The Handi-Quilter HQ Sixteen rides on two tracks along the 11 foot length of the table, with an unsupported 8 foot span between the legs on each end:

Contemporary versions of the table have support struts in the middle that our OG version lacks and, as a result, our table had a distinct sag in the middle. During the course of aligning the table top into a plane surface with tapered wood shims, I discovered the floor was half an inch out of level between the table legs.

Now that the whole thing has settled into place, I measured the shim thicknesses and made tidy blocks to replace them:

The OpenSCAD code has an array with the thickness and the number of blocks:

SHIM_THICK = 0;

SHIM_COUNT = 1;

Shims = [

[3.5,1],

[5.0,3],

[6.0,2],

[6.5,1],

[7.0,1]

];

Yes, I call them “blocks” here and wrote “shims” in the code. A foolish consistency, etc.

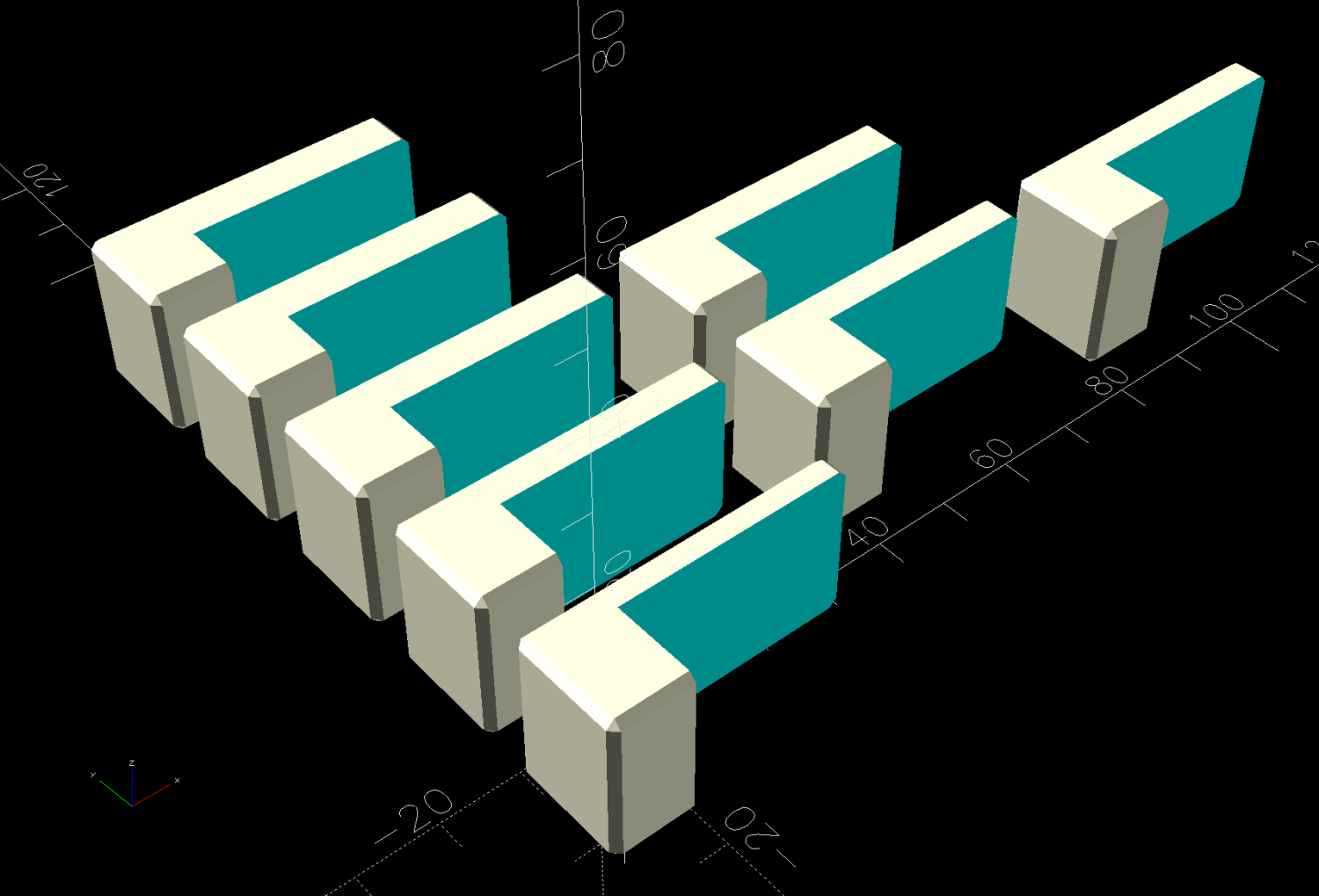

The model is a chamfered block with a chunk removed to leave a tongue of the appropriate thickness:

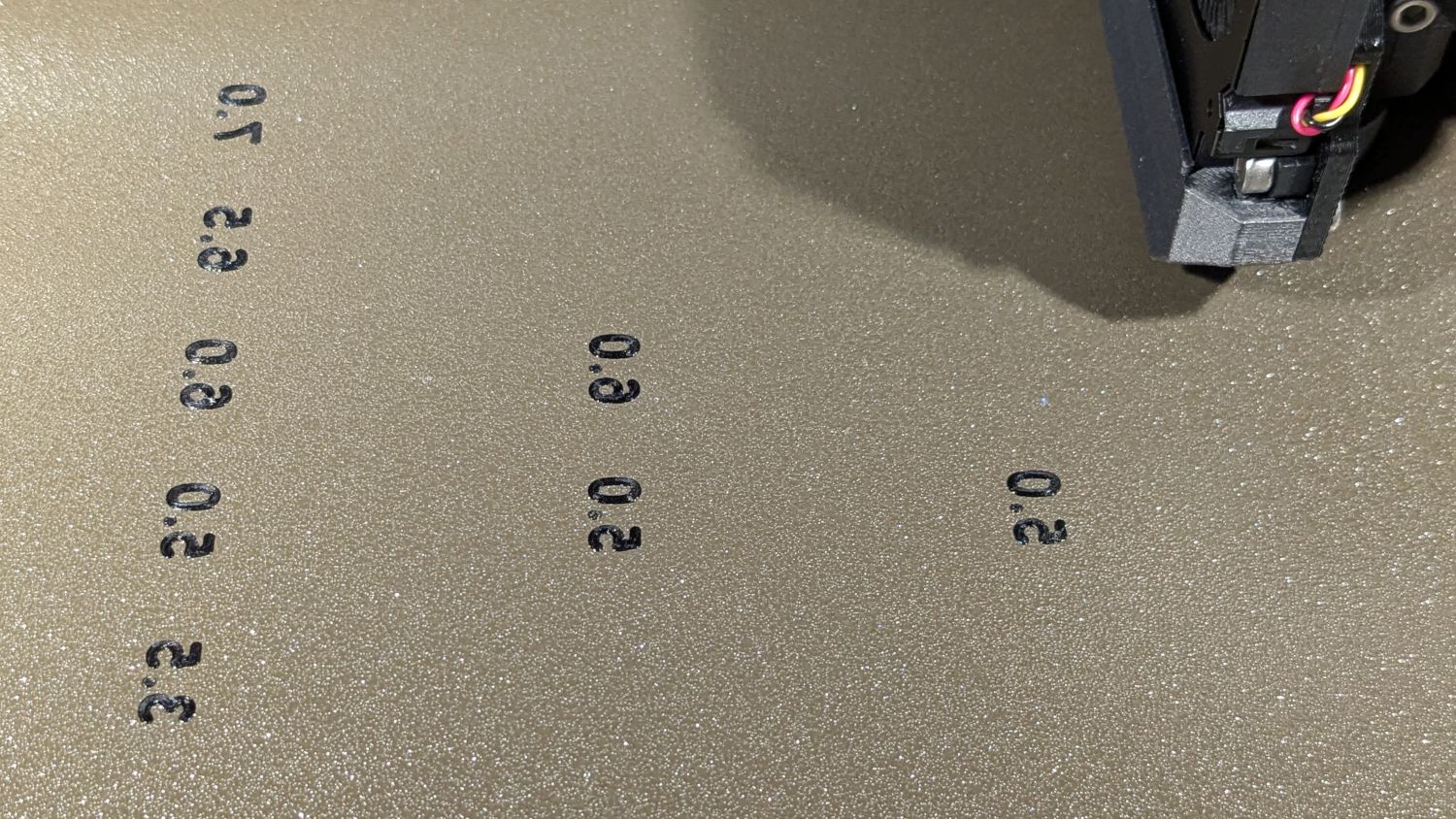

Building them with the label against the platform produces a nice nubbly surface:

The labels print first and look lonely out there by themselves:

The rest of the first layer fills in around the labels:

Putting the labels on the bottom makes the wipe tower only two layers tall and eliminates filament changes above those layers. Those eight blocks still took a little over three hours, because there’s a lot of perimeter wrapped around not much interior.

Having had the foresight to draw a sketch showing where each block would go, I slid one next to its wood shim, yanked the shim out, and declared victory:

The tension rod welded under the table rail prevents even more sag, but the struts under the new version of the table show other folks were unhappy with the sag of this one. Another leg or two seems appropriate.

With the table leveled and the surface aligned, the HQ Sixteen glides easily in all directions. The result isn’t perfect and Mary keeps the anchor block at hand, but the machine now displays much less enthusiasm for rolling toward the middle of the table.

The OpenSCAD source code as a GitHub Gist:

| // HQ Sixteen – table shims | |

| // Ed Nisley – KE4ZNU | |

| // 2025-02-27 | |

| include <BOSL2/std.scad> | |

| Layout = "Show"; // [Show,Build] | |

| /* [Hidden] */ | |

| SHIM_THICK = 0; | |

| SHIM_COUNT = 1; | |

| Shims = [ | |

| [3.5,1], | |

| [5.0,3], | |

| [6.0,2], | |

| [6.5,1], | |

| [7.0,1] | |

| ]; | |

| Block = [40.0,20.0,15.0]; // overall shim size | |

| Grip = 10.0; // … handle length | |

| BlockRadius = 1.0; // corner rounding / chamfer | |

| LabelThick = 0.4; | |

| LabelSize = 5.5; | |

| LabelFont = "Arial:style:Bold"; | |

| LabelColor = "Red"; | |

| Protrusion = 0.1; | |

| Gap = 5.0; | |

| //———- | |

| // Define shim shape | |

| module ShimBlock(Height = Shims[0][SHIM_THICK],Part="All") { | |

| if (Part == "Block" || Part == "All") | |

| difference() { | |

| left(Grip) | |

| cuboid(Block,anchor=BOTTOM + LEFT,chamfer=BlockRadius); | |

| up(Height) | |

| cube(Block + 2*[Protrusion,Protrusion,0],anchor=BOTTOM + LEFT); | |

| left(Grip/2 – BlockRadius/2) fwd(Block.y/2 – LabelThick) up(Block.z/2) | |

| xrot(90) zrot(-90) | |

| linear_extrude(height=LabelThick + Protrusion,convexity=20) | |

| text(text=format_fixed(Height,1),size=LabelSize,spacing=1.00, | |

| font=LabelFont,halign="center",valign="center"); | |

| } | |

| if (Part == "Text" || Part == "All") | |

| color(LabelColor) | |

| left(Grip/2 – BlockRadius/2) fwd(Block.y/2 – LabelThick) up(Block.z/2) | |

| xrot(90) zrot(-90) | |

| linear_extrude(height=LabelThick,convexity=20) | |

| text(text=format_fixed(Height,1),size=LabelSize,spacing=1.00, | |

| font=LabelFont,halign="center",valign="center"); | |

| } | |

| //———- | |

| // Build them all | |

| if (Layout == "Show") | |

| ShimBlock(); | |

| if (Layout == "Build") { | |

| for (j=[0:len(Shims)-1]) | |

| back(j*(Block.z + Gap)) | |

| for (i=[0:(Shims[j][SHIM_COUNT] – 1)]) | |

| right(i*(Block.x + Gap)) | |

| up(Block.y/2) xrot(90) | |

| ShimBlock(Shims[j][SHIM_THICK],Part="Block"); | |

| for (j=[0:len(Shims)-1]) | |

| back(j*(Block.z + Gap)) | |

| for (i=[0:(Shims[j][SHIM_COUNT] – 1)]) | |

| right(i*(Block.x + Gap)) | |

| up(Block.y/2) xrot(90) | |

| ShimBlock(Shims[j][SHIM_THICK],Part="Text"); | |

| } | |

Comments

3 responses to “HQ Sixteen: Table Leveling Blocks”

[…] feet for the HQ Sixteen long-arm machine’s table for the high side of the […]

[…] devoted considerable effort to smoothing the HQ Sixteen’s path across the table, with commensurate improvement, Mary reported the […]

[…] higher speeds as Mary practices using its stitch regulator and the vibrations shook several of the table shims (blocks, whatever) onto the floor. I hope a layer of EVA foam provides enough compliance to keep […]