The garden hose leading from the standpipe / hose bibs outside Mary’s garden to her drip irrigation plumbing has an octagonal fitting requiring more torque than her hand can easily produce. I offered to make a larger grip for the fitting, which amounts to a disk with a grippy rim sized to her hand and an interior opening suitable for gluing to the fitting.

A couple of laser-cut MDF sizing prototypes accompanied me to the garden:

The springy fingers around the fitting soak up the inevitable distortions found in a battered hose and will eventually be filled with adhesive to lock the grip in place.

MDF being obviously the wrong material for a permanent installation, the final grip will be 3D printed, with the LightBurn layout modified to produce the internal structure:

From left to right:

- The stacked pieces in order of printing

- Main grip with springy fingers

- Spacer keeping the fingers away from the narrower opening

- Support layer

- Narrow opening to align the grip with the end of the fitting

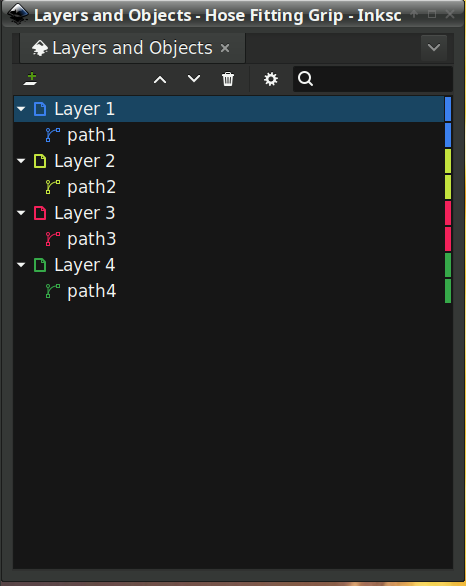

Exporting the SVG images and making a bank shot off Inkscape to create layer names:

The ascending layer name + numbers allow a simple OpenSCAD program to extract the SVG shapes by name, extrude them to the proper thickness, put them at the proper height, then combine the result:

Recenter = [-140,-108,0];

Thick = [0,8.0,1.0,0.2,1.0];

Level = [0,

Thick[1],

Thick[1]+Thick[2],

Thick[1]+Thick[2]+Thick[3],

Thick[1]+Thick[2]+Thick[3]+Thick[4]];

Colors = ["Black","Red","Gray","Yellow","Green"];

union()

for (i = [1:len(Thick)-1]) {

color(Colors[i])

translate(Recenter + [0,0,Level[i-1]])

linear_extrude(height=Thick[i],convexity=10)

import("/mnt/bulkdata/Project Files/Laser Cutter/Gardening/Hose Fitting Grip/Hose Fitting Grip - Inkscape layout.svg",

layer=str("Layer ",i));

}

The hideous mess generating the Level vector happens because OpenSCAD does not have mutable variables and I hate retyping numbers. One can use a recursive function to add the values, but copypasta makes more sense in this case.

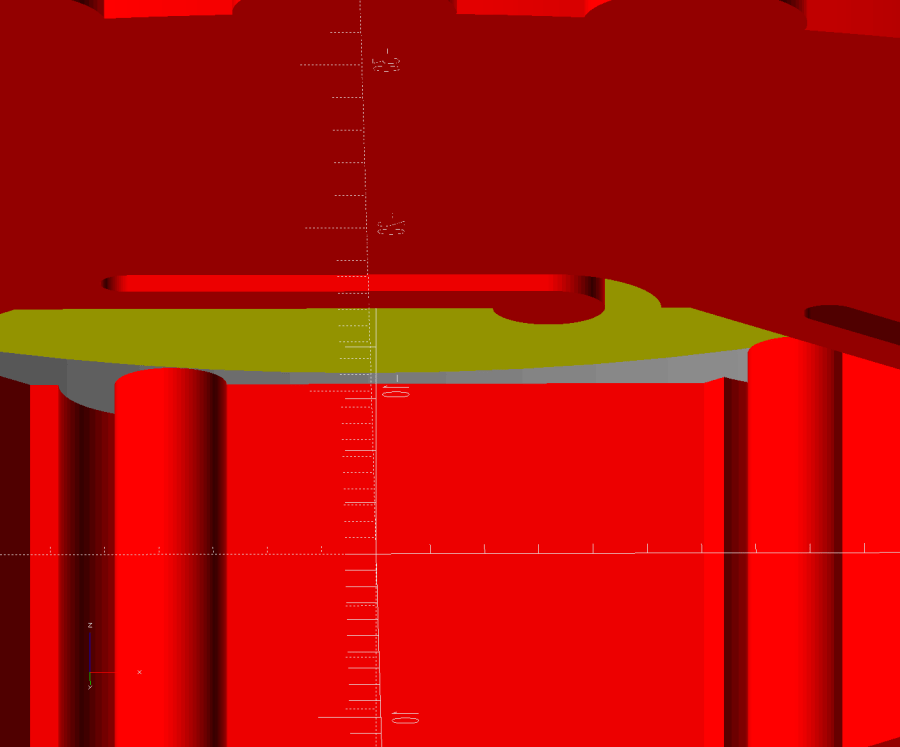

Which produces this solid model, with garish colors for pedagogic purposes:

The thin yellow band will be one thread thick to provide support for the green layer with a smaller ID than the springs below it. The gray layer below the yellow is the air gap above the springs.

Peering inside the bottom shows the (gray) layer providing clearance between the springs and the (yellow) support layer:

Exporting the model as a 3mf file, importing it into PrusaSlicer, and slicing it with suitable parameters (Extrusion Multipler = 0.8) does what you’d expect. This top view shows the internal structure just below the support bridge across the middle:

Printing it in gray PETG-CF was uneventful, with the bridging layer coming out surprisingly well:

The springs definitely have an air gap in there:

And the support layer cuts out neatly with an Xacto knife:

We’ve had enough rain over the last few days (something to do with a continental-scale storm) to keep me and my adhesives out of the garden, but it hasn’t needed any watering, either.

Comments

4 responses to “Garden Hose Fitting Grip: MVP”

I recently did something similar :

https://www.thingiverse.com/thing:6710730

Using a heat gun to make it fit is great!

Your knobs look more finger-friendly than mine …

One of the hose companies did that in the late ’90s for several years. The OEM version with black plastic is still in service, while the cheapenified one with uncolored plastic had the grip die from UV exposure.

I like the slightly oversized aluminum ends on some of the newer hoses. They work well for me.

I used PETG-CF to see how it withstands sunlight: the description says nothing about outdoor survivability.

Of course, I can always make another when it disintegrates.