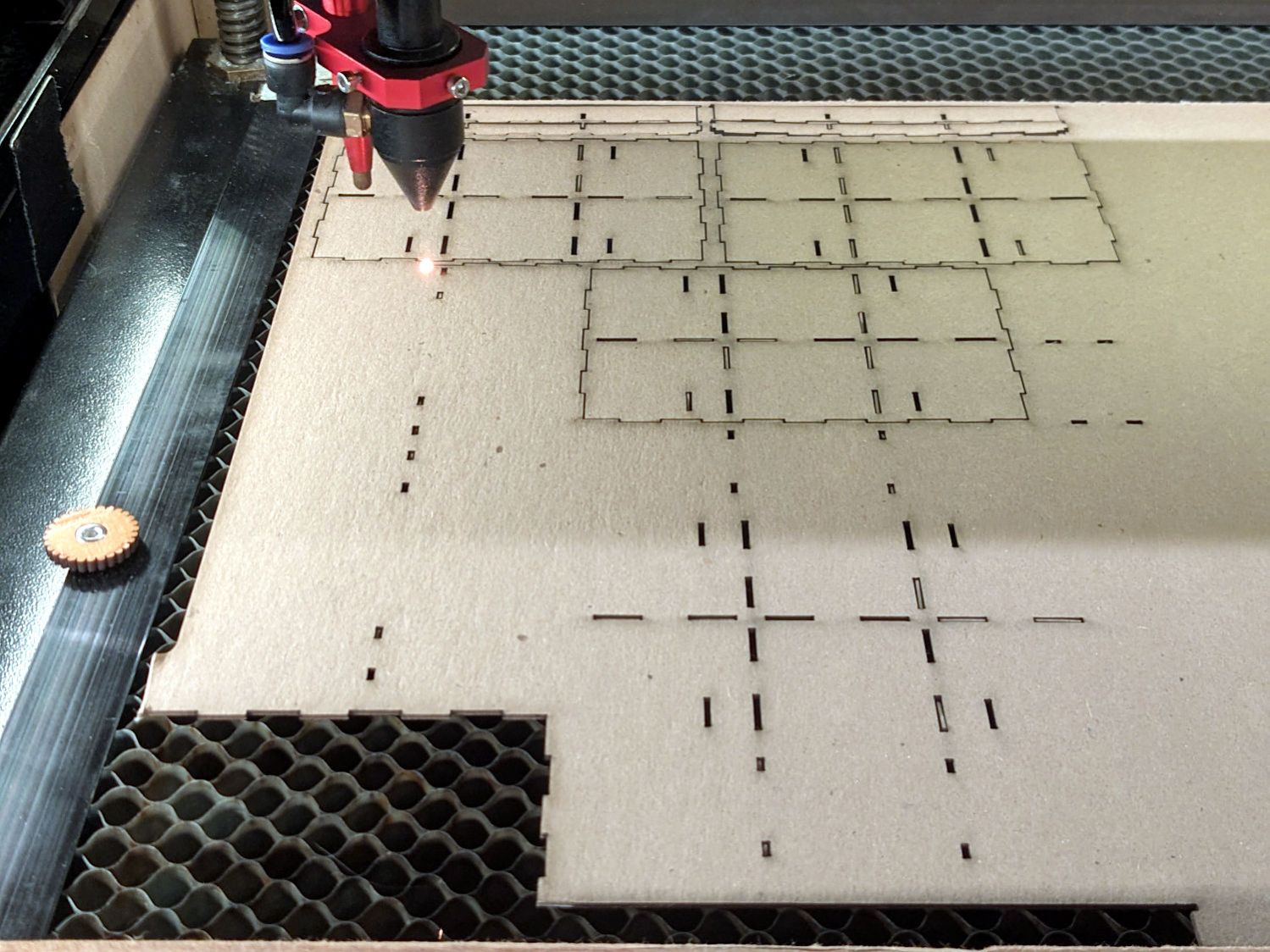

The OMTech 60 W laser has a 24 V + 5 V power supply for the stepper motors and, I had always assumed, the feeble LED strip light on the gantry:

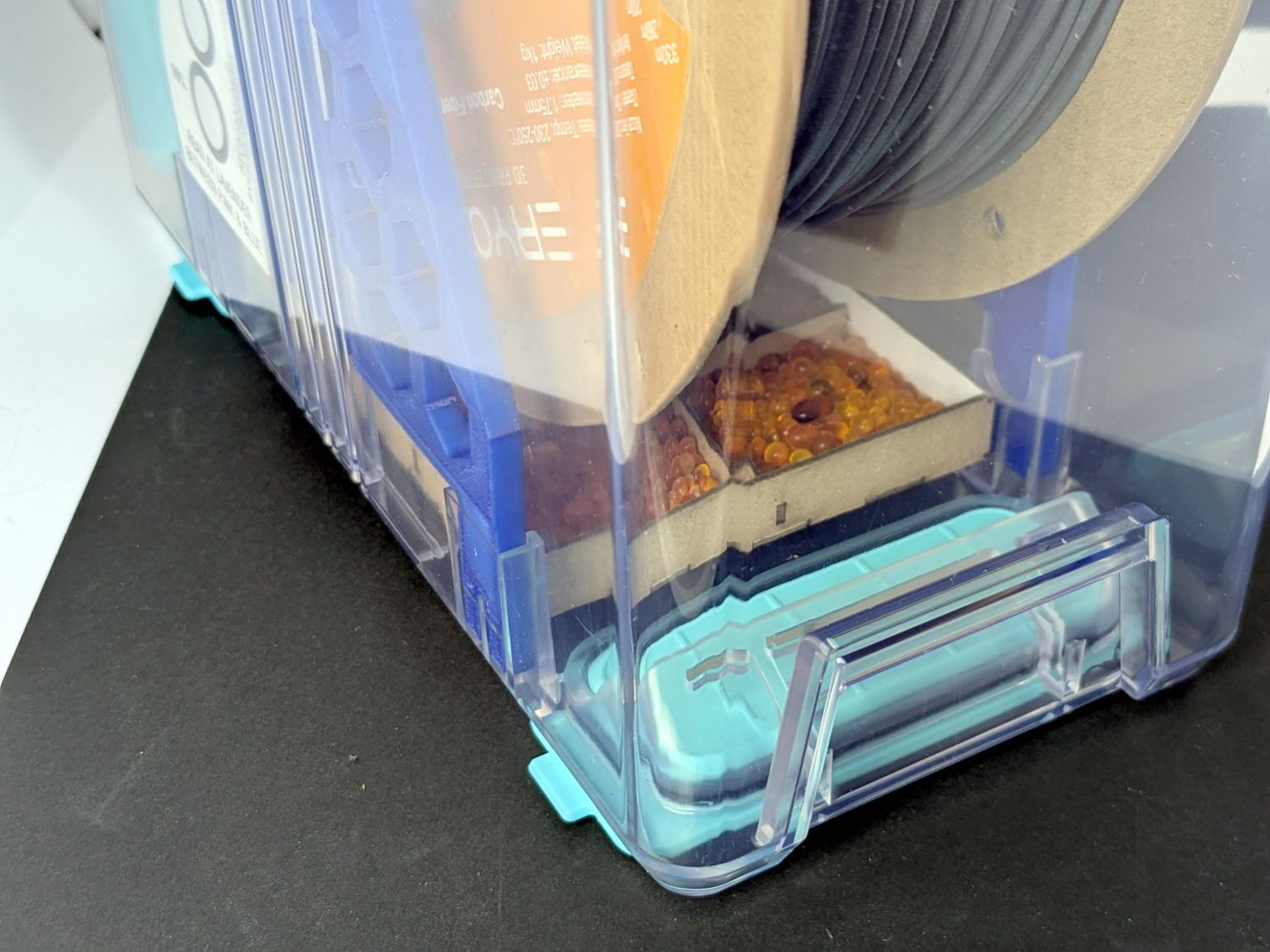

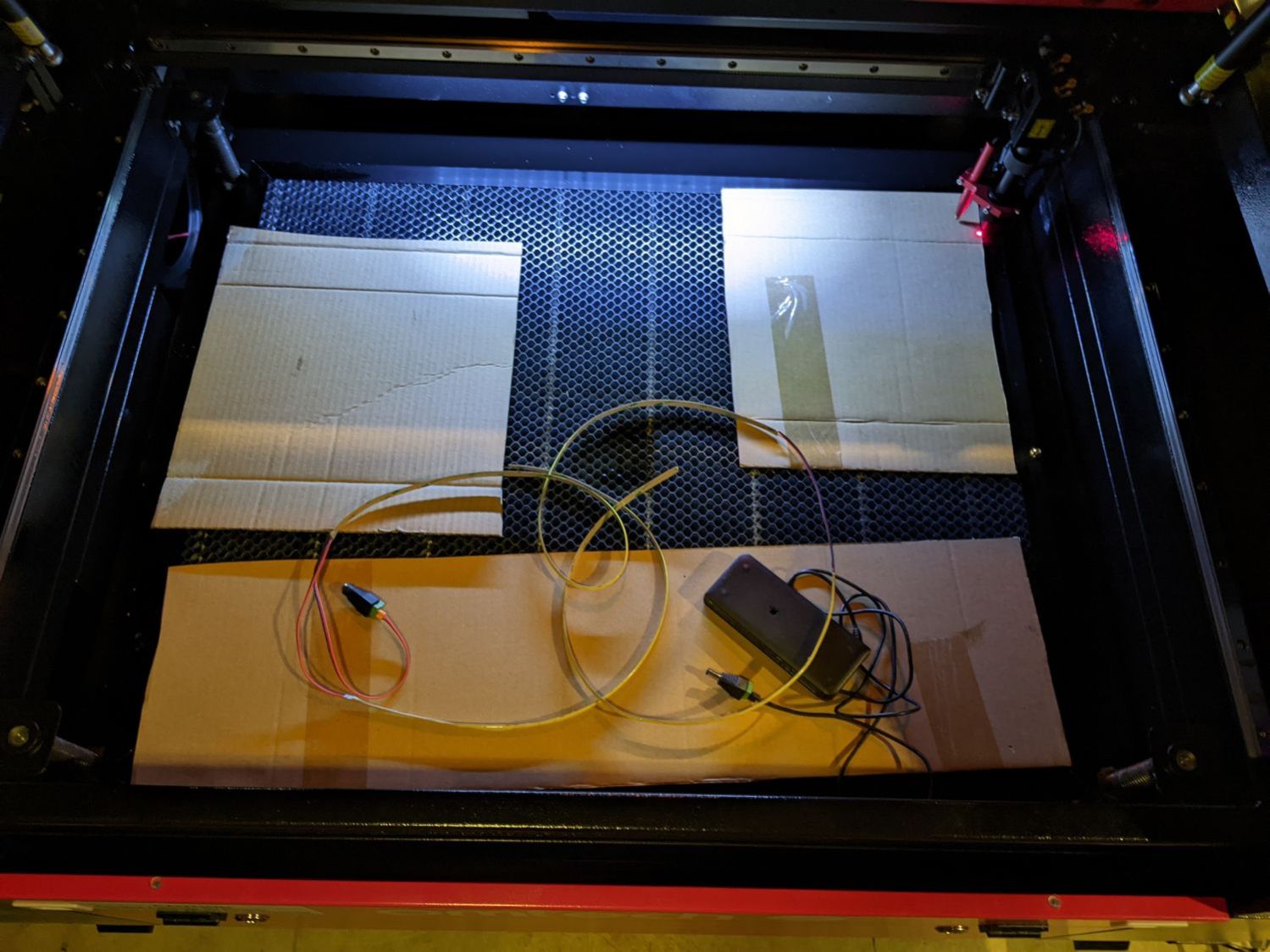

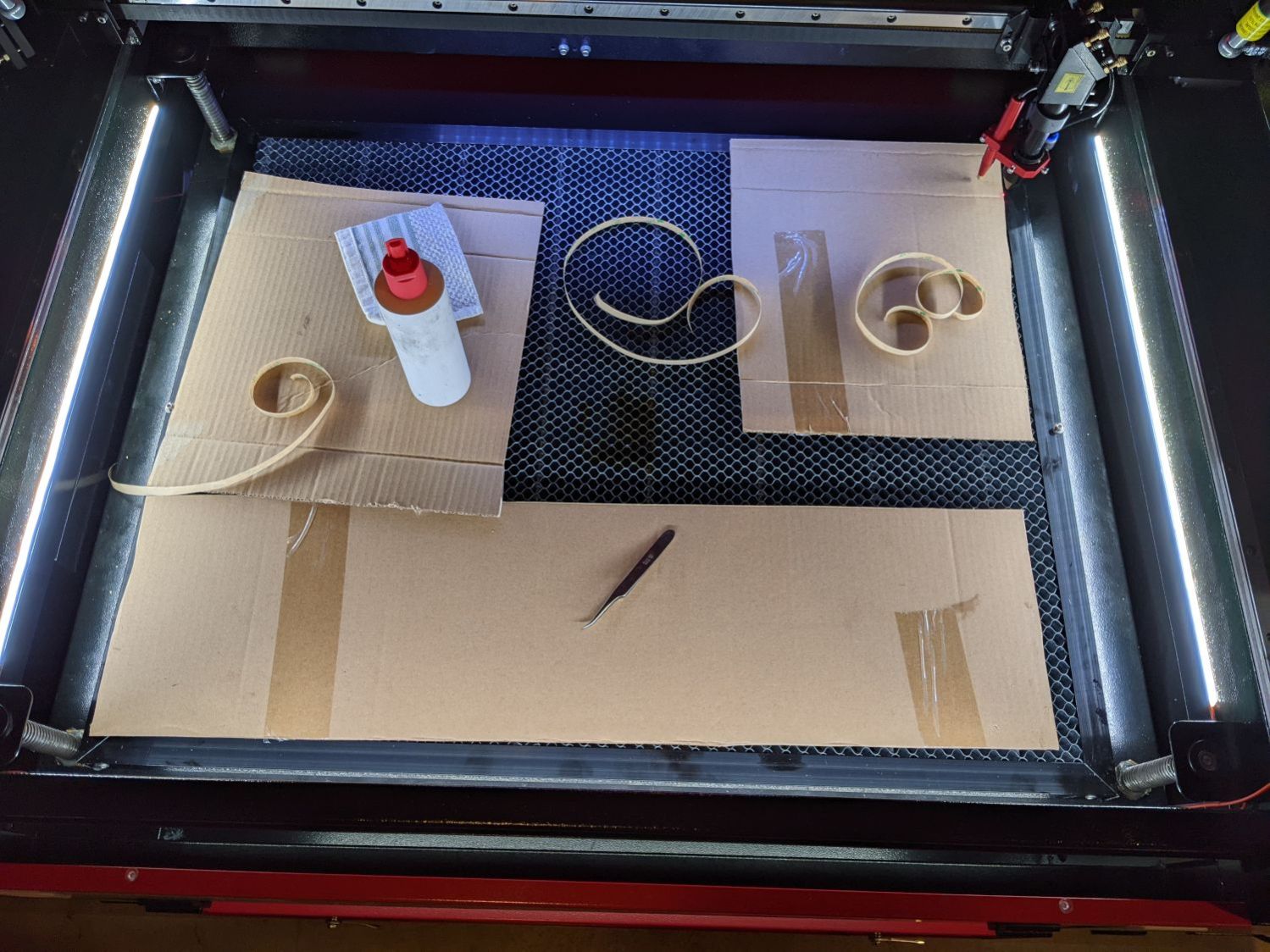

The stepper motor driver settings, plus a few amps for the controller and suchlike, added up to something over 12 A, far more than the 24 V supply’s 6 A spec should produce. When I added the COB strip lights around the platform, I dropped a 24 V wall wart into the electronics bay to avoid abusing that poor supply:

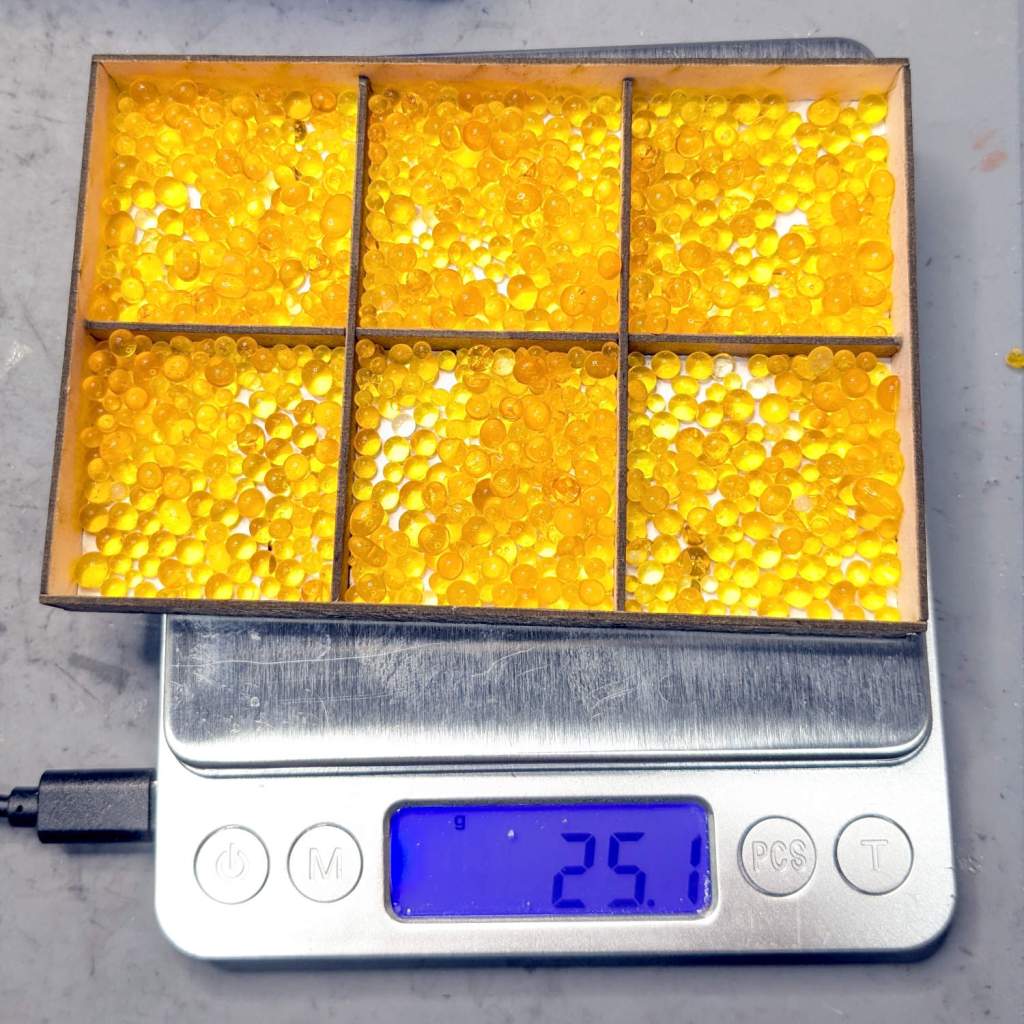

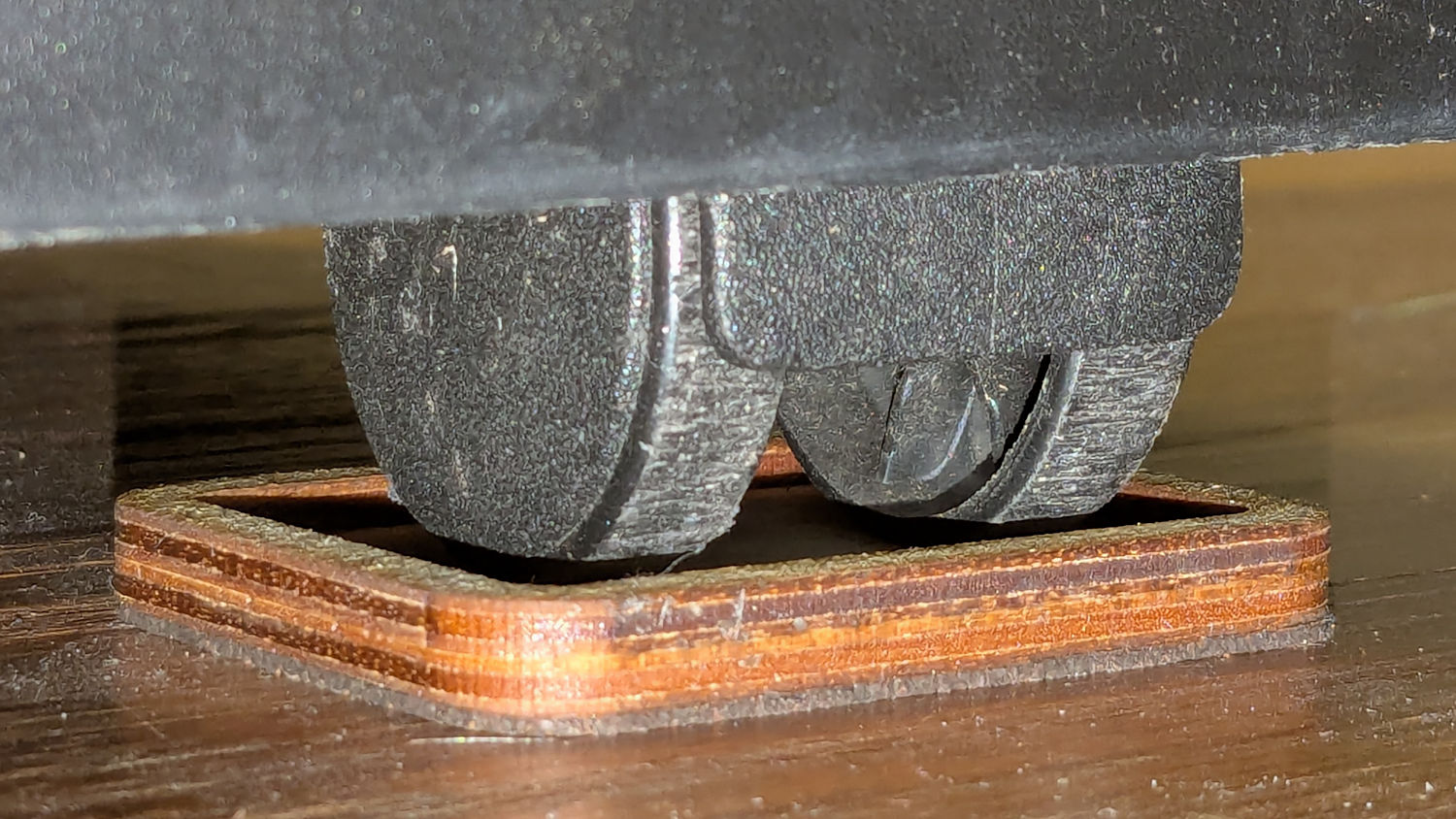

For reasons to be described later, it’s now time to upgrade that 24 V power supply to a 15 A supply that’s been on the shelf for far too long. However, it does not have a 5 V output, so it’s also time to figure out how much 5 V power the laser really needs.

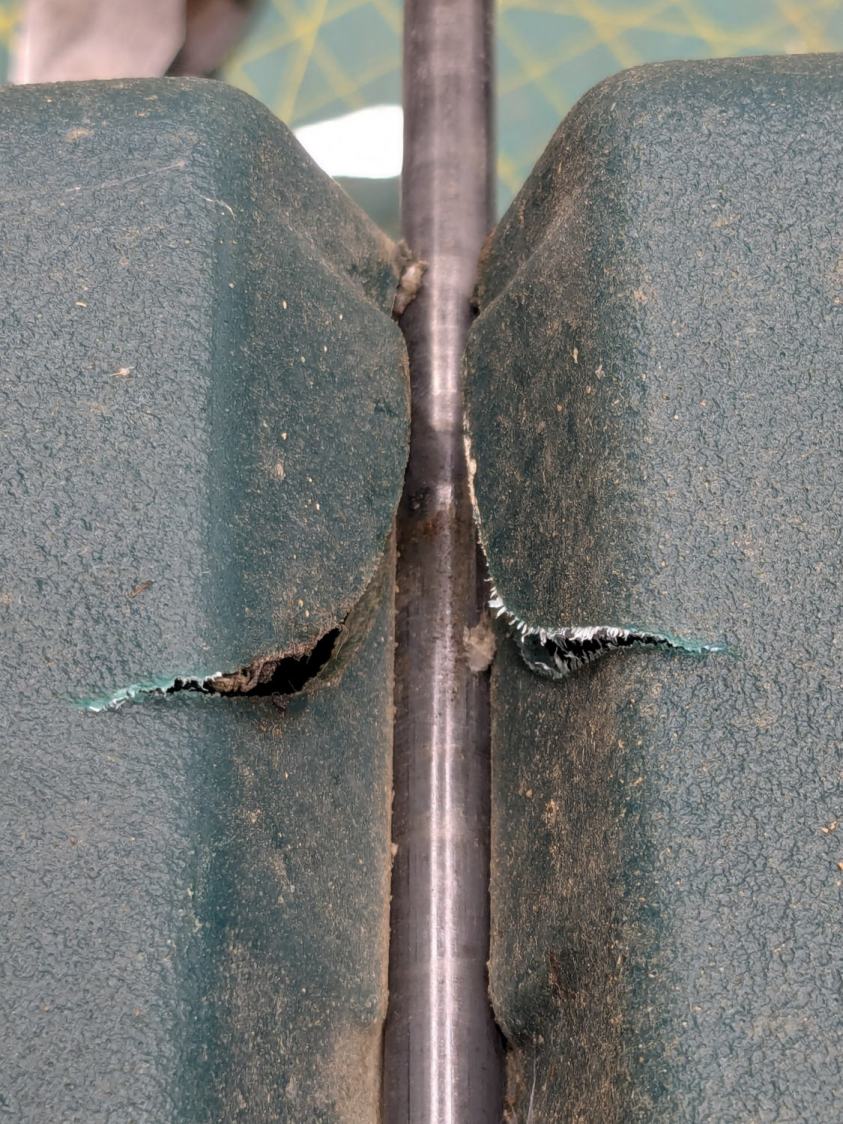

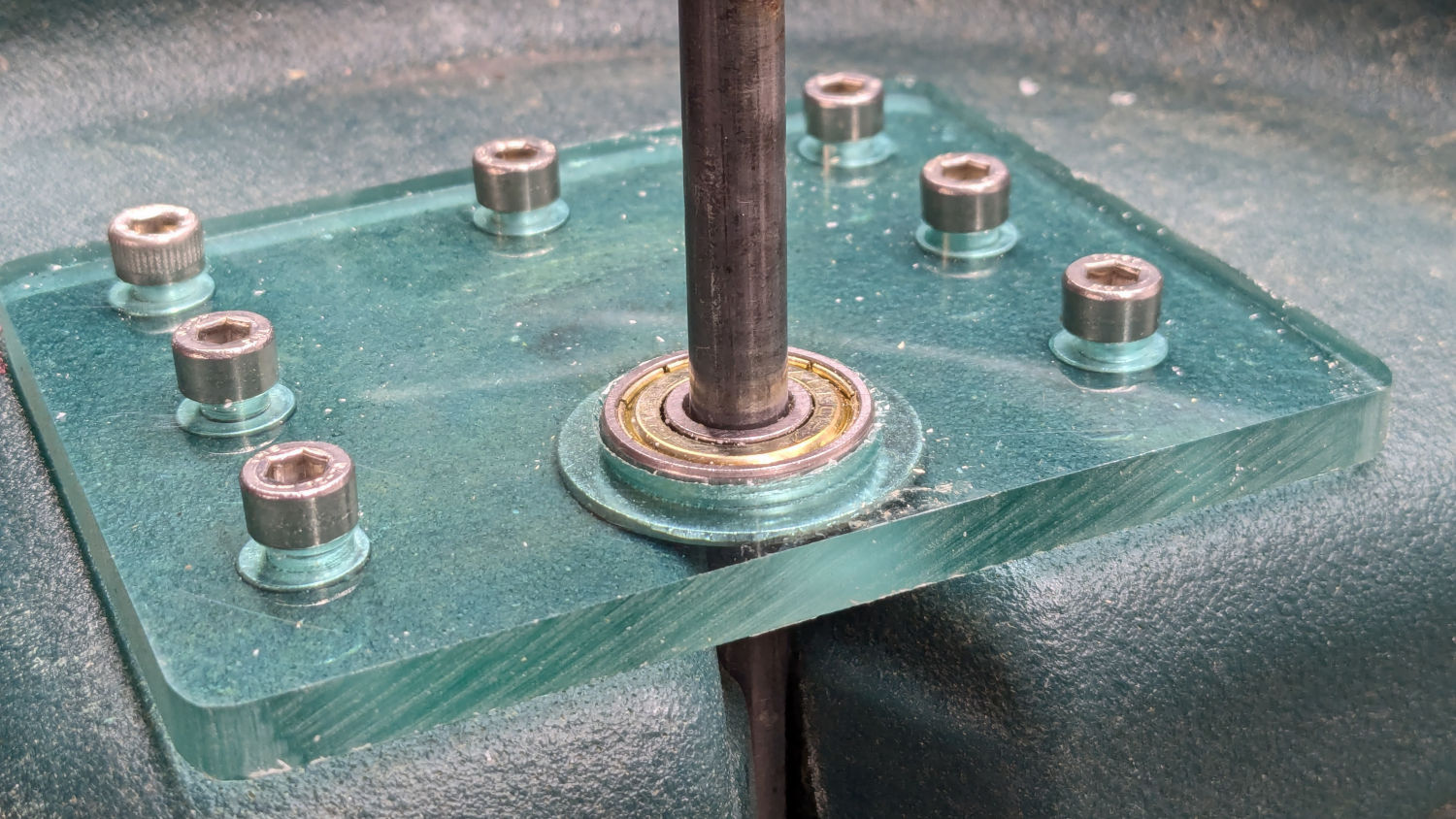

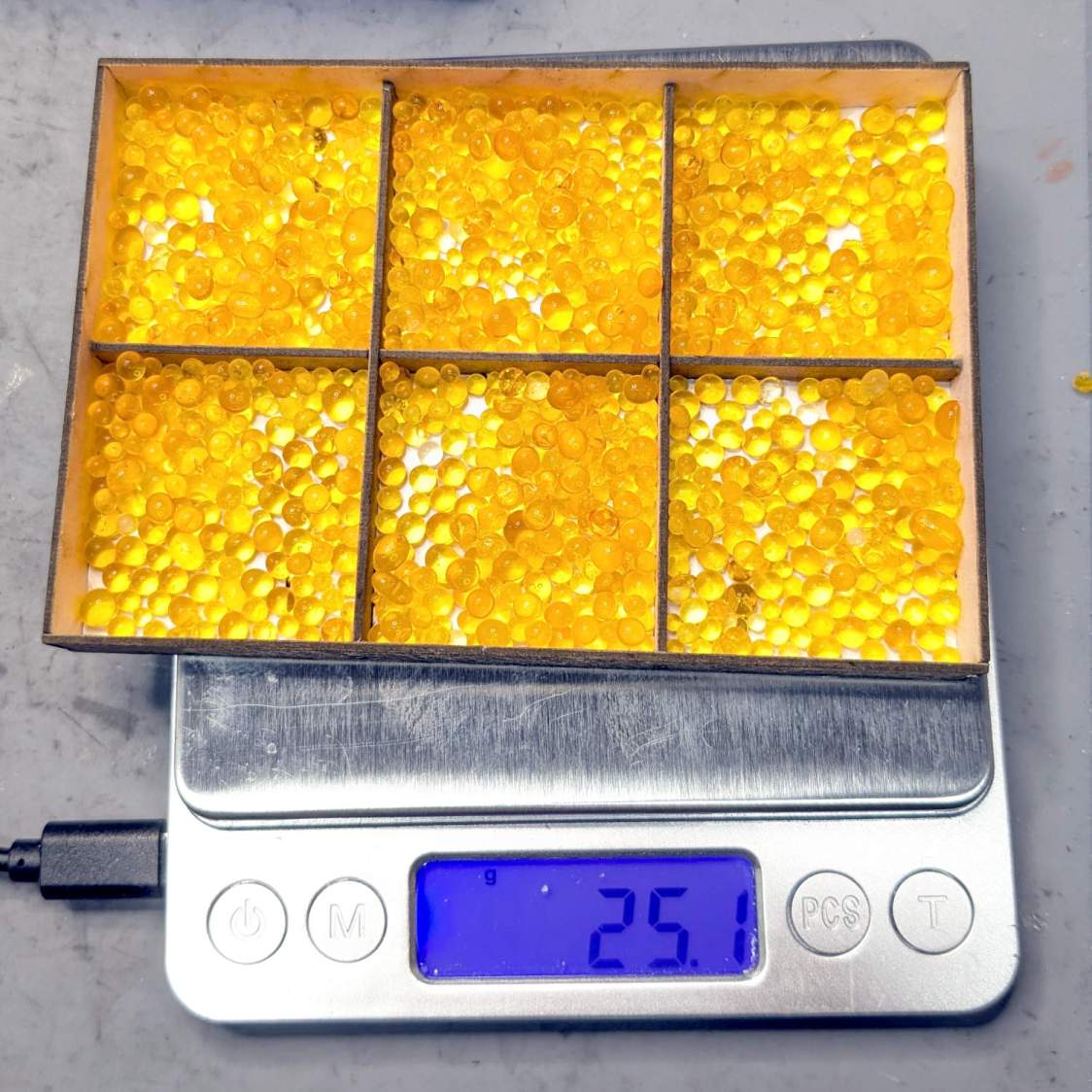

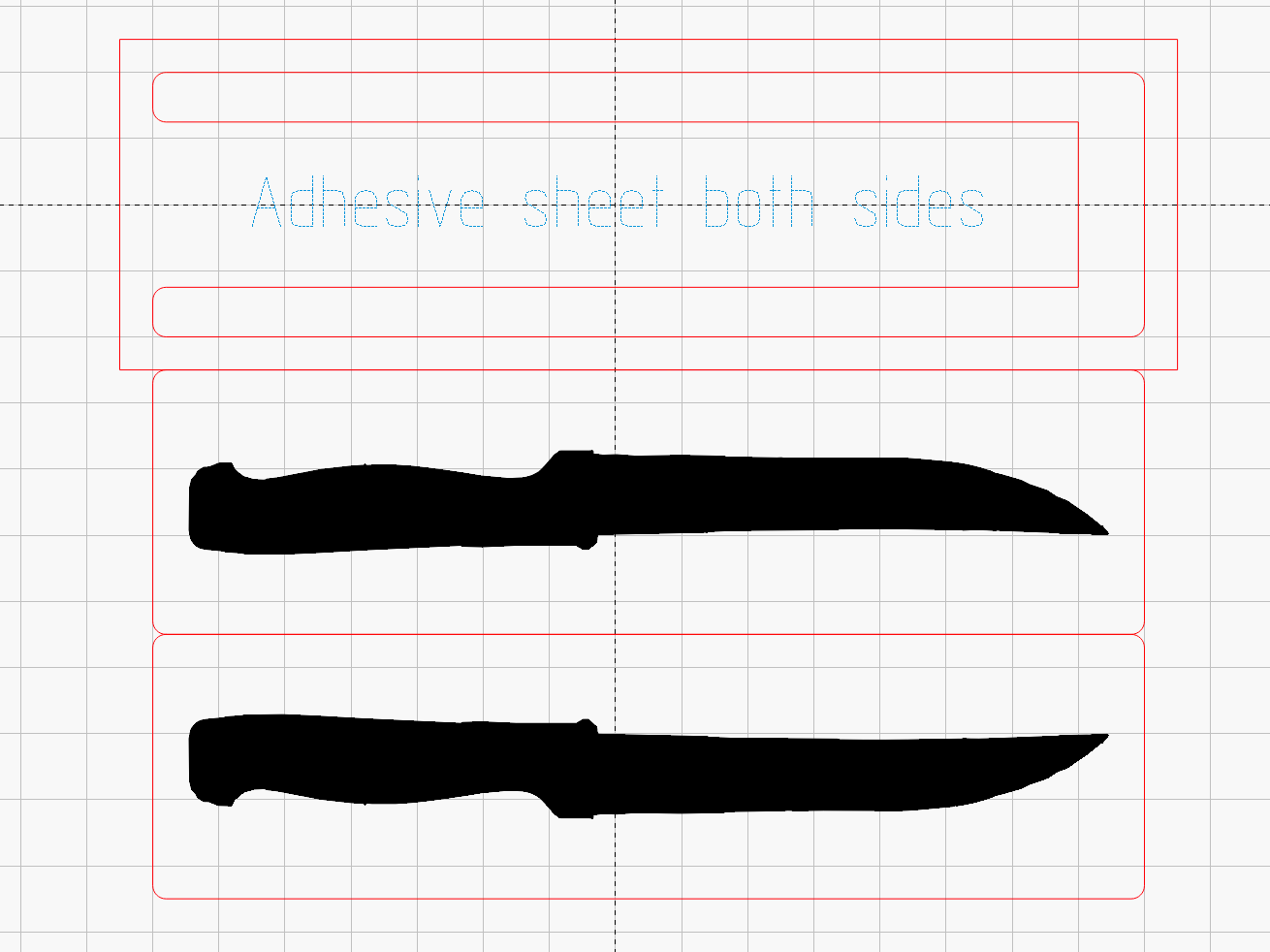

A quick measurement suggested the 5 V output delivered 20 mA to something. After convincing myself the multimeter was working and that the gantry LED strip was still lit, I finally tracked the wire pair to the red-dot pointer:

Yeah, a whole dual-output power supply for one red-dot laser module.

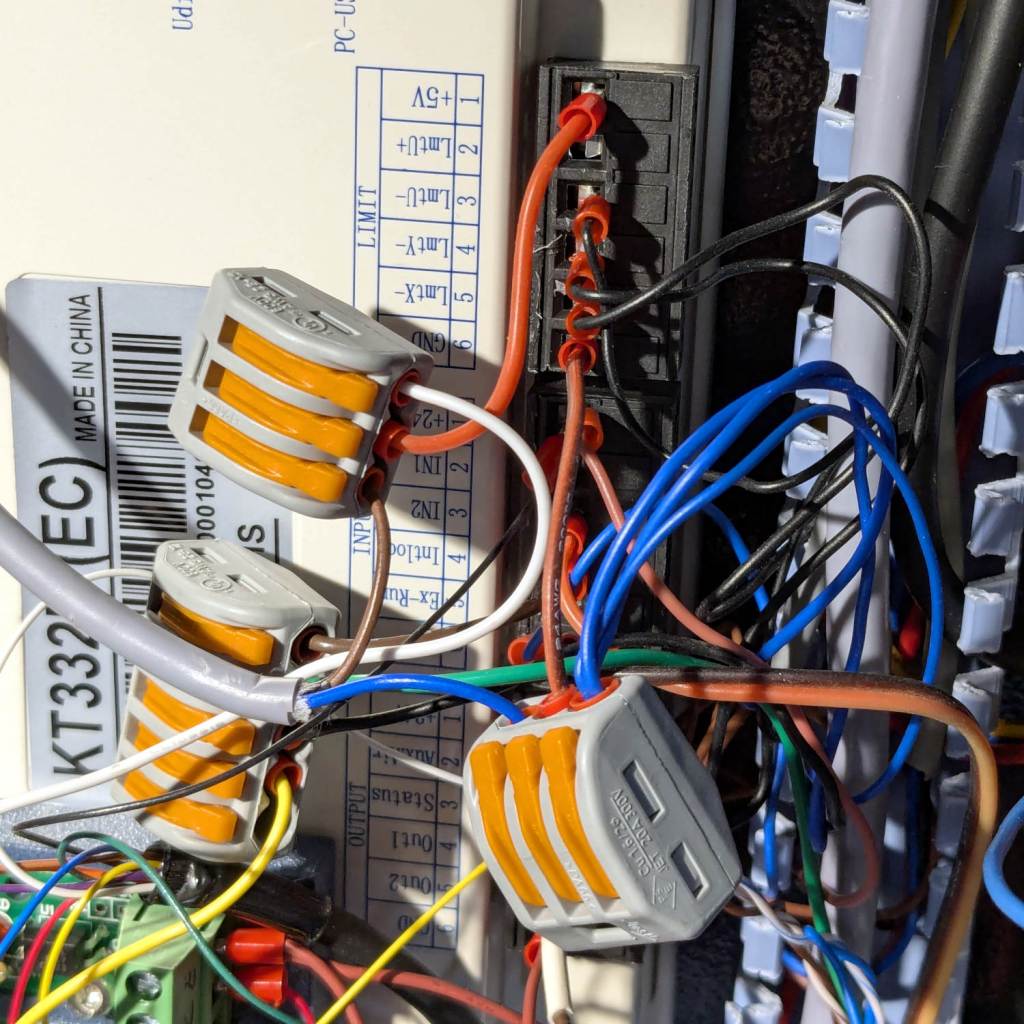

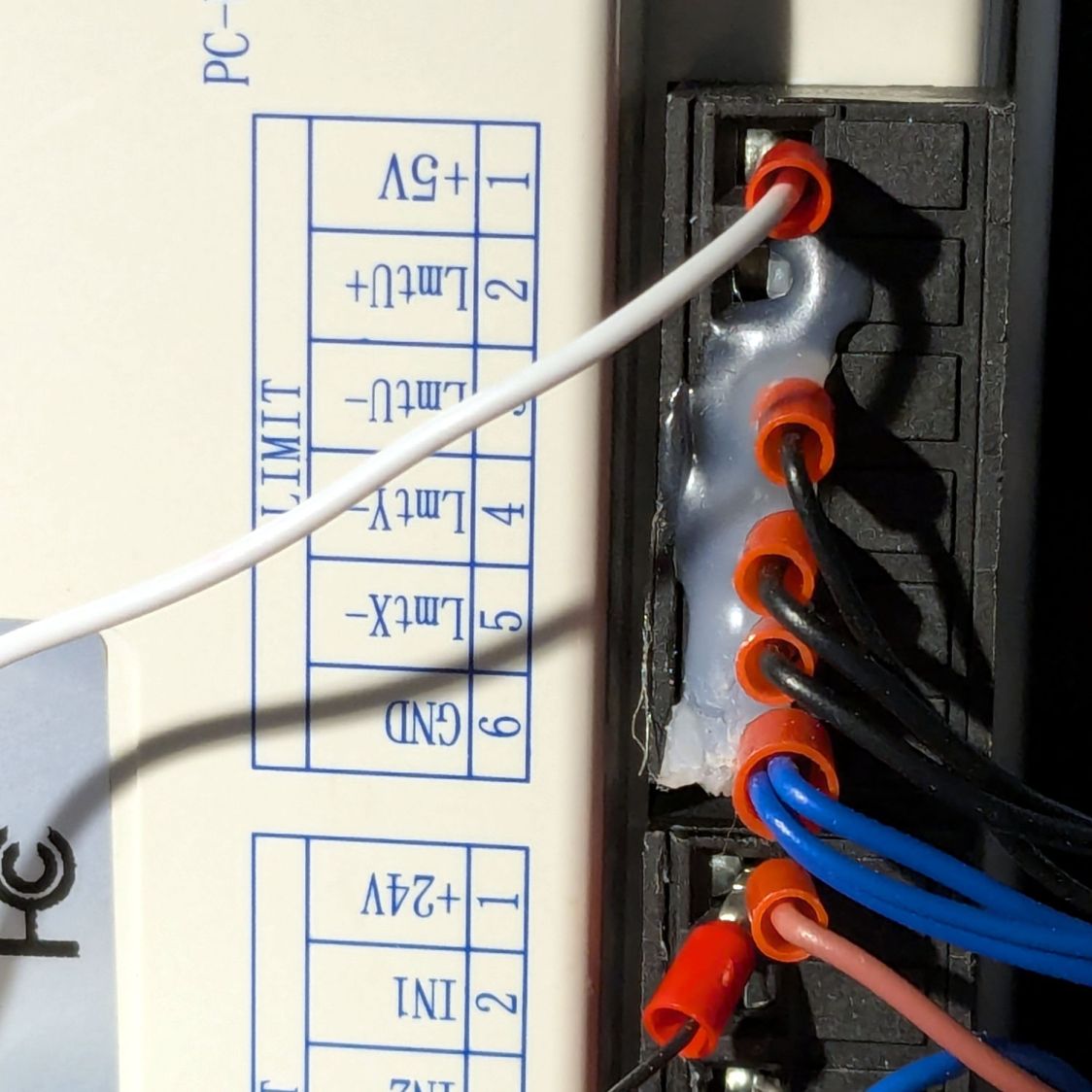

Conveniently, the KT332N controller has several 5 V outputs and the LIMIT terminal block even has a GND terminal on the other end:

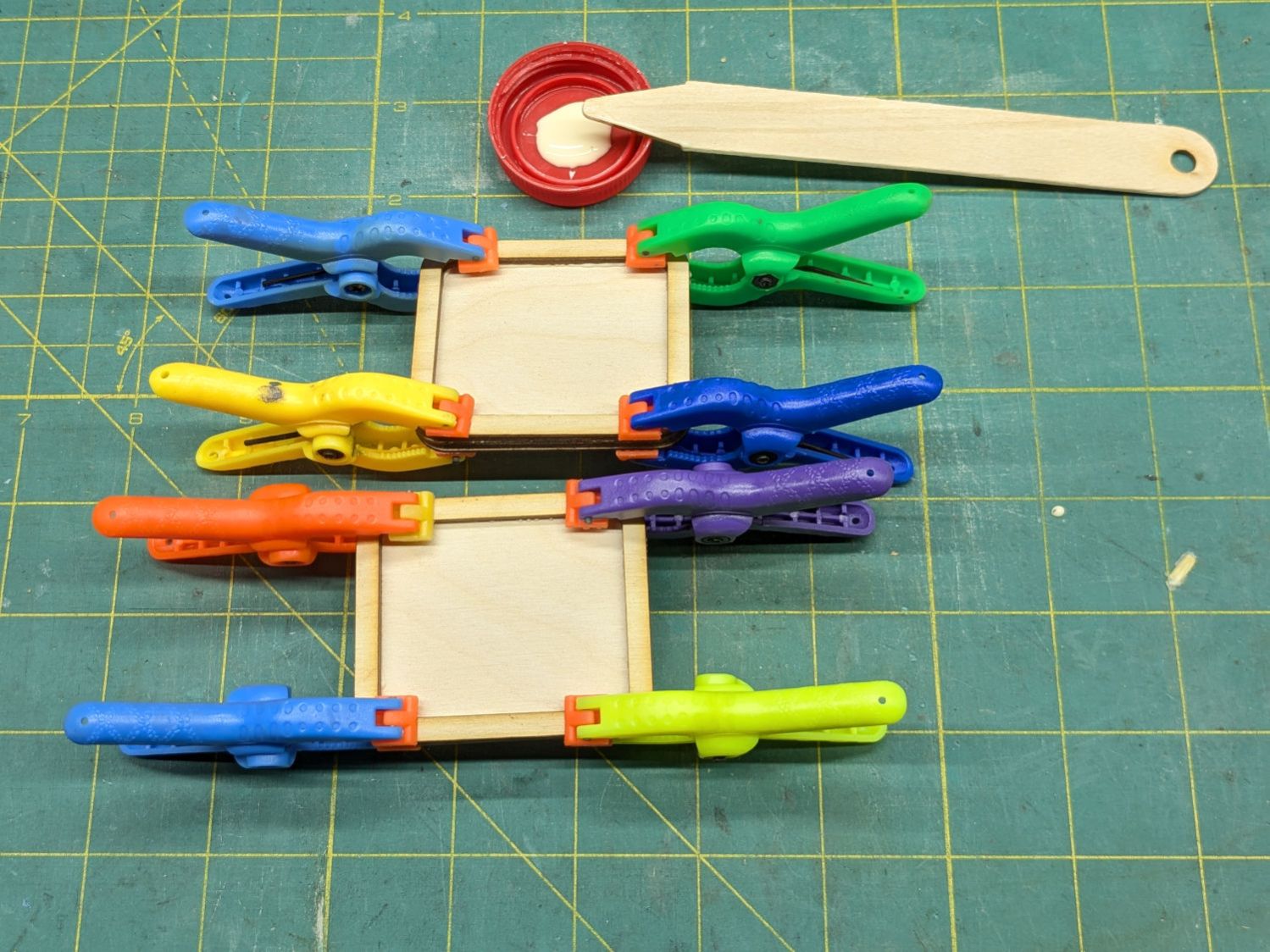

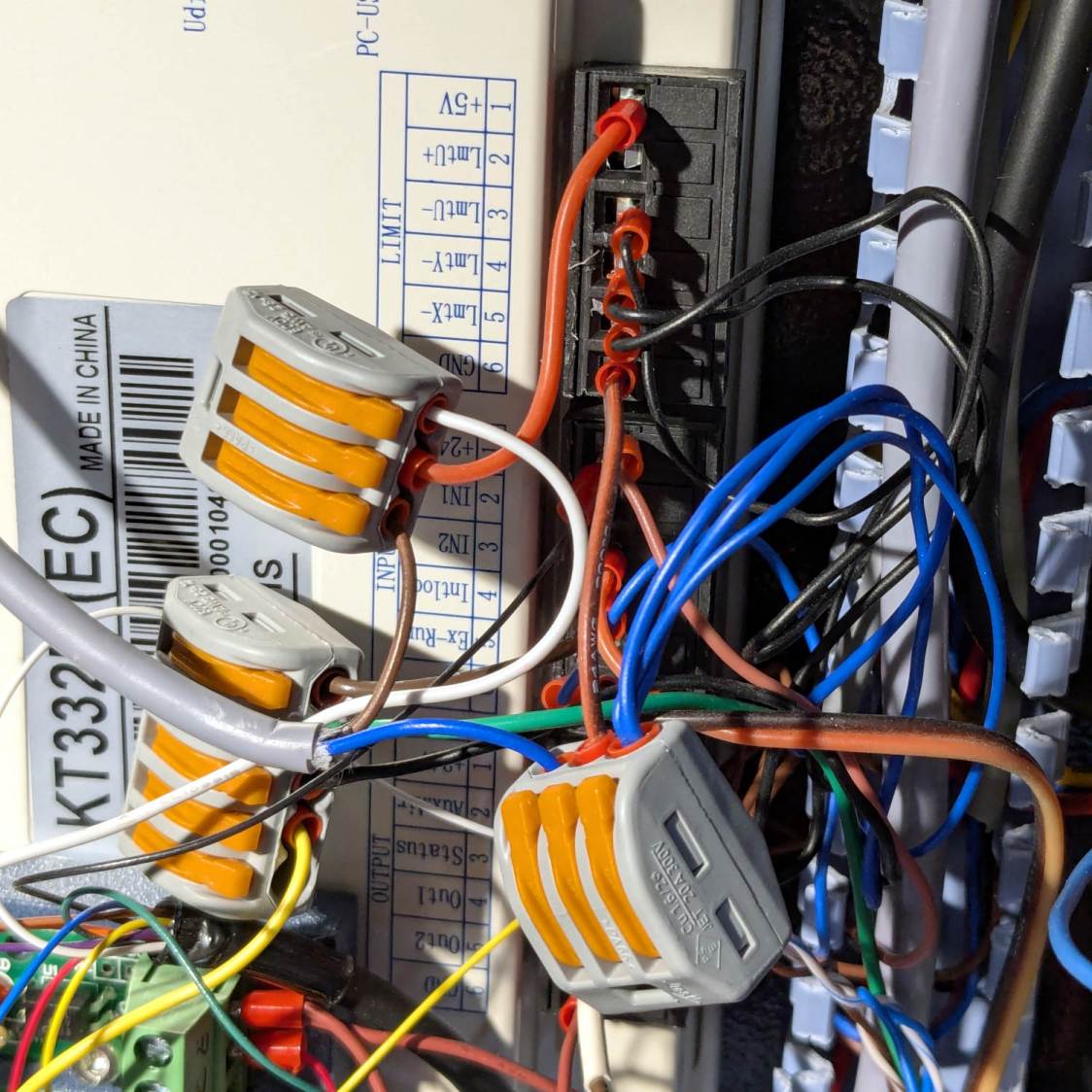

Prying off the hot melt glue, extracting the red-dot pointer wiring from the raceway, crimping ferrules on a couple of jumpers, and deploying a pair of Wago connectors:

I am still not accustomed to the color code:

- Black = signal

- Brown = power

- Blue = GND

But it’s like that and that’s the way it is.

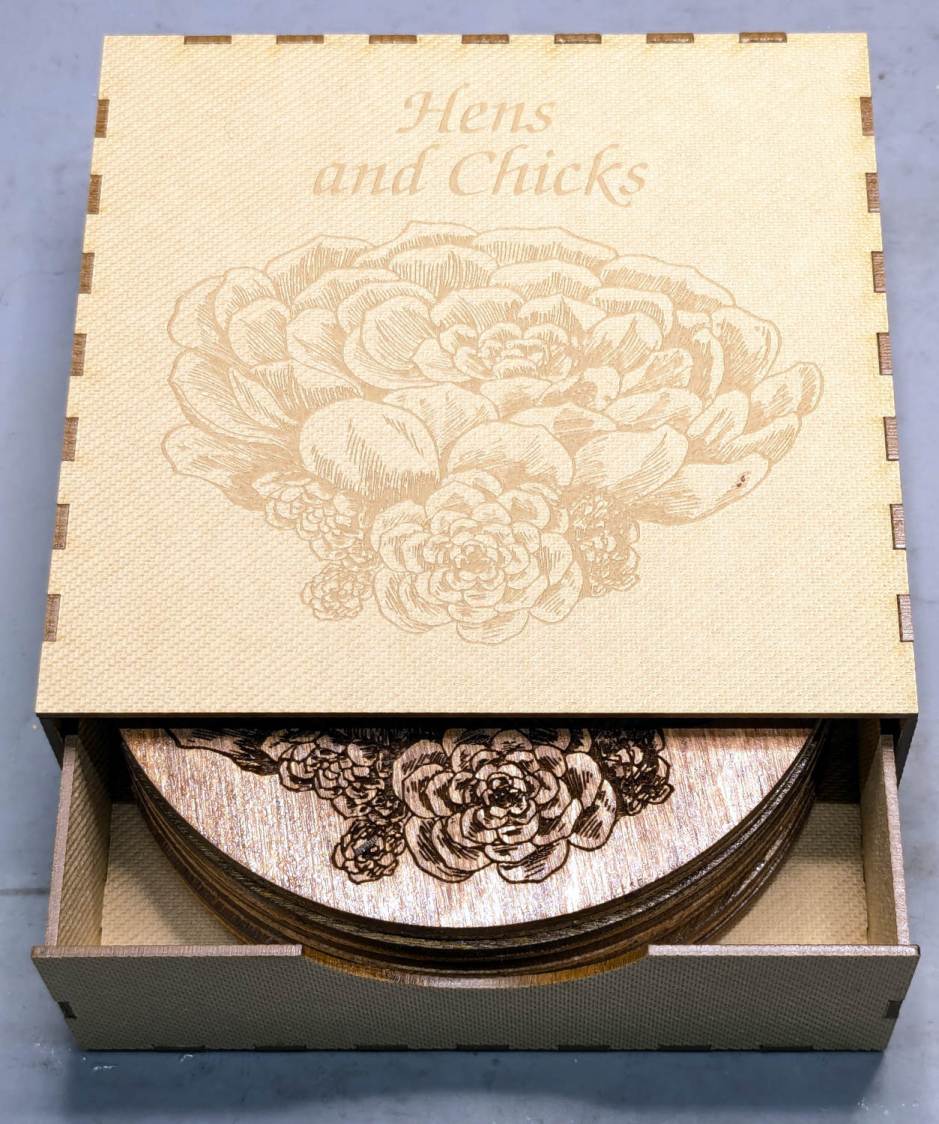

The red dot lit right up, the gantry LED strip obviously uses 24 V power, and I must shoehorn a slightly larger 24 V supply into the space currently occupied by the old supply.