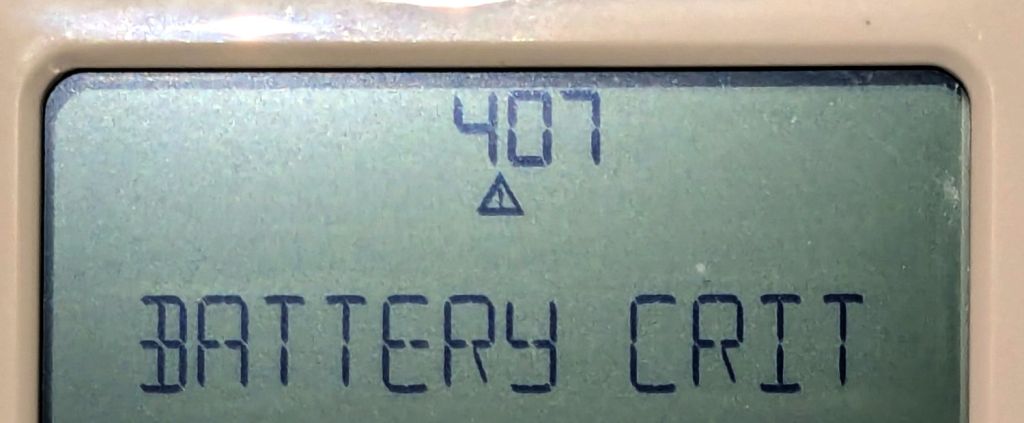

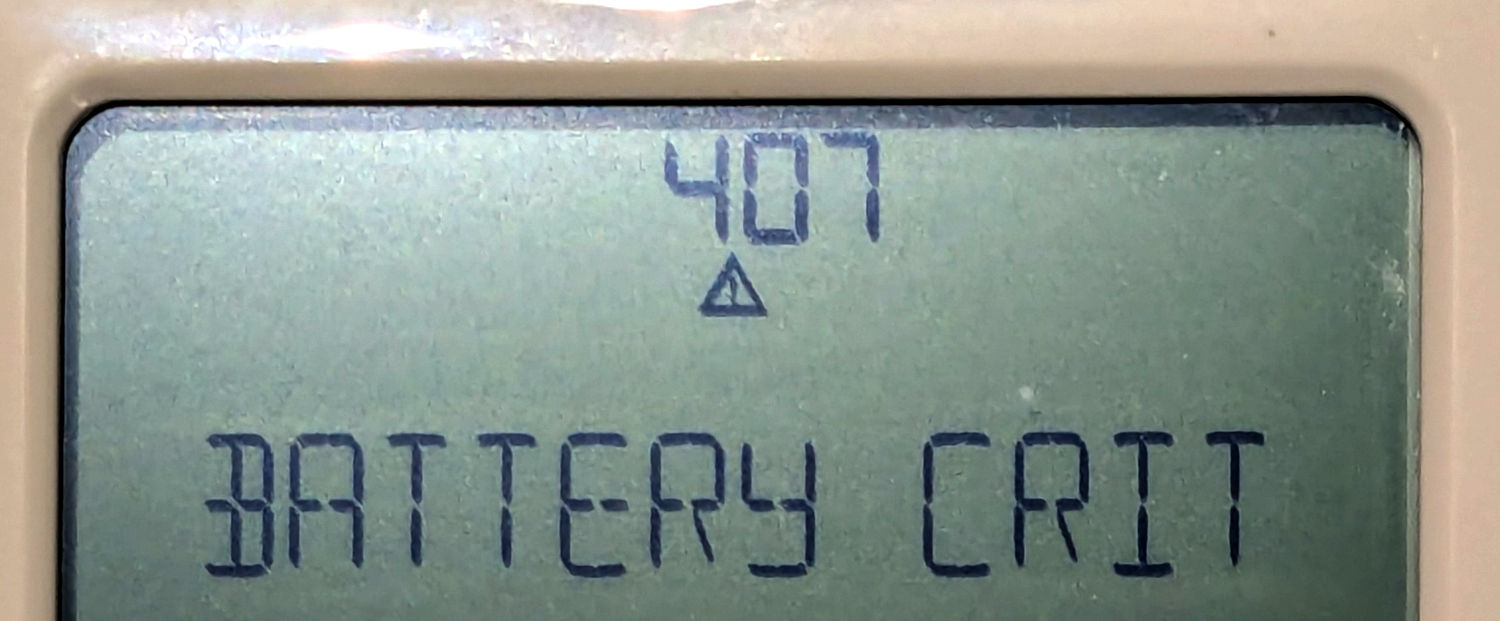

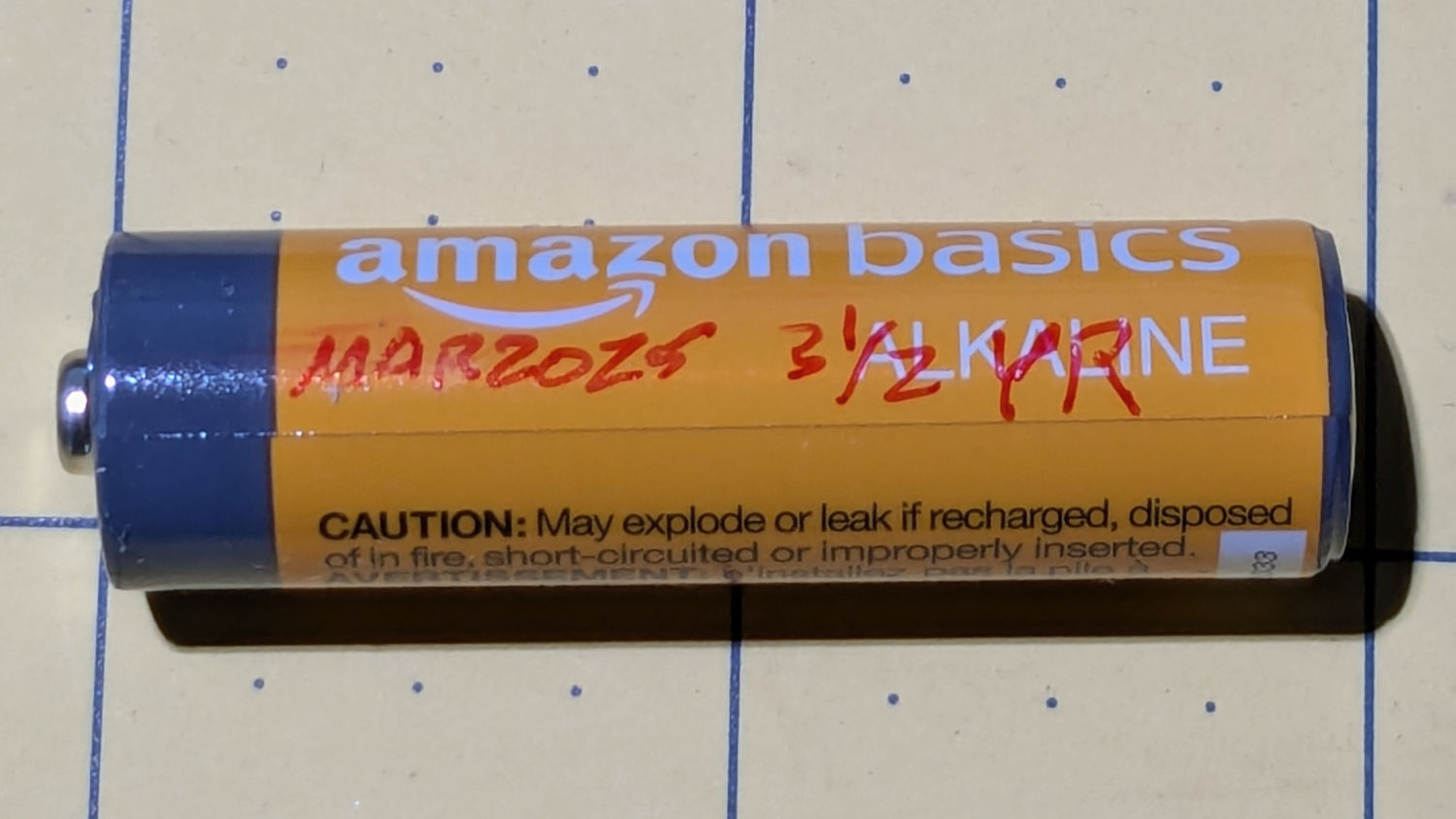

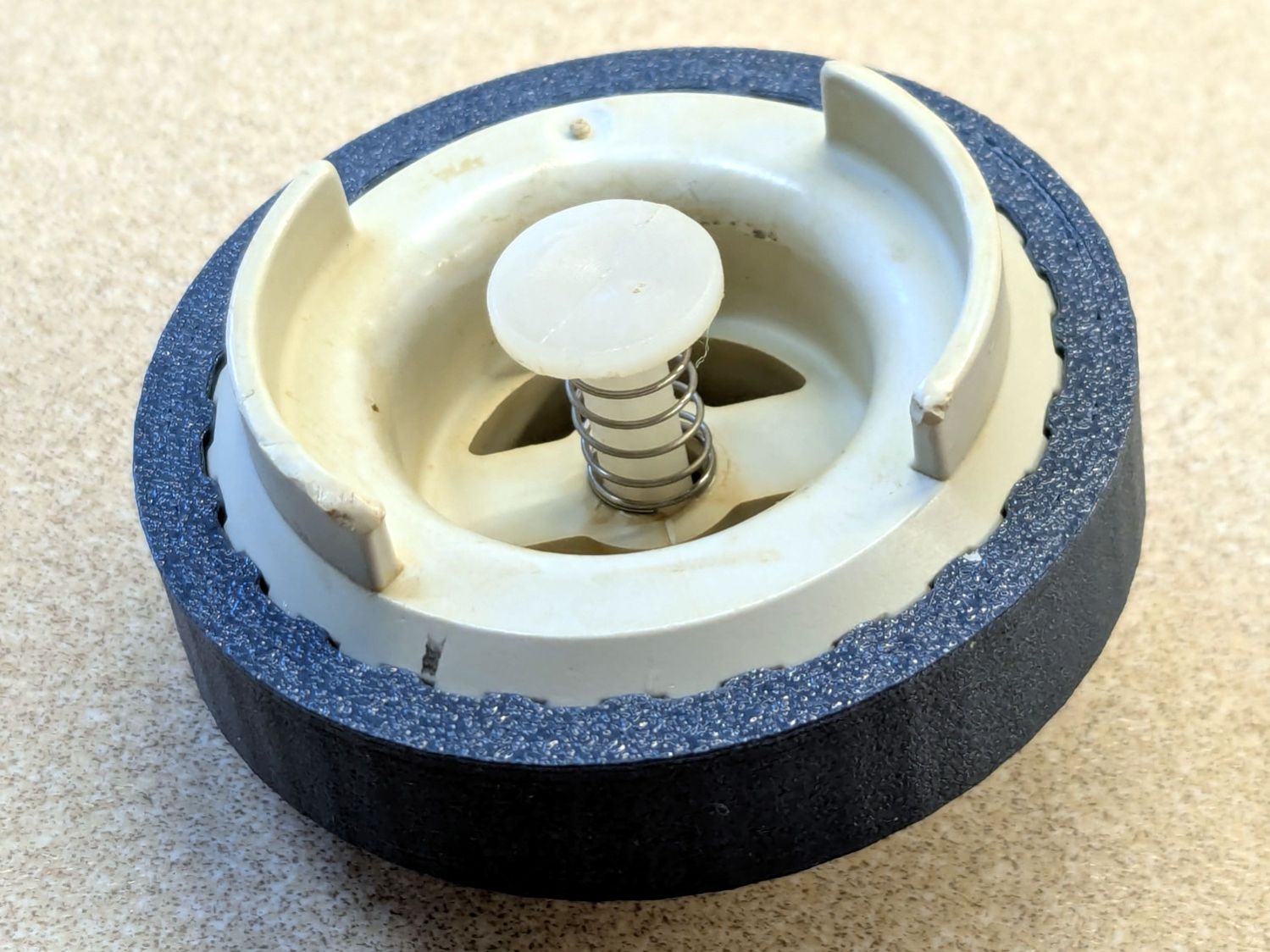

In the midst of the humidification season, I spotted this while refilling one of the ancient Sears Humidifier bottles:

While it’s possible to buy replacement caps, this seemed more appropriate:

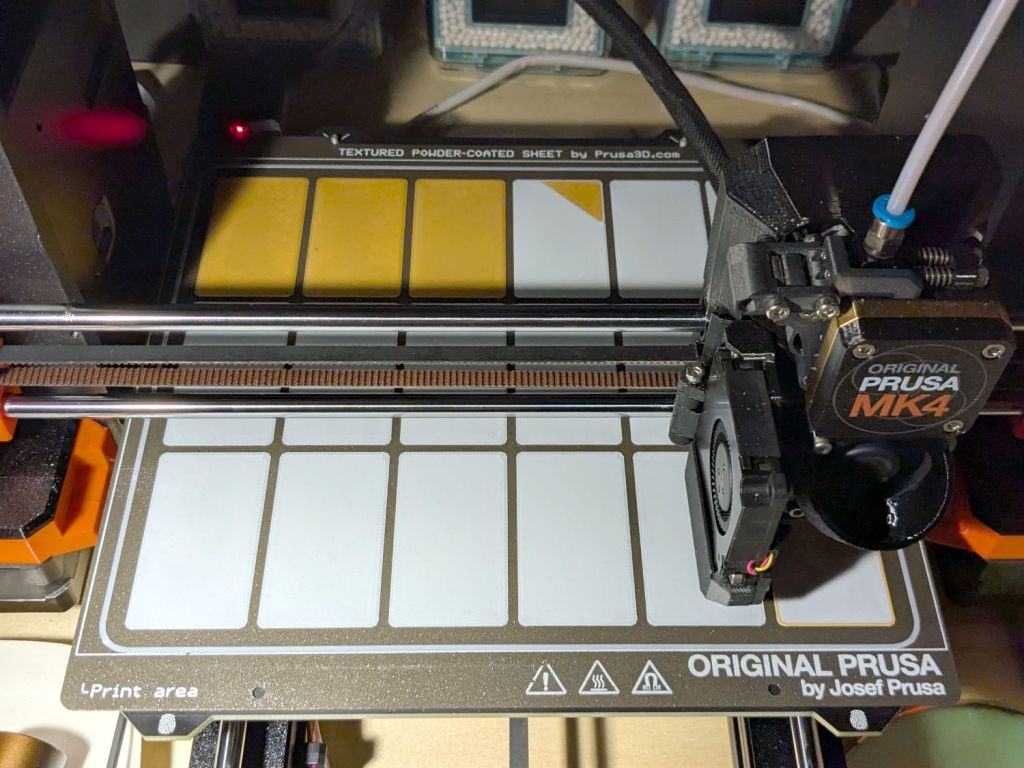

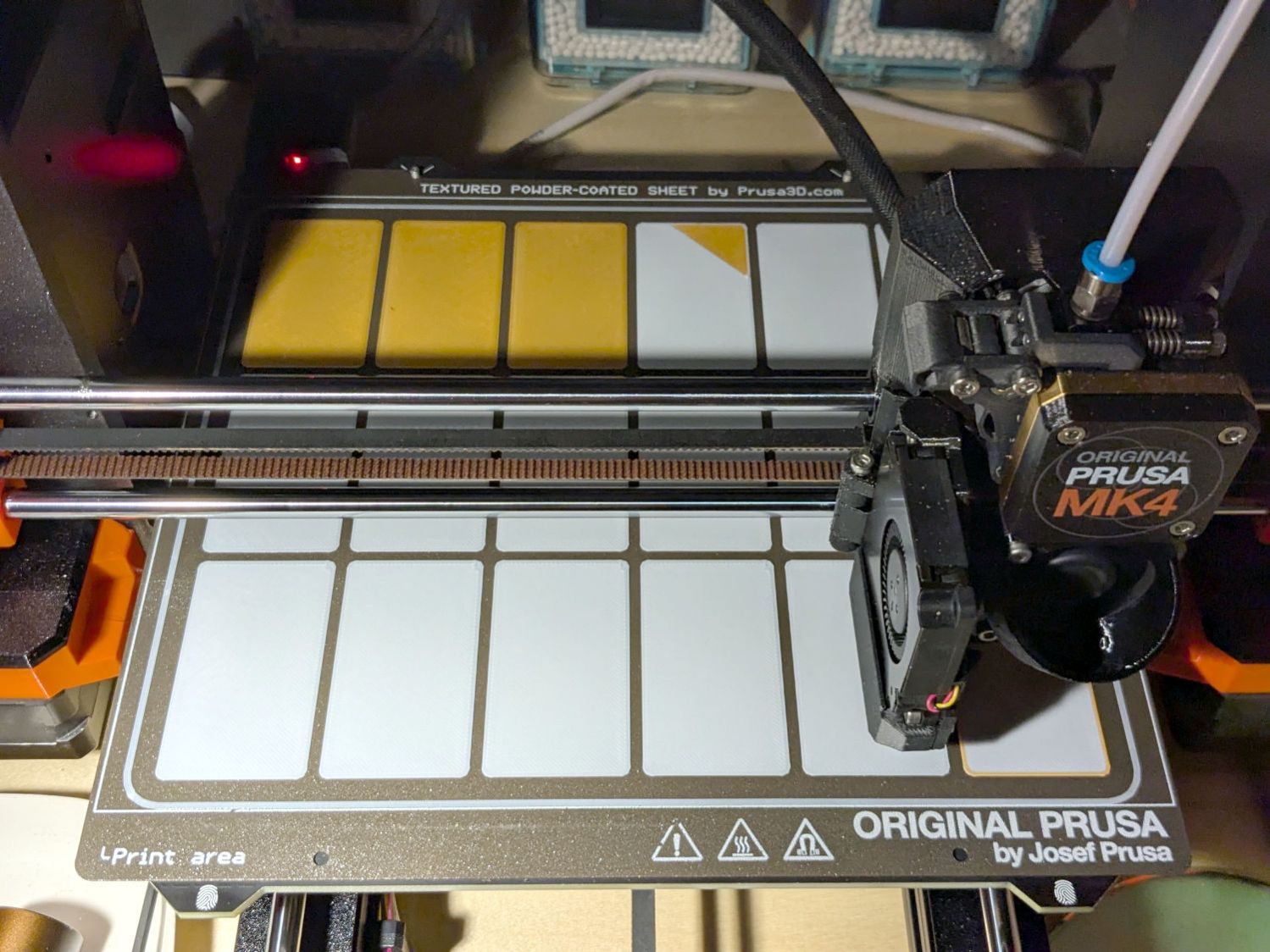

It’s PETG-CF, of course:

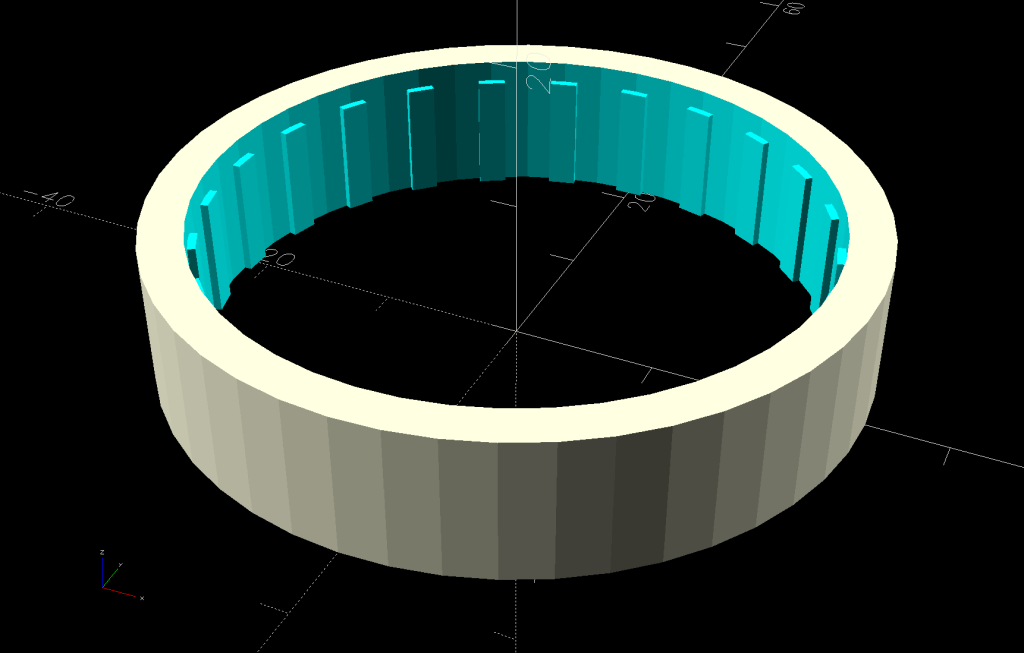

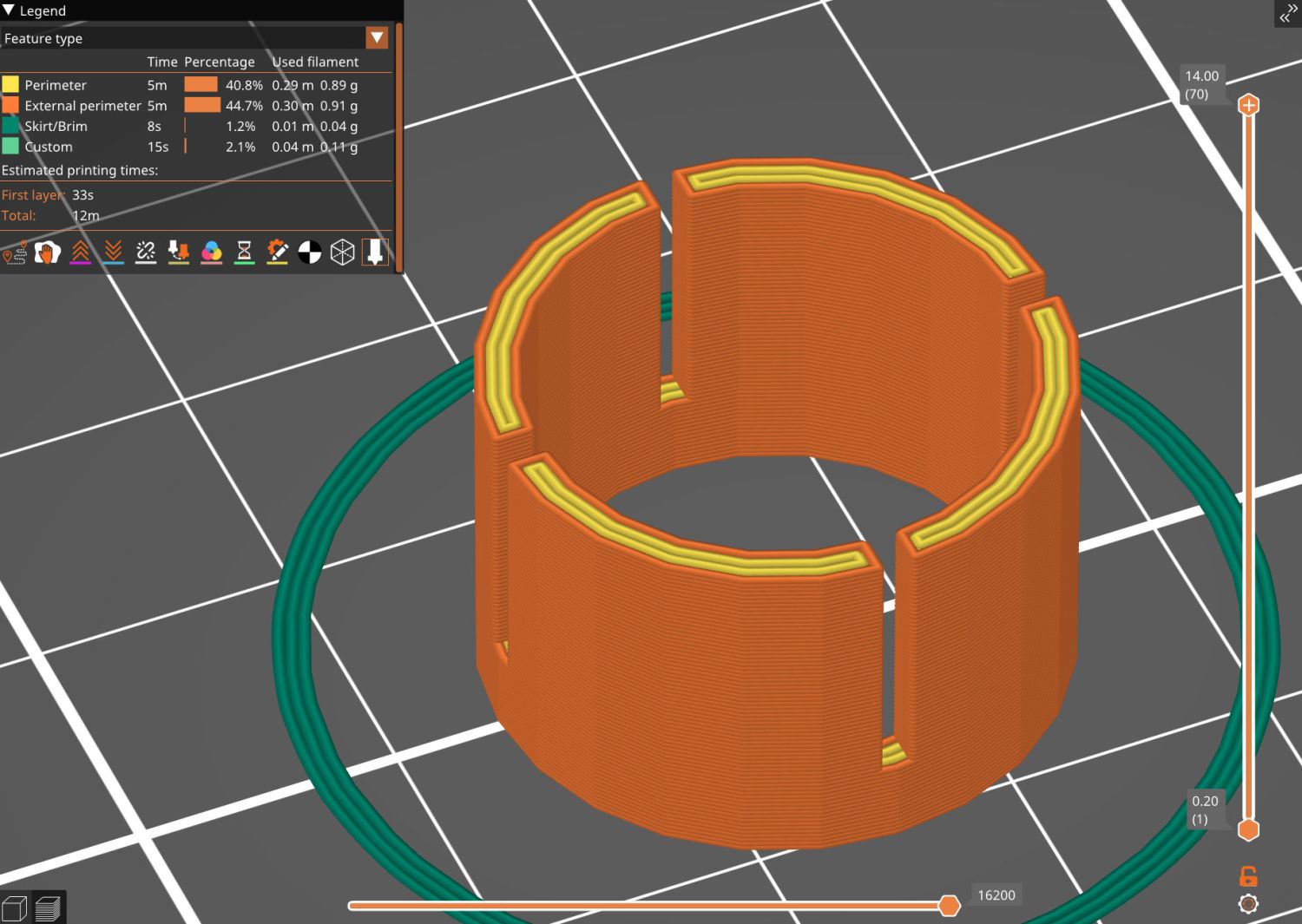

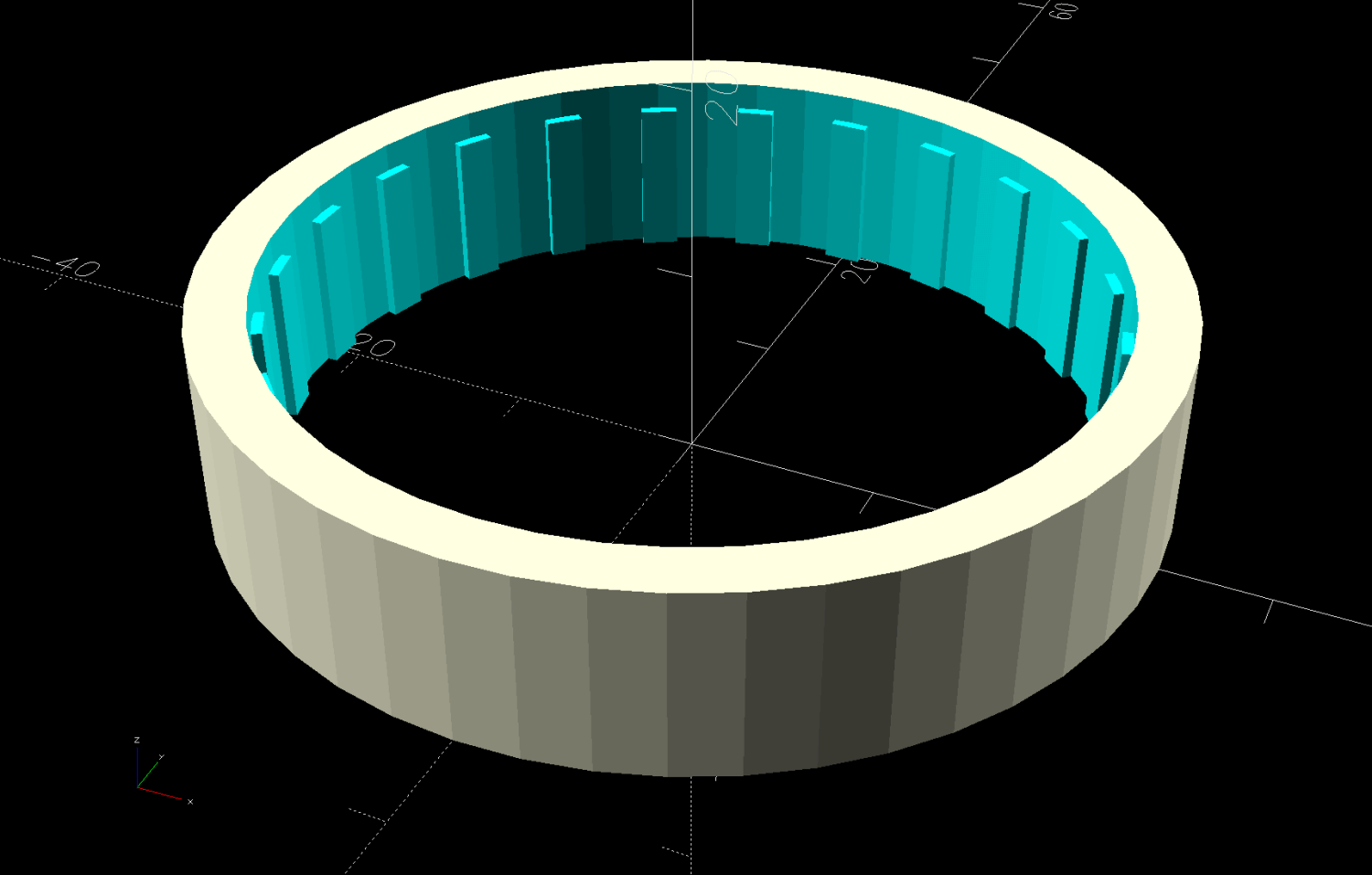

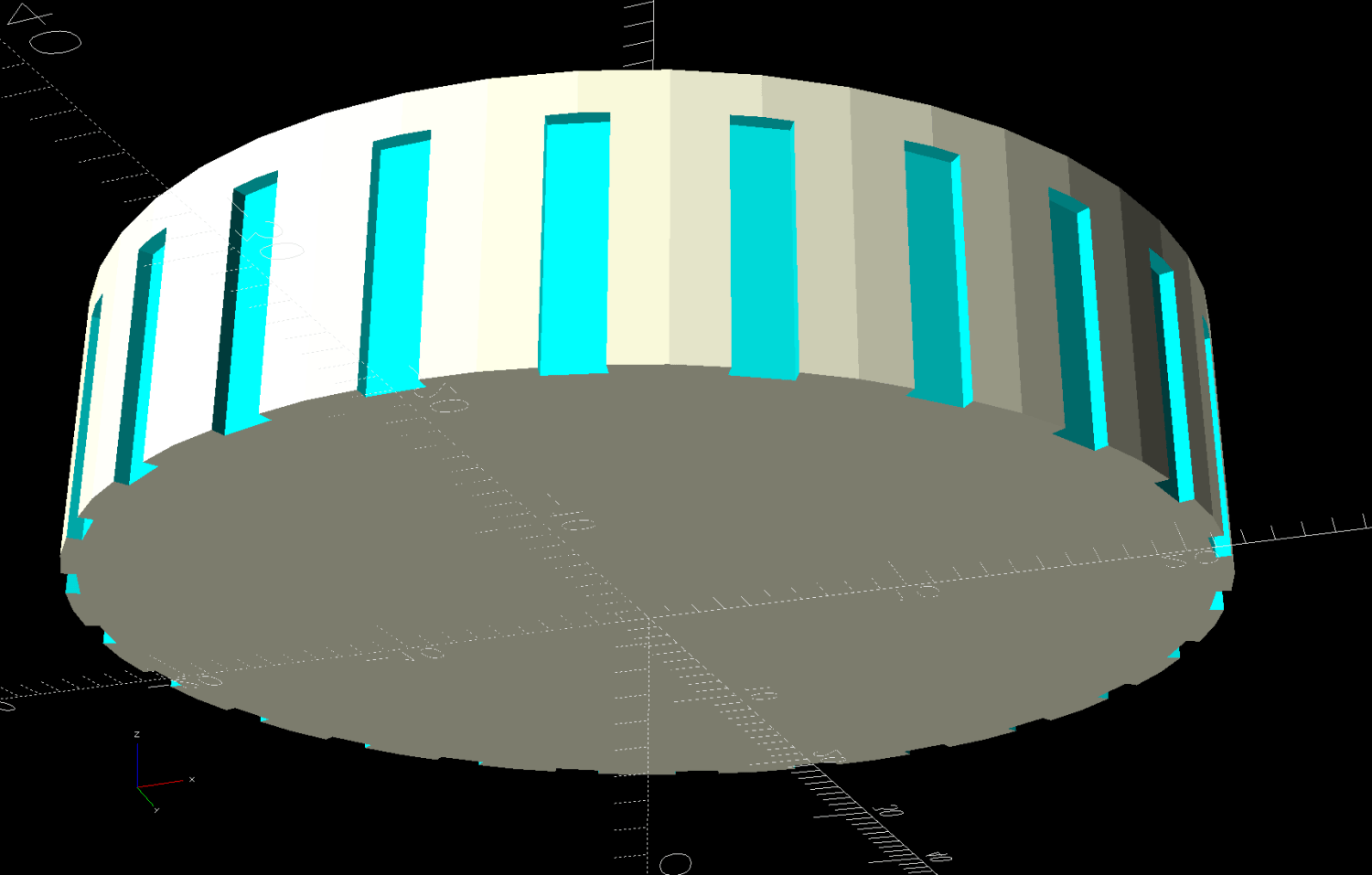

The shape is a ring with a simplified model of the cap removed from the middle:

It fits snugly over the cap atop a thin layer of JB PlasticBonder that should hold it in place forevermore:

The other side shows the crack over on the right:

Close inspection showed a few smaller cracks, so that cap was likely an original.

I made another ring for the other cap, only to find it was slightly larger with a black washer inside: apparently a previous owner had replaced one of the caps. The OpenSCAD program has measurements for both, not that you have either.

The OpenSCAD source code as a GitHub Gist:

| // Humidifier bottle cap reinforcement | |

| // Ed Nisley – KE4ZNU | |

| // 2025-11-29 | |

| include <BOSL2/std.scad> | |

| Layout = "Show"; // [Show,Build,Cap] | |

| /* [Hidden] */ | |

| Protrusion = 0.1; | |

| //—– | |

| // Bottle cap/valve | |

| // Collects all the magic numbers in one place | |

| Left = false; // the caps are different, of course | |

| CapODs = Left ? [43.0,42.1] : [43.1,42.9]; // [0] = base of cap | |

| CapHeight = 10.0; | |

| Notch = [0.6,2.0,8.5 + Protrusion]; // Z + hack for slight angle | |

| NumRibs = 24; | |

| RibAngle = 90 – atan(CapHeight/((CapODs[0]-CapODs[1])/2)); | |

| echo(RibAngle=RibAngle); | |

| $fn=2*NumRibs; | |

| module Cap() { | |

| difference() { | |

| cyl(CapHeight,d1=CapODs[1],d2=CapODs[0],anchor=BOTTOM); | |

| for (a=[0:NumRibs-1]) | |

| zrot(a*360/NumRibs) | |

| right(CapODs[1]/2) down(Protrusion) | |

| yrot(RibAngle) | |

| cuboid(Notch,anchor=RIGHT+BOTTOM); | |

| } | |

| } | |

| //—– | |

| // Reinforcing ring | |

| RingThick = 3.0; | |

| module Ring() { | |

| render() | |

| difference() { | |

| tube(CapHeight,od=CapODs[0] + 2*RingThick,id=CapODs[1] – 2*Notch.x,anchor=BOTTOM); | |

| Cap(); | |

| } | |

| } | |

| // Build things | |

| if (Layout == "Cap") | |

| Cap(); | |

| if (Layout == "Build" || Layout == "Show") | |

| Ring(); | |