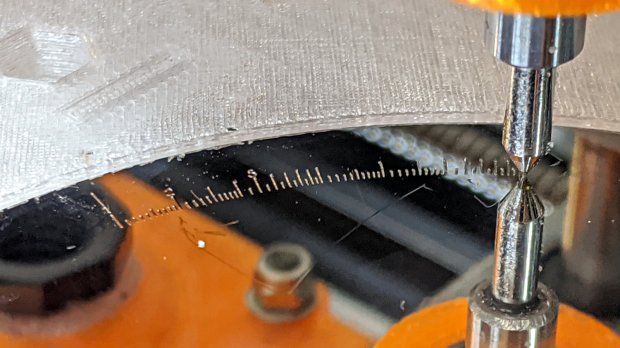

Engraving the Tektronix Circuit Computer bottom deck on a scrap hard drive platter suggested I’m entirely too much of a sissy about downforce on the diamond drag bit:

That’s at Z=-5 mm for 350 g of downforce, with the spring preloaded with 100 g at a 50 g/mm rate. More or less, anyhow.

The GCMC code automagically scales everything by the ratio of the actual platter OD to the original Tek bottom deck. Using 93 mm for a hard drive platter (actual OD = 95 mm) sets the scaling to 0.197 = 93/197, which makes the scale legends just barely visible:

The thing looks lovely, though, with ticks engraved at 2400 mm/min and the text at 2000 mm/min. The problem turns out to be the time taken to run the Z axis down and up while engraving so many ticks and characters!

I cranked on another 2 mm = 100 g of preload:

The top graph shows the downforce in 0.1 mm increments, rising from 0.0 to 217 g in 0.3 mm, which illustrates what the Y intercept of the plot means in real life.

Engraving at Z=-3 mm will now produce 350 g of downforce and cut the Z axis travel time down by a bit less than half. I have no idea what the right force might be; more experiments are in order.

Comments

3 responses to “Diamond Drag Bit: Moah Downforce!”

[…] The tiny engravings don’t photograph well, because they’re floating atop the transparent disc and the rainbow patterns from the data layer, but they still come out OK even when scaled to fit on a hard drive platter: […]

[…] tool in the (much better) CNC 3018XL LM6UU holder has engraved mostly plastic, plus a few hard drive platters, and seems only slightly […]

[…] downforces of 225, 250, and 300 g. In retrospect, the range wasn’t really broad enough, so Moah Force may be in […]