The hairline on the second machined cursor looks pretty good:

Based on manually scratching some acrylic, the GCMC code retraced the hairline four times to help the Sharpie stick to the groove. Maybe fewer passes would be better?

Affix a PETG scrap to the milling fixture for some manual CNC action:

Just to see what happened, I made the first scratch through the protective film and, because it’s hard to tell which side is up, the scratch went through the white film.

Repeat several times with variations in number of passes & downforce:

- 2 passes, 300 g, through film

- 2 passes, 300 g, no film

- 1 pass, 300 g

- 3 passes, 300 g

- 4 passes, 300 g

- 1 pass, 260 g

- 1 pass, 330 g

A closer look through the PETG sheet, as you’d see finished hairline, with the scratches in the same order as above:

They may be easier to see against a blank background:

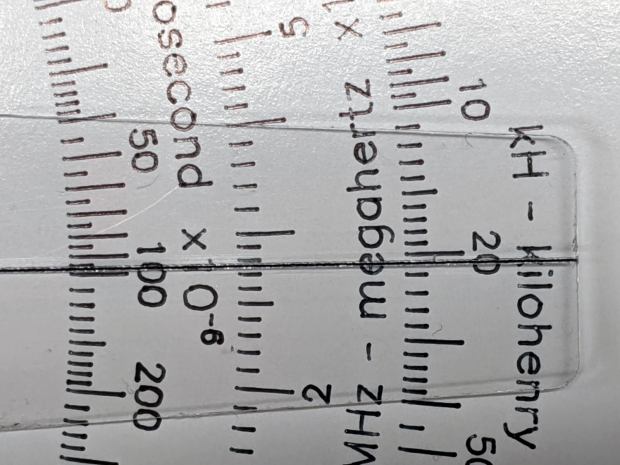

Or in a hairline’s natural environment:

The absolute best-looking line is at the top, with the diamond point scribing through the (white) protective plastic film.

Multiple passes average out the waves / glitches / irregularities, at the cost of broadening the hairline.

The bottom hairline suggests a single pass with more downforce produces a broader groove and a finer line of Sharpie ink at the bottom; the top appears more rounded and the bottom more ragged.

Doing one pass with enough pressure to cut through the thinner (?) transparent(-ish) film may produce a better overall result. This will require me to get the orientation right.

The Real Hairline in my K&E Deci-Lon slipstick is a smoothly engraved, neatly half-cylindrical, channel with a smooth thread of red (!) ink / paint / pigment laid along the middle. Obviously, my engraving hand is weak …

The nightmare scenario: engraving a smooth hairline groove, completely backfilling it with paint, sanding (that side of) the cursor smooth to leave the groove’s paint flush with the surface, then polishing the plastic back to full transparency. Even I agree that’s crazy talk, at least for a circular slide rule made with laminated paper decks.

Comments

4 responses to “PETG Diamond Drag Engraving Tests”

It isn’t crazy if the outcome makes you happy.

A guy makes (& sells!) replacement K&E slide rule cursor lenses: laser-fused hairlines on hand-ground glass.

I may not be crazy, but it’s clearly visible from where I’m standing!

[…] This time, I diamond-scribed three PETG cursors through the transparent protective film, with two / four / six passes: […]

[…] Engraving a PETG sheet with a diamond drag engraver on the Sherline and filling the scratch produces a good-looking hairline, but there’s a tradeoff between having the protective sheet pull the paint out of the scratch and having the crayon scuff the unprotected surface. This time around, I scribbled the crayon through the protective film, let it cure for a few days, then scraped the surface to level the paint and see what happens. […]