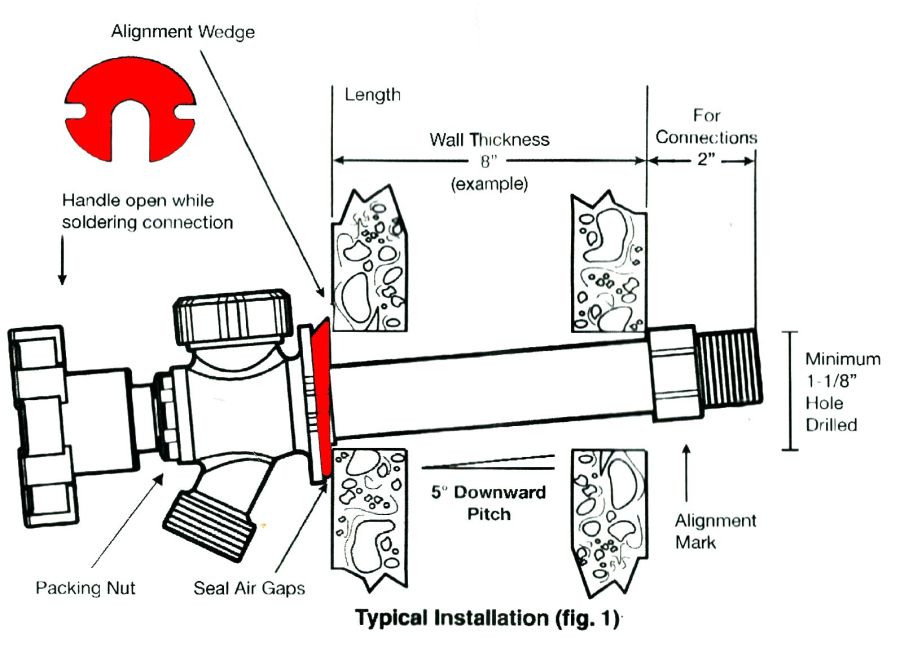

A pair of frost-free sillcock faucets arrived to replace the house’s leaky and un-repairable hose bibs. The faucet must be mounted at a 5° angle to let the water drain out when it’s closed:

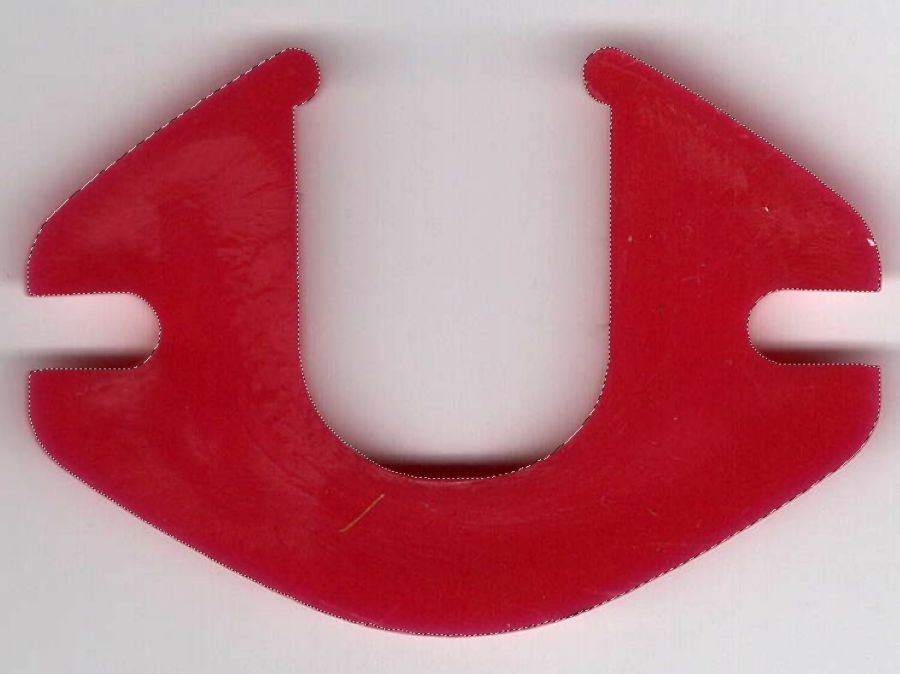

One might expect the Alignment Wedge included with the faucet to have a 5° angle. Because I can both measure and math, it has a 1° angle.

Well, I can fix that.

Start by scanning the bottom (widest side) of the wedge and apply GIMP’s Select by color tool:

After a little manual cleanup in Quick Mask mode, apply a 1 mm inset to ensure it snaps around the pipe, convert the selection to a path, export it as an SVG image, and import it into OpenSCAD to cut the angle:

// Sillcock faucet alignment wedge

// Ed Nisley KE4ZNU - May 2024

MaxThick = 5.0;

Tilt = -5.0;

PlateOA = [60,40,MaxThick]; // XY = original angle plate size

difference() {

linear_extrude(height=MaxThick,convexity=5)

offset(r=-1.0)

import("/mnt/bulkdata/Cameras/2024/Shop Projects/Sillcock Faucets/Sillcock faucet angle washer - outline.svg",

center=true);

translate([-PlateOA.x/2,-PlateOA.y/2,MaxThick])

rotate([Tilt,0,0])

cube(PlateOA,center=false);

}

The solid model goes into PrusaSlicer for duplication & slicing:

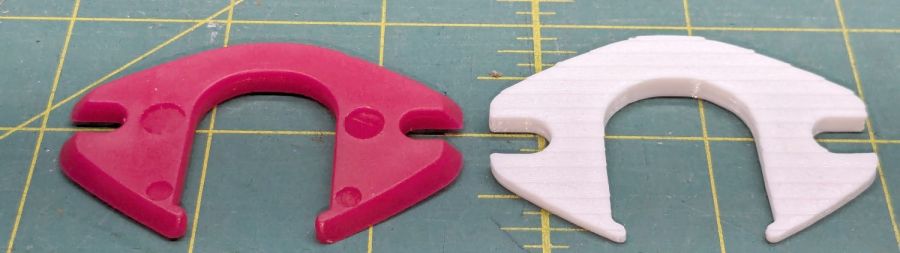

And comes off the printer looking just about like you’d expect:

The far side of both wedges are 5 mm tall, but you can see the difference four more degrees makes in the front.

It’s even more obvious from the edge:

The wood siding where these will fit is perfectly vertical, so getting the wedge angle right isn’t really optional.

I must drill the existing hole in the sill plate out to 1-1/8 inch to clear the pipe fittings, plus the wood around the screws holding the current bibs to the wall will surely need some buttressing, but all that’s in the nature of fine tuning.

FWIW, this was the first 3D print after the move and I’m happy to say the M2 had no any need of adjustments.

The WordPress AI image generator apparently ignored the post text and produced a stylin’ picture of an arched bathroom faucet over a rimless sink, which I shall leave to your imagination.

Comments

5 responses to “Sillcock Faucet Alignment Wedge: Getting the Angle Right”

Have you ruminated on why they don’t cast the angle into the fitting?

Some of the installations are through lapped siding (like our place), so there’s no One True Angle that will work.

The house has cedar-oid shakes with the bottom course flat against the exterior wall; I had to measure it before I believed it. The rest of the courses all slant the wrong way, so the wedge would need even more angle to compensate. Not sure what they were intending, but it doesn’t advance the project toward the goal!

It’d make sense, wouldn’t it?

[…] The shutoff valve for the hose bib in the front of the house, mounted knob-downward, has been dripping quietly for many many years before I replaced it: […]