Despite cogent reasons for not buying another Sears vacuum cleaner, the brand currently represents a local maximum of the desirability curve: cheap, readily available, works well enough, and, surprisingly, bags for the defunct Progressive (whatever that meant) vacuum seem to fit just fine.

But the new one does come with some annoyances, starting with trendy dark gray engraved / molded control markings:

Quick: from the other end of the vacuum hose, which one must you stomp to turn it off?

Well, I can fix that:

After the Progressive’s bizarre and overly complex tool fittings, the new unit has tools that slip-fit onto a classic steel tube, which means I can throw all those adapters into a box of 3D printing examples for use in the unlikely event I ever do another show-n-tell presentation.

It also has a simple rotating suction control ring at the handle:

Which, as you can tell from the fluorescent tape, featured the same embossed and unreadably small dark gray markings.

Because that ring and its glaring tape is invisible from the user’s end of the handle, I eventually duct-taped the ring in position to prevent another inadvertent loss-of-suction accident.

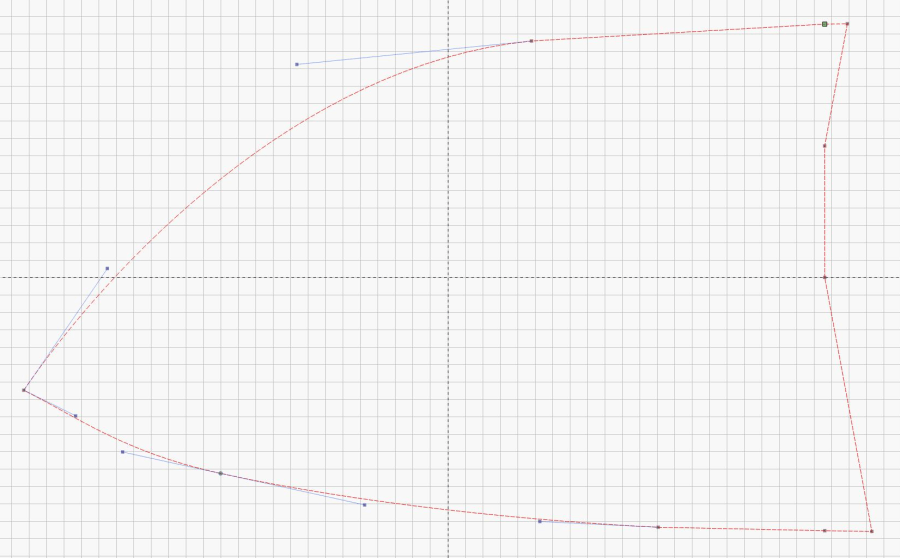

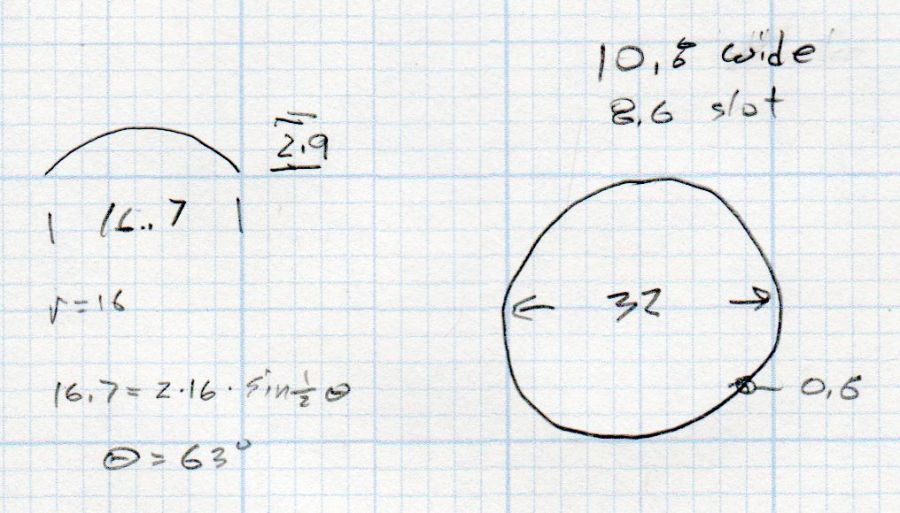

If we ever need reduced suction on a regular basis, I’ll conjure a better ring from the vasty digital deep:

I obviously no longer form deep emotional attachments to these things …