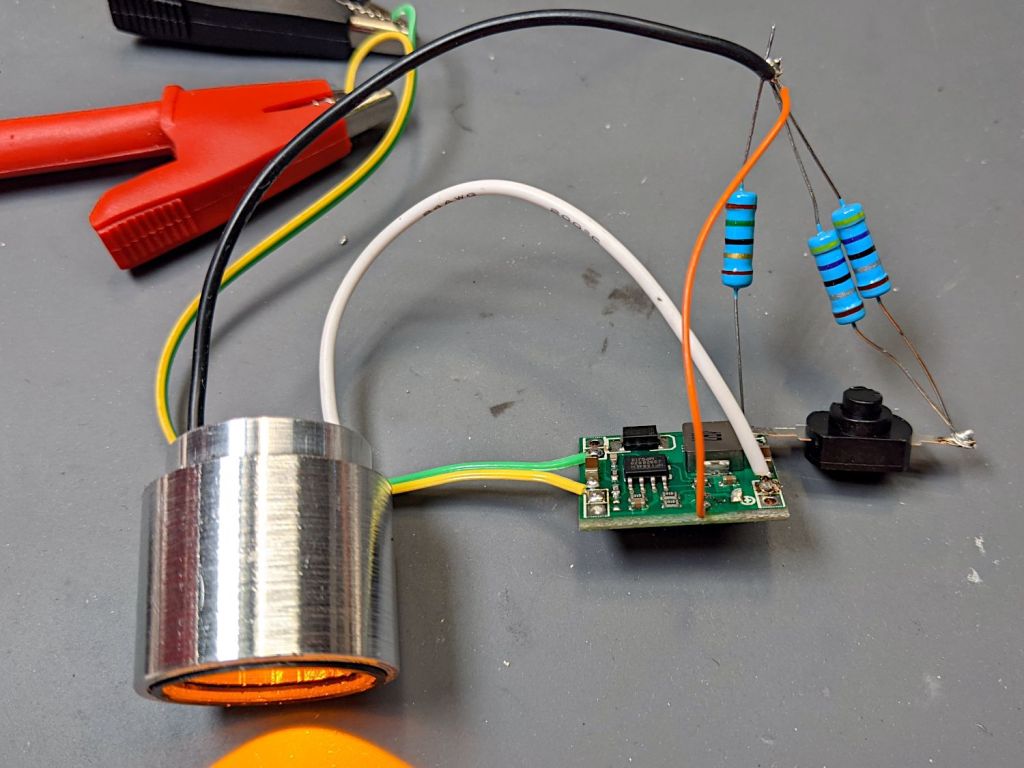

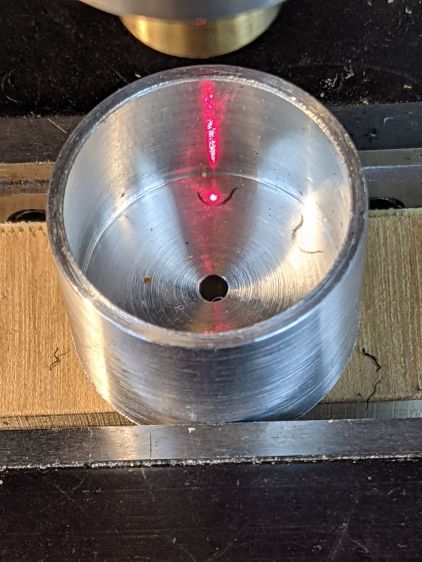

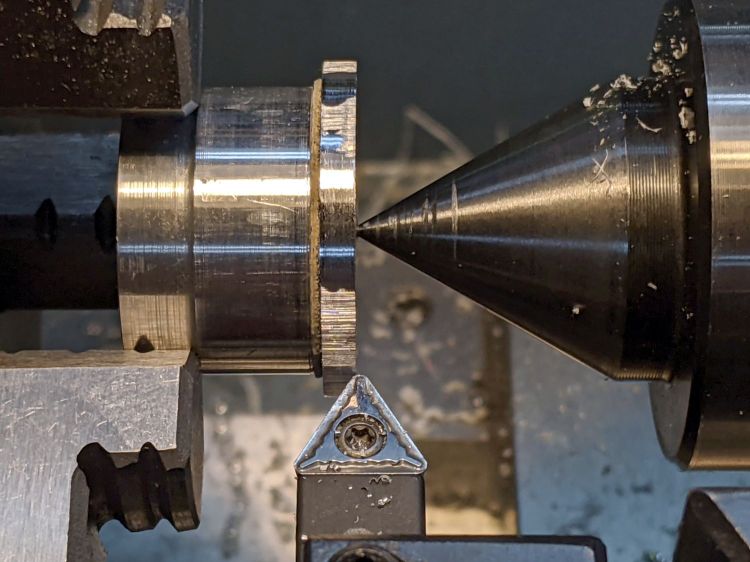

Machining the disk required using the scrap of aluminum rod left over from the heatsink as a fixture with a piece of sandpaper stuck to the front surface:

The live center presses the bandsawed + disk sanded cap against the sandpaper, providing barely enough traction for sissy cuts reducing the disk to the proper diameter:

It actually worked pretty well, although next time I’ll skip the sandpaper, affix the disk directly to the double sided duct tape, and be done with it.

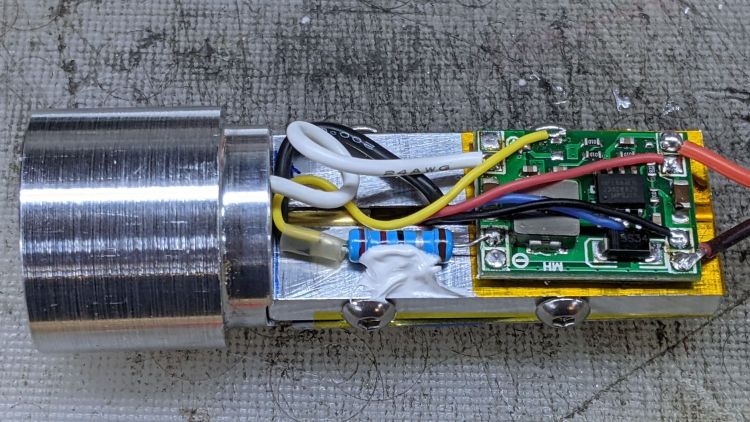

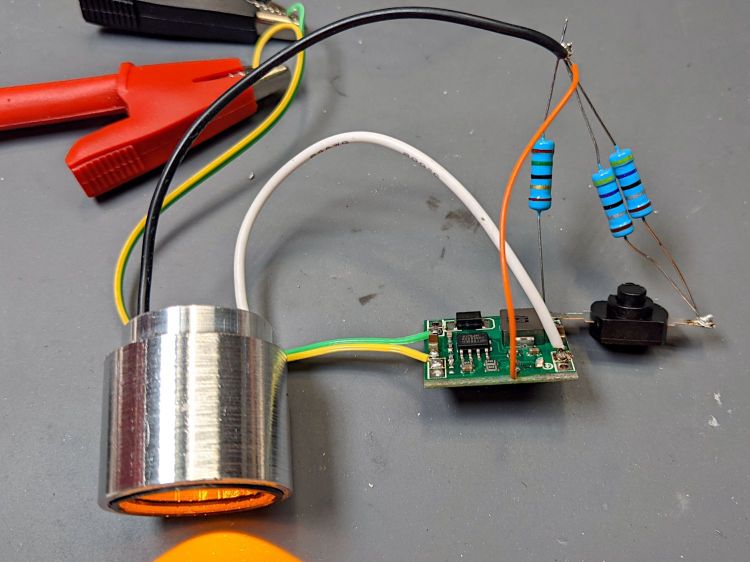

Line up the center punch dimple and drill a hole for the M3 screw:

The power cable port turned into a little slot bandsawed into the edge of the disk with the sharp edges filed off.

Basically, the thing needs some road testing before I build one for real …