Because the BOSL2 library includes a gear generator, I can now avoid creating a gear outline in Inkscape and importing it into my stacked change gear generator.

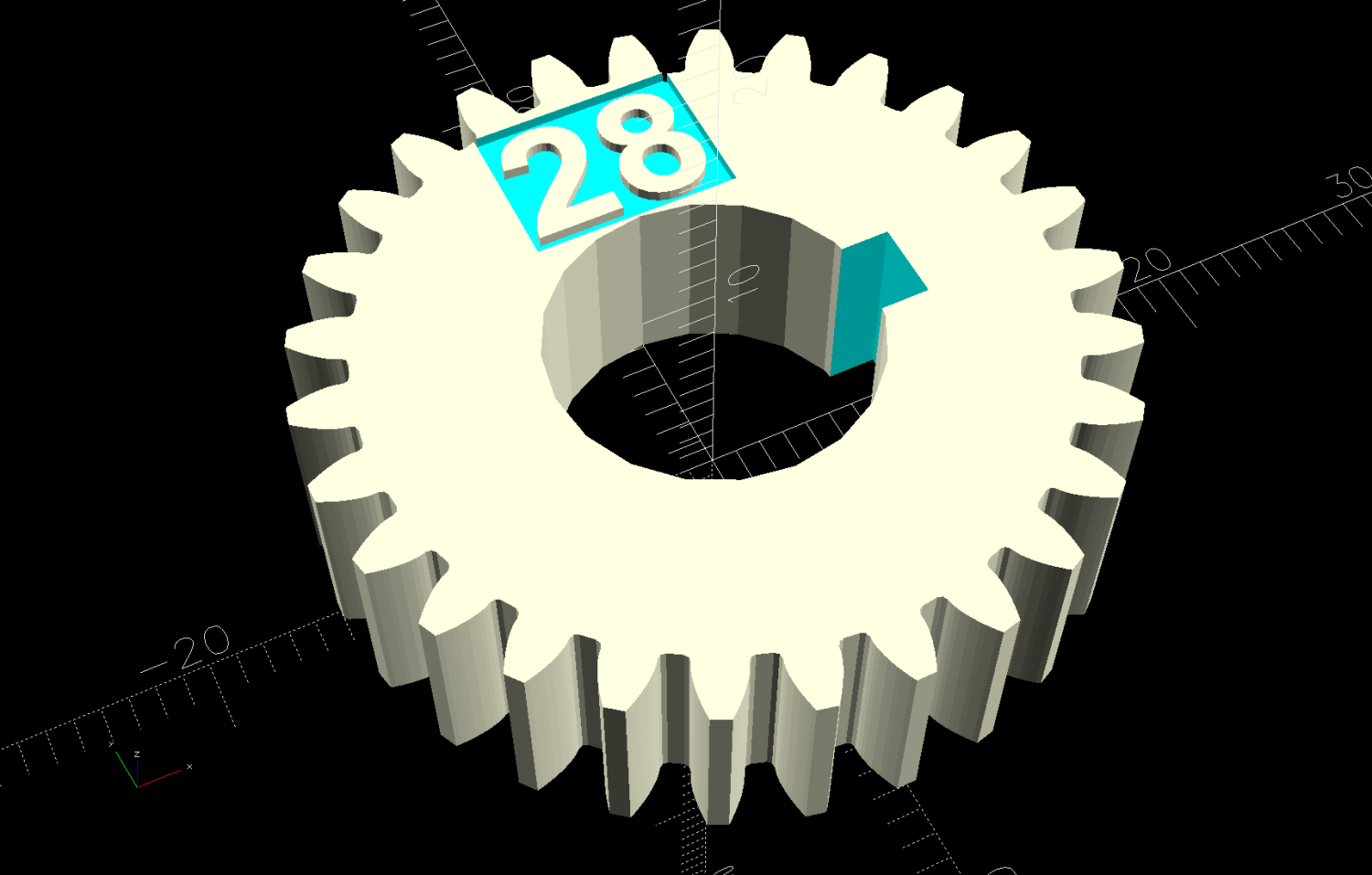

The labels now snuggle closer to the shaft and (barely) fit on smaller gears:

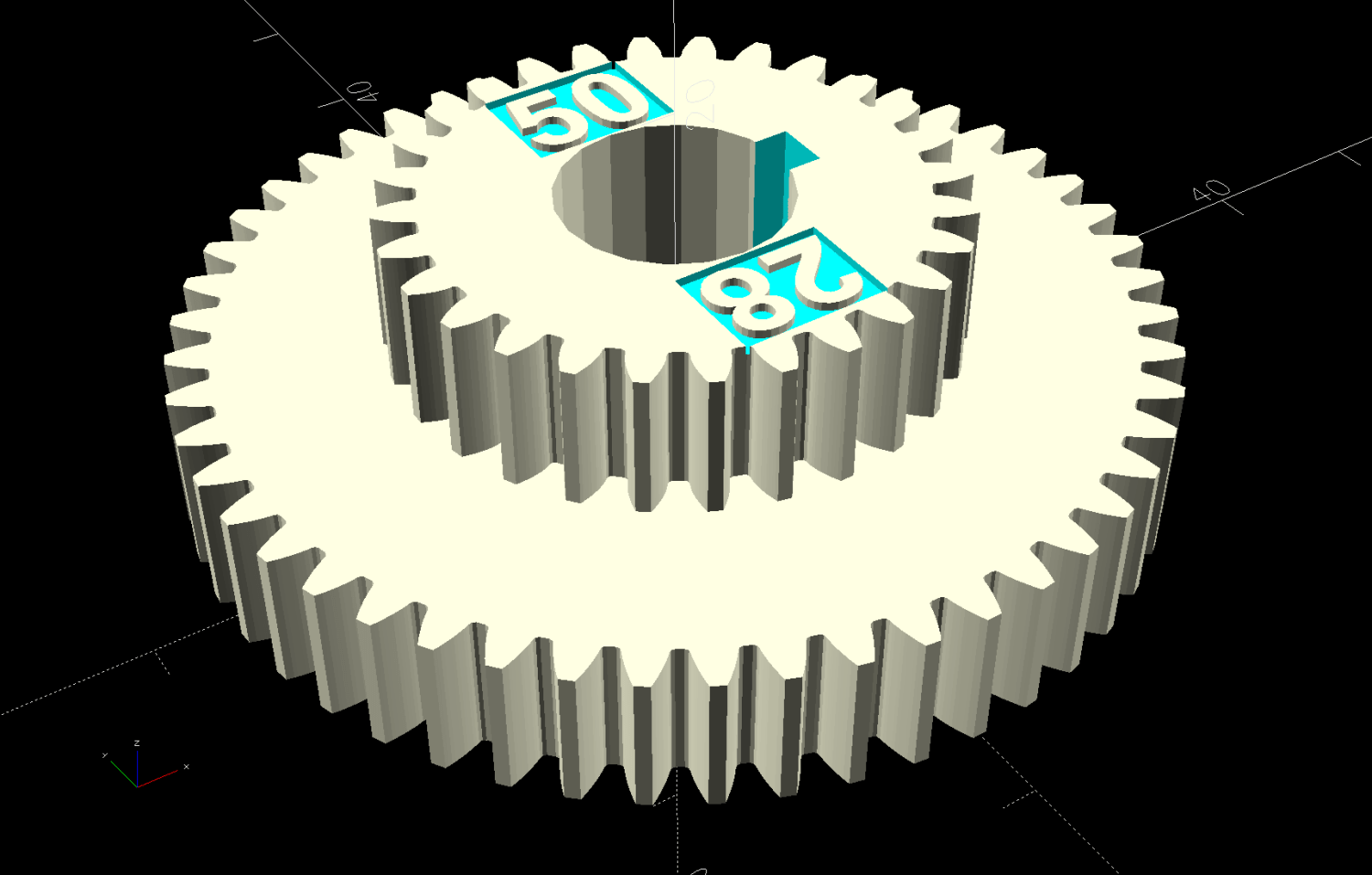

The stacked B-C gears for the jack shaft work as before, with both labels on the top gear:

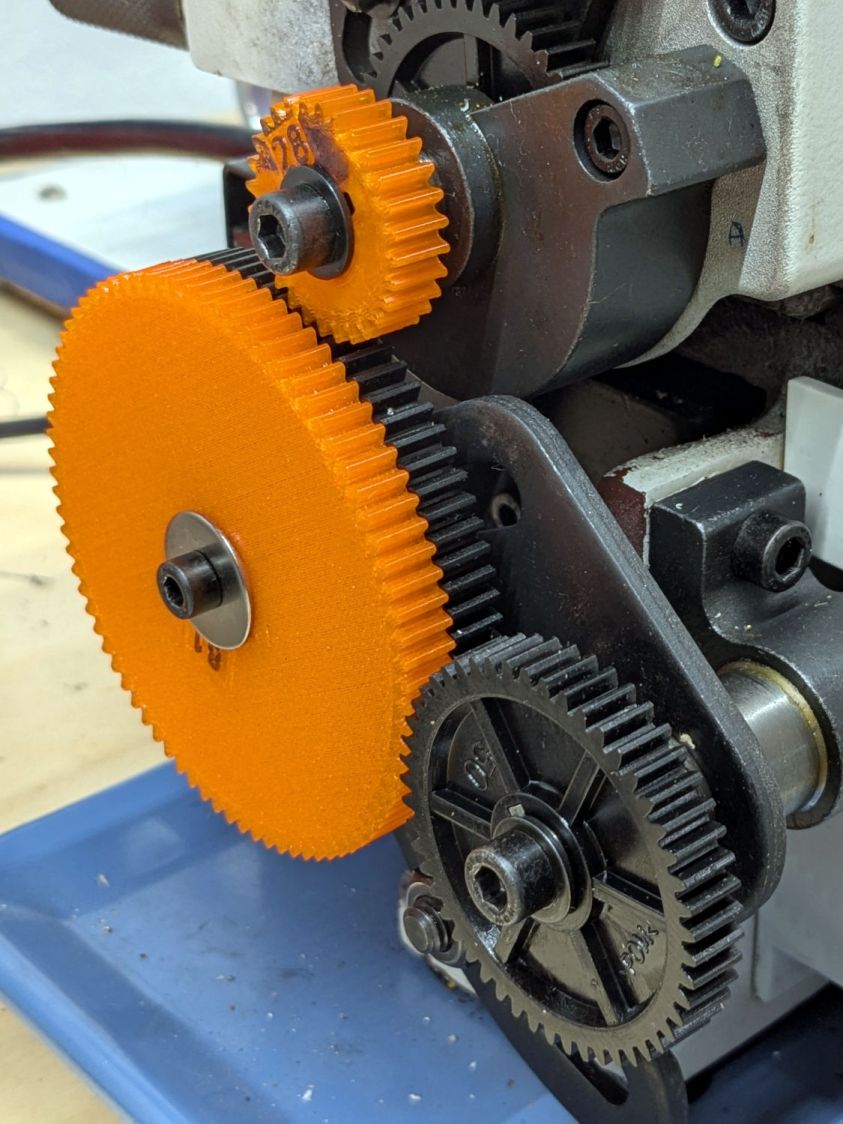

The admittedly flimsy motivation for all this was to make a 28 tooth gear to cut a 0.9 mm pitch, thus filling an obvious hole in the gear table.

My collection of gears could do 21-60-81-50, but the 81 T gear collides with the screw holding the 21 T gear. Rearranging it to 21-50-81-60 showed the B-C gears exceeded the space available.

Because it’s all ratios and a 28 T gear is 4/3 bigger than 21 T, reducing the rest of the train by 3/4 should work. In fact, it produced a reasonable 28-80-81-50 chain:

The fact that I do not anticipate ever needing to cut a 0.9 mm pitch has nothing whatsoever to do with it; that gear will surely come in handy for something.

While I was at it, I made a 27 T gear, because 27 = 21 × 9/7:

You can never have enough change gears. Right?

The OpenSCAD source code as a GitHub Gist:

| // LMS Mini-Lathe | |

| // Change gears with stacking | |

| // Ed Nisley – KE4ZNU | |

| // 2020-05 use Inkscape SVG gears | |

| // 2025-12 use BOSL2 gear generator | |

| include <BOSL2/std.scad> | |

| include <BOSL2/gears.scad> | |

| /* [Gears] */ | |

| TopGear = 0; // zero for single gear | |

| BottomGear = 28; | |

| /* [Hidden] */ | |

| ThreadThick = 0.20; | |

| HoleWindage = 0.2; | |

| Protrusion = 0.1; // make holes end cleanly | |

| /* [Dimensions] */ | |

| ShaftOD = 12.0; | |

| GearThick = 7.75; | |

| Keyway = [3.5,3.0,3*GearThick]; // x on radius, y on perim | |

| LegendEnable = (TopGear == 0 && BottomGear > 27) || (TopGear > 27); | |

| LegendThick = 2*ThreadThick; | |

| LegendZ = (TopGear ? 2*GearThick : GearThick) – LegendThick; | |

| LegendSize = 5; | |

| LegendRecess = [8,6,LegendThick]; | |

| LegendOffset = [0,LegendRecess.y/2 + ShaftOD/2 + HoleWindage,LegendZ + LegendRecess.z/2]; | |

| //———————– | |

| // Build it! | |

| union() { | |

| difference() { | |

| union() { | |

| spur_gear(mod=1,teeth=BottomGear,thickness=GearThick,shaft_diam=ShaftOD + HoleWindage,anchor=BOTTOM); | |

| if (TopGear) | |

| spur_gear(mod=1,teeth=TopGear,thickness=2*GearThick,shaft_diam=ShaftOD + HoleWindage,anchor=BOTTOM); | |

| } | |

| right(ShaftOD/2) | |

| down(Protrusion) | |

| cube(Keyway,anchor=CENTER+BOTTOM); | |

| if (LegendEnable) { | |

| translate(LegendOffset) | |

| cube(LegendRecess + [0,0,Protrusion],anchor=CENTER); | |

| if (TopGear) | |

| zrot(180) | |

| translate(LegendOffset) | |

| cube(LegendRecess + [0,0,Protrusion],anchor=CENTER); | |

| } | |

| } | |

| if (LegendEnable) | |

| translate([0,0,LegendZ – Protrusion]) | |

| linear_extrude(height=LegendThick + Protrusion,convexity=10) { | |

| translate([LegendOffset.x,LegendOffset.y]) | |

| text(text=str(BottomGear),size=LegendSize,font="Arial:style:Bold",halign="center",valign="center"); | |

| if (TopGear) | |

| zrot(180) | |

| translate([LegendOffset.x,LegendOffset.y]) | |

| text(text=str(TopGear),size=LegendSize,font="Arial:style:Bold",halign="center",valign="center"); | |

| } | |

| } |

Spam comments get trashed, so don’t bother. Comment moderation may cause a delay.