With the geometry set up, cutting earrings with surface coatings is just a matter of tweaking a few settings:

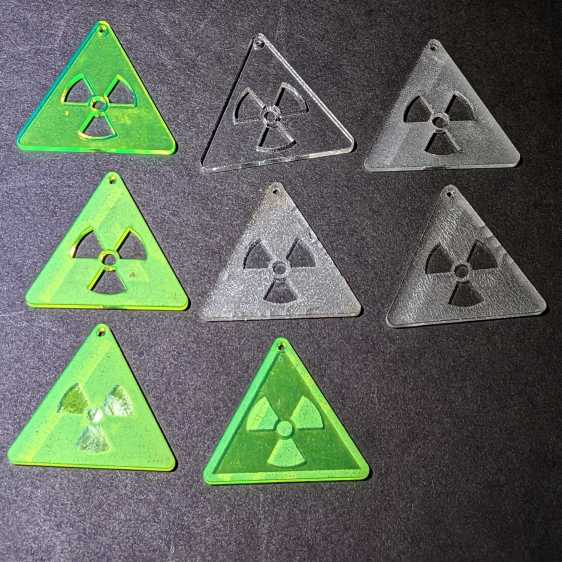

From left to right:

- Green PSA vinyl on black acrylic

- Black PSA vinyl on edge-lit acrylic

- GITD tape stuck on black acrylic

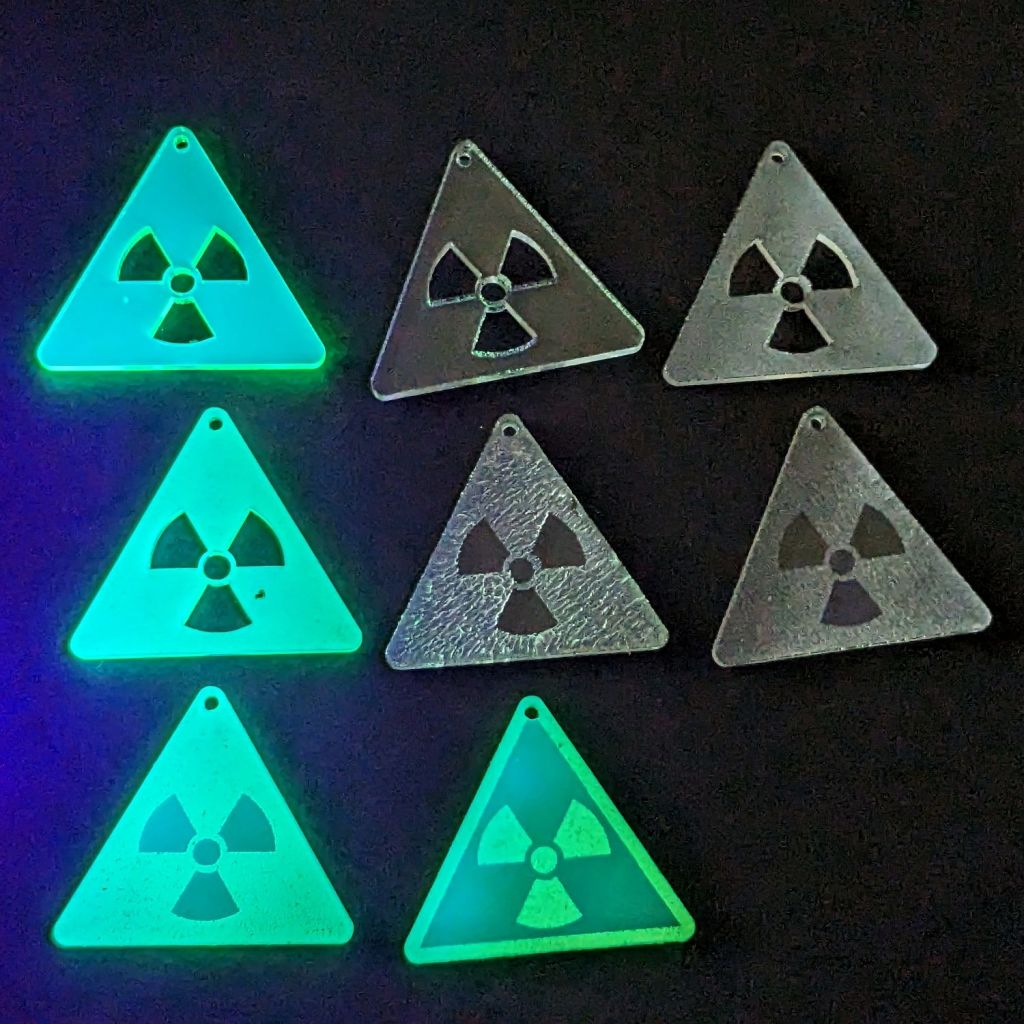

UV lights up the edge-lit samples:

And UV powers up GITD tape something fierce:

Cutting the central pattern out of the GITD earring might make it look even better, but I like the subtle presentation.

If it’s flash you want, then retroreflective tape is your fashion friend:

The bolder kiss-cut lines in the middle earring might suffice, but the cutouts on the right definitely look more distinctive. Perhaps the kiss-cut perimeter line would set the pattern off a little better.

Assuming PSA vinyl sticks to itself and GITD tape well enough to survive normal handling, that would make multicolor earrings an option:

On the left: blue PSA vinyl on GITD tape. On the right: green PSA vinyl on red PSA vinyl on black acrylic. Peeling the PSA vinyl is tedious and I’m still not good enough to avoid small nicks in the underlying layer.

GITD FTW:

Now, to work on more patterns …