|

from chiplotle import * |

|

from math import * |

|

from datetime import * |

|

from time import * |

|

from types import * |

|

import random |

|

|

|

|

|

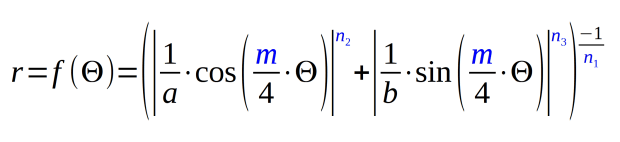

def superformula_polar(a, b, m, n1, n2, n3, phi): |

|

''' Computes the position of the point on a |

|

superformula curve. |

|

Superformula has first been proposed by Johan Gielis |

|

and is a generalization of superellipse. |

|

see: http://en.wikipedia.org/wiki/Superformula |

|

Tweaked to return polar coordinates |

|

''' |

|

|

|

t1 = cos(m * phi / 4.0) / a |

|

t1 = abs(t1) |

|

t1 = pow(t1, n2) |

|

|

|

t2 = sin(m * phi / 4.0) / b |

|

t2 = abs(t2) |

|

t2 = pow(t2, n3) |

|

|

|

t3 = -1 / float(n1) |

|

r = pow(t1 + t2, t3) |

|

if abs(r) == 0: |

|

return (0, 0) |

|

else: |

|

# return (r * cos(phi), r * sin(phi)) |

|

return (r, phi) |

|

|

|

|

|

def supershape(width, height, m, n1, n2, n3, |

|

point_count=10 * 1000, percentage=1.0, a=1.0, b=1.0, travel=None): |

|

'''Supershape, generated using the superformula first proposed |

|

by Johan Gielis. |

|

|

|

– `points_count` is the total number of points to compute. |

|

– `travel` is the length of the outline drawn in radians. |

|

3.1416 * 2 is a complete cycle. |

|

''' |

|

travel = travel or (10 * 2 * pi) |

|

|

|

# compute points… |

|

phis = [i * travel / point_count |

|

for i in range(1 + int(point_count * percentage))] |

|

points = [superformula_polar(a, b, m, n1, n2, n3, x) for x in phis] |

|

|

|

# scale and transpose… |

|

path = [] |

|

for r, a in points: |

|

x = width * r * cos(a) |

|

y = height * r * sin(a) |

|

path.append(Coordinate(x, y)) |

|

|

|

return Path(path) |

|

|

|

|

|

# RUN DEMO CODE |

|

|

|

if __name__ == '__main__': |

|

|

|

override = False |

|

|

|

plt = instantiate_plotters()[0] |

|

# plt.write('IN;') |

|

|

|

if plt.margins.soft.width < 11000: # A=10365 B=16640 |

|

maxplotx = (plt.margins.soft.width / 2) – 100 |

|

maxploty = (plt.margins.soft.height / 2) – 150 |

|

legendx = maxplotx – 2900 |

|

legendy = -(maxploty – 750) |

|

tscale = 0.45 |

|

numpens = 4 |

|

# prime/10 = number of spikes |

|

m_values = [n / 10.0 for n in [11, 13, 17, 19, 23]] |

|

# ring-ness 0.1 to 2.0, higher is larger |

|

n1_values = [ |

|

n / 100.0 for n in range(55, 75, 2) + range(80, 120, 5) + range(120, 200, 10)] |

|

else: |

|

maxplotx = plt.margins.soft.width / 2 |

|

maxploty = plt.margins.soft.height / 2 |

|

legendx = maxplotx – 3000 |

|

legendy = -(maxploty – 900) |

|

tscale = 0.45 |

|

numpens = 6 |

|

m_values = [n / 10.0 for n in [11, 13, 17, 19, 23, 29, 31, |

|

37, 41, 43, 47, 53, 59]] # prime/10 = number of spikes |

|

# ring-ness 0.1 to 2.0, higher is larger |

|

n1_values = [ |

|

n / 100.0 for n in range(15, 75, 2) + range(80, 120, 5) + range(120, 200, 10)] |

|

|

|

print " Max: ({},{})".format(maxplotx, maxploty) |

|

|

|

# spiky-ness 0.1 to 2.0, higher is spiky-er (mostly) |

|

n2_values = [ |

|

n / 100.0 for n in range(10, 60, 2) + range(65, 100, 5) + range(110, 200, 10)] |

|

|

|

plt.write(chr(27) + '.H200:') # set hardware handshake block size |

|

plt.set_origin_center() |

|

# scale based on B size characters |

|

plt.write(hpgl.SI(tscale * 0.285, tscale * 0.375)) |

|

# slow speed for those abrupt spikes |

|

plt.write(hpgl.VS(10)) |

|

|

|

while True: |

|

|

|

# standard loadout has pen 1 = fine black |

|

plt.write(hpgl.PA([(legendx, legendy)])) |

|

pen = 1 |

|

plt.select_pen(pen) |

|

plt.write(hpgl.PA([(legendx, legendy)])) |

|

plt.write(hpgl.LB("Started " + str(datetime.today()))) |

|

|

|

if override: |

|

m = 4.1 |

|

n1_list = [1.15, 0.90, 0.25, 0.59, 0.51, 0.23] |

|

n2_list = [0.70, 0.58, 0.32, 0.28, 0.56, 0.26] |

|

else: |

|

m = random.choice(m_values) |

|

n1_list = random.sample(n1_values, numpens) |

|

n2_list = random.sample(n2_values, numpens) |

|

|

|

pen = 1 |

|

for n1, n2 in zip(n1_list, n2_list): |

|

n3 = n2 |

|

print "{0} – m: {1:.1f}, n1: {2:.2f}, n2=n3: {3:.2f}".format(pen, m, n1, n2) |

|

plt.select_pen(pen) |

|

plt.write(hpgl.PA([(legendx, legendy – 100 * pen)])) |

|

plt.write( |

|

hpgl.LB("Pen {0}: m={1:.1f} n1={2:.2f} n2=n3={3:.2f}".format(pen, m, n1, n2))) |

|

e = supershape(maxplotx, maxploty, m, n1, n2, n3) |

|

plt.write(e) |

|

pen = pen + 1 if (pen % numpens) else 1 |

|

|

|

pen = 1 |

|

plt.select_pen(pen) |

|

plt.write(hpgl.PA([(legendx, legendy – 100 * (numpens + 1))])) |

|

plt.write(hpgl.LB("Ended " + str(datetime.today()))) |

|

plt.write(hpgl.PA([(legendx, legendy – 100 * (numpens + 2))])) |

|

plt.write(hpgl.LB("More at https://softsolder.com/?s=7475a")) |

|

plt.select_pen(0) |

|

plt.write(hpgl.PA([(-maxplotx,maxploty)])) |

|

|

|

print "Waiting for plotter… ignore timeout errors!" |

|

sleep(40) |

|

while NoneType is type(plt.status): |

|

sleep(5) |

|

|

|

print "Load more paper, then …" |

|

print " … Press ENTER on the plotter to continue" |

|

plt.clear_digitizer() |

|

plt.digitize_point() |

|

|

|

plotstatus = plt.status |

|

while (NoneType is type(plotstatus)) or (0 == int(plotstatus) & 0x04): |

|

plotstatus = plt.status |

|

|

|

print "Digitized: " + str(plt.digitized_point) |

|

|