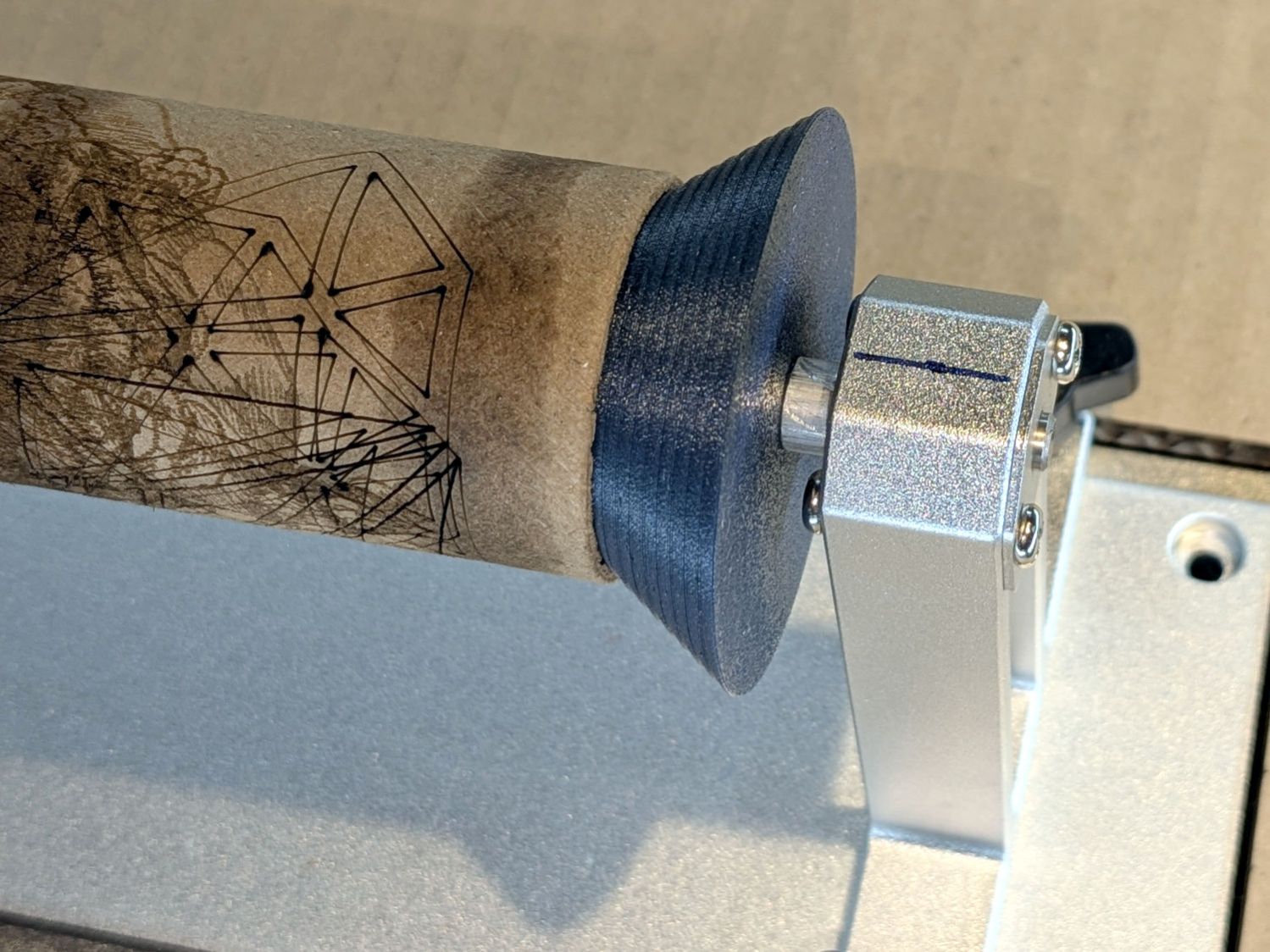

A conical (a.k.a. bullnose) center in the tailstock simplifies supporting cylindrical objects:

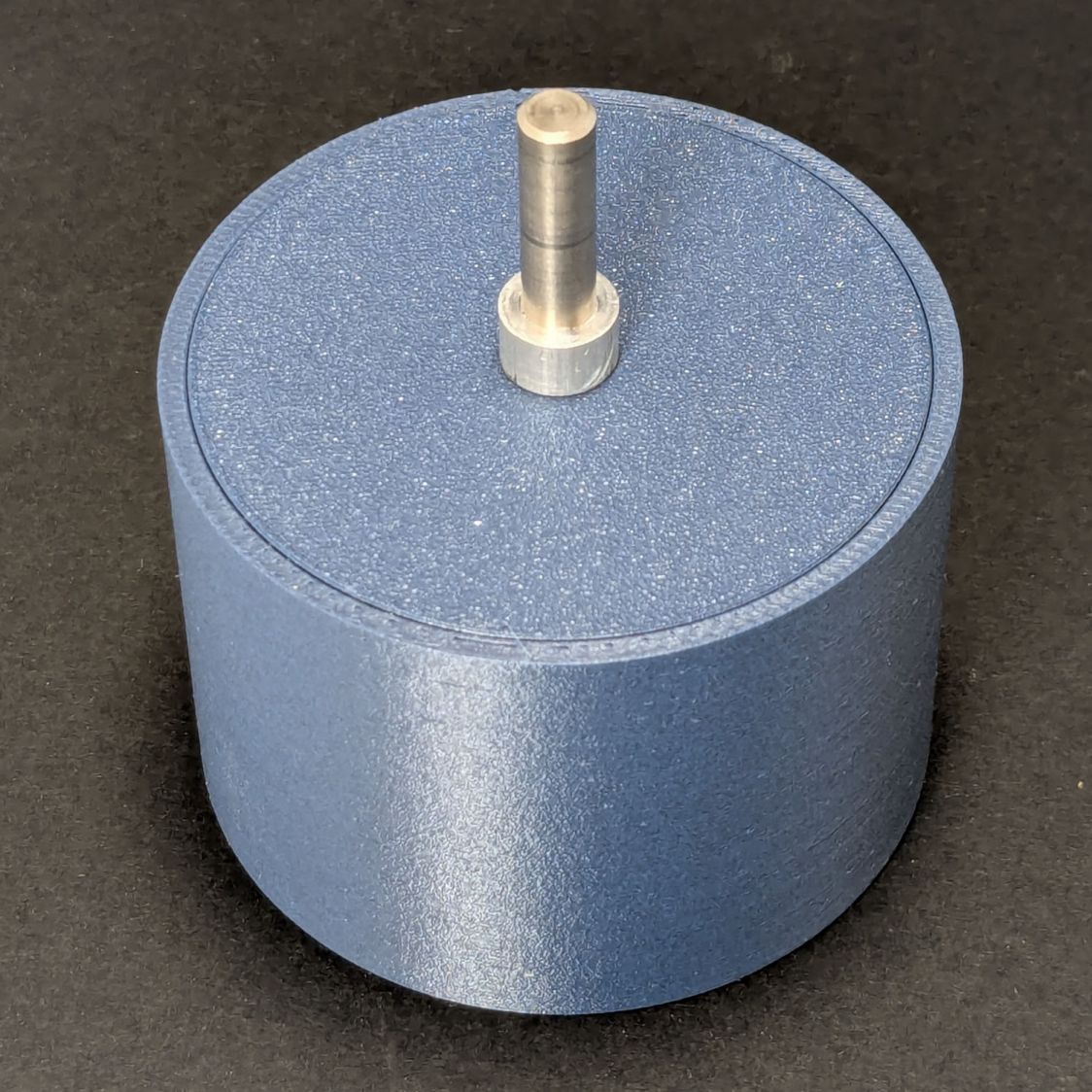

The spring-loaded tailstock bearing has a 5 mm bore. The bullnose rests against a small spacer on its 5 mm shaft to hold it away from the bearing’s mounting screws with some bearing spring compression. I turned the spacer from aluminum rod because lathe work is satisfying, but a printed spacer would work fine.

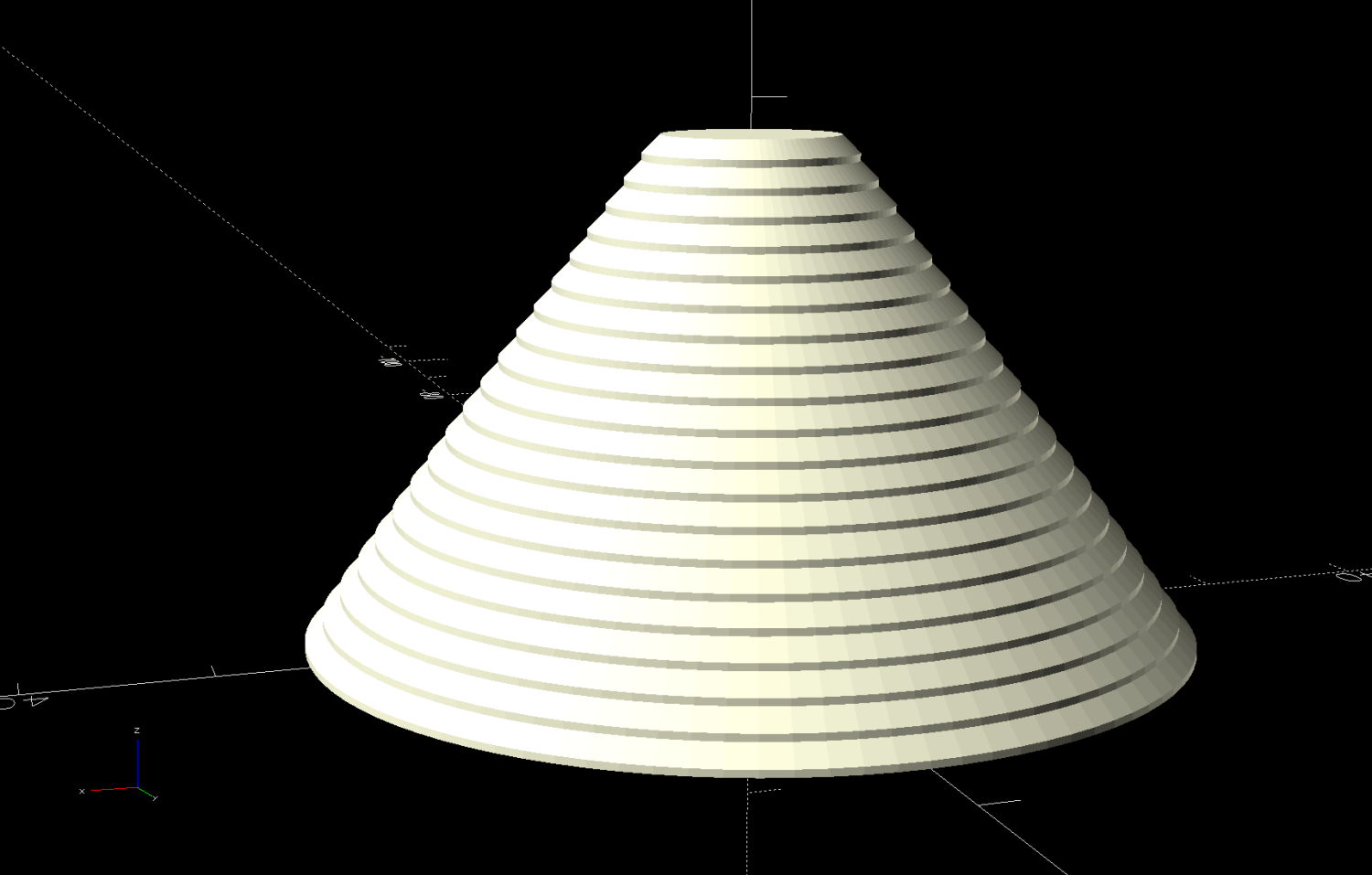

The bullnose is a cone with steps encouraging the cylinder to sit properly:

With both ends centered, the cylinder sits concentric with the chuck axis:

The chuck grabs the OD and the bullnose supports the ID, so removing crud from both ends is in order.

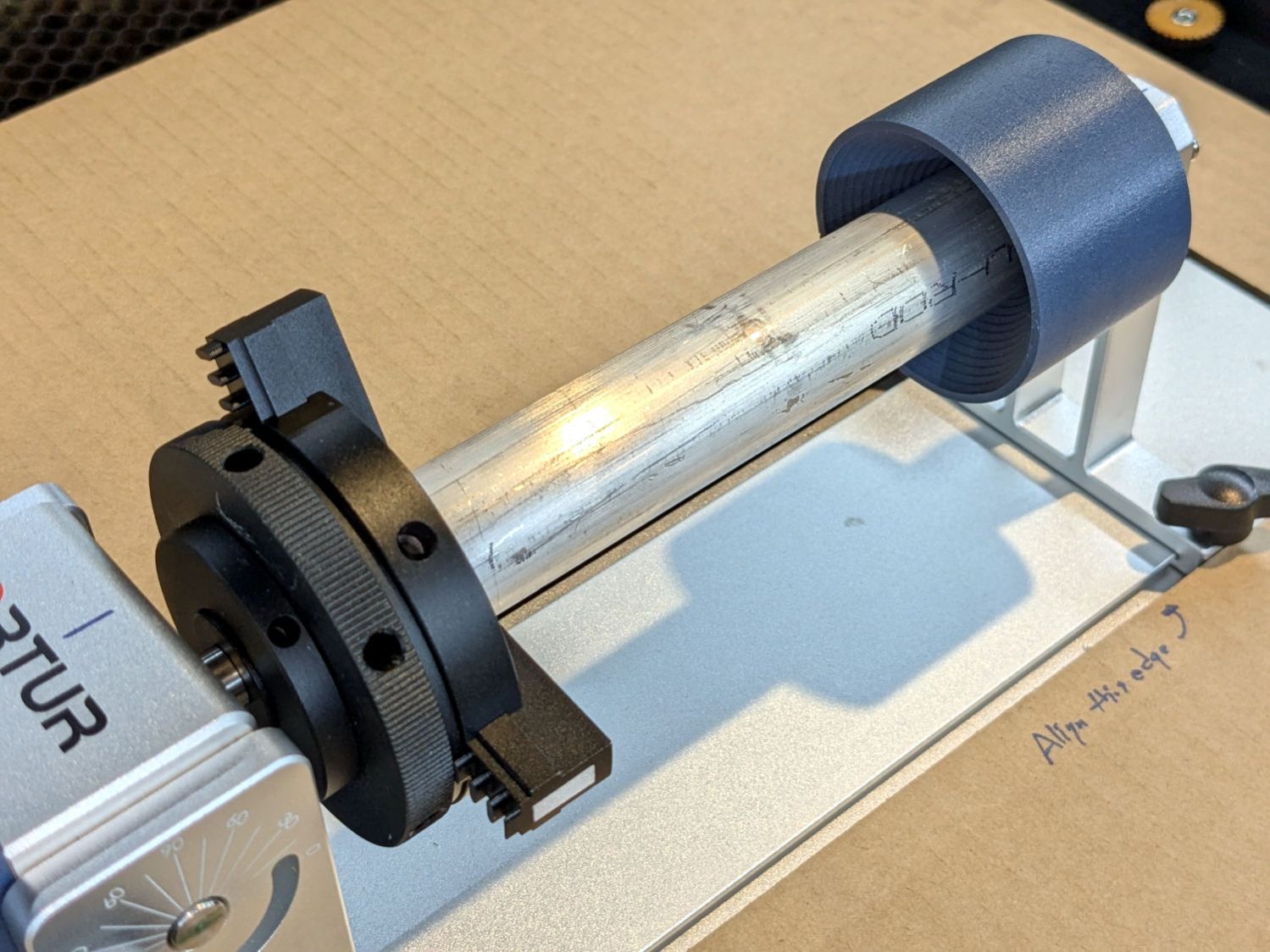

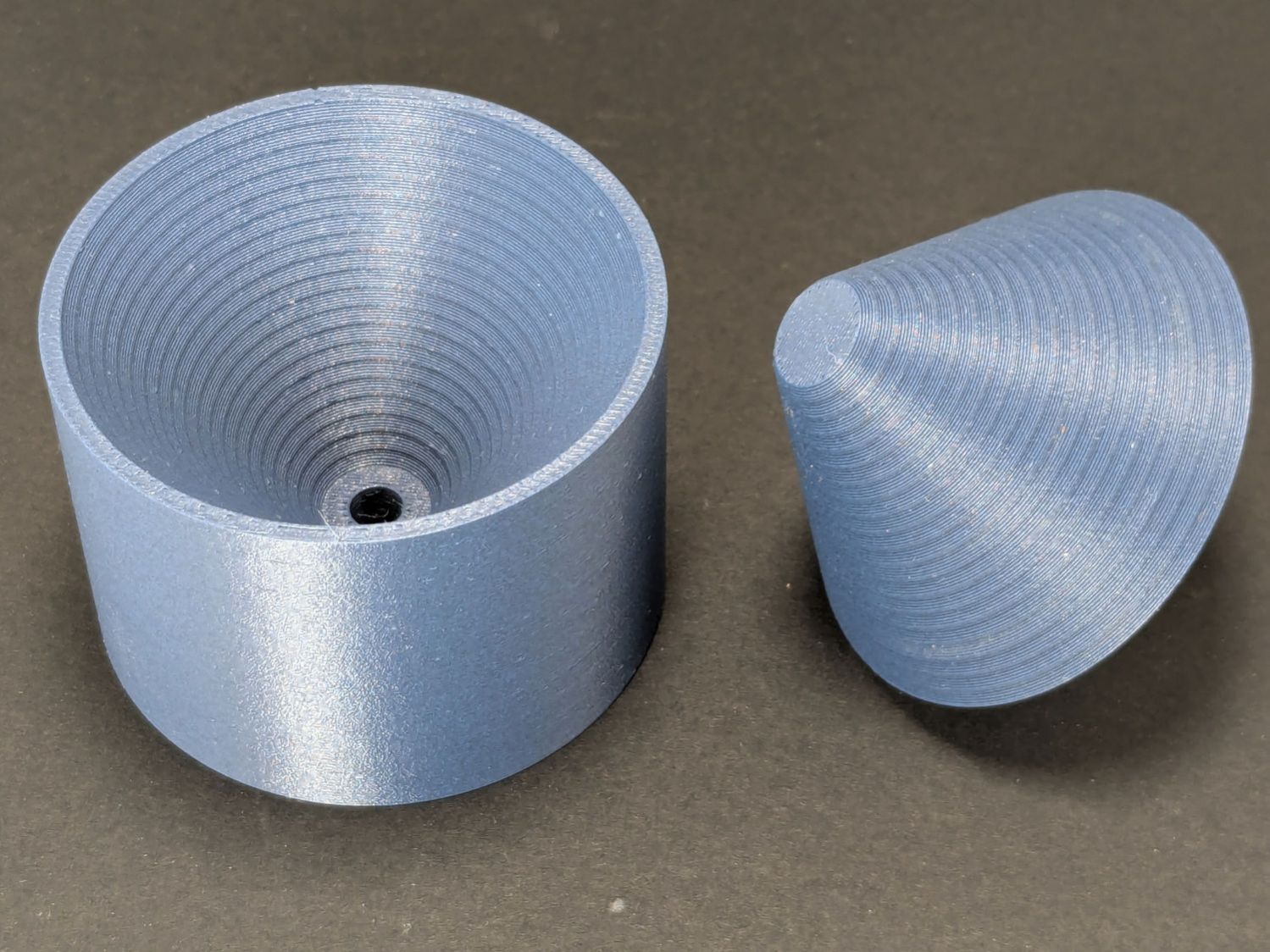

The bullnose won’t work for a solid rod, so a negative cone = cup center may come in handy:

Stipulated: A CO₂ laser will bounce right off a solid aluminum rod. Imagine I chucked up a wood dowel, OK?

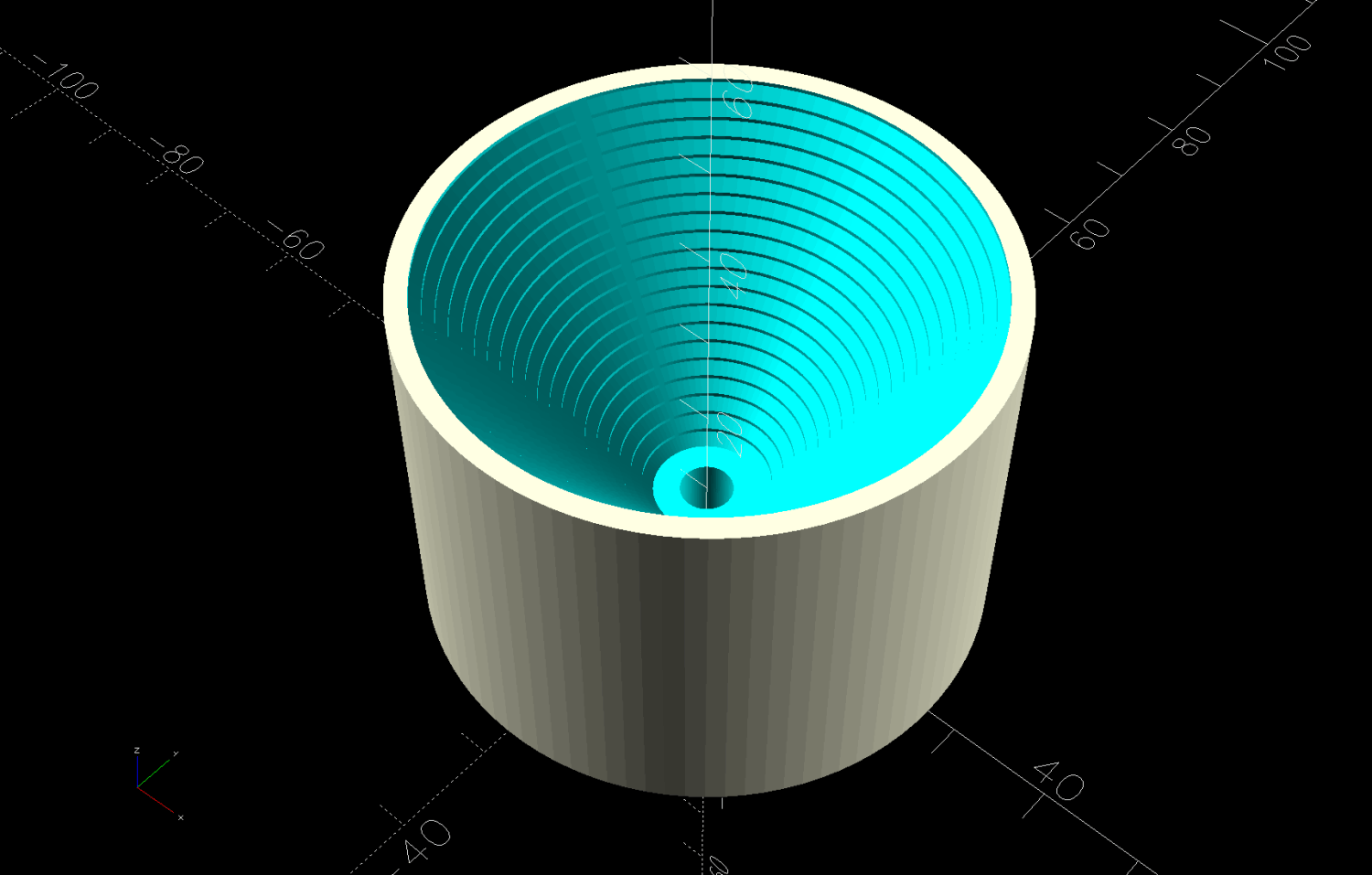

A cup center is what remains afteryoinking a bullnose out of a cylinder:

Looks like I did exactly that:

Somewhat surprisingly, the two parts nest perfectly:

That’s without the shaft installed on the cup, so they won’t sit quite so neatly on the shelf.

Aligning the rotary axis along the laser’s X axis and setting the focus requires attention to detail, but a decent tailstock center makes that effort meaningful.

The OpenSCAD code as a GitHub Gist:

| // Ortur Rotary Conical centers | |

| // Ed Nisley – KE4ZNU | |

| // 2025-12-27 | |

| include <BOSL2/std.scad> | |

| Style = "Bullnose"; // [Build,Cone,Bullnose,Cup,Cone] | |

| MinDia = 10.0; | |

| MaxDia = 50.0; | |

| /* [Hidden] */ | |

| LayerThick = 0.2; // should match slicer thickness | |

| Ramp = 1.0; | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| HoleWindage = 0.2; | |

| Protrusion = 0.1; | |

| NumSides = 8*3*4; | |

| $fn=NumSides; | |

| Gap = 5.0; | |

| WallThick = 2.0; | |

| TailBearing = [5.0,7.0,10.0]; // tailstock shaft, LENGTH = insert depth | |

| StepHeight = 2*LayerThick; | |

| NumSteps = (((MaxDia – MinDia)/2) / Ramp); | |

| ConeOAH = NumSteps * (Ramp + StepHeight); | |

| //—– | |

| // Bullnose shape | |

| module Bullnose() { | |

| difference() { | |

| union() | |

| for (i = [0:NumSteps – 1]) | |

| up(i*(Ramp + StepHeight)) hull() | |

| cyl(StepHeight + Protrusion,r=(MaxDia/2 – i*Ramp),anchor=BOTTOM) position(TOP) | |

| cyl(Ramp,r1=(MaxDia/2 – i*Ramp),r2=(MaxDia/2 – (i+1)*Ramp),anchor=BOTTOM); | |

| } | |

| } | |

| module Cone() { | |

| difference() { | |

| Bullnose(); | |

| down(Protrusion) | |

| cyl(TailBearing[LENGTH] + Protrusion,d=TailBearing[ID],circum=true,anchor=BOTTOM); | |

| } | |

| } | |

| module Cup() { | |

| difference() { | |

| cyl(ConeOAH + TailBearing[LENGTH],d=MaxDia + 2*WallThick,anchor=BOTTOM); | |

| up(ConeOAH + TailBearing[LENGTH] + Protrusion) | |

| yrot(180) | |

| Bullnose(); | |

| down(Protrusion) | |

| cyl(TailBearing[LENGTH] + 2*Protrusion,d=TailBearing[ID],circum=true,anchor=BOTTOM); | |

| } | |

| } | |

| //—– | |

| // Build things | |

| if (Style == "Bullnose") | |

| Bullnose(); | |

| if (Style == "Cone") | |

| Cone(); | |

| if (Style == "Cup") | |

| Cup(); | |

| if (Style == "Build") { | |

| right(MaxDia/2 + Gap) | |

| Cone(); | |

| left(MaxDia/2 + WallThick + Gap) | |

| Cup(); | |

| } |

Spam comments get trashed, so don’t bother. Comment moderation may cause a delay.