|

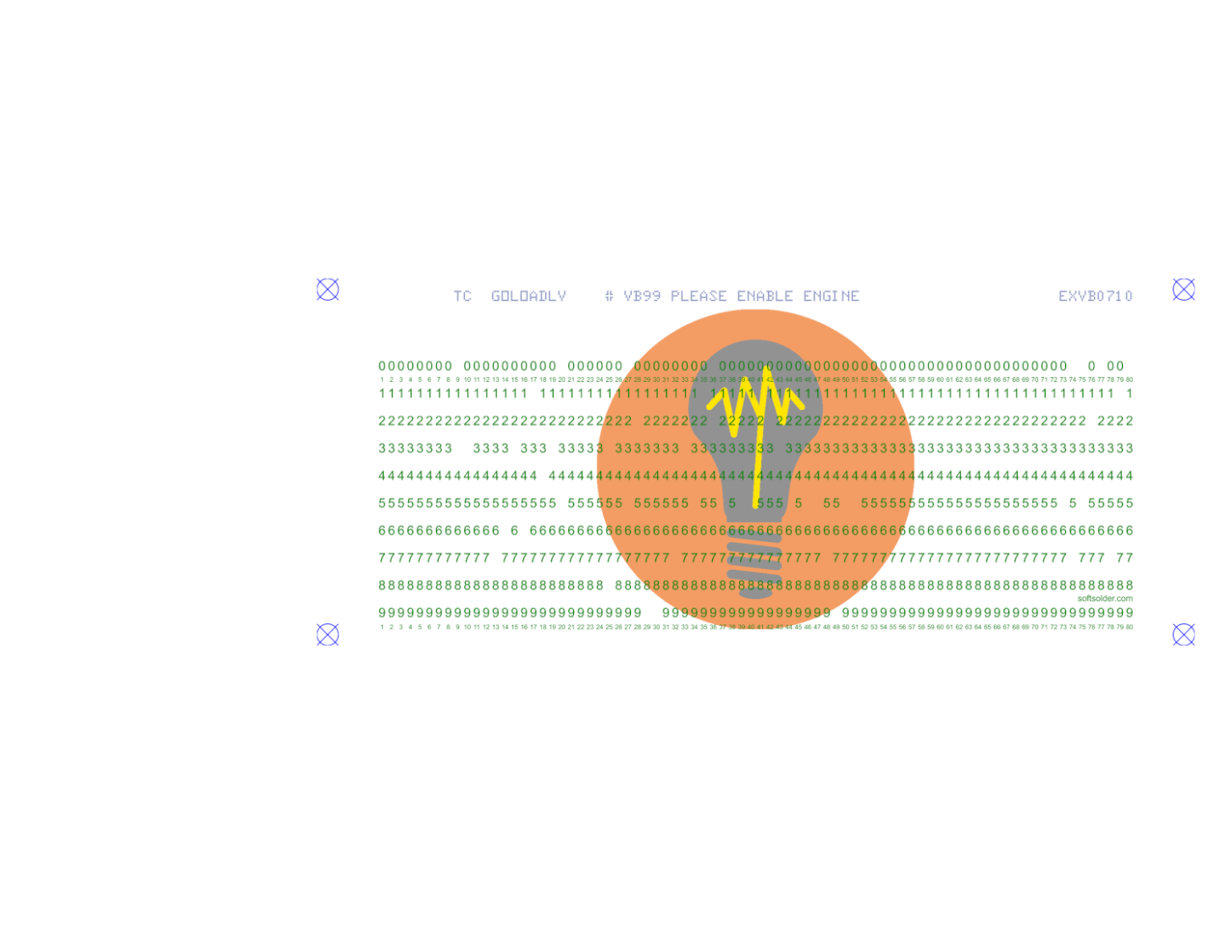

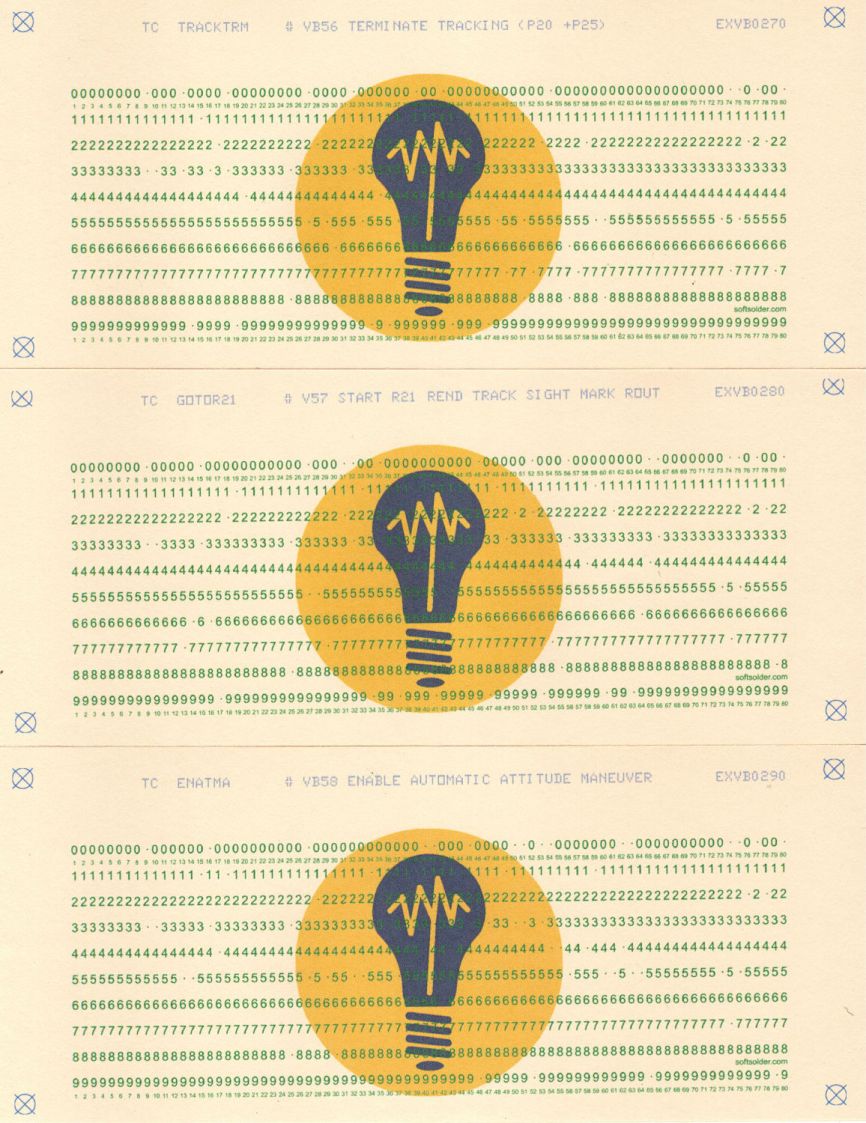

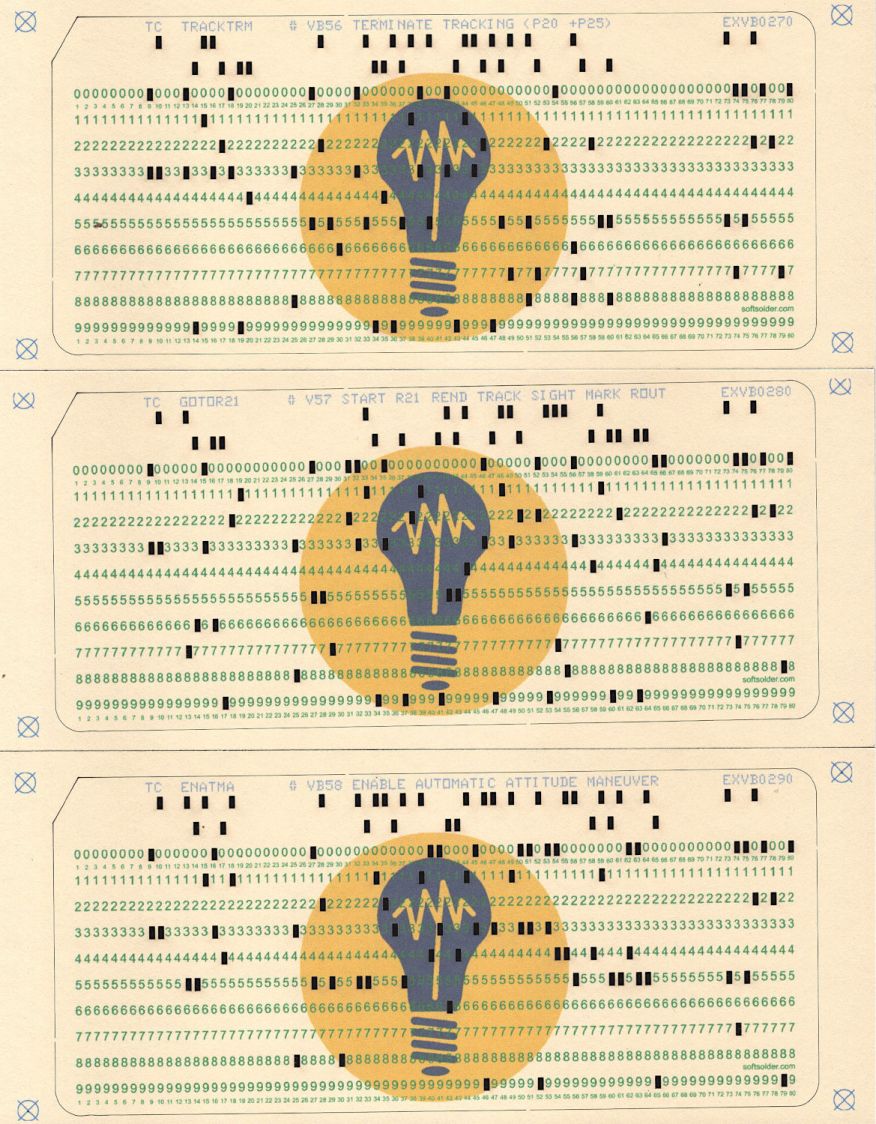

# Generator for punched cards |

|

# Ed Nisley – KE4ZNU |

|

# 2026-01-20 cargo-culted from various sources |

|

|

|

import svg |

|

import math |

|

from argparse import ArgumentParser |

|

from pathlib import Path |

|

import curses.ascii |

|

import itertools |

|

|

|

INCH = 25.4 |

|

X = 0 |

|

Y = 1 |

|

|

|

SVGSCALE = 96.0/25.4 # converts "millimeters as SVG points" to real millimeters |

|

|

|

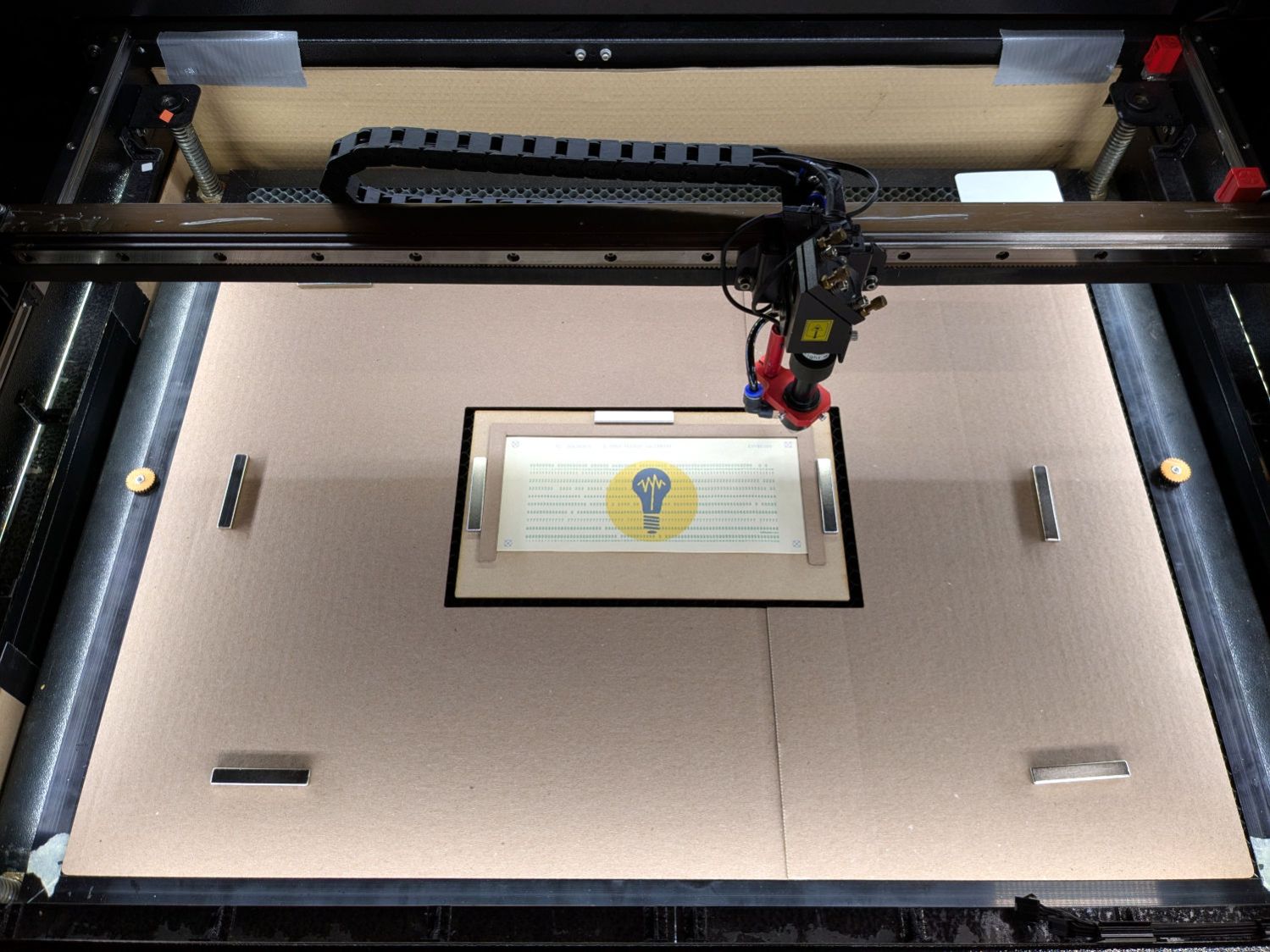

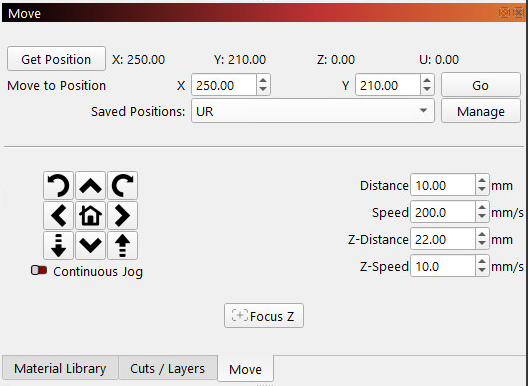

parser = ArgumentParser(description="Create SVG files to print & laser-cut a punched card") |

|

|

|

parser.add_argument('–debug',action='store_true', |

|

help="Enable various test outputs, do not use XML file") |

|

parser.add_argument('–lower',action='store_true', |

|

help="Fake lowercase with italics") |

|

parser.add_argument('–test', type=int, choices=range(7), default=0, |

|

help="Various test patterns to verify card generation") |

|

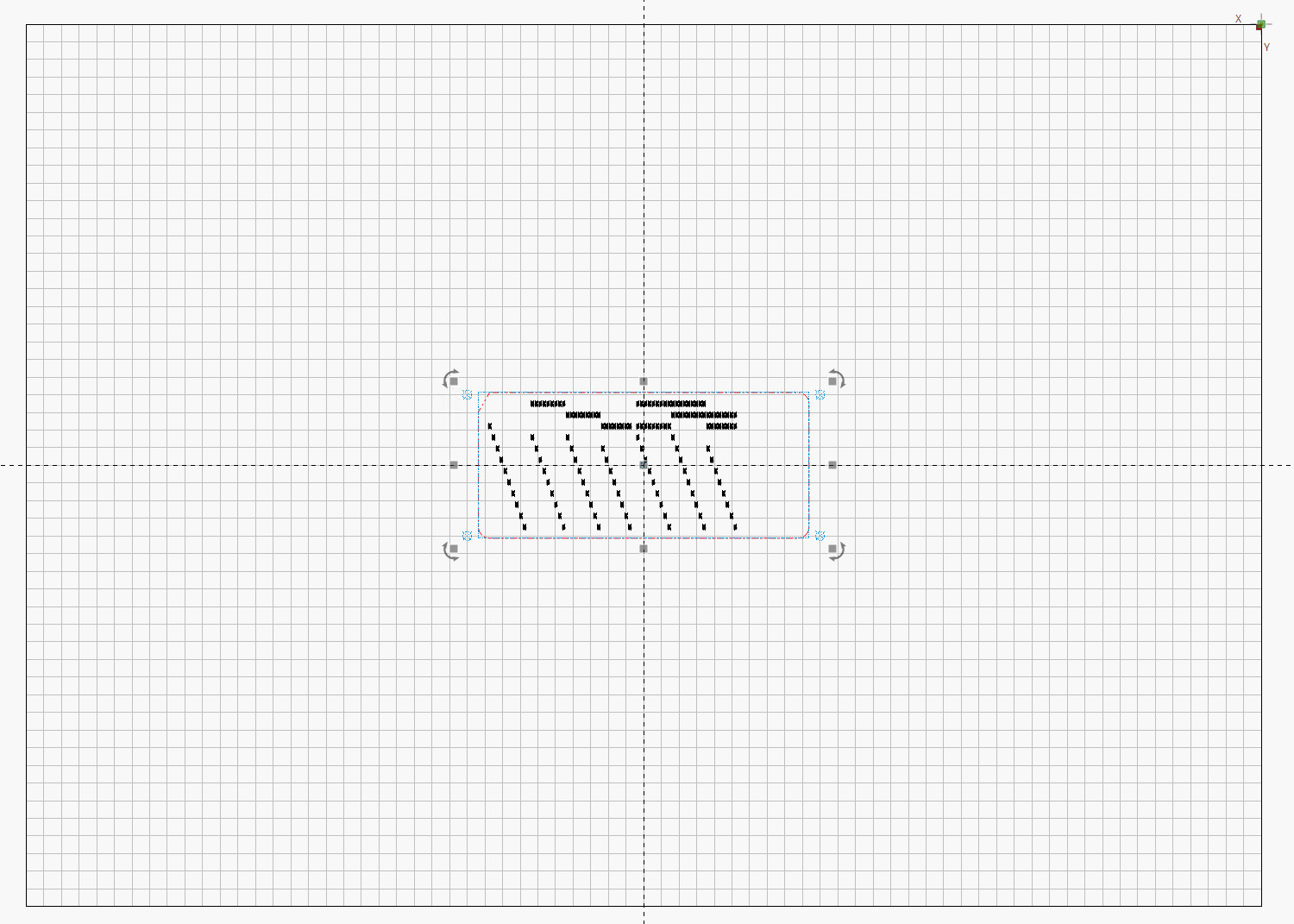

parser.add_argument('–lbsvg', action='store_true', |

|

help="Work around LightBurn SVG issues") |

|

parser.add_argument('–layout', default="print", choices=["laser","print"], |

|

help="Laser-engrave hole & char text into card") |

|

parser.add_argument('–seq',type=int, default=0, |

|

help="If nonzero, use as squence number in col 72-80") |

|

parser.add_argument('–logofile', default="Card logo.png", |

|

help="Card logo filename") |

|

parser.add_argument('–prefix', default="", |

|

help="Card number prefix, no more than 5 characters") |

|

parser.add_argument('contents',nargs="*",default='Your text goes here', |

|

help="Line of text to be punched on card") |

|

args = parser.parse_args() |

|

|

|

PageSize = (round(8.5*INCH,3), round(11.0*INCH,3)) # sheet of paper |

|

|

|

CardSize = (7.375*INCH,3.25*INCH) # punch card bounding box |

|

|

|

NumCols = 80 |

|

NumRows = 12 |

|

|

|

HoleSize = (0.055*INCH,0.125*INCH) # punched hole |

|

HoleOC = (0.087*INCH,0.250*INCH) |

|

|

|

BaseHoleAt = (0.251*INCH,0.250*INCH) # center point |

|

|

|

TargetOC = (200,80) # alignment targets around card |

|

TargetOD = 5 |

|

|

|

#— map ASCII / Unicode characters to rows |

|

# rows are names, not indexes: Row 12 is along the top of the card |

|

# Row 10 is the same as Row 0 |

|

|

|

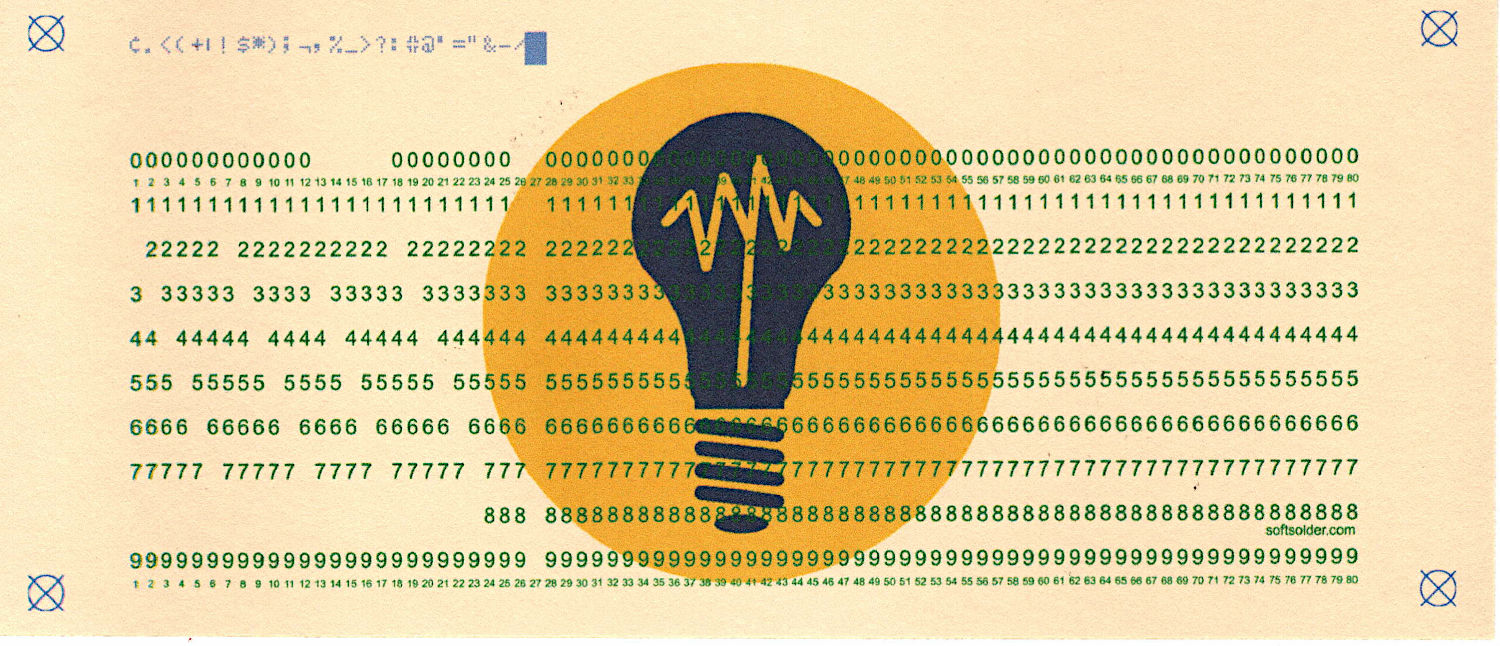

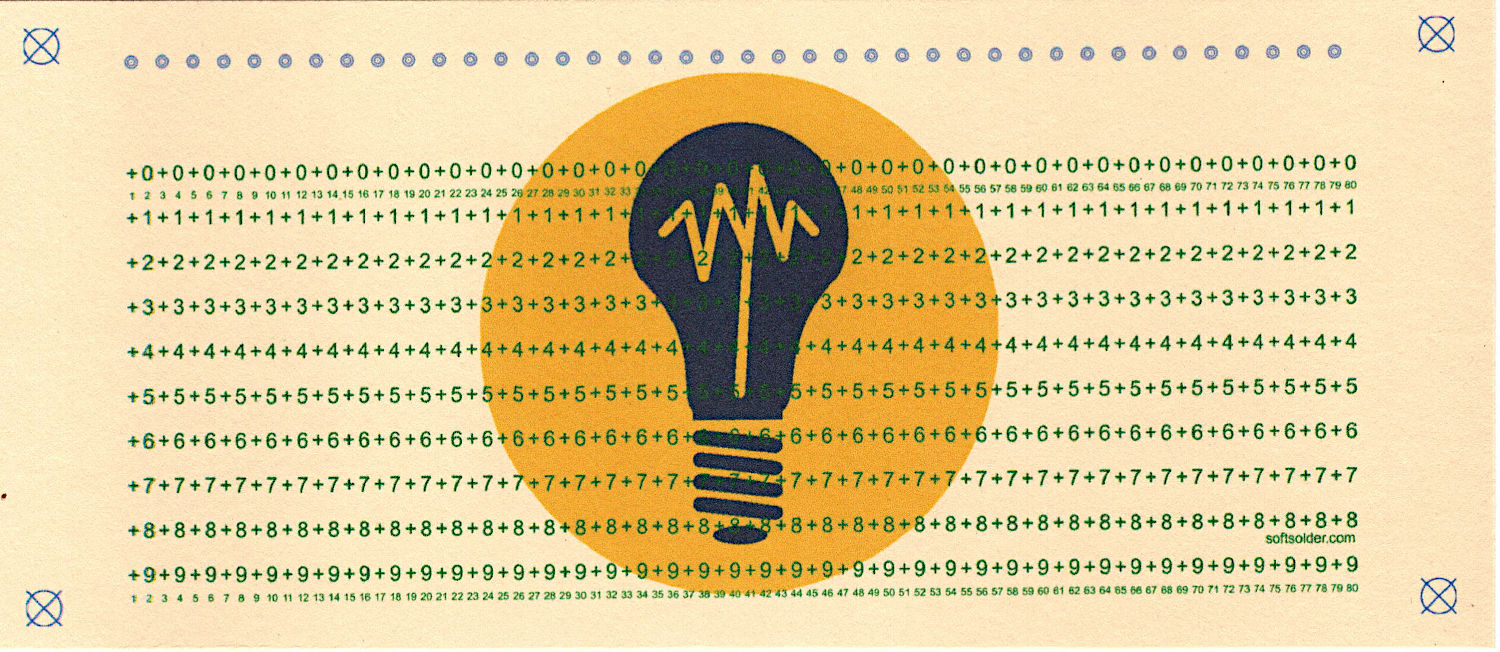

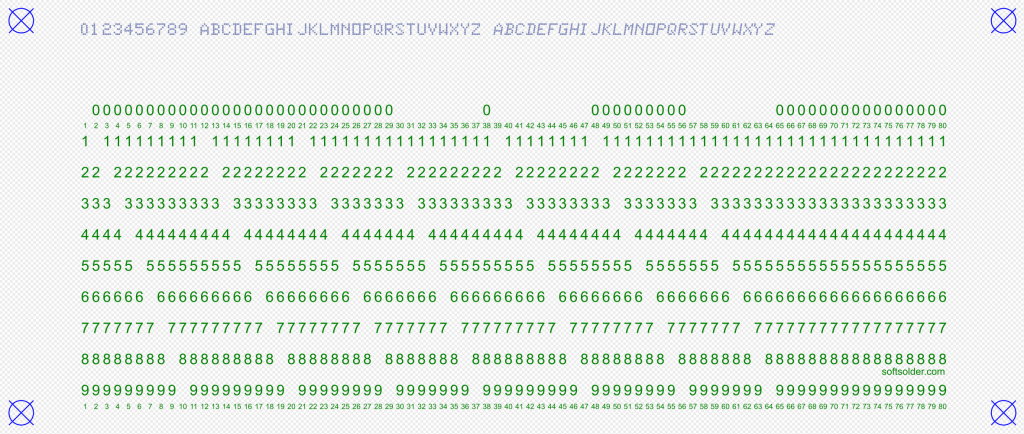

CharMap = { |

|

" ": (), |

|

"0": (0,), |

|

"1": (1,), |

|

"2": (2,), |

|

"3": (3,), |

|

"4": (4,), |

|

"5": (5,), |

|

"6": (6,), |

|

"7": (7,), |

|

"8": (8,), |

|

"9": (9,), |

|

"A": (12,1), |

|

"B": (12,2), |

|

"C": (12,3), |

|

"D": (12,4), |

|

"E": (12,5), |

|

"F": (12,6), |

|

"G": (12,7), |

|

"H": (12,8), |

|

"I": (12,9), |

|

"J": (11,1), |

|

"K": (11,2), |

|

"L": (11,3), |

|

"M": (11,4), |

|

"N": (11,5), |

|

"O": (11,6), |

|

"P": (11,7), |

|

"Q": (11,8), |

|

"R": (11,9), |

|

"S": (10,2), |

|

"T": (10,3), |

|

"U": (10,4), |

|

"V": (10,5), |

|

"W": (10,6), |

|

"X": (10,7), |

|

"Y": (10,8), |

|

"Z": (10,9), |

|

"a": (12,10,1), |

|

"b": (12,10,2), |

|

"c": (12,10,3), |

|

"d": (12,10,4), |

|

"e": (12,10,5), |

|

"f": (12,10,6), |

|

"g": (12,10,7), |

|

"h": (12,10,8), |

|

"i": (12,10,9), |

|

"j": (12,11,1), |

|

"k": (12,11,2), |

|

"l": (12,11,3), |

|

"m": (12,11,4), |

|

"n": (12,11,5), |

|

"o": (12,11,6), |

|

"p": (12,11,7), |

|

"q": (12,11,8), |

|

"r": (12,11,9), |

|

"s": (10,11,2), |

|

"t": (10,11,3), |

|

"u": (10,11,4), |

|

"v": (10,11,5), |

|

"w": (10,11,6), |

|

"x": (10,11,7), |

|

"y": (10,11,8), |

|

"z": (10,11,9), |

|

"¢": (12,2,8), |

|

".": (12,3,8), |

|

"<": (12,4,8), |

|

"(": (12,5,8), |

|

"+": (12,6,8), |

|

"|": (12,7,8), |

|

"!": (11,2,8), |

|

"$": (11,3,8), |

|

"*": (11,4,8), |

|

")": (11,5,8), |

|

";": (11,6,8), |

|

"¬": (11,7,8), |

|

",": (10,3,8), |

|

"%": (10,4,8), |

|

"_": (10,5,8), |

|

">": (10,6,8), |

|

"?": (10,7,8), |

|

":": (2,8), |

|

"#": (3,8), |

|

"@": (4,8), |

|

"'": (5,8), |

|

"=": (6,8), |

|

'"': (7,8), |

|

"&": (12,), |

|

"-": (11,), |

|

"/": (10,1), |

|

"█": (12,11,10,1,2,3,4,5,6,7,8,9), # used for lace card test pattern |

|

"▯": (12,10,2,4,6,8), # used for alignment tests with hack for row numbers |

|

} |

|

|

|

#— map row name to physical row offset from top |

|

|

|

RowMap = (2,3,4,5,6,7,8,9,10,11,2,1,0) |

|

|

|

RowGlyphs = "0123456789⁰¹²▯" # last four should never appear, hollow box is a hack |

|

|

|

#— pretty punch patterns |

|

|

|

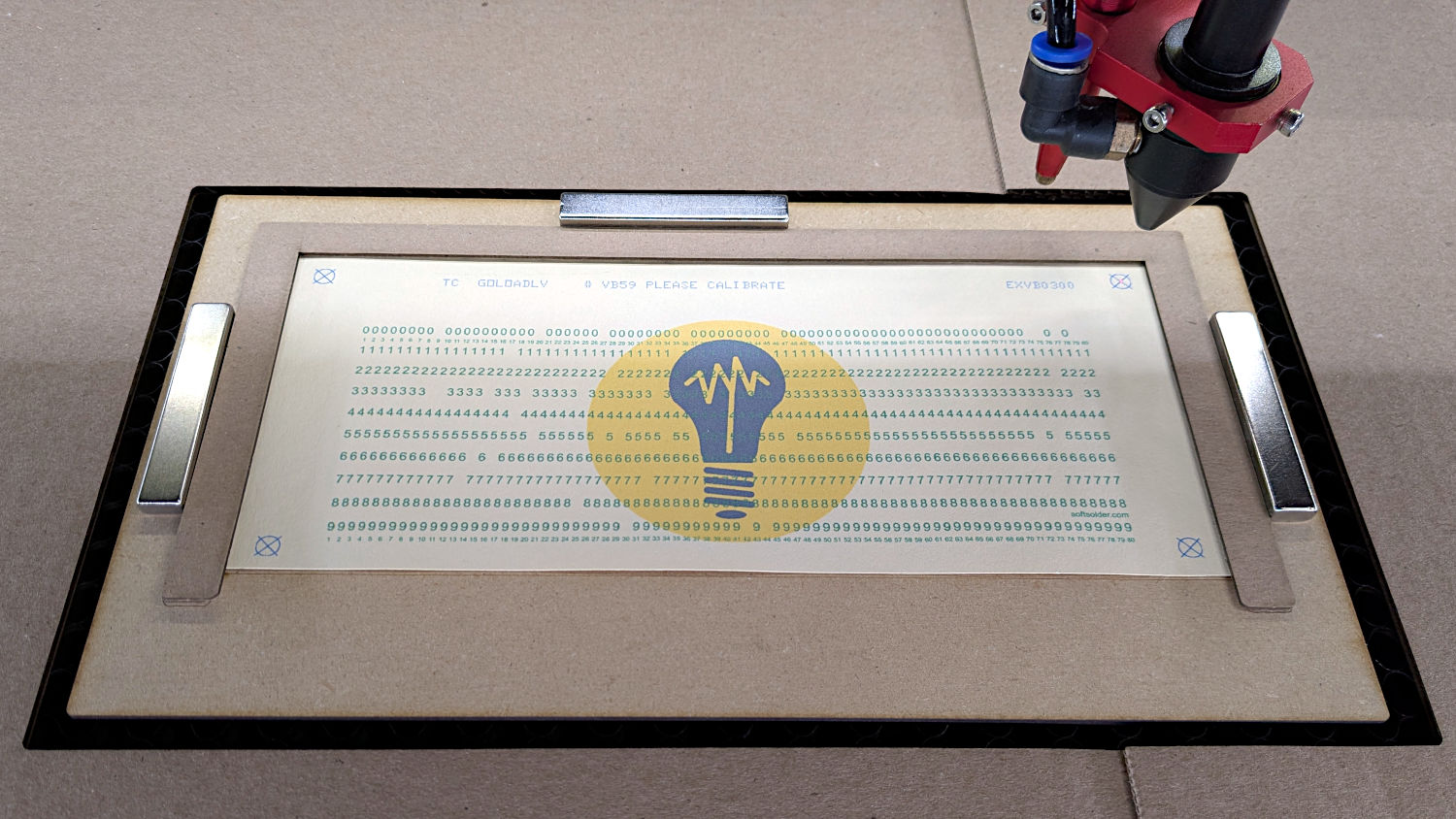

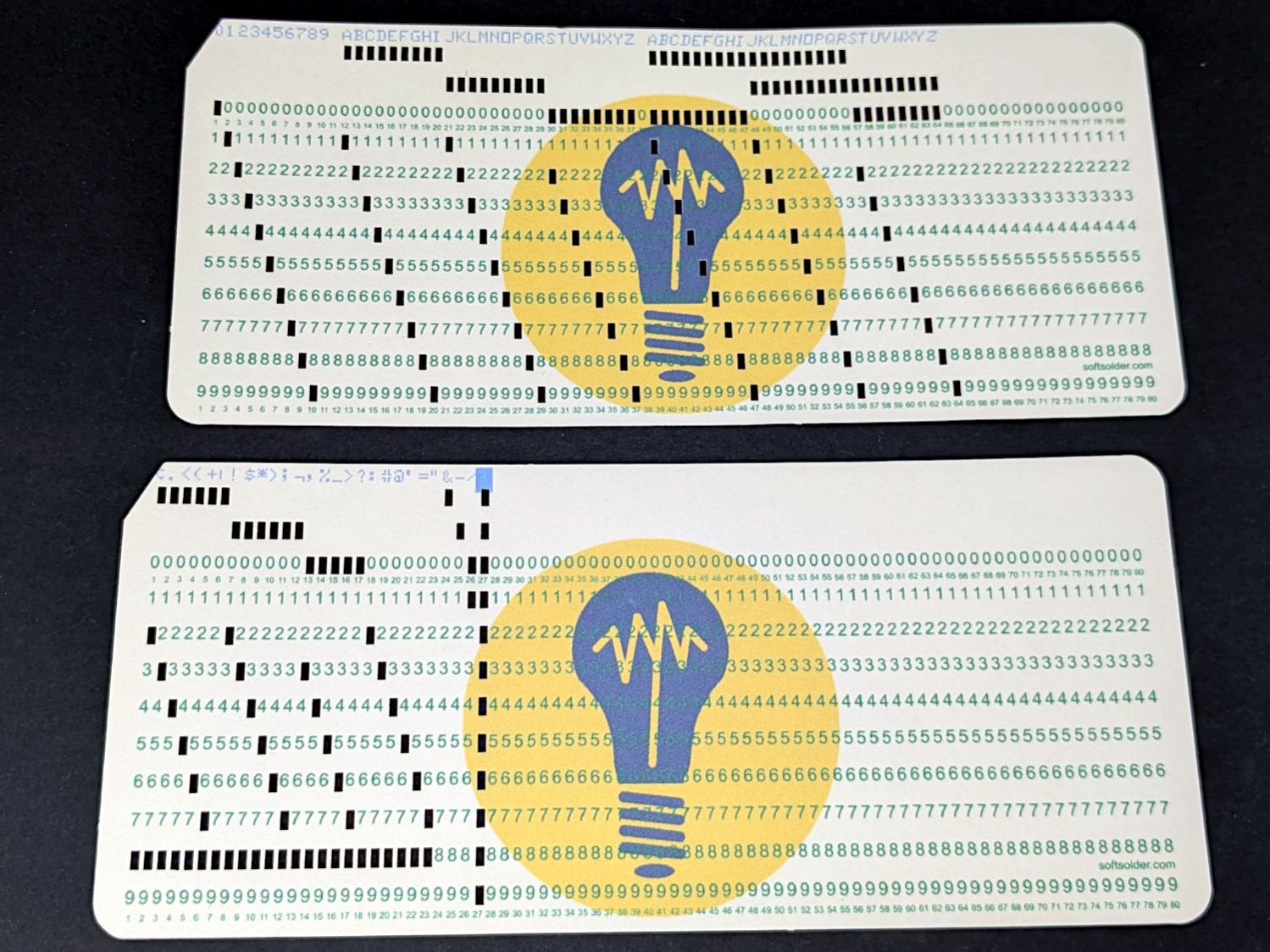

TestStrings = ( " " * NumCols, # blank card for printing |

|

"█" * NumCols, # lace card for amusement |

|

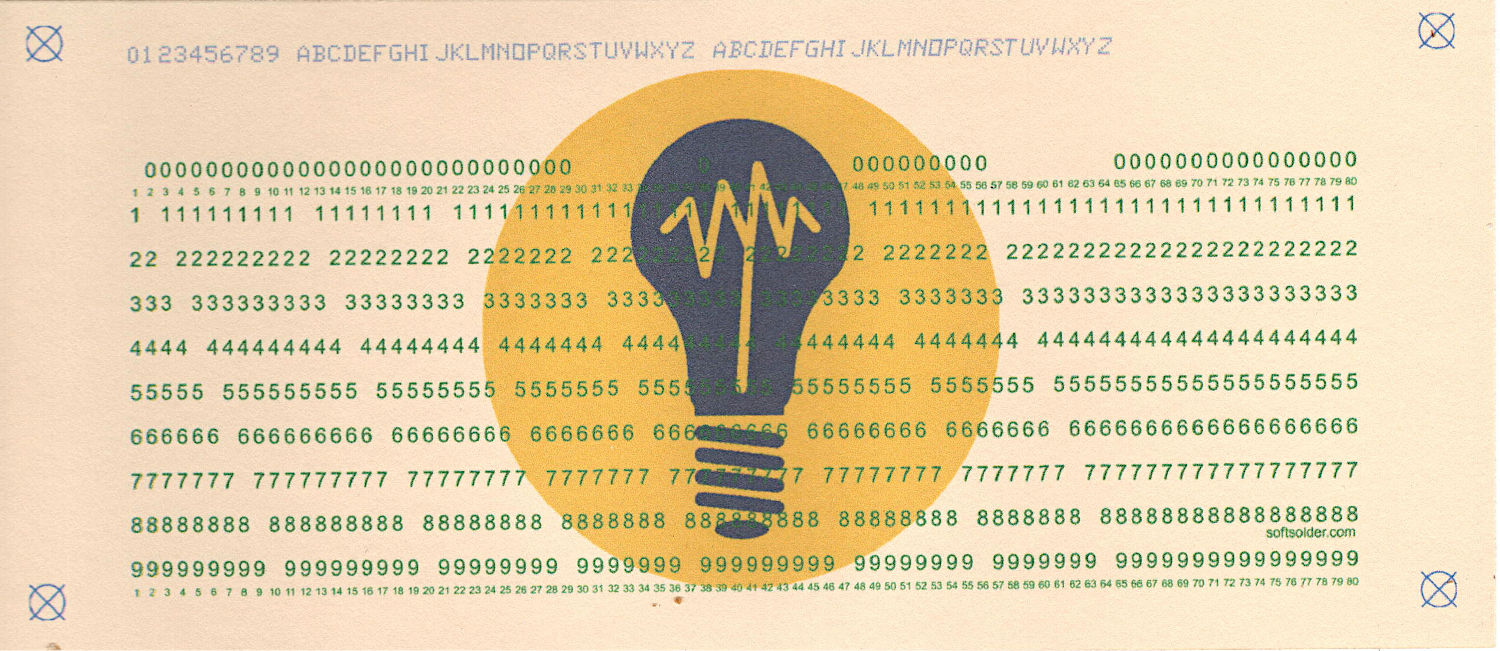

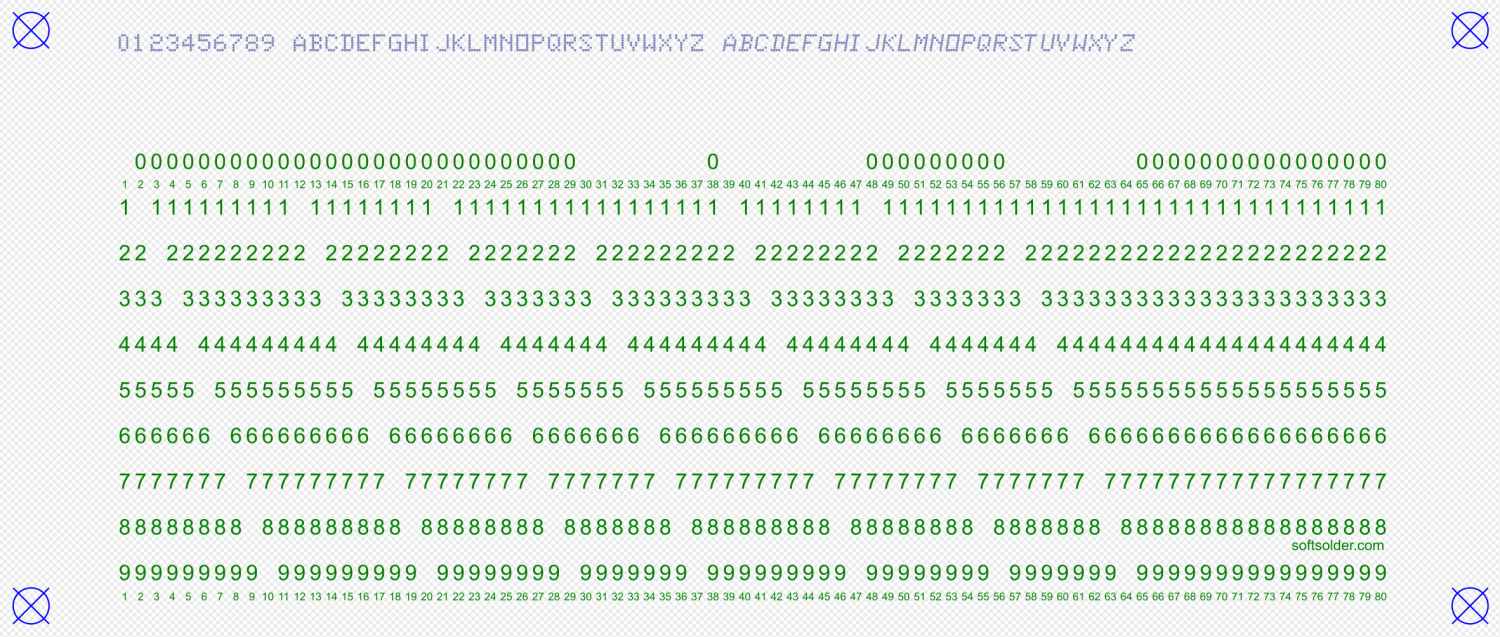

"0123456789 ABCDEFGHIJKLMNOPQRSTUVWXYZ abcdefghijklmnopqrstuvwxyz", |

|

"¢.<(+|!$*);¬,%_>?:#@'=" + '"' + "&-/█", |

|

"▯" * NumCols, # hack for row number alignment |

|

) |

|

|

|

#— LightBurn layer colors |

|

|

|

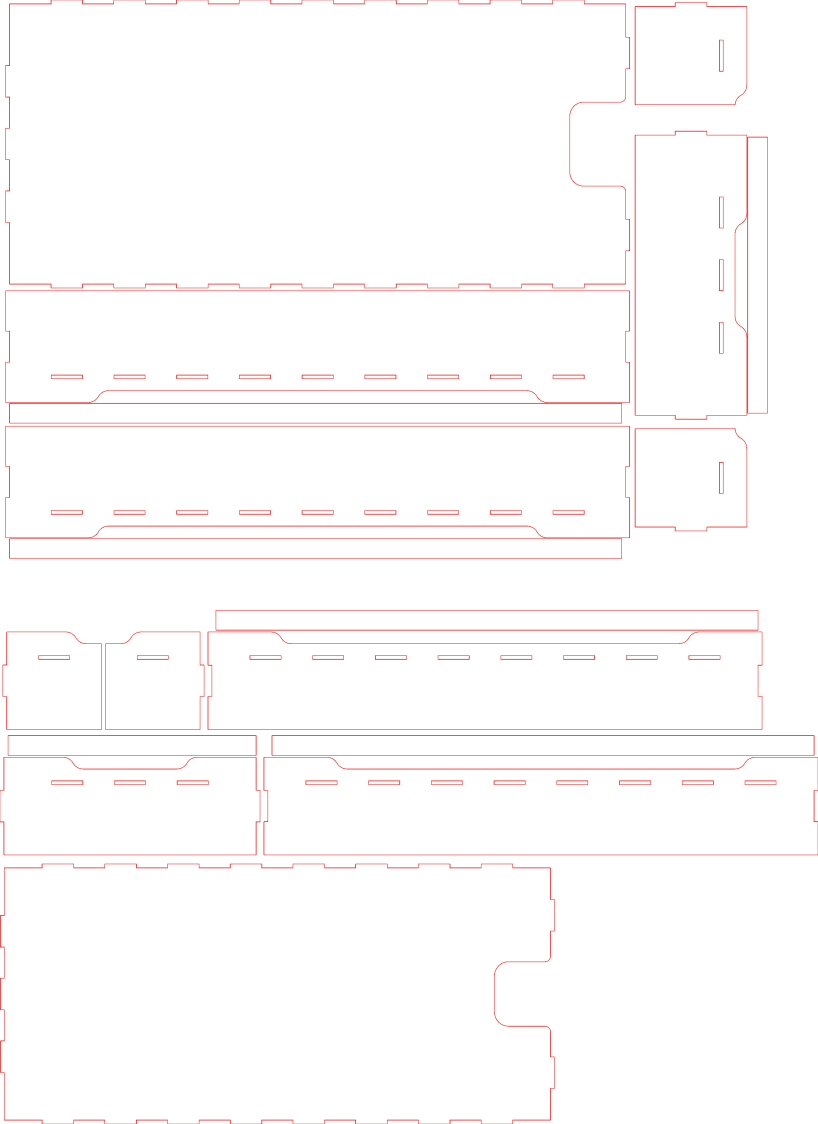

HoleCut = "black" # C00 Black |

|

CardMark = "blue" # C01 Blue |

|

CardCut = "red" # C02 Red |

|

CardText = "green" # C03 Green |

|

CardGray = "rgb(125,135,185)" # C17 Dark Gray |

|

Tooling = "rgb(12,150,217)" # T2 Tool |

|

|

|

#— LightBurn uses only the stroke |

|

|

|

DefStroke = 0.20 |

|

DefFill = "none" |

|

|

|

#——————— |

|

# Set up card contents |

|

|

|

if args.test: # test patterns used without changes |

|

Contents = TestStrings[args.test – 1].ljust(NumCols,' ') |

|

|

|

else: # real cards need cleaning |

|

Contents = ''.join(itertools.chain(*args.contents)) |

|

|

|

if args.seq: |

|

nl = 8 – len(args.prefix) |

|

Contents = Contents.ljust(NumCols – 8,' ')[:(NumCols – 8)] |

|

Contents = Contents + f"{args.prefix}{args.seq:0{nl}d}" |

|

else: |

|

Contents = Contents.ljust(NumCols,' ')[:NumCols] |

|

|

|

if not args.lower: |

|

Contents = Contents.upper() |

|

|

|

|

|

|

|

#— accumulate tooling layout |

|

|

|

ToolEls = [] |

|

|

|

# mark center of card for drag-n-drop location |

|

|

|

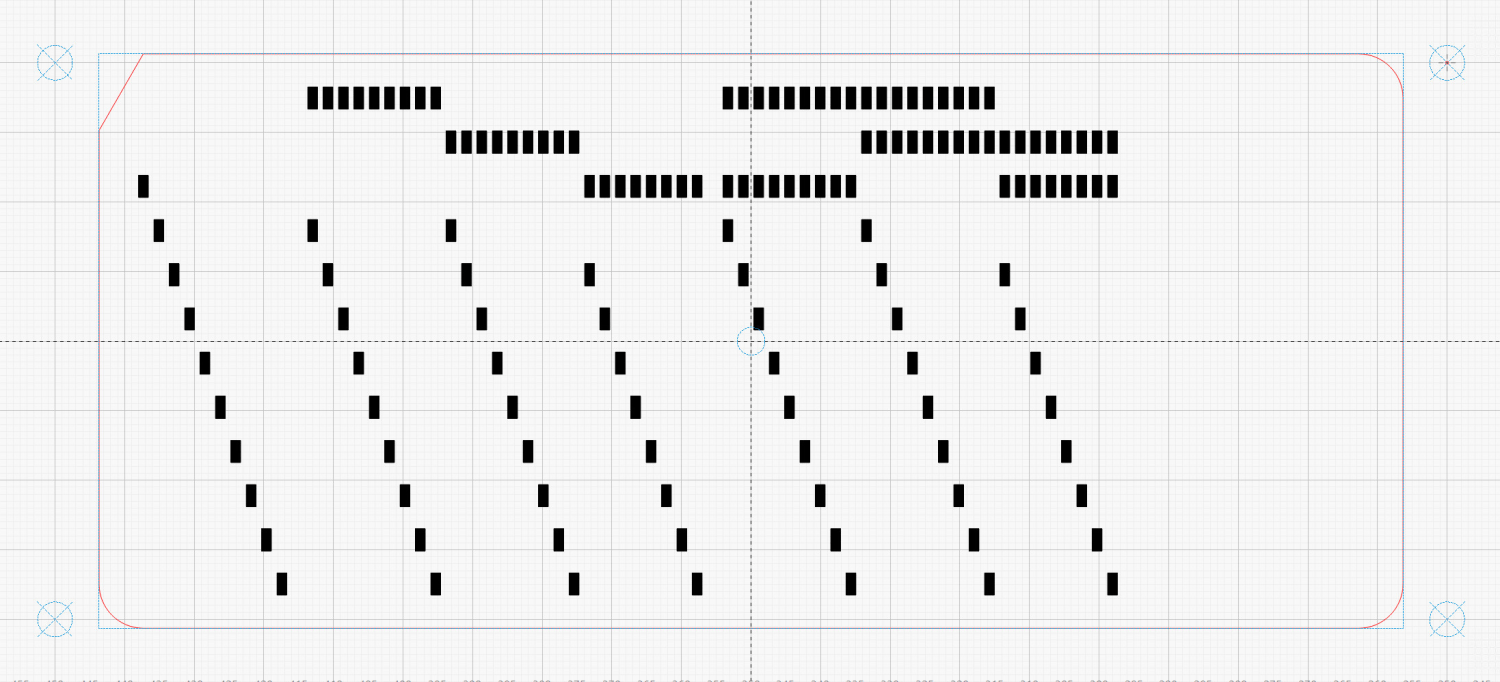

if args.layout == "laser": |

|

ToolEls.append( |

|

svg.Circle( |

|

cx=svg.mm(CardSize[X]/2), |

|

cy=svg.mm(CardSize[Y]/2), |

|

r="2mm", |

|

stroke=Tooling, |

|

stroke_width=svg.mm(DefStroke), |

|

fill="none", |

|

) |

|

) |

|

# mark card perimeter for alignment check |

|

|

|

if args.layout == "laser": |

|

ToolEls.append( |

|

svg.Rect( |

|

x=0, |

|

y=0, |

|

width=svg.mm(CardSize[X]), |

|

height=svg.mm(CardSize[Y]), |

|

stroke=Tooling, |

|

stroke_width=svg.mm(DefStroke), |

|

fill="none", |

|

) |

|

) |

|

|

|

#— accumulate alignment targets |

|

|

|

MarkEls = [] |

|

|

|

# alignment targets |

|

|

|

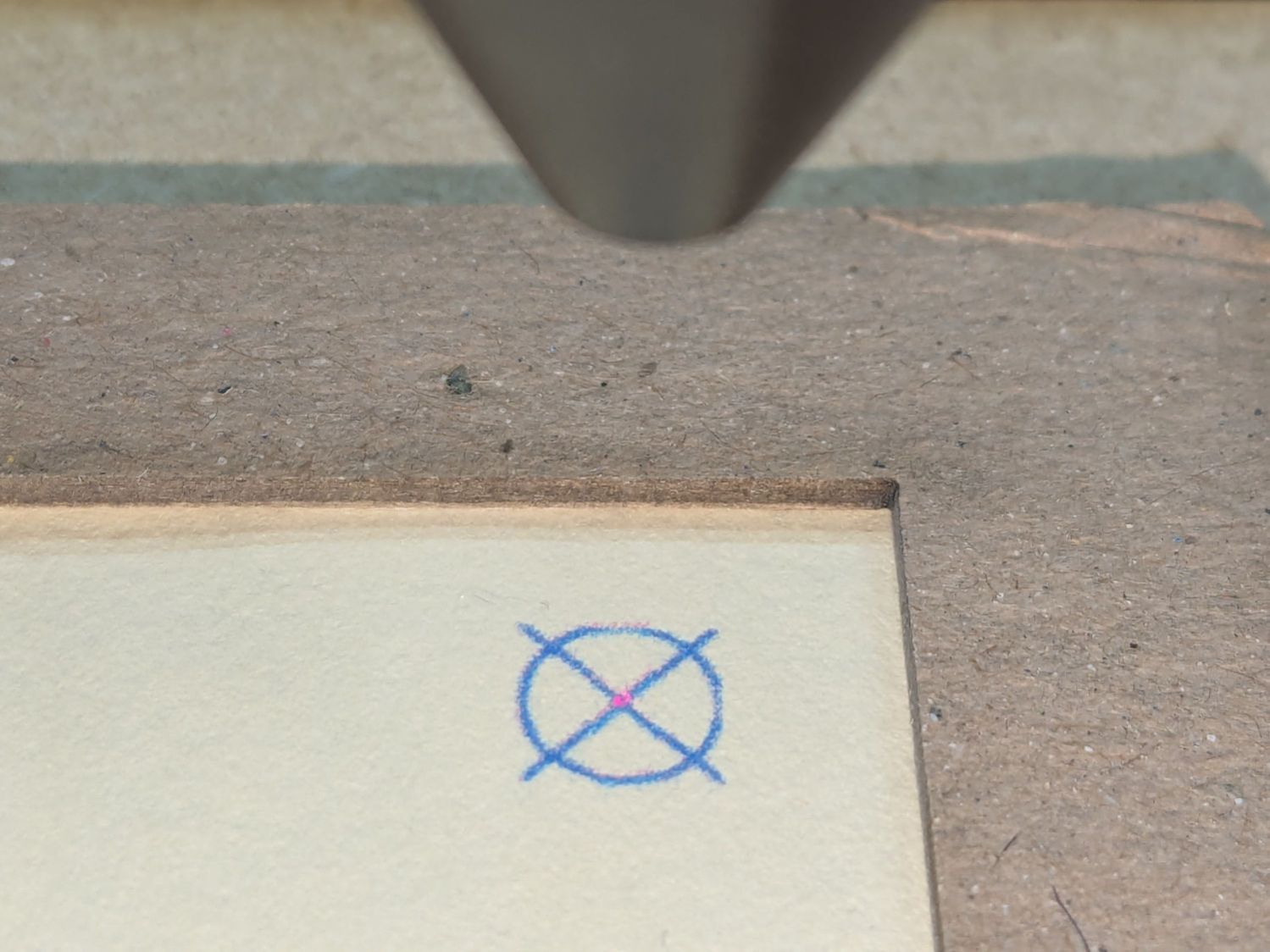

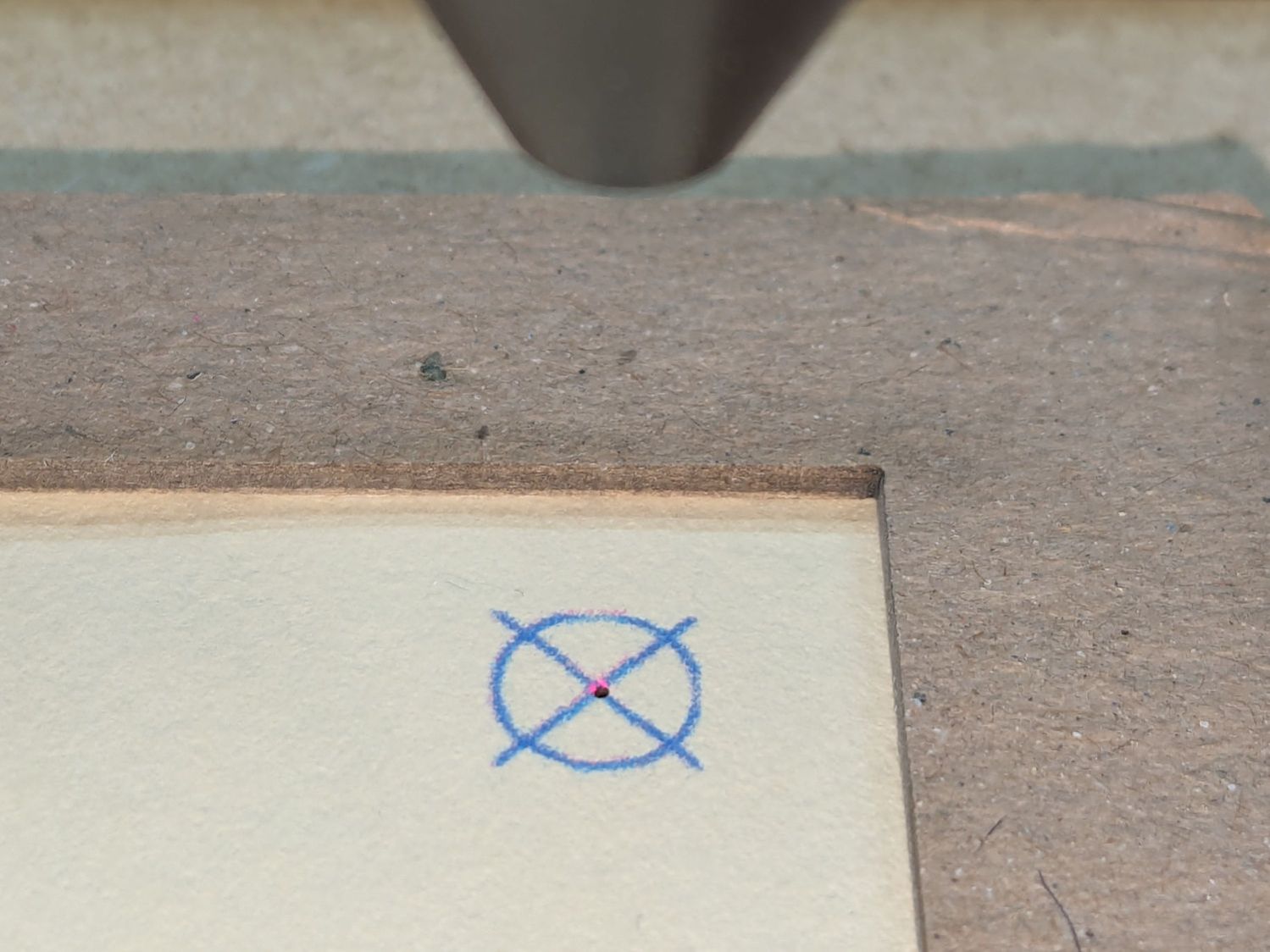

for c in ((1,1),(-1,1),(-1,-1),(1,-1)): |

|

ctr = (CardSize[X]/2 + c[X]*TargetOC[X]/2,CardSize[Y]/2 + c[Y]*TargetOC[Y]/2) |

|

MarkEls.append( |

|

svg.Circle( |

|

cx=svg.mm(ctr[X]), |

|

cy=svg.mm(ctr[Y]), |

|

r=svg.mm(TargetOD/2), |

|

stroke=Tooling if args.layout == "laser" else CardMark, |

|

stroke_width=svg.mm(DefStroke), |

|

fill="none", |

|

) |

|

) |

|

MarkEls.append( |

|

svg.Path( |

|

d=[ |

|

svg.M(ctr[X] + TargetOD/2,ctr[Y] – TargetOD/2), |

|

svg.l(-TargetOD,TargetOD), |

|

svg.m(0,-TargetOD), |

|

svg.l(TargetOD,TargetOD), |

|

], |

|

transform="scale(" + repr(1.0 if args.lbsvg else SVGSCALE) + ")", |

|

stroke=Tooling if args.layout == "laser" else CardMark, |

|

stroke_width=svg.mm(DefStroke if args.lbsvg else DefStroke/SVGSCALE), |

|

fill="none", |

|

) |

|

) |

|

|

|

#— accumulate card cuts |

|

|

|

CardEls = [] |

|

|

|

# card perimeter with magic numbers from card dimensions |

|

|

|

if args.layout == "laser": |

|

CardEls.append( |

|

svg.Path( |

|

d=[ |

|

svg.M(0.25*INCH,0), |

|

svg.h(CardSize[X] – 2*0.25*INCH), |

|

svg.a(0.250*INCH,0.25*INCH,0,0,1,0.25*INCH,0.25*INCH), |

|

svg.v(CardSize[Y] – 2*0.25*INCH), |

|

svg.a(0.25*INCH,0.25*INCH,0,0,1,-0.25*INCH,0.25*INCH), |

|

svg.H(0.25*INCH), |

|

svg.a(0.25*INCH,0.25*INCH,0,0,1,-0.25*INCH,-0.25*INCH), |

|

svg.V(0.25*INCH/math.tan(math.radians(30))), |

|

svg.Z(), |

|

], |

|

transform="scale(" + repr(1.0 if args.lbsvg else SVGSCALE) + ")", |

|

stroke=CardCut if args.layout == "laser" else Tooling, |

|

stroke_width=svg.mm(DefStroke if args.lbsvg else DefStroke/SVGSCALE), |

|

fill="none", |

|

), |

|

) |

|

|

|

# label hole positions in rows 0-9 |

|

# special hack for outline boxes |

|

|

|

TextEls = [] |

|

|

|

if args.layout == "print": |

|

xoffset = 0.3 # tiny offsets to align chars with cuts |

|

yoffset = 1.5 |

|

for c in range(NumCols): |

|

glyph = Contents[c] |

|

rnx = CharMap[glyph] # will include row name 10 aliased as row name 0 |

|

for rn in range(10): |

|

pch = RowGlyphs[rn] # default is digit for row |

|

if ((rn in rnx) or ((rn == 0) and (10 in rnx))): # suppress punched holes |

|

pch = "▯" if glyph == "▯" else " " # except for alignment tests |

|

r = RowMap[rn] |

|

TextEls.append( |

|

svg.Text( |

|

x=svg.mm(BaseHoleAt[X] + c*HoleOC[X] + xoffset), |

|

y=svg.mm(BaseHoleAt[Y] + r*HoleOC[Y] + yoffset), |

|

class_=["holes"], |

|

font_family="Arial", # required by LightBurn |

|

font_size="3.0mm", # required by LightBurn |

|

text_anchor="middle", |

|

text=pch |

|

) |

|

) |

|

|

|

# number the columns in tiny print |

|

|

|

if args.layout == "print": |

|

xoffset = 0.3 |

|

yoffset = 0.5 |

|

#xoffset = -0.25 if args.lbsvg else 0.0 # original hack |

|

for c in range(NumCols): |

|

for y in (22.7,80.0): # magic numbers between the rows |

|

TextEls.append( |

|

svg.Text( |

|

x=svg.mm(BaseHoleAt[X] + c*HoleOC[X] + xoffset), |

|

y=svg.mm(y + yoffset), |

|

class_=["cols"], |

|

font_family="Arial", # required by LightBurn |

|

font_size="1.5mm", # required by LightBurn |

|

text_anchor="middle", |

|

text=f"{c+1: 2d}", |

|

) |

|

) |

|

|

|

# add text attribution |

|

|

|

if args.layout == "print": |

|

TextEls.append( |

|

svg.Text( |

|

x=svg.mm(175.3), |

|

y=svg.mm(72.5 if args.lbsvg else 73.0), |

|

class_=["attrib"], |

|

font_family="Arial", # required by LightBurn |

|

font_size="2.0mm", # ignored by LightBurn |

|

text_anchor="middle", |

|

dominant_baseline="middle", |

|

text="softsolder.com", |

|

) |

|

) |

|

|

|

|

|

#— accumulate holes |

|

|

|

HoleEls = [] |

|

|

|

# punch the holes |

|

|

|

if args.layout == "laser": |

|

for c in range(len(Contents)): |

|

glyph = Contents[c] |

|

if not (glyph in CharMap): |

|

glyph = ' ' |

|

for rn in CharMap[glyph]: |

|

r = RowMap[rn] |

|

HoleEls.append( |

|

svg.Rect( |

|

x=svg.mm(BaseHoleAt[X] + c*HoleOC[X] – HoleSize[X]/2), |

|

y=svg.mm(BaseHoleAt[Y] + r*HoleOC[Y] – HoleSize[Y]/2), |

|

width=svg.mm(HoleSize[X]), |

|

height=svg.mm(HoleSize[Y]), |

|

stroke=HoleCut, |

|

stroke_width=svg.mm(DefStroke), |

|

fill="none", |

|

) |

|

) |

|

|

|

# print punched characters across the top edge |

|

# The KEYPUNCH029 font does not include lowercase characters, so |

|

# fake lowercase with italics, which LightBurn ignores |

|

|

|

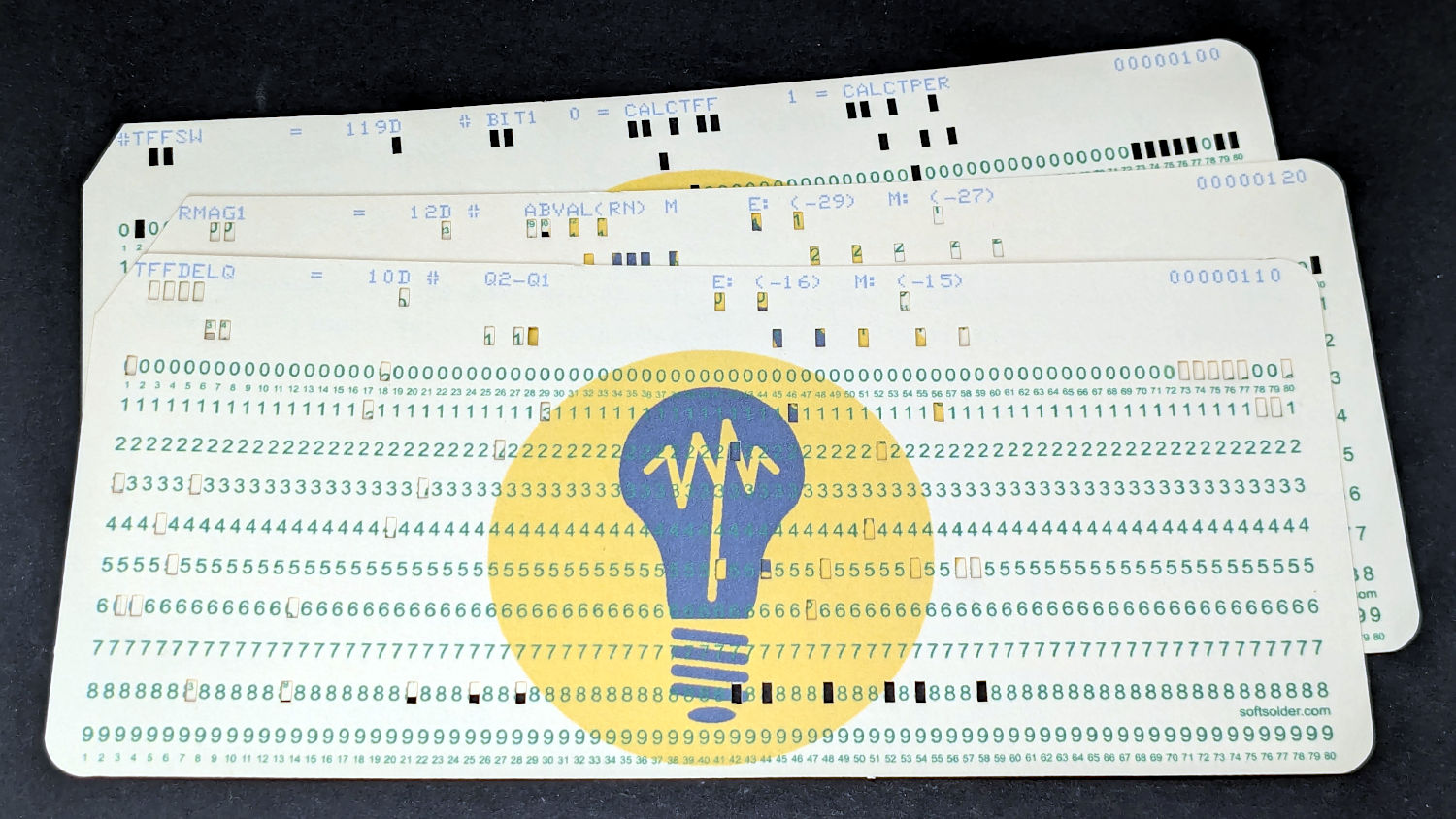

if args.layout == "print": |

|

xoffset = 0.3 |

|

for c in range(len(Contents)): |

|

glyph = Contents[c] |

|

if not (glyph in CharMap): |

|

glyph = ' ' |

|

fc = "dottylc" if curses.ascii.islower(glyph) else "dotty" |

|

glyph = svg.escape(glyph) # escape the characters that wreck SVG syntax |

|

TextEls.append( |

|

svg.Text( |

|

x=svg.mm(BaseHoleAt[X] + c*HoleOC[X] + xoffset), |

|

y=svg.mm(5.0), # align just below card edge |

|

class_=[fc], |

|

font_family="KEYPUNCH029", # required by LightBurn |

|

font_size="4.0mm", # required by LightBurn |

|

text_anchor="middle", |

|

text=glyph |

|

) |

|

) |

|

|

|

#— assemble and blurt out the SVG file |

|

|

|

if not args.debug: |

|

canvas = svg.SVG( |

|

width=svg.mm(PageSize[X]), |

|

height=svg.mm(PageSize[Y]), |

|

elements=[ |

|

svg.Style( |

|

text = f"\n.attrib{{ font: 2mm Arial; fill:{CardText}}}" + |

|

f"\n.holes{{ font: 3.0mm Arial; fill:{CardText}}}" + |

|

f"\n.cols{{ font: 1.5mm Arial; fill:{CardText}}}" + |

|

f"\n.dotty{{ font: 4.0mm KEYPUNCH029; fill:{CardGray}}}" + |

|

f"\n.dottylc{{ font: italic 4.0mm KEYPUNCH029; fill:{CardGray}}}" |

|

), |

|

ToolEls, |

|

MarkEls, |

|

CardEls, |

|

TextEls, |

|

HoleEls, |

|

], |

|

) |

|

|

|

print(canvas) |