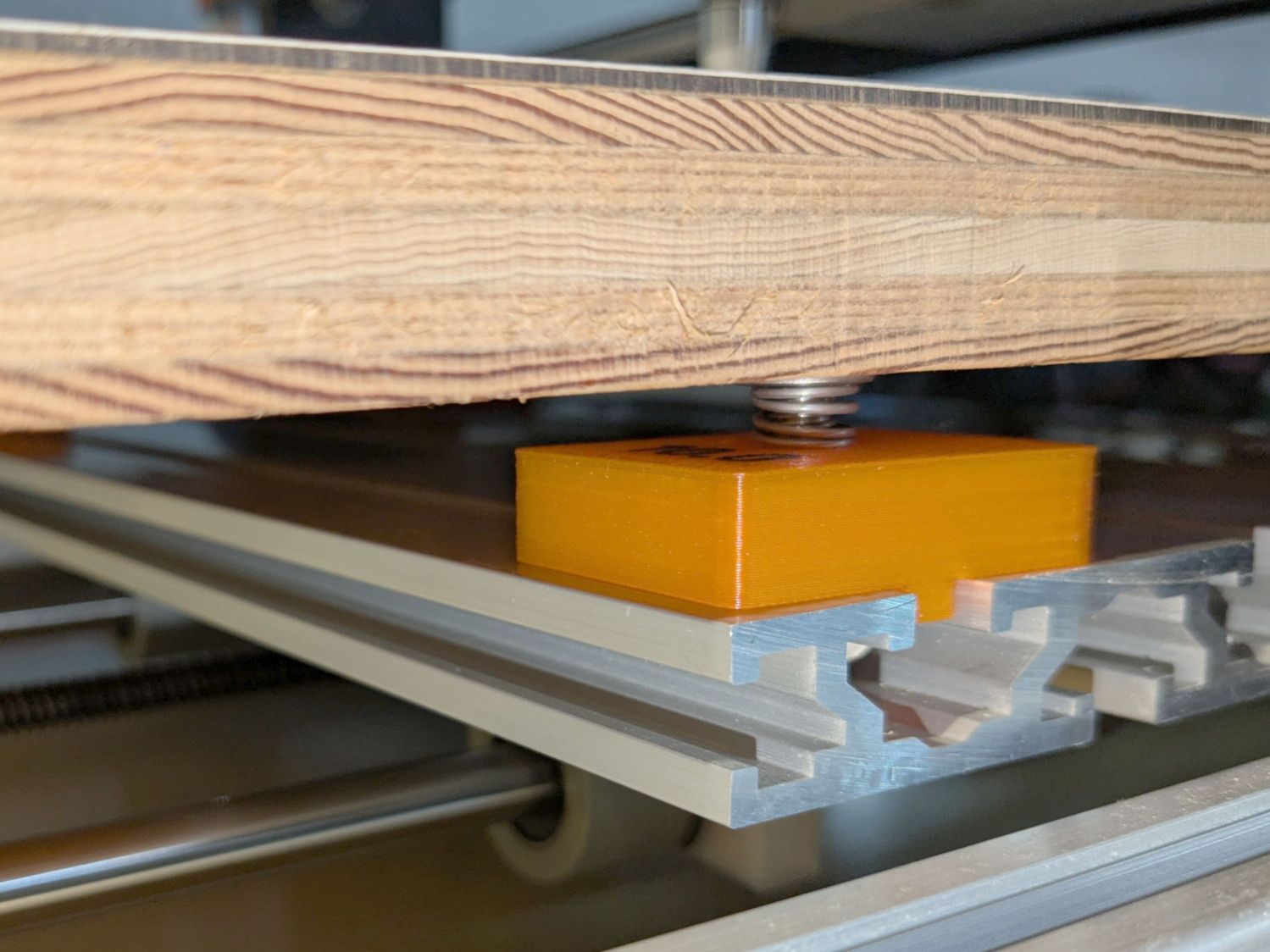

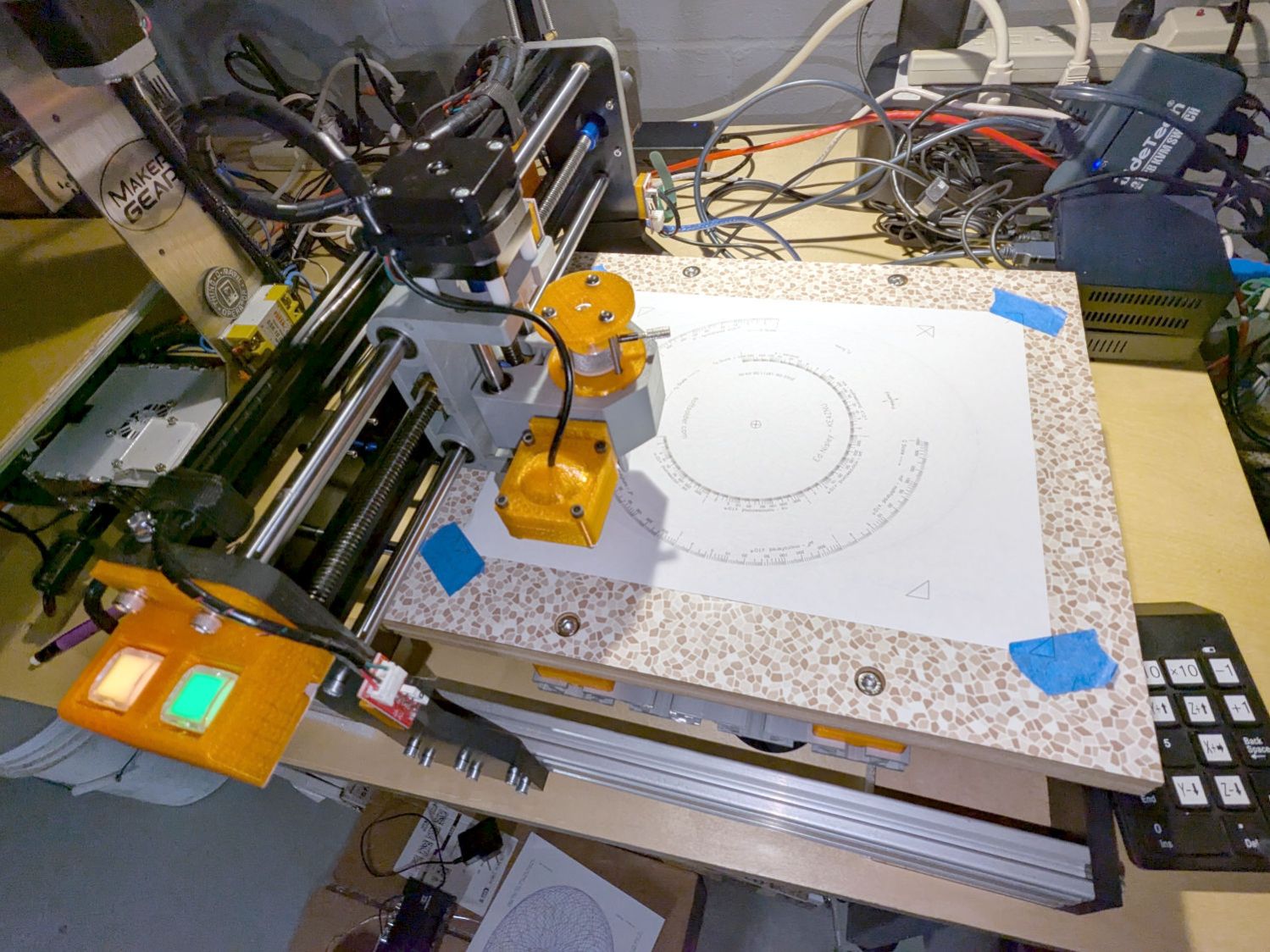

The CNC-3018XL fit into its new home with the Run/Hold buttons toward the front:

Which is rotated 180° from its previous orientation, putting Quadrant I and the most-positive coordinates in the left-front corner. Rather than stand on my head while trying to use the jog keypad upside-down, I reversed the axis directions by changing the GRBL Direction port invert mask value from its previous 4:

$3=7

Because the home switch positions haven’t changed, reverse the Homing dir invert mask from 0:

$23=3

The XY origin remains in the center of the platform, so the G54 XY offset didn’t change. The Z offset puts the Pilot pen tip 10 mm above the platform, which will change as you (well, I) touch it off on the paper:

G10 L2 P1 X-169.0 Y-149.5 Z-44.0

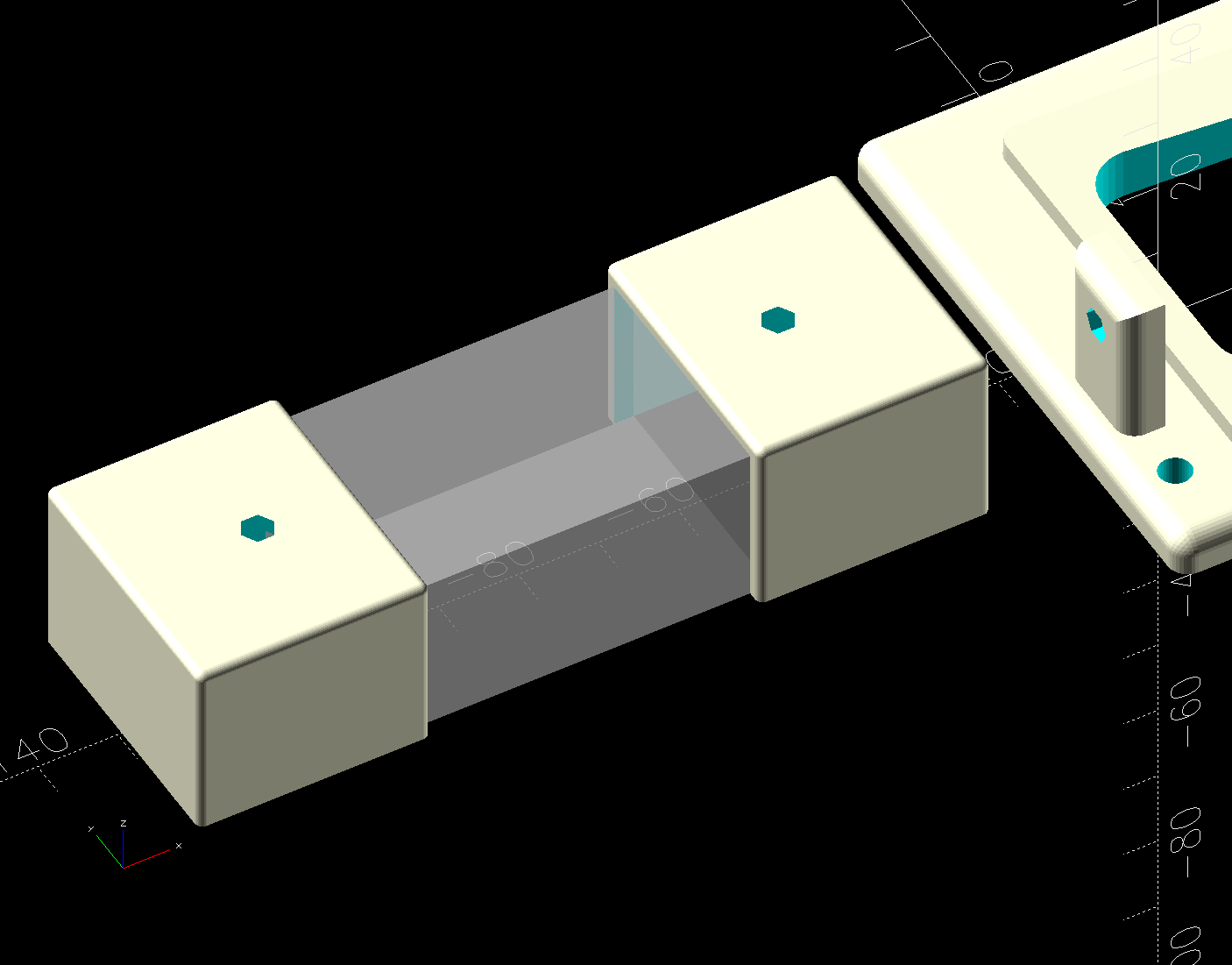

Jog to the left rear corner (with Z at the home position) and set the G28 park position:

G28.1

Jog to the right front corner (also Z homed) where (manual) tool changes take place:

G30.1

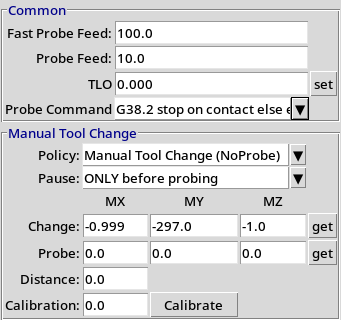

Configure bCNC for manual tool changes without probing at the G30 position:

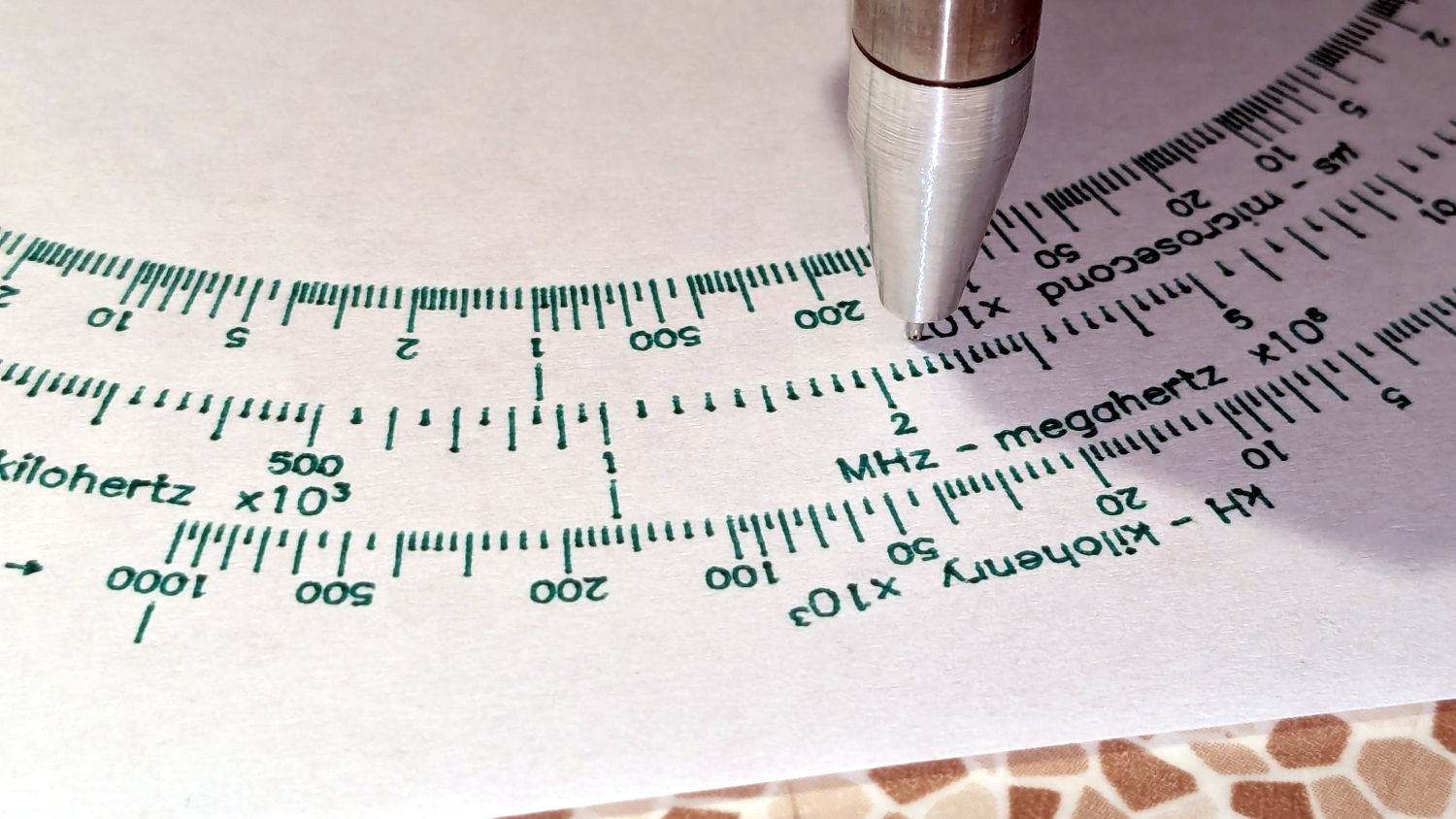

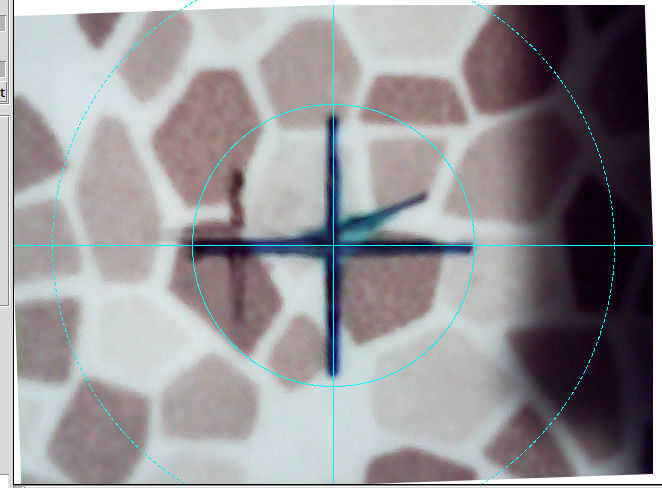

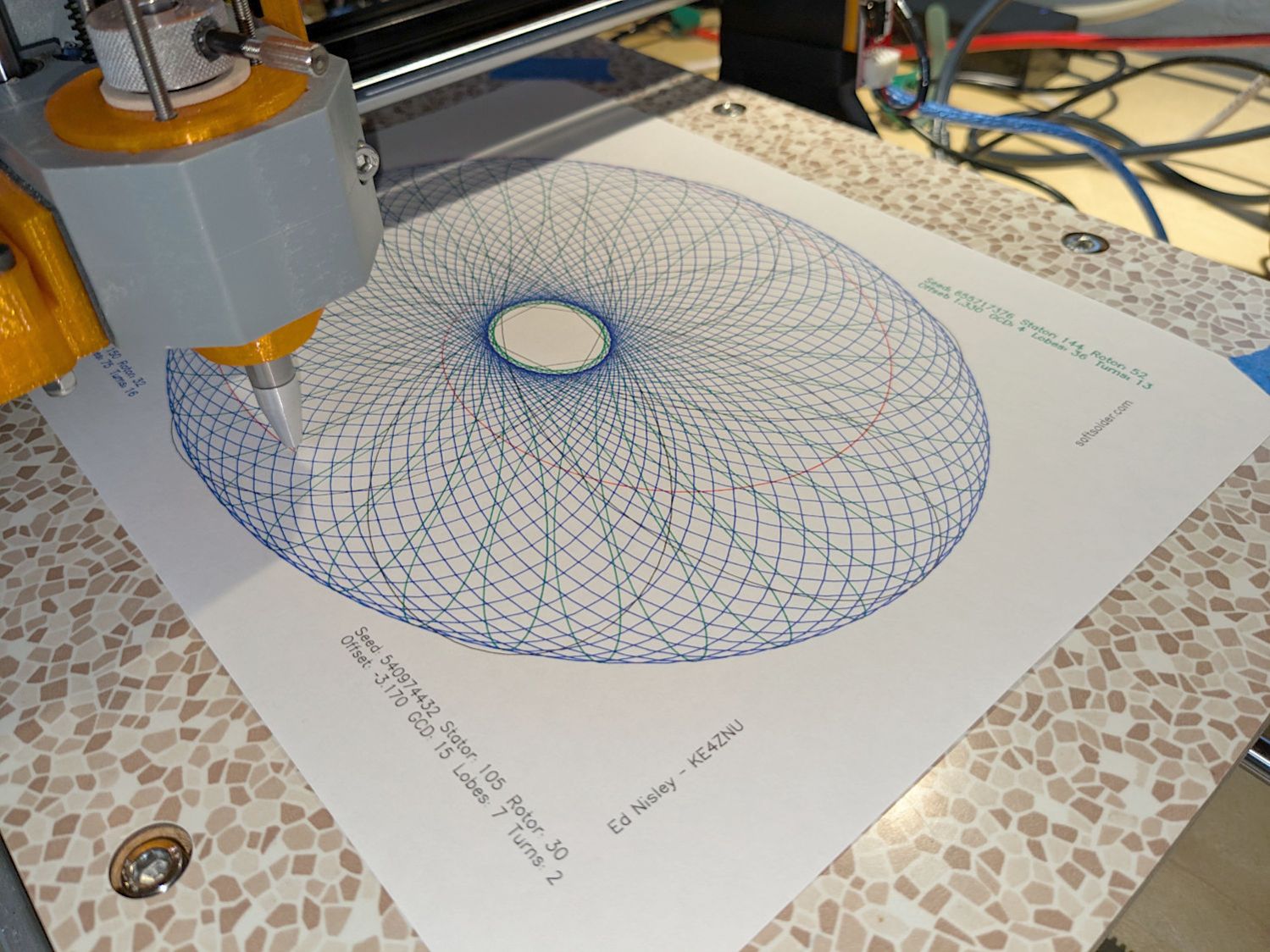

The machine will move to the tool change position at each Tn M6, the operator (that would be me) inserts tool pen n as needed, pokes the Run button, and watches it draw pretty pictures in a resolutely techie manner:

For completeness, the current GRBL settings:

$$

$0=10

$1=100

$2=0

$3=7

$4=0

$5=0

$6=0

$10=1

$11=0.010

$12=0.020

$13=0

$20=1

$21=0

$22=1

$23=3

$24=100.000

$25=2000.000

$26=25

$27=1.250

$30=1000

$31=0

$32=0

$100=401.284

$101=400.000

$102=400.000

$110=3000.000

$111=3000.000

$112=3000.000

$120=1000.000

$121=1000.000

$122=1000.000

$130=338.000

$131=299.000

$132=44.000

$#

[G54:-169.000,-149.500,-34.450]

[G55:0.000,0.000,0.000]

[G56:0.000,0.000,0.000]

[G57:0.000,0.000,0.000]

[G58:0.000,0.000,0.000]

[G59:0.000,0.000,0.000]

[G28:-335.000,-3.310,-3.450]

[G30:-1.000,-297.000,-1.000]

[G92:0.000,0.000,0.000]

[TLO:0.000]

[PRB:0.000,0.000,0.000:0]

The weird $100 X axis step/mm value is correct, because QC escapes are a thing.