One of the sticky traps absorbed a mighty blow during the season and its ski-pole mount snapped off. Rather then rebuild the whole thing, I decided to just epoxy the pieces together and stick a reinforcing plate on the bottom.

I added a pair of screw holes to the OpenSCAD model and produced a projection of the bottom layer:

if (Layout == "Projection") {

projection(cut=true) {

Attachment();

Cap();

}

}

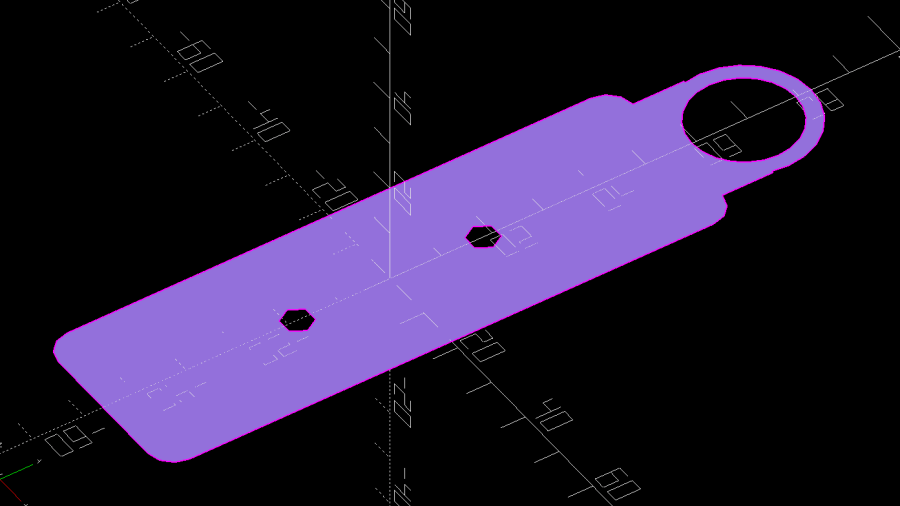

Which looked like this:

Cutting that shape from an adhesive sheet looks the same:

The somewhat raggedy large hole seems to come from OpenSCAD’s somewhat low-res SVG outline conversion.

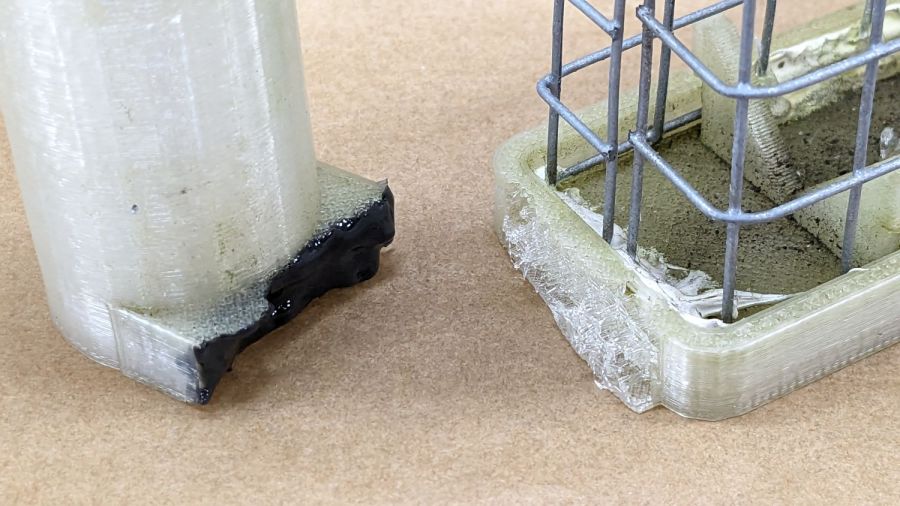

Fill the broken part with epoxy:

Clamp it together on a plate to keep the bottom aligned:

Cut an acrylic baseplate:

Apply adhesive sheet to acrylic, stick it on the bottom of the cage, add a pair of stainless steel screws, and declare victory:

We’ll see how long that lasts out in the garden next year …

Comments

4 responses to “Onion Maggot Fly Sticky Trap Repair”

Maybe the SVG output polygonalization is driven by the same “number of facets” setting as the solid models are?

The SVG output follows my low-poly spec, but the laser cuttery includes additional jank.

Seen with cold eyes, I have the sickening suspicion Something Is Loose in the laser hardware, because it looks a lot like mechanical wobbulation at the vertices of those polygon sides. I’m in the middle of re-aligning the mirrors & suchlike, so maybe something will fall out of that mess.

Our AF2028-60 (twinsies?) arrived desperately needing mirror alignment, either due to travel or a bump it took while moving the beast downstairs. A daunting task for a newbie! First and second try were not so good. I’m pretty happy with the third try, and many fun projects have been made. So far the belts seem good; no major wobbles detected. I’m still a fan of the auto-focus, and I see they just updated it to a new method without the low-riding dongle (any time I buy tech you can expect an update shortly thereafter).

As clumsy as the autofocus is, it’s wonderful.

However much I would love to get rid of the “autofocus pen”, a mechanical switch seems more stable than any possible optical proximity sensor.

The angled red-dot laser pointer definitely needs major improvement. :mutter: