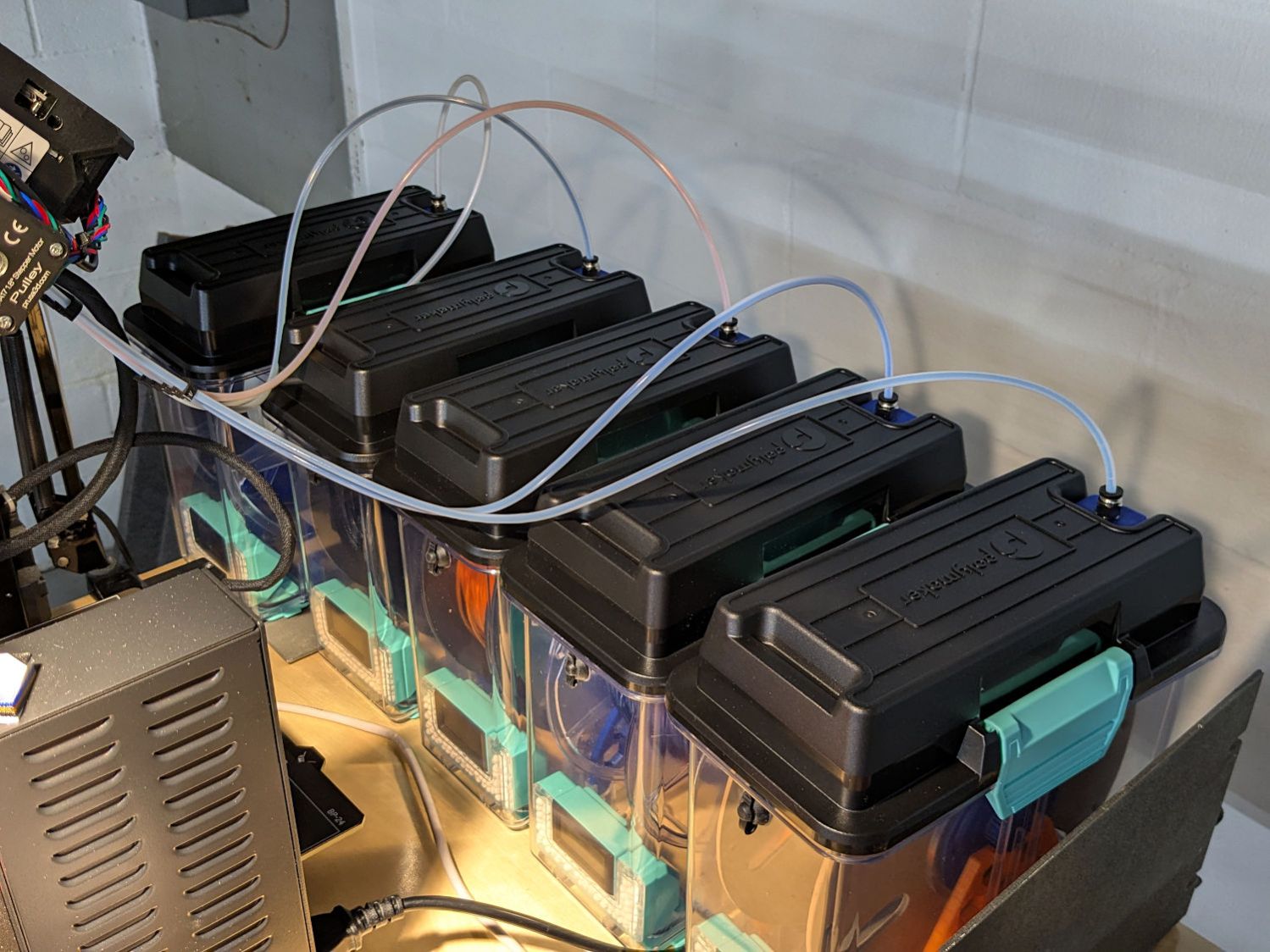

Having recently replaced the MMU3’s filament buffer with Polymaker PolyDryer boxes and auto-rewind spindles:

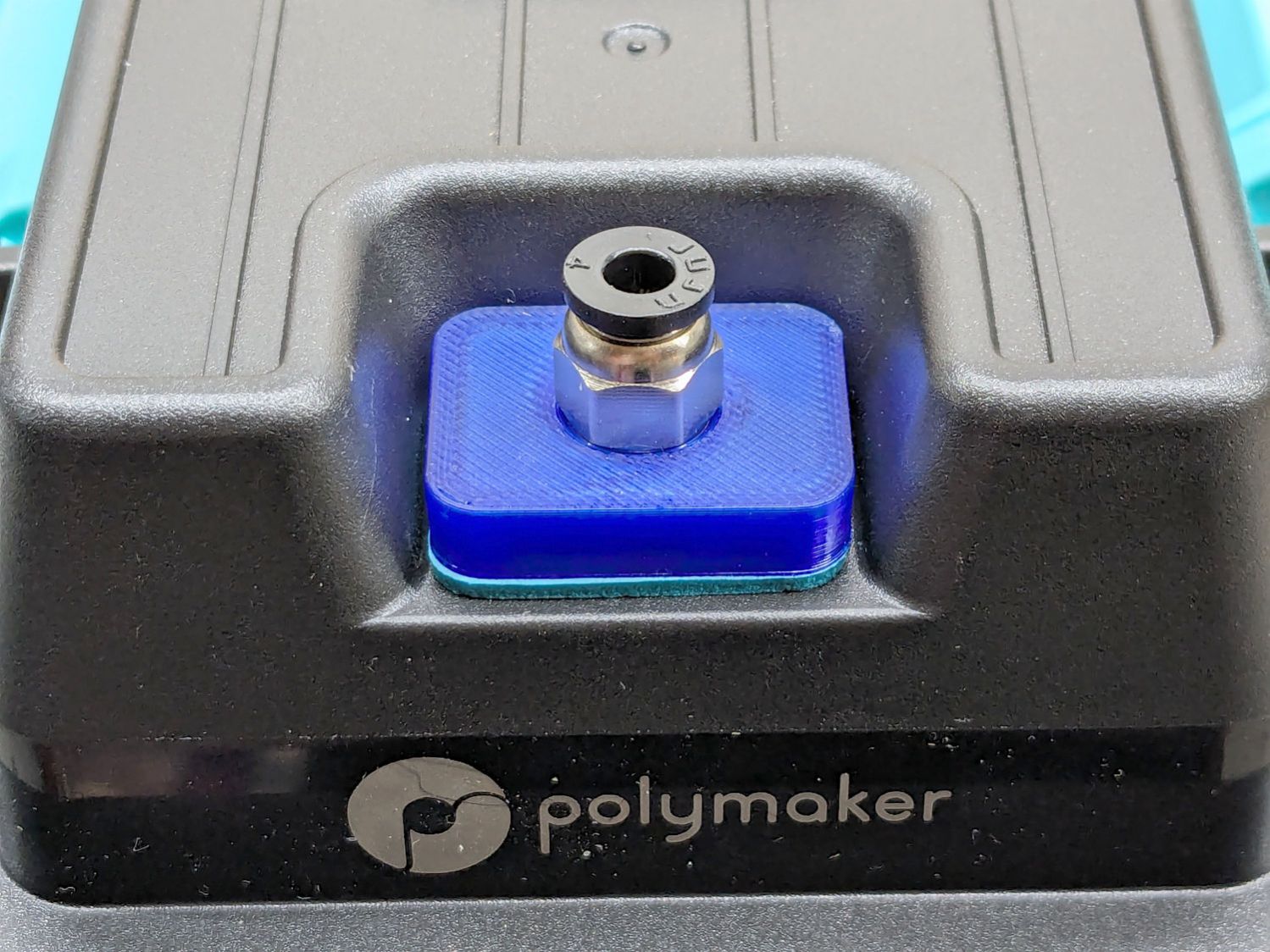

Their rubbery port covers work best with 6 mm OD PTFE tubes, but let the MMU3’s 4 mm tubes slide into / out of the boxes under normal filament extrusion / retraction forces, so I conjured an adapter for PC4-M10 pneumatic fittings:

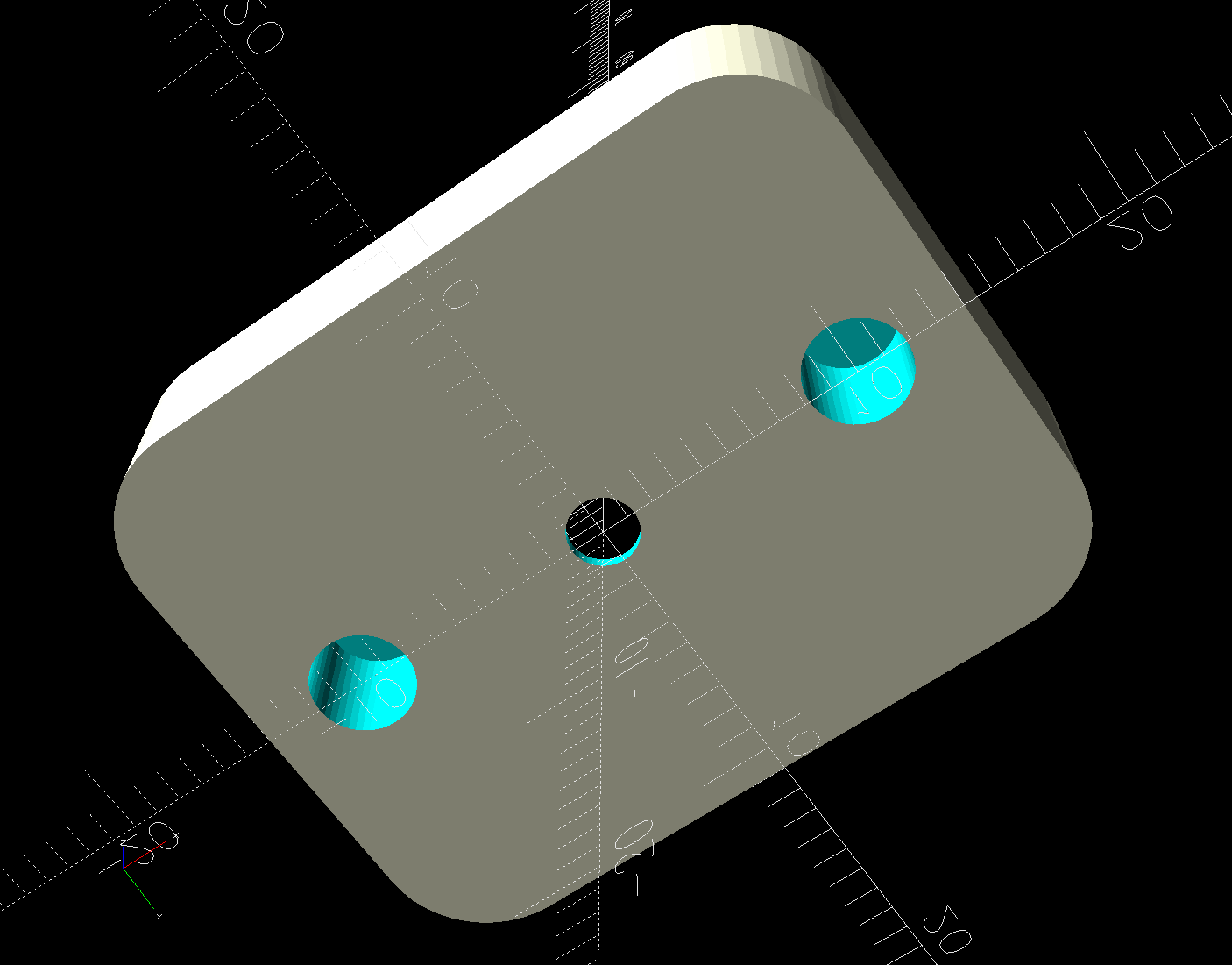

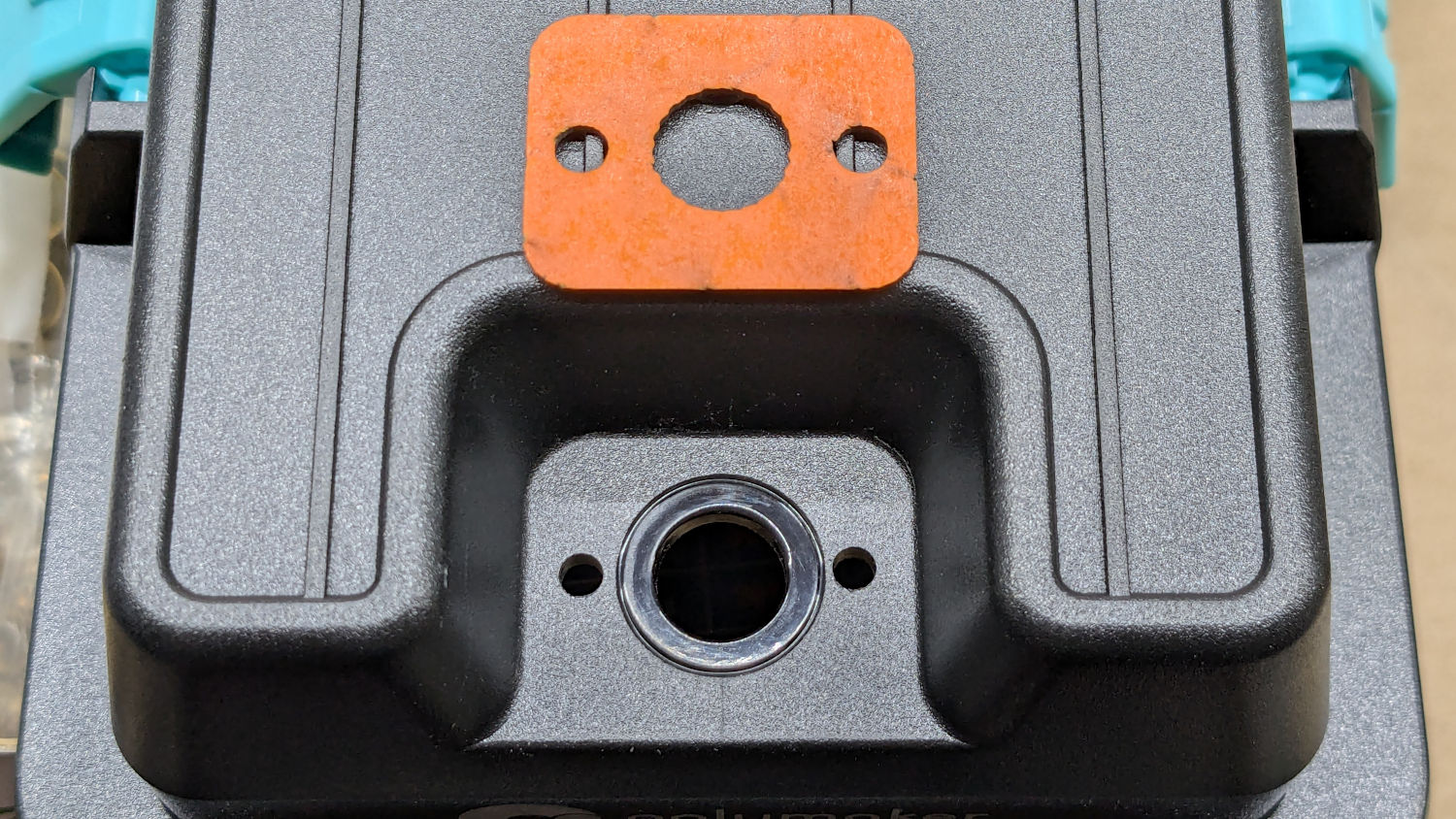

A pair of M3 screws hold the adapter plate in place, with an EVA foam gasket sealing against the cover:

The PC4-M10 fittings let the 4 mm tubing slide right through, so the adapter has a 0.5 mm bottom sheet to block the tube, with a small hole for the filament:

You could use PC4-M6 fittings to block the tubing, but the 2 mm lumen on the fittings I have barely pass 1.75 mm nominal filament. Comments found elsewhere suggest identical PC4-M6 fittings have smaller lumens that snag the filament as it moves in one direction or the other.

The two blind holes get heat-staked 4×4mm M3 brass inserts.

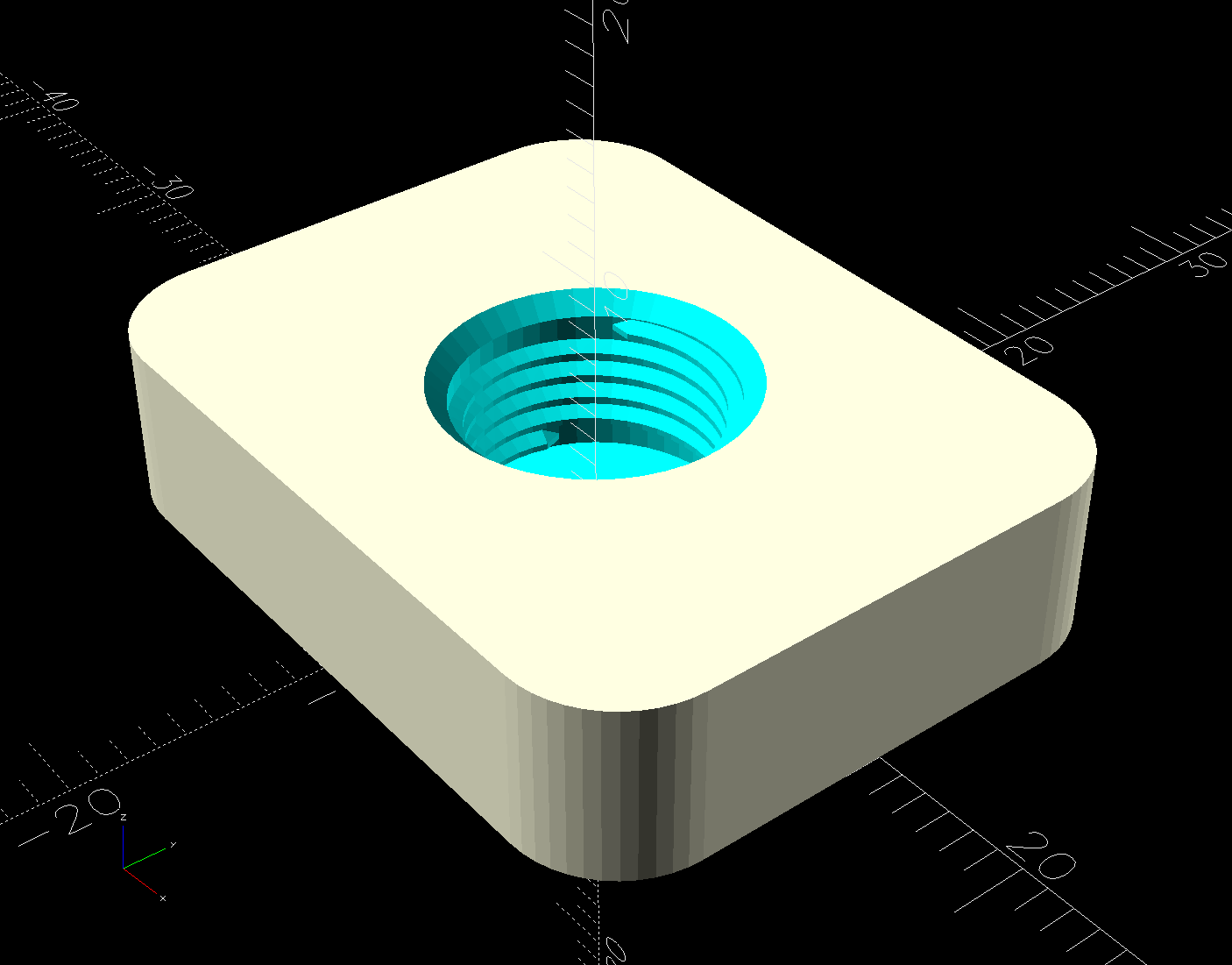

The top has a threaded hole for the fitting:

Despite what the description says, the thread is not an M10 metric straight thread: it is a tapered pipe thread used for gas- and liquid-tight fittings. Considerable measurement & searching suggested a ⅛BSP-28 thread, because:

- British Standard Pipe threads are used everywhere in the world except the USA

- Both my metric tap sets have a ⅛BSP-28 tap along with all their hard-metric straight taps

The thread is painfully close to ⅛NPT-27, which would probably work in a pinch if it was the only tap you had.

Those PC4-M6 fittings might sport 1/16BSP-28 threads, but you’re on your own.

Further searching suggests nobody uses the corresponding tapered female pipe threads and everybody goes with a straight internal thread, so I conjured a stumpy threaded rod using the BOSL2 library and removed it from the adapter plate:

threaded_rod(d=9.7,l=ThreadLength + Protrusion,pitch=INCH/28,internal=true,bevel2=true,anchor=BOTTOM);

The 9.7 mm diameter is the ⅛BSP-28 “major diameter”, rather than its “gauge diameter”, simply because it produced a good fit. The beveled top guides the fitting into the hole, but I still managed to cross-thread one.

The OpenSCAD code also produces SVG files to laser-cut the foam gasket and a drill template:

The holes were step-drilled to ⅛ inch (which has a historic relation to the ⅛BSP-28 size, because iron pipe) for a generous fit around the M3 screws.

That was way more complicated than I expected and I’m really glad to live in the future where this is a 3D printer project, not a metalworking project involving an actual tap in, say, steel.

The OpenSCAD source code as a GitHub Gist:

| // PC4 Fitting Plates for PolyDryer | |

| // Ed Nisley – KE4ZNU | |

| // 2025-05-02 | |

| include <BOSL2/std.scad> | |

| include <BOSL2/threading.scad> | |

| Layout = "Plate"; // [Plate,Gasket,DrillGuide] | |

| /* [Hidden] */ | |

| HoleWindage = 0.2; | |

| Protrusion = 0.1; | |

| NumSides = 3*3*4; | |

| Gap = 5.0; | |

| TubeStop = 0.5; // prevent PTFE tube from sliding through | |

| ThreadLength = 6.0; | |

| PlateOA = [28.0,22.0,ThreadLength + TubeStop]; | |

| ScrewOC = 20.0; | |

| $fn=4*3*4; | |

| //———- | |

| // Define it | |

| module Plate() { | |

| difference() { | |

| cuboid(PlateOA,anchor=BOTTOM,rounding=4.0,edges="Z"); // plate to fit PolyDryer | |

| up(TubeStop) // thread for fitting | |

| threaded_rod(d=9.7,l=ThreadLength + Protrusion,pitch=INCH/28,internal=true,bevel2=true,anchor=BOTTOM); | |

| down(Protrusion) | |

| for (i = [-1,1]) | |

| right(i*ScrewOC/2) | |

| cylinder(4.5 + TubeStop + Protrusion,d=3.7,anchor=BOTTOM); // M3 4×4 inserts | |

| down(Protrusion) | |

| cylinder(2*TubeStop,d=2.5,anchor=BOTTOM); // filament clearance | |

| } | |

| } | |

| //———- | |

| // Build things | |

| if (Layout == "Plate") | |

| Plate(); | |

| if (Layout == "Gasket") | |

| projection(cut=true) | |

| Plate(); | |

| if (Layout == "DrillGuide") | |

| difference() { | |

| projection(cut=true) | |

| Plate(); | |

| circle(d=10); | |

| } |

Comments

5 responses to “Polymaker PolyDryer Box: PC4 Fitting Adapter”

I think those two references to BSP-27 (rather than 28) are typos?

I have some Yanmar diesel engines in my life with BSPT ports. Everyone shoves NPT connections into them. The results in cast iron are … not nice.

Good catch: thanks!

Just reading the Wikipedia articles was enough to knock me right out: So. Many. Standards.

[…] auto-rewind spindles for PolyDryer boxes fit a variety of spools, but recessed hubs like this require a pair of washers to center the […]

[…] TPU to the stable called for better humidity control, so I set up a bunch of PolyMaker PolyDryer boxes with Auto-rewind […]

[…] recent pair of boxes (intended to simplify changing the desiccant in the collection feeding the MMU3 atop the Prusa MK4 3D printer) produced […]