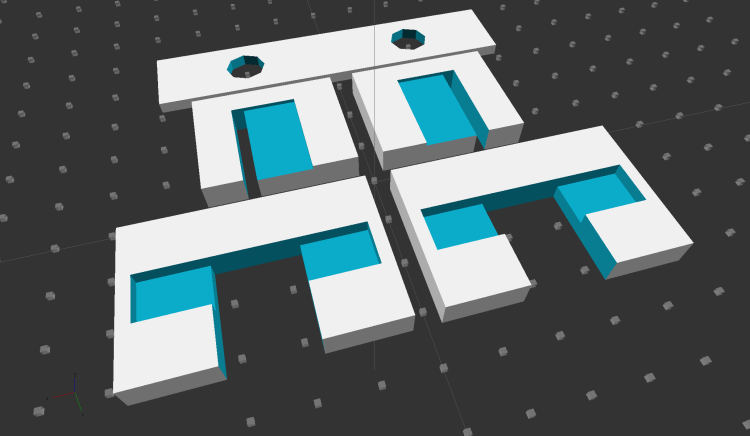

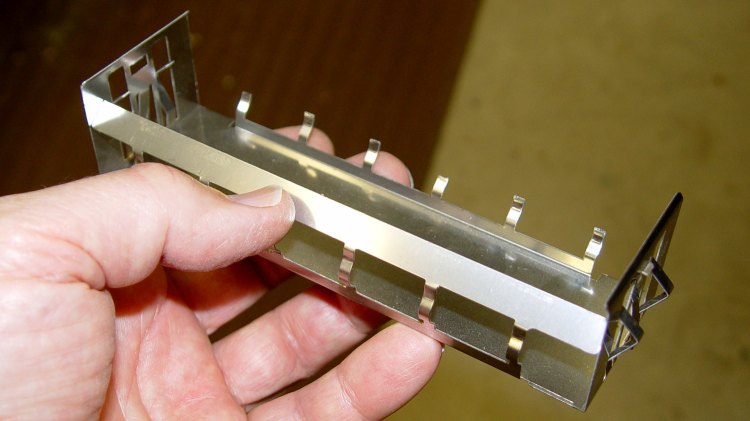

Built back in 2004, the Dell GX270 PC had PS/2 keyboard and mouse ports on its back panel, so I put a PS/2 plug on the cable from the Hall effect sensor in the foot pedal. Although the original sockets mounted on a complex system board structure that I can’t repurpose, it’s easy enough to conjure up a mount for a single socket on the back panel:

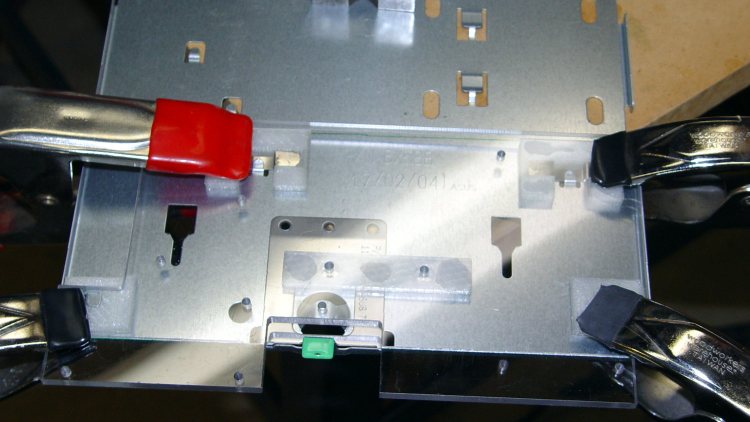

A quick fit check verified the dimensions:

Astonishingly, the socket slid firmly into its slot. I love it when that happens on the first try!

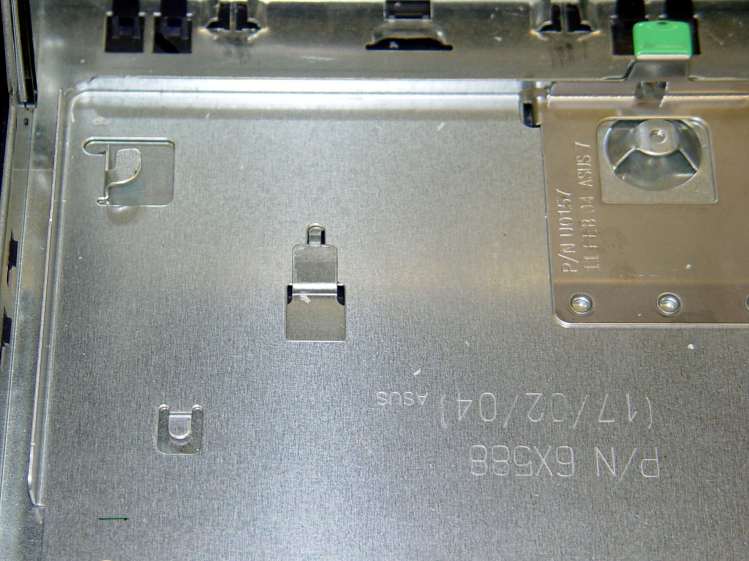

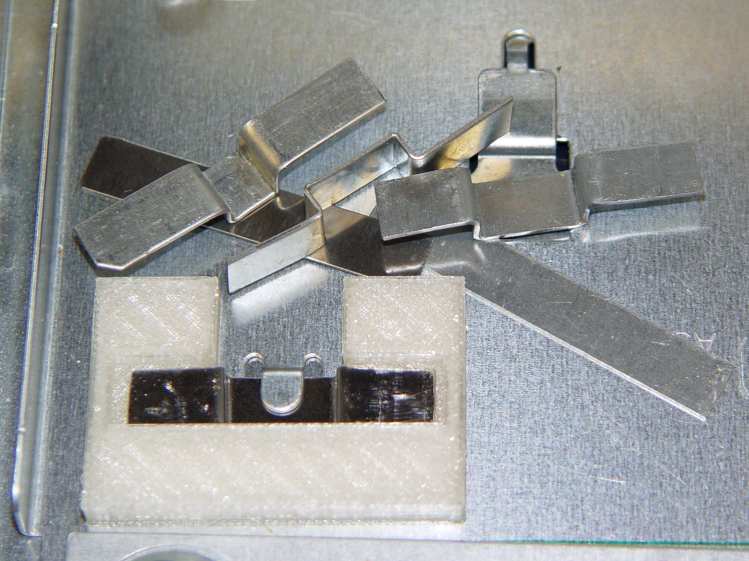

The flat plate in front of the mount snaps into the chassis cutout to locate the 2-56 screw hole positions:

The screws thread directly into the mount, with the holes tapped for 2-56. PLA isn’t all that strong, but there’s enough meat to hold the mount firmly enough for my simple purposes.

And it looks pretty good, in a post-apocalyptic missing-windows sort of way:

That was easy…

The OpenSCAD source code:

// PS/2 Socket Mount

// Ed Nisley - KE4ZNU - October 2014

Layout = "Build"; // Build Socket Guide

//- Extrusion parameters must match reality!

ThreadThick = 0.20;

ThreadWidth = 0.40;

HoleWindage = 0.2; // extra clearance

Protrusion = 0.1; // make holes end cleanly

AlignPinOD = 1.70; // assembly alignment pins: filament dia

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit);

//----------------------

// Dimensions

Socket = [14.1,13.3,13.0]; // PS/2 socket outline, minus tabs & wires on bottom

Flange = 6.0;

WallThick = IntegerMultiple(2.0,ThreadWidth);

Mount = Socket + [2*Flange,WallThick,WallThick];

ScrewTap = 1.90; // 2-56 tap for machine screws

ScrewOC = 19.0;

echo(str("Screw OC: ",ScrewOC));

ChassisHole = [13.0,13.0,1.0];

GuideLayers = IntegerMultiple(0.5,ThreadThick);

//----------------------

// Useful routines

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2);

FixDia = Dia / cos(180/Sides);

cylinder(r=(FixDia + HoleWindage)/2,

h=Height,

$fn=Sides);

}

module ShowPegGrid(Space = 10.0,Size = 1.0) {

RangeX = floor(100 / Space);

RangeY = floor(125 / Space);

for (x=[-RangeX:RangeX])

for (y=[-RangeY:RangeY])

translate([x*Space,y*Space,Size/2])

%cube(Size,center=true);

}

//-- Build the mount

module SocketMount() {

difference() {

translate([0,Mount[1]/2,Mount[2]/2])

cube(Mount,center=true);

translate([0,Socket[1]/2,Socket[2]/2])

cube(Socket + [0,Protrusion,Protrusion],center=true);

for (i=[-1,1]) // holes centered on socket, not mount

translate([i*ScrewOC/2,-Protrusion,Socket[2]/2])

rotate([-90,0,0])

rotate(180/6)

PolyCyl(ScrewTap,Mount[1] + 2*Protrusion,6);

}

}

//-- Totally ad-hoc drill guide to center holes on PS/2 cutout

module DrillGuide() {

union() {

intersection() {

translate([0,0,GuideLayers])

cube([2*Mount[0],2*Mount[1],2*GuideLayers],center=true);

translate([0,-Socket[2]/2,Mount[1]])

rotate([-90,0,0])

SocketMount();

}

translate([0,0,Protrusion])

linear_extrude(height=(3*GuideLayers - Protrusion)) {

circle(d=ChassisHole[0],$fn=8*4);

translate([-ChassisHole[0]/2,0])

square([ChassisHole[0],(ChassisHole[1] - ChassisHole[0]/2)],center=false);

}

}

}

//----------------------

// Build it

ShowPegGrid();

if (Layout == "Socket")

SocketMount();

if (Layout == "Guide")

DrillGuide();

if (Layout == "Build") {

translate([0,-Mount[2],0])

DrillGuide();

translate([0,0,Mount[1]])

rotate([-90,0,0])

SocketMount();

}