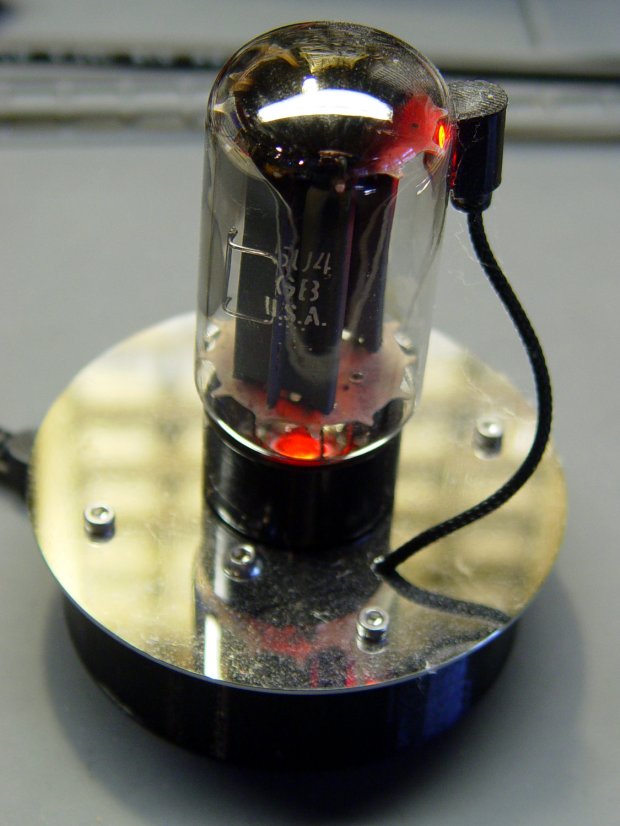

With the wrecked 5U4GB safely in the trash, I popped a smaller, somewhat less stately triode from the Big Box o’ Hollow-State Electronics and wired it up with a pair of SK6812 RGBW LEDs:

The tube’s markings have long since vanished, but, at this late date, all that matters is an intact glass envelope!

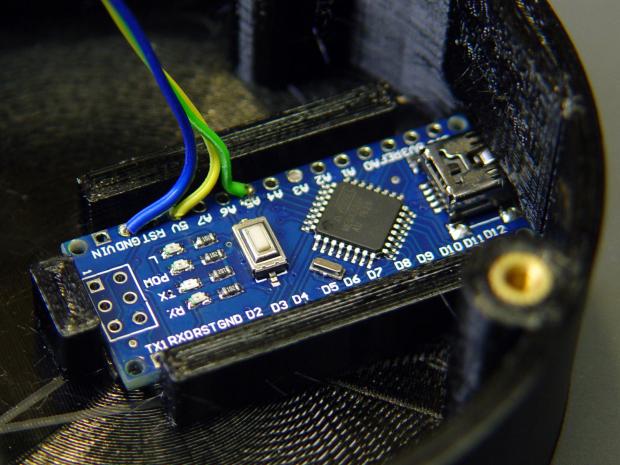

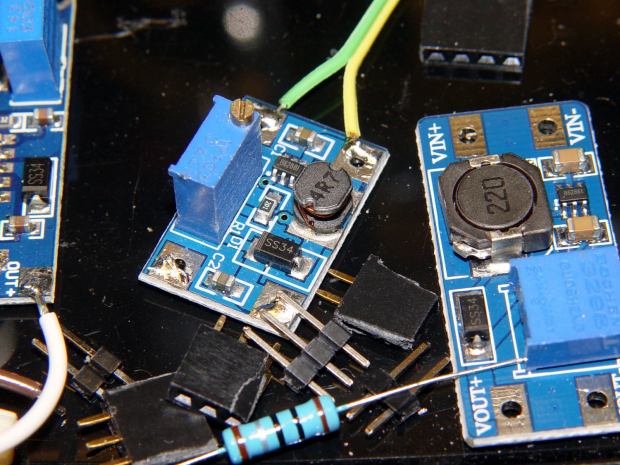

After two years, the ordinary white foam tape holding the knockoff Arduino Nano lost most of its sticktivity and easily popped off the 3D printed base:

Two layers of 3M outdoor-rated foam tape clear the bottom-side components and, based on current evidence, its stickiness should stick forever more:

The alert reader will notice the mis-soldered 1 kΩ SMT resistor above-and-right of the CH340 USB interface chip. I think those two resistors are the isolators between the 328P microcontroller and the CH340, letting you use the TX and RX lines as ordinary I/O without killing either chip.

Despite the mis-soldering, it evidently passed their QC and works fine. Seeing as how I didn’t notice it until just now, it’ll remain in place until I must open the lamp base for some other reason, which may never happen.

The data output is now on pin A5, to match the rest of the glowing widgetry:

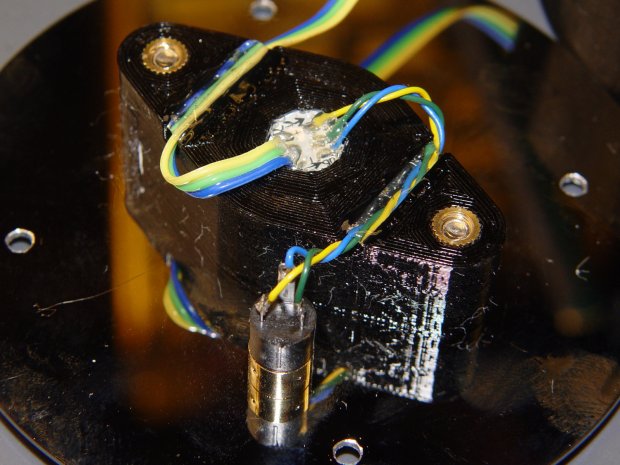

Blobs of hot melt glue affix the SK6812 and wiring to the socket:

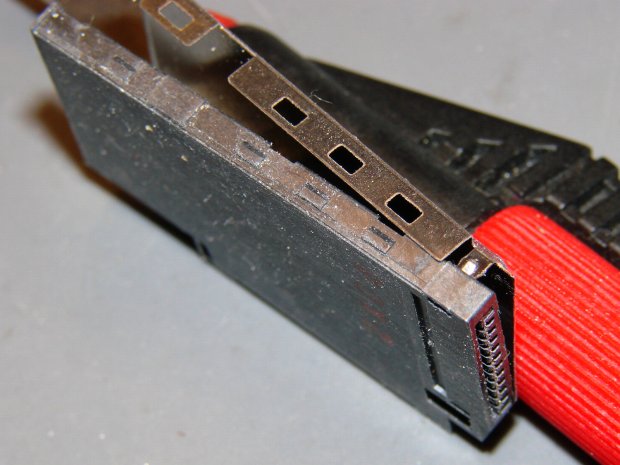

The original “plate cap” wiring ran directly through a hole in the hard drive platter, which I embiggened for a 3.5 mm panel-mount headphone jack. The knurled metal plug looms next to this smaller tube, but it looks better (in a techie sense) than the raw hole:

Octal tubes have an opaque Bakelite base, so I devoted some Quality Shop Time™ to the post:

Although I’d made a shell drill for 5U4’s base, this base was so crumbly I simply joysticked the spinning cutter around to knock off the rest of the post:

The shell drill would open the bottom to admit a bit more light. I may do that to see if it makes any visible difference.

I didn’t expect the serrations in the top mica plate to cast interesting patterns around the platter:

Memo to Self: use the shell drill to avoid nicking the evacuation tip!