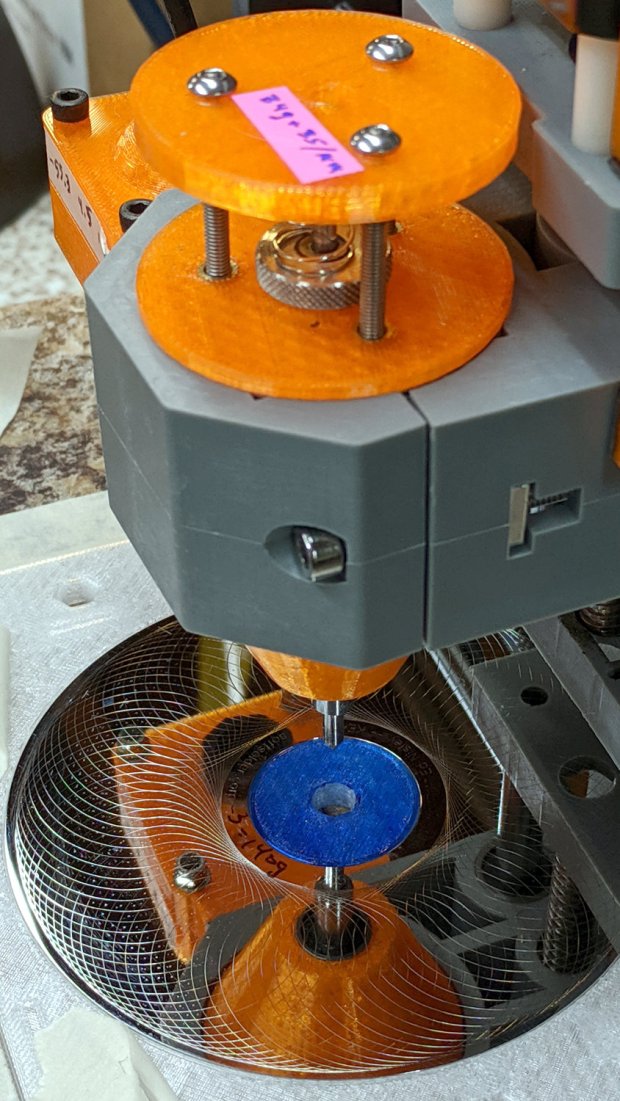

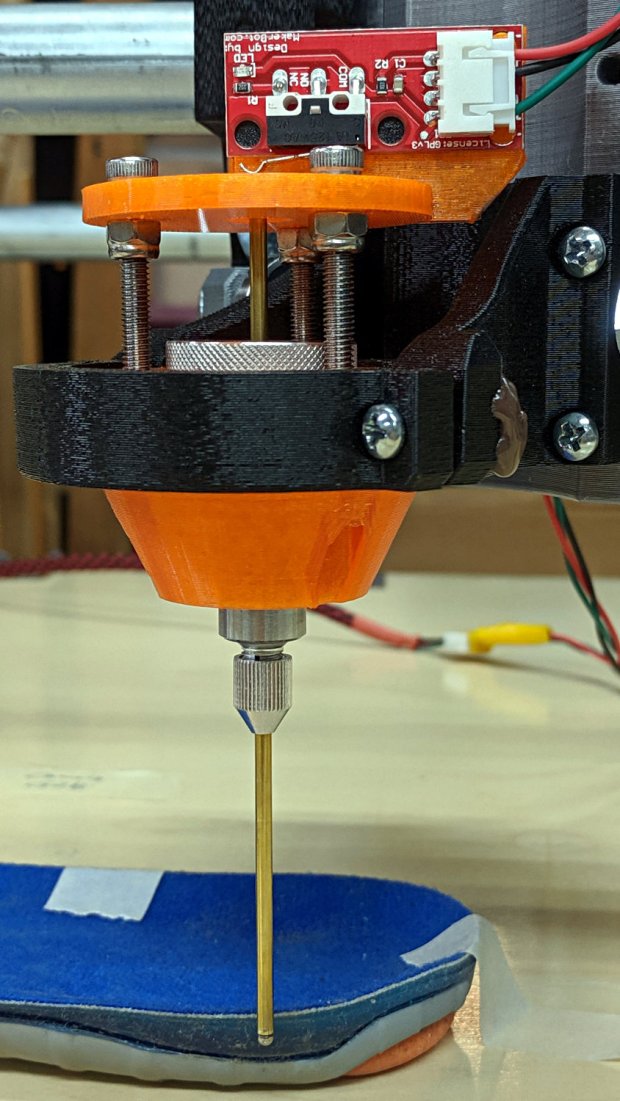

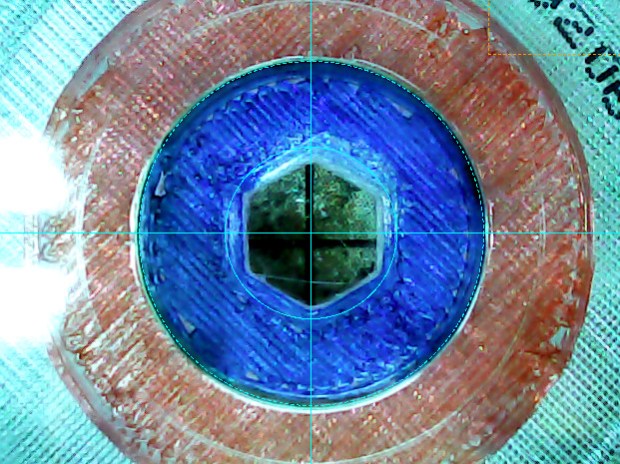

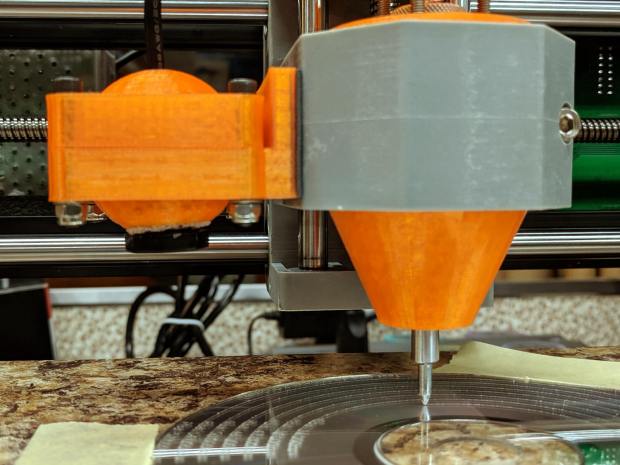

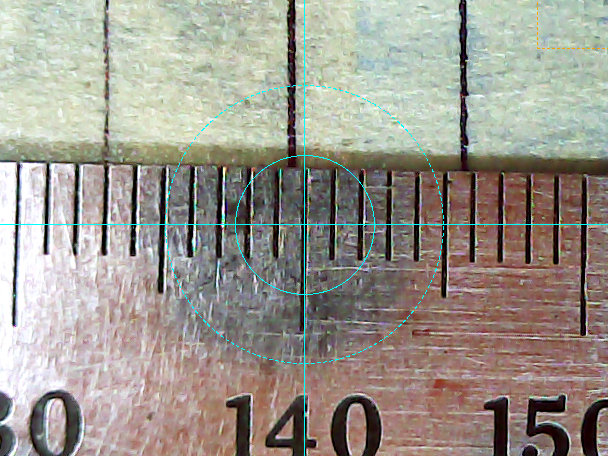

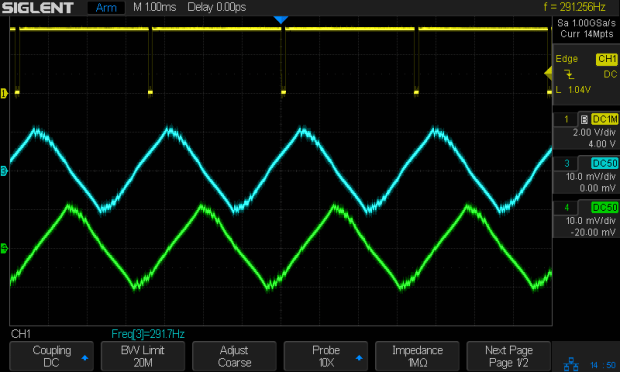

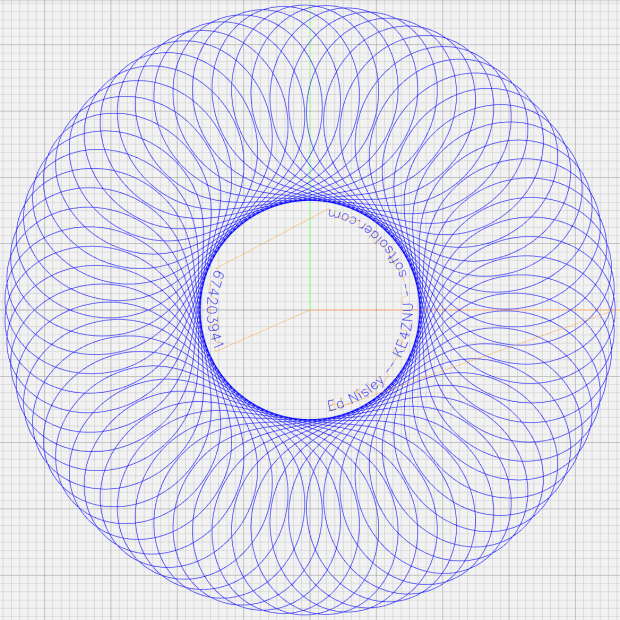

Engraving Spirograph / Guilloché patterns on scrap CDs and hard drive platters now works better than ever:

After, that is, I realized:

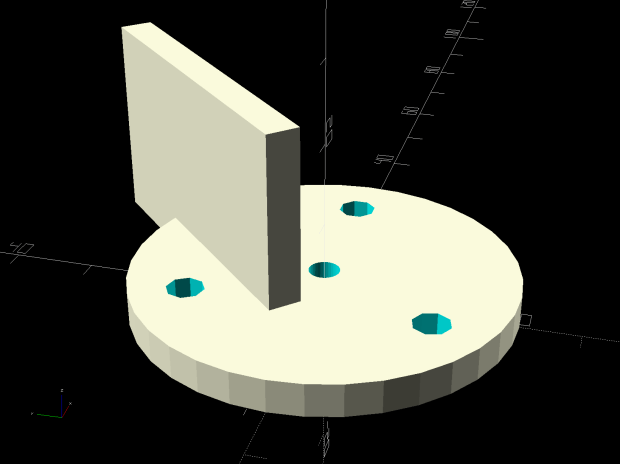

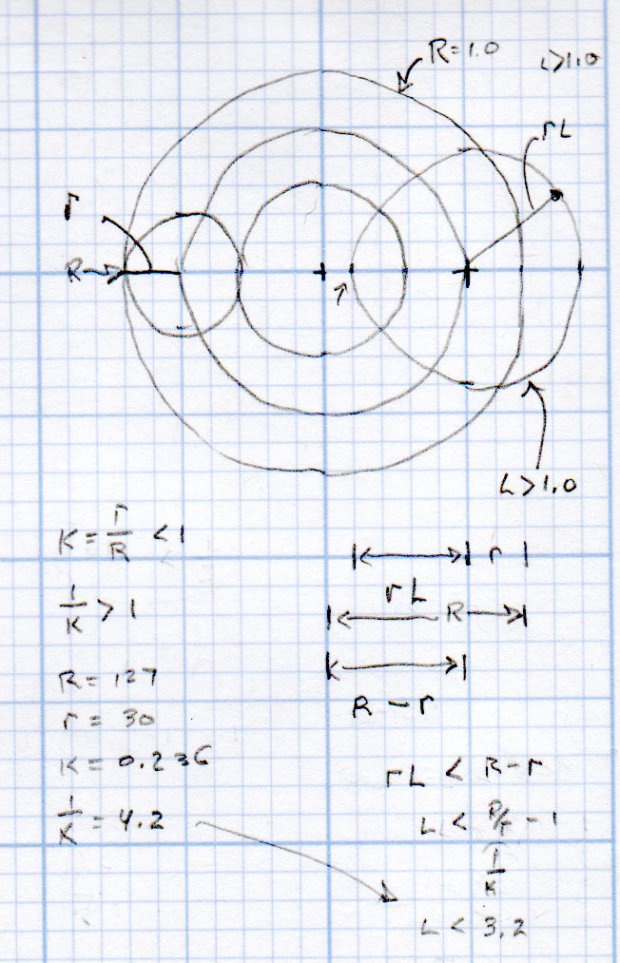

- Any Rotor will work, as long as it’s smaller than the Stator

- You must pick pen offset L so the pattern never crosses the stator center point

- L ≥ 1 is perfectly fine

- You must scale the resulting pattern to fit the actual space on the disk

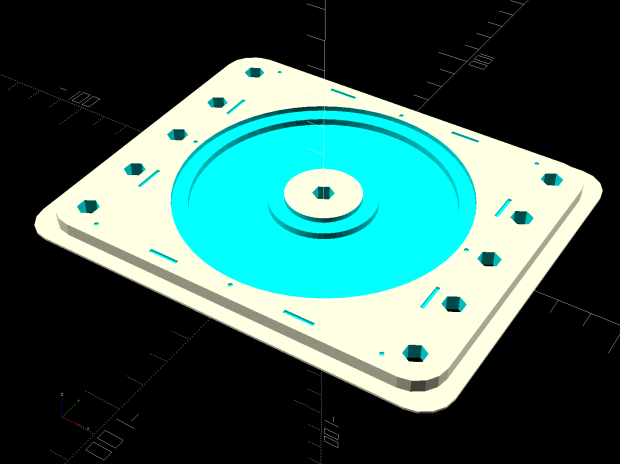

One of my final doodles showing how the variables relate to each other, although the Wikipedia article may be useful for the underlying math and other posts have more pix on various machines:

Cheat sheet:

- Stator has tooth count (∝ radius) R

- Rotor has tooth count (∝ radius) r

- K = r/R, so if you normalize R=1, K=r

- Pen offset L puts it at radius rL in the rotor

Picking a suitable rotor requires iterating with random choices until one fits:

RotorTeeth = Stators[-1];

n = 0;

while (RotorTeeth >= floor(0.95 * StatorTeeth) || RotorTeeth < 5) {

RotorTeeth = (XORshift() & 0x007f); // this is why Stator can't have more than 127 teeth

n++;

}

comment("Rotor: ",RotorTeeth," in ",n," iterations");The 5% buffer on the high end ensures there will be an L keeping a hole in the middle of the pattern. Requiring at least five teeth on the low end just seems like a Good Idea.

Given the stator & rotor tooth counts, iterate on random L values until one works:

n = 0;

do {

L = (to_float((XORshift() & 0x1f) + 1) / 32.0) * (1.0/K - 1.0); // allow L > 1.0

n++;

} while (L >= (1.0/K - 1.0) || L < 0.01);

}

comment("Offset L: ", L," in ",n," iterations");With L chosen to leave a hole in the middle of the pattern, then the pattern traced by the pen in the rotor is centered at 1.0 – K (the normalized Stator radius minus the normalized Rotor radius) and varies by ±LK (the offset times the normalized Rotor radius) on either side:

RotorMin = 1.0 - 2*K;

comment("Rotor Min: ",RotorMin);

BandCtr = 1.0 - K; // band center radius

BandMin = BandCtr - L*K; // ... min radius

BandMax = BandCtr + L*K; // ... max radius

BandAmpl = BandMax - BandCtr;

comment("Band Min: ",BandMin," Ctr: ",BandCtr," Max: ",BandMax);Knowing that, rescaling the pattern to fit the disk limits goes like this:

FillPath = {};

foreach (Path; pt) {

a = atan_xy(pt); // recover angle to point

r = length(pt); // ... radius to point

br = (r - BandCtr) / BandAmpl; // remove center bias, rescale to 1.0 amplitude

dr = br * (OuterRad - MidRad); // rescale to fill disk

pr = dr + MidRad; // set at disk centerline

x = pr * cos(a); // find new XY coords

y = pr * sin(a);

FillPath += {[x,y]};

}

comment("Path has ",count(FillPath)," points");The final step prunes coordinates so close together as to produce no useful motion, which I define to be 0.2 mm:

PointList = {FillPath[0]}; // must include first point

lp = FillPath[0];

n = 0;

foreach (FillPath; pt) {

if (length(pt - lp) <= Snuggly) { // discard too-snuggly point

n++;

}

else {

PointList += {pt}; // otherwise, add it to output

lp = pt;

}

}

PointList += {FillPath[-1]}; // ensure closure at last point

comment("Pruned ",n," points, ",count(PointList)," remaining");The top of the resulting G-Code file contains all the various settings for debugging:

(Disk type: CD)

(Outer Diameter: 117.000mm)

( Radius: 58.500mm)

(Inner Diameter: 38.000mm)

( Radius: 19.000mm)

(Mid Diameter: 77.500mm)

( Radius: 38.750mm)

(Legend Diameter: 30.000mm)

( Radius: 15.000mm)

(PRNG seed: 674203941)

(Stator 8: 71)

(Rotor: 12 in 1 iterations)

(Dia ratio K: 0.169 1/K: 5.917)

(GCD: 1)

(Lobes: 71)

(Turns: 12)

(Offset L: 3.227 in 1 iterations)

(Rotor Min: 0.662)

(Band Min: 0.286 Ctr: 0.831 Max: 1.376)

(Path has 43201 points)

(Pruned 14235 points, 28968 remaining)The GCMC source code as a GitHub Gist:

| // Spirograph simulator for MPCNC used as plotter | |

| // Ed Nisley KE4ZNU – 2017-12-23 | |

| // Adapted for Guillioche plots with ball point pens – 2018-09-25 | |

| // 2019-06 Text on circular arcs | |

| // 2019-08 Coordinate pruning | |

| // 2019-09 Allow L > 1.0, proper scale to fit disk | |

| // Spirograph equations: | |

| // https://en.wikipedia.org/wiki/Spirograph | |

| // Loosely based on GCMC cycloids.gcmc demo: | |

| // https://gitlab.com/gcmc/gcmc/tree/master/example/cycloids.gcmc | |

| //—– | |

| // Library routines | |

| include("tracepath.inc.gcmc"); | |

| include("engrave.inc.gcmc"); | |

| //—– | |

| // Define useful constants | |

| SafeZ = 10.00mm; | |

| TravelZ = 1.00mm; | |

| AngleStep = 0.1deg; | |

| Snuggly = 0.2mm; // prune coordinates when closer | |

| TextFont = FONT_HSANS_1_RS; | |

| TextSize = [1.5mm,1.5mm]; | |

| //—– | |

| // Command line parameters | |

| // -D DiskType="string" | |

| if (!isdefined("DiskType")) { | |

| DiskType = "CD"; | |

| } | |

| if (DiskType != "CD" && // list all possible types | |

| DiskType != "3.5" && | |

| DiskType != "TrimCD" | |

| ) { | |

| error("Unknown disk type: ",DiskType); | |

| } | |

| comment("Disk type: ",DiskType); // default is "CD" | |

| Margin = 1.5mm; // clamping margin around disk OD | |

| DiskDia = (DiskType == "3.5") ? 95.0mm : | |

| (DiskType == "TrimCD") ? 95.0mm : | |

| 120.0mm; | |

| OuterDia = DiskDia – 2*Margin; | |

| OuterRad = OuterDia / 2; | |

| comment("Outer Diameter: ",OuterDia); | |

| comment(" Radius: ",OuterRad); | |

| InnerDia = (DiskType == "3.5") ? 33.0mm : | |

| (DiskType == "TrimCD") ? 38.0mm : | |

| 38.0mm; | |

| InnerDia = InnerDia; | |

| InnerRad = InnerDia / 2; | |

| comment("Inner Diameter: ",InnerDia); | |

| comment(" Radius: ",InnerRad); | |

| MidDia = (InnerDia + OuterDia) / 2; | |

| MidRad = MidDia / 2; | |

| comment("Mid Diameter: ",MidDia); | |

| comment(" Radius: ",MidRad); | |

| LegendDia = (DiskType == "3.5") ? 31.0mm : | |

| (DiskType == "TrimCD") ? 31.0mm : | |

| 30.0mm; | |

| LegendDia = LegendDia; | |

| LegenRad = LegendDia / 2; | |

| comment("Legend Diameter: ",LegendDia); | |

| comment(" Radius: ",LegenRad); | |

| // -D PRNG_Seed=integer non-zero random number seed | |

| if (isdefined("PRNG_Seed")) { // did we get a seed? | |

| if (!PRNG_Seed) { // .. it must not be zero | |

| PRNG_Seed = 347221084; | |

| } | |

| } | |

| else { // no incoming seed, so use a constant | |

| PRNG_Seed = 674203941; | |

| } | |

| comment("PRNG seed: ",PRNG_Seed); | |

| PRNG_State = PRNG_Seed; // set initial state | |

| // -D various other useful tidbits | |

| // add unit to speeds and depths: 2000mm / -3.00mm / etc | |

| if (!isdefined("PlotSpeed")) { | |

| PlotSpeed = 2400mm; | |

| } | |

| if (!isdefined("TextSpeed")) { | |

| TextSpeed = 2000mm; | |

| } | |

| // Force is proportional to depth, but you must know the coefficent! | |

| if (!isdefined("PlotZ")) { | |

| PlotZ = (DiskType == "3.5") ? -3.00 : -0.25mm; | |

| } | |

| if (!isdefined("Legend")) { | |

| Legend = "Ed Nisley – KE4ZNU – softsolder.com"; | |

| } | |

| //—– | |

| // Spirograph tooth counts mooched from: | |

| // http://nathanfriend.io/inspirograph/ | |

| // Stators includes both inside and outside counts, because we're not fussy | |

| // Stator with prime tooth count will always produce that number of lobes | |

| // Prime numbers: | |

| // https://en.wikipedia.org/wiki/Prime_number | |

| // Table of primes: | |

| // https://www.factmonster.com/math/numbers/prime-numbers-facts-examples-table-all-1000 | |

| // Must be sorted and should not exceed 127 teeth, which will make plenty of lobes | |

| Stators = [37,41,43,47,53,59,61,67,71,73,79,83,89,97,101,103,107,109,113,127]; | |

| // Rotor tooth count chosen randomly, these are for the old method | |

| Rotors = [24, 30, 32, 36, 40, 45, 48, 50, 52, 56, 60, 63, 64, 72, 75, 80, 84]; | |

| //Rotors = [5,7,11,13,17,19,23,31,37,41,47]; | |

| //—– | |

| // Greatest Common Divisor | |

| // https://en.wikipedia.org/wiki/Greatest_common_divisor#Using_Euclid's_algorithm | |

| // Inputs = integers without units | |

| // This is unused with prime rotor tooth counts left here for completeness | |

| function gcd(a,b) { | |

| if (!isnone(a) || isfloat(a) || !isnone(b) || isfloat(b)) { | |

| error("GCD params must be dimensionless integers. a: ",a," b: ",b); | |

| } | |

| local d = 0; // power-of-two counter | |

| while (!((a | b) & 1)) { // remove and tally common factors of two | |

| a >>= 1; | |

| b >>= 1; | |

| d++; | |

| } | |

| while (a != b) { | |

| if (!(a & 1)) {a >>= 1;} // discard non-common factor of 2 | |

| elif (!(b & 1)) {b >>= 1;} // … likewise | |

| elif (a > b) {a = (a – b) >> 1;} // gcd(a,b) also divides a-b | |

| else {b = (b – a) >> 1;} // … likewise | |

| } | |

| local GCD = a*(1 << d); // form gcd | |

| // message("GCD: ",GCD); | |

| return GCD; | |

| } | |

| //—– | |

| // Max and min functions | |

| function max(x,y) { | |

| return (x > y) ? x : y; | |

| } | |

| function min(x,y) { | |

| return (x < y) ? x : y; | |

| } | |

| //—– | |

| // Pseudo-random number generator | |

| // Based on xorshift: | |

| // https://en.wikipedia.org/wiki/Xorshift | |

| // http://www.jstatsoft.org/v08/i14/paper | |

| // Requires initial state from calling script | |

| // -D "PRNG_Seed=whatever" | |

| // Bash (et. al.) supplies nine reasonably random digits from $(date +%N) | |

| function XORshift() { | |

| local x = PRNG_State; // fetch current state | |

| x ^= x << 13; | |

| x ^= x >> 17; | |

| x ^= x << 5; | |

| PRNG_State = x; // save state for next invocation | |

| return x; | |

| } | |

| //—– | |

| // Bend text around an arc | |

| function ArcText(TextPath,Center,Radius,BaseAngle,Align) { | |

| PathLength = TextPath[-1].x; | |

| Circumf = 2*pi()*Radius; | |

| TextAngle = to_deg(360 * PathLength / Circumf); | |

| AlignAngle = BaseAngle + (Align == "Left" ? 0 : | |

| Align == "Center" ? -TextAngle / 2 : | |

| Align == "Right" ? -TextAngle : | |

| 0); | |

| ArcPath = {}; | |

| foreach(TextPath; pt) { | |

| if (!isundef(pt.x) && !isundef(pt.y) && isundef(pt.z)) { // XY motion, no Z | |

| r = Radius – pt.y; | |

| a = 360deg * (pt.x / Circumf) + AlignAngle; | |

| ArcPath += {[r*cos(a) + Center.x, r*sin(a) + Center.y,-]}; | |

| } | |

| elif (isundef(pt.x) && isundef(pt.y) && !isundef(pt.z)) { // no XY, Z up/down | |

| ArcPath += {pt}; | |

| } | |

| else { | |

| error("Point is not pure XY or pure Z: " + to_string(pt)); | |

| } | |

| } | |

| return ArcPath; | |

| } | |

| //—– | |

| // Set up gearing | |

| s = (XORshift() & 0xffff) % count(Stators); | |

| StatorTeeth = Stators[s]; | |

| comment("Stator ",s,": ",StatorTeeth); | |

| // When Stator has prime teeth, any Rotor will have GCD = 1 | |

| if (1) { | |

| RotorTeeth = Stators[-1]; | |

| n = 0; | |

| while (RotorTeeth >= floor(0.95 * StatorTeeth) || RotorTeeth < 5) { | |

| RotorTeeth = (XORshift() & 0x007f); // this is why Stator can't have more than 127 teeth | |

| n++; | |

| } | |

| comment("Rotor: ",RotorTeeth," in ",n," iterations"); | |

| } | |

| else { | |

| r = (XORshift() & 0xffff) % count(Rotors); | |

| RotorTeeth = Rotors[r]; | |

| comment("Rotor ",r,": ",RotorTeeth); | |

| } | |

| K = to_float(RotorTeeth) / to_float(StatorTeeth); // find normalized rotor dia | |

| comment("Dia ratio K: ",K," 1/K: ",1.0/K); | |

| GCD = gcd(StatorTeeth,RotorTeeth); // reduce teeth to ratio of least integers | |

| comment("GCD: ",GCD); | |

| Lobes = StatorTeeth / GCD; // compute useful values | |

| comment("Lobes: ", Lobes); | |

| Turns = RotorTeeth / GCD; | |

| comment("Turns: ", Turns); | |

| // Find normalized pen offset to never cross Stator center | |

| if (1) { | |

| n = 0; | |

| do { | |

| L = (to_float((XORshift() & 0x1f) + 1) / 32.0) * (1.0/K – 1.0); // allow L > 1.0 | |

| // comment(" test L: ",L); | |

| n++; | |

| } while (L >= (1.0/K – 1.0) || L < 0.01); | |

| } | |

| else { | |

| n = 0; | |

| do { | |

| L = to_float((XORshift() & 0x1f) + 1) / 32.0; // force L < 1.0 | |

| n++; | |

| } while (L >= (1.0/K – 1.0) || L < 0.01); | |

| } | |

| comment("Offset L: ", L," in ",n," iterations"); | |

| //—– | |

| // Crank out a list of points in normalized coordinates | |

| Path = {}; | |

| for (a = 0.0deg ; a <= Turns*360deg ; a += AngleStep) { | |

| x = (1 – K)*cos(a) + L*K*cos(a*(1 – K)/K); | |

| y = (1 – K)*sin(a) – L*K*sin(a*(1 – K)/K); | |

| Path += {[x,y]}; | |

| } | |

| //—– | |

| // Calculate normalized limits for band traced by pen in rotor at offset L | |

| // L was chosen to produce a band around the rotor center point | |

| RotorMin = 1.0 – 2*K; | |

| comment("Rotor Min: ",RotorMin); | |

| BandCtr = 1.0 – K; // band center radius | |

| BandMin = BandCtr – L*K; // … min radius | |

| BandMax = BandCtr + L*K; // … max radius | |

| BandAmpl = BandMax – BandCtr; | |

| comment("Band Min: ",BandMin," Ctr: ",BandCtr," Max: ",BandMax); | |

| //—– | |

| // Scale normalized band to fill physical limits centered at mid-disk radius | |

| FillPath = {}; | |

| foreach (Path; pt) { | |

| a = atan_xy(pt); // recover angle to point | |

| r = length(pt); // … radius to point | |

| br = (r – BandCtr) / BandAmpl; // remove center bias, rescale to 1.0 amplitude | |

| dr = br * (OuterRad – MidRad); // rescale to fill disk | |

| pr = dr + MidRad; // set at disk centerline | |

| x = pr * cos(a); // find new XY coords | |

| y = pr * sin(a); | |

| FillPath += {[x,y]}; | |

| } | |

| comment("Path has ",count(FillPath)," points"); | |

| //—– | |

| // Prune too-snuggly physical coordinates | |

| PointList = {FillPath[0]}; // must include first point | |

| lp = FillPath[0]; | |

| n = 0; | |

| foreach (FillPath; pt) { | |

| if (length(pt – lp) <= Snuggly) { // discard too-snuggly point | |

| n++; | |

| } | |

| else { | |

| PointList += {pt}; // otherwise, add it to output | |

| lp = pt; | |

| } | |

| } | |

| PointList += {FillPath[-1]}; // ensure closure at last point | |

| comment("Pruned ",n," points, ",count(PointList)," remaining"); | |

| //—– | |

| // Convert coordinate list to G-Code | |

| comment("Pattern begins"); | |

| feedrate(PlotSpeed); | |

| goto([-,-,SafeZ]); | |

| goto([0,0,-]); | |

| goto([-,-,TravelZ]); | |

| tracepath(PointList, PlotZ); | |

| //—– | |

| // Draw the legend | |

| comment("Legend begins"); | |

| if (Legend) { | |

| tp = scale(typeset(Legend,TextFont),TextSize); | |

| tpa = ArcText(tp,[0mm,0mm],LegenRad,0deg,"Center"); | |

| feedrate(TextSpeed); | |

| engrave(tpa,TravelZ,PlotZ); | |

| } | |

| tp = scale(typeset(to_string(PRNG_Seed),TextFont),TextSize); | |

| tpa = ArcText(tp,[0mm,0mm],LegenRad,180deg,"Center"); | |

| feedrate(TextSpeed); | |

| engrave(tpa,TravelZ,PlotZ); | |

| goto([-,-,SafeZ]); // done, so get out of the way | |

| goto([0,0,-]); | |

| comment("Disk ends"); |

| #!/bin/bash | |

| # Guilloche and Legend Generator | |

| # Ed Nisley KE4ZNU – 2019-06 | |

| Disk='DiskType="CD"' | |

| PlotZ='PlotZ=-3.00mm' | |

| Legend='Legend="Ed Nisley — KE4ZNU — softsolder.com"' | |

| Flags='-P 3 –pedantic' | |

| # Set these to match your file layout | |

| LibPath='/opt/gcmc/library' | |

| Prolog='/mnt/bulkdata/Project Files/CNC 3018-Pro Router/Patterns/gcmc/prolog.gcmc' | |

| Epilog='/mnt/bulkdata/Project Files/CNC 3018-Pro Router/Patterns/gcmc/epilog.gcmc' | |

| Script='/mnt/bulkdata/Project Files/CNC 3018-Pro Router/Patterns/Platter Engraving.gcmc' | |

| ts=$(date +%Y%m%d-%H%M%S) | |

| if [ -n "$1" ] # if random seed parameter exists | |

| then | |

| rnd=$1 # .. use it | |

| else | |

| rnd=$(date +%N) # .. otherwise use nanoseconds | |

| fi | |

| fn="Disk_${ts}_${rnd}.ngc" | |

| echo Output: $fn | |

| Seed="PRNG_Seed=$rnd" | |

| rm -f $fn | |

| echo "(File: "$fn")" > $fn | |

| gcmc -D "$Disk" -D "$Seed" -D "$Legend" -D "$PlotZ" $Flags \ | |

| –include "$LibPath" –prologue "$Prolog" –epilogue "$Epilog" \ | |

| "$Script" >> "$fn" | |