Sean reports that the first field test of the Tux Cookie Cutter went well:

I obviously need a few samples for QC purposes…

The Smell of Molten Projects in the Morning

Ed Nisley's Blog: Shop notes, electronics, firmware, machinery, 3D printing, laser cuttery, and curiosities. Contents: 100% human thinking, 0% AI slop.

Things around the home & hearth

Sean reports that the first field test of the Tux Cookie Cutter went well:

I obviously need a few samples for QC purposes…

At some point we brought home a fruit fly starter kit that produced a zillion fruit flies in the worm compost bin; every time we opened the cover, half a zillion flies would emerge. After a bit of fiddling with the usual Internet recipes, I managed to produce something useful:

The trick involves making the liquid enticing enough to get the flies through the hole in the coffee filter top:

I used about a cup of water, an ice cube of apple juice for sweetness (they are, after all, fruit flies), a tablespoon of vinegar for that delicious rotten aroma (they prefer damaged, easy to eat fruit), and a few drops of dishwashing detergent so when they hit the liquid they’re sunk.

The container must be tall enough to let them rise past the entrance opening on their way toward the light; I settled on the 2 pound ricotta cheese containers we have in abundance:

That’s the catch after maybe a month at the end of the season, but it represents a week of activity back when we were breaking the infestation. I deployed four of those traps atop the compost bin to catch the half-zillion escaped flies and fired up the vacuum cleaner to extract the half-zillion remaining inside every time we opened the lid. After a few weeks of that, we’d managed to get ahead of their breeding cycle and the problem pretty much Went Away.

A garden sprayer awaiting repair emerged from the benchtop clutter. It’s an old one, with a metal shell and actual screws, so I could dismantle it to reveal the problem:

It’s evidently impossible to make a good, cheap, corrosion-resistant spring (pick any two, I suppose):

Some rummaging in the Big Box o’ Medium Springs produced a slightly smaller spring that should last for a while; it’s good, free, and rust-able, if a bit too short.

Much to my astonishment, I found a length of 3/8 inch Marine Bronze rod in the stockpile and made a bushing to take up the remainder of the space:

It won’t get a good test until gardening season opens next year, but it seems to seal well enough.

This brass dragonfly has graced our garden for some years, but what seemed like a gentle tap during fall cleanup knocked both eyeballs out. The original adhesive looked like urethane, so I cleaned the sockets, applied a layer around the rim, and popped the marbles back in place.

The clamping looks painful…

Of course, that’s an unbroken Harbor Freight clamp…

Having missed the fall driveway paving deadline, we will have a gravel section in the middle of the driveway until next spring. All the water from the garage downspouts and the back yard runs down the driveway, which dumps it directly into the gravel patch and the new retaining wall’s foundation. That means the gravel patch, at least, will become a mud hole, which I take to be a Bad Thing.

So I bandsawed some 4 inch DWV pipe & fittings in half lengthwise, glued them together as a gutter to capture the runoff and divert it into 80 feet of DWV pipe leading to the bottom end of the wall, then filled the half-pipes with gravel to let us drive right over the whole mess. Unfortunately, the top end of the gravel patch has the driveway ending in broken asphalt, Item 4 gravel, fine gravel, and rubble that make it impossible to snug the pipes up against the asphalt. That means the runoff would pretty much vanish before it reached the gutters.

So I excavated just barely enough gravel to ensure a downhill slope from the remaining asphalt, mixed up a random bag of mortar that’s been kicking around in the garage for a few years, and troweled an apron from the asphalt to the half-pipes. Generally I sign my work, but this kludge need last only a few months and I left it to cure.

The next morning I discovered one of the chipmunks felt the work really needed a signature:

That’s OK with me…

FWIW, this is why you need Too Many Clamps:

The Moen sink faucet in our black bathroom (so named because of its black tile, white trim, and gray floor) began piddling a few days ago, which seemed odd: Moen says it has a good-for-your-lifetime ceramic valve. So I took it apart, extracting an impressive vector of internal parts in the process.

The “notch” that indicates the hot-cold alignment isn’t particularly obvious, but evidently forward corresponds to the usual hot-on-the-left plumbing:

The retainer clip holding that white stop sleeve in place requires a bit of tweaking from a small pointy probe, but after you expose the hole in that notch the clip comes out easily enough:

With all the frippery out of the way, then “Using pliers, pull the cartridge out of the body by the stem”, which simply did not work for me. No matter what, the cartridge body didn’t budge:

There’s nothing about turning / unscrewing the transparent (looks black here) shell around the stem, so I didn’t try.

Putting enough of the parts back together to keep the cartridge from blowing out in my face (even if I can’t remove it, it’ll certainly blow out on its own), the faucet valve worked fine. You’re supposed to turn the gray pivot retainer 1/4 turn beyond hand tight, which compresses a wavy washer under the retainer. The retainer had been quite loose when I dismantled the faucet, which suggests that either it hadn’t been tightened at the factory or had worked itself loose. That would tend to hold the handle up just a bit, perhaps enough to prevent the valve from completely closing.

After snugging that retainer down tight and reassembling everything, the faucet worked perfectly: happy dance!

I removed the nozzle aerator and found a surprising amount of grit for something that’s downstream of the whole-house water filter and softener:

Cleaned that out and it’s all good again.

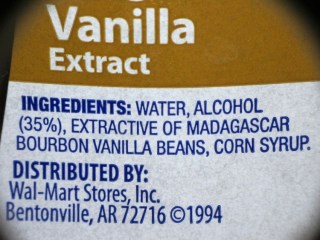

This look at the ingredients found in various commercial vanilla extracts (plus their prices) finally pushed me over the edge into brewing up that DIY vanilla extract.

We’ve been using McCormick vanilla forever, mostly because it has the simplest and shortest list of ingredients:

Nielson-Massey vanilla seemed about the same, although it’s not clear why it needs more sugar than those “vanilla bean extractives”:

Wal-Mart vanilla doesn’t smell like vanilla, even though it has more “extractive” than corn syrup:

All three extracts have “Pure” on the label, which (according to Wikipedia, anyway) means that they have at least 13.35 ounce of vanilla bean per gallon of extract. I didn’t weigh the three beans in my 8 ounces of hooch, but I suspect they weighed far less than the regulation 0.834 ounce. Next time, for sure, I’ll go for triple strength extract!

Despite that, my DIY hooch has turned brown and smells pretty good…

These full-frame pix used my new close-up lens gizmo; even with some vignetting the results seem perfectly usable. Normally I crop pix down to the central section, so this will be as bad as it gets.