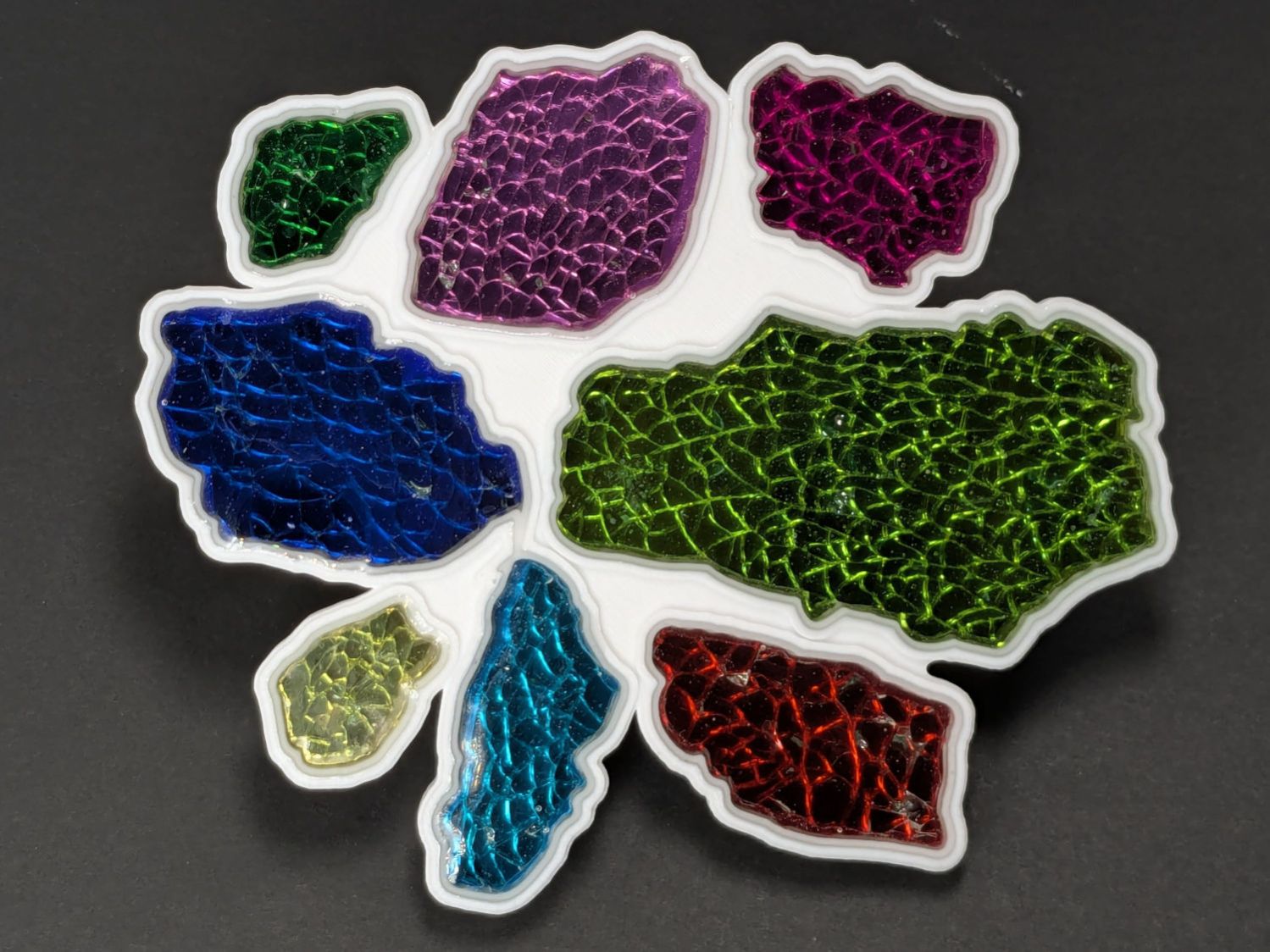

The printed coaster frame sits on a cork base:

A sheet of craft adhesive holds them together; stick a generous rectangle of adhesive on the cork, then cut them at the same time. However, given the irregular perimeter, it’s basically impossible (for me, anyway) to align the cork + adhesive with the printed frame.

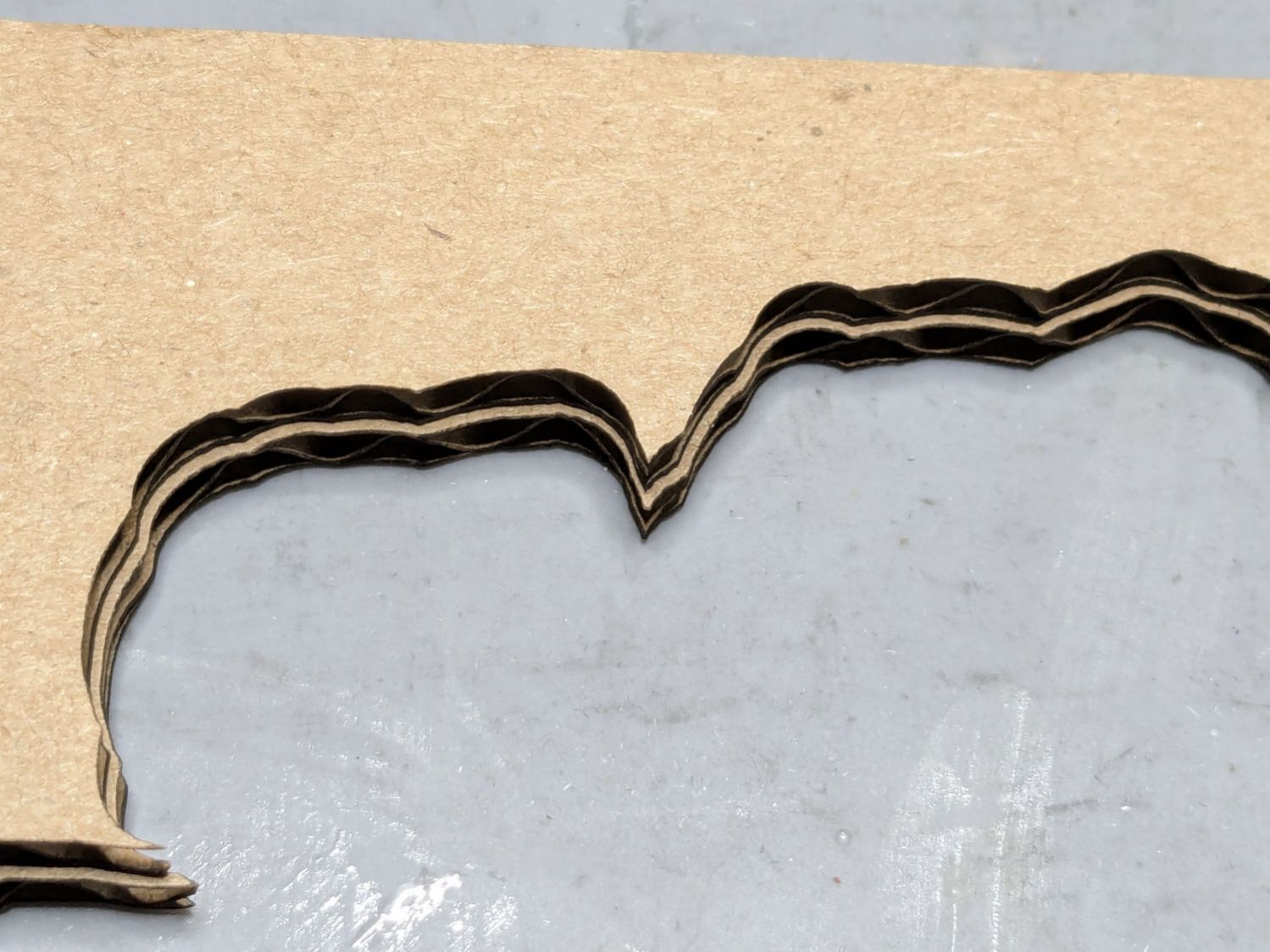

A single-use fixture made from corrugated cardboard make that task trivially easy:

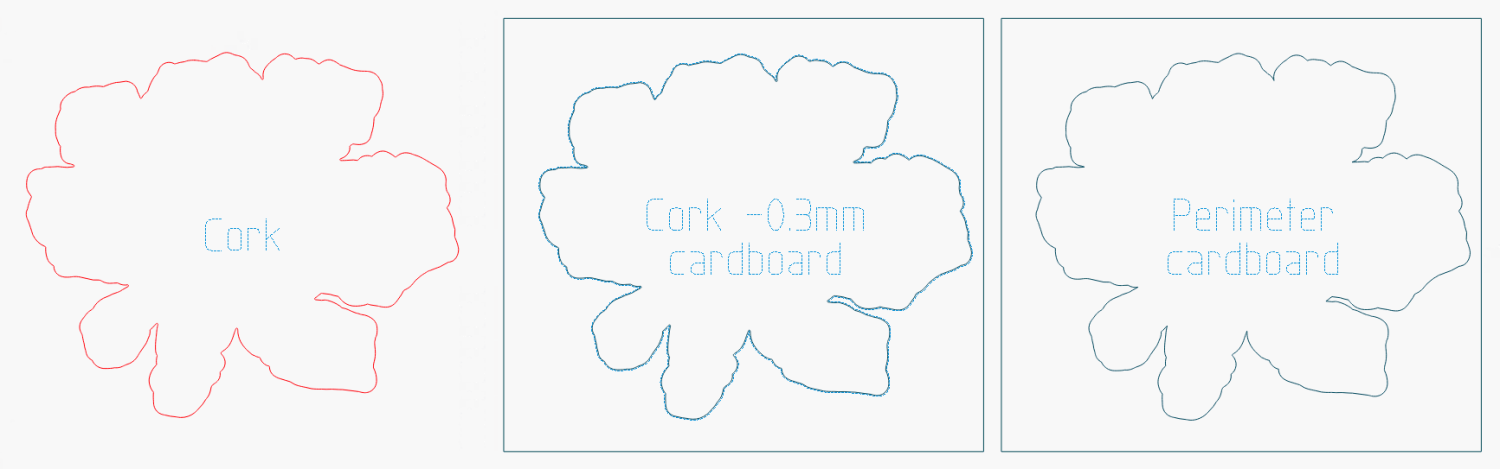

The LightBurn layout shows the cork layer and the two fixture pieces:

The cork shape is offset 0.5 mm inward from the Perimeter shape, but I found offsetting the cardboard cut by only 0.3 mm inward produced a snug fit around the cork. The other piece of cardboard gets cut with the exact Perimeter shape and no offset, with the laser kerf providing just enough clearance for a very snug fit on the printed shape.

Align the two pieces of cardboard by eye to match their inner shapes as shown in the picture, tape them together, and the fixture is ready. In principle, the outer edges should exactly coincide: Trust, but verify.

Peel off the craft adhesive paper and put the cork in the bottom of the fixture. The cork comes off a roll and really wants to roll up again, making the masking tape holding it flat mandatory:

Yes, that’s a different coaster.

Flip the fixture over, drop the coaster in place, press firmly together, peel the tape, and pull out the finished coaster:

The fixture goes in the recycling bin, as those fragments will never pass this way again.

Spam comments get trashed, so don’t bother. Comment moderation may cause a delay.