For a variety of reasons that aren’t relevant here, I must dramatically reduce the amount of stuff in the Basement Laboratory / Machine Shop / Warehouse.

If you (or someone you know) has / is starting / will start a makerspace or similar organization, here’s an opportunity to go from zero to hero with a huge infusion of tools / instruments / make-froms / raw material / gadgets / surplus gear.

Think of it as a Makerspace Starter Kit: everything you need in one acquisition.

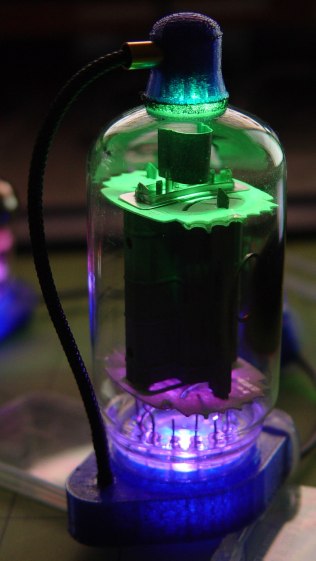

You’ve seen much of the stuff in these blog posts during the past five years, although I tightly crop the photos for reasons that should be obvious when you consider the backgrounds.

A few glimpses, carefully chosen to make the situation look much tidier than it really is:

This slideshow requires JavaScript.

I’m not a hoarder, but I can look right over the fence into that territory…

I want to donate the whole collection to an organization that can figure out how to value it and let me write it off. Failing that, I’m willing to sell the whole collection to someone who will move it out and enjoy it / put it to good use / part it out / hoard it.

We can quibble over the value, which surely lies between scrap metal and filet mignon.

As nearly as I can estimate from our last two moves, I have 6±2 short tons of stuff:

- Metal shop: old South Bend lathe / vertical mill-drill / bandsaw / hand tools / arbor press

- Cabinets / shelves loaded with cutters / tools / micrometers / calipers / whatever

- Gas & electric welding equipment, gas foundry furnace

- Walls / bins / drawers of fasteners / wire nuts / plumbing fittings / pipe clamps / you-name-its

- Bookshelves of references / magazines / databooks; I’ll keep at most one set of the magazines with my columns

- Ham radio equipment / antennas / cables

- Radial saw, blades, clamps, tooling, and a lumber / plywood stockpile

- Labeled boxes of make-froms on steel shelving; you get the shelves, the boxes, and their contents.

- Solvents, chemicals, metals, minerals, elements, etc.

- Electronic / optical / mechanical surplus & doodads

- Stockpiles of metal rods / pipes / beams / flanges / sheets / scrap parts

- Tools & toys & treasures beyond your wildest imagination

When we left Raleigh, the moving company estimator observed “This will be like moving a Home Depot!”

You must take everything, which means you must have the ability & equipment to handle 6±2 tons of stuff in relatively small, rather heavy, not easily stackable lumps. You’ll need 1000+ square feet of space with at least a seven-foot ceiling on your end to unload the truck(s) and create a solid block of stuff with skinny aisles between the shelves. This is not a quick afternoon trip for you, your BFF, a pickup truck, and a storage unit.

I plan to keep the Sherline, the M2 3D printer, various small tools, some hardware / parts / stock, most of the electronic instruments (antique-ish, at best) and components, plus odds and ends. I’ll extract or clearly mark those items, leaving your team to move everything else without (too many) on-the-fly decisions.

I can provide photos and descriptions, but, realistically, you should evaluate the situation in person.

Although we’re not planning to move in the near future, if you’re thinking of moving into the Mid Hudson Valley and always wanted a house with a ready-to-run Basement Shop, we can probably work something out. Note: all of the online real estate descriptions, including Zillow, seem confused, as the two houses on our two-acre property contain the total square footage / rooms / baths / whatever. Contact us for the Ground Truth after you’ve contemplated the satellite view.

As the saying goes, “Serious inquiries only.”