The Skeinforge Dimension plugin subsumes the obsolete Reversal plugin’s features. At the end of each thread, if the nozzle will move more than the Minimum Travel distance (1 mm by default, which is what I’m using) to the start of the next thread, the extruder yanks Retraction Distance of filament out of the hot end at the Retraction Speed.

Some experimentation at 30 mm/s showed that 2 mm of filament would eliminate all drooling, 1.5 mm left thin threads, and 1.0 mm wasn’t nearly enough.

Similar experimentation suggested 60 mm/s as the upper limit for Retraction Speed, with the SJFW acceleration limiting parameters set for 250 mm/s2. The usual extrusion speed isn’t much faster than a crawl, so the distance required to reach a backwards 60 mm/s is:

dist = (60 mm/s)2 / (2 * 250 mm/s2) = 7.2 mm

What that means, of course, is that the extruder doesn’t have enough torque to reach the programmed speed in the required distance. Assuming SJFW uses trapezoidal limiting, it will accelerate to some maximum speed at the halfway point and decelerate to a stop at the same rate. Pegging the midpoint at 1 mm, the extruder will reach a peak speed of:

v = √(2 * 250 mm/s2 * 1 mm) = 22 mm/s

In order to hit 60 mm/s in the middle of the retraction, the extruder must accelerate at:

a = (60 mm/s)2 / (2 * 1 mm) = 1800 mm/s2

Which requires way more torque than the piddly little motor I’m using can provide.

While I could swap in that larger motor, crank the current up a bit, and goose the extruder acceleration, the current Reversal Zittage is small enough for my purposes. I’d rather expend that effort on doodling up a direct-drive extruder, but that’s on the back burner until something horrible happens to the current extruder.

One easy alternative: lower the perimeter speed sufficiently far as to reduce the pressure in the hot end enough that the current speeds can suppress the zits. Notice the difference in the pix below; what you can’t see is that the first layer has no zittage whatsoever. Of course, that means the perimeter must trundle along at maybe 10 mm/s…

Herewith, a Reversal Zittage bestiary at various perimeter speeds, with Dimension set as described above and these extrusion settings:

- 0.25 mm layer height

- 0.50 mm thread width

- 60 mm/s infill

- 250 mm/s travel

A Dishwasher Rack Protector vertical tube at 30 mm/s:

The tube’s interior had equivalent zits that cleaned out easily with a twist drill.

Some of the half-tube ends came out slightly angled with zits here & there, but remember that they’re 4.5 mm tall:

The Zire 71 Protector had a lot more infill with very few perimeter joints. This corner shows a few zits at 30 mm/s:

One of the Dr. Who Cookie Cutters showed much more conspicuous zittage on the inside of a corner at 20 mm/s:

Than on the outside of the same corner:

The zits on the other cutter fell along one edge. The inside:

And the outside:

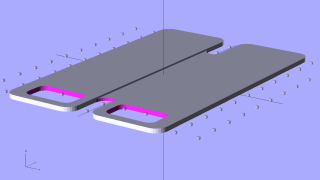

The Dr. Who set included flat cookie presses with patterns. Although these islands show some zittage, they’re about 1 mm tall and perhaps 5 mm long:

The rest of the perimeter extrusions look essentially perfect, so these really are very minor imperfections.