A new battery for my electrified Tour Easy recumbent arrived. It has newer 21700 lithium cells in the same overall box, but the baseplate requires new blocks adapting it to the frame:

The top profile fits snugly into the battery mounting plate, with clearance on the sides for the latches:

However, I had enough trouble measuring those recesses that I broke down and added a projection() view to the OpenSCAD code:

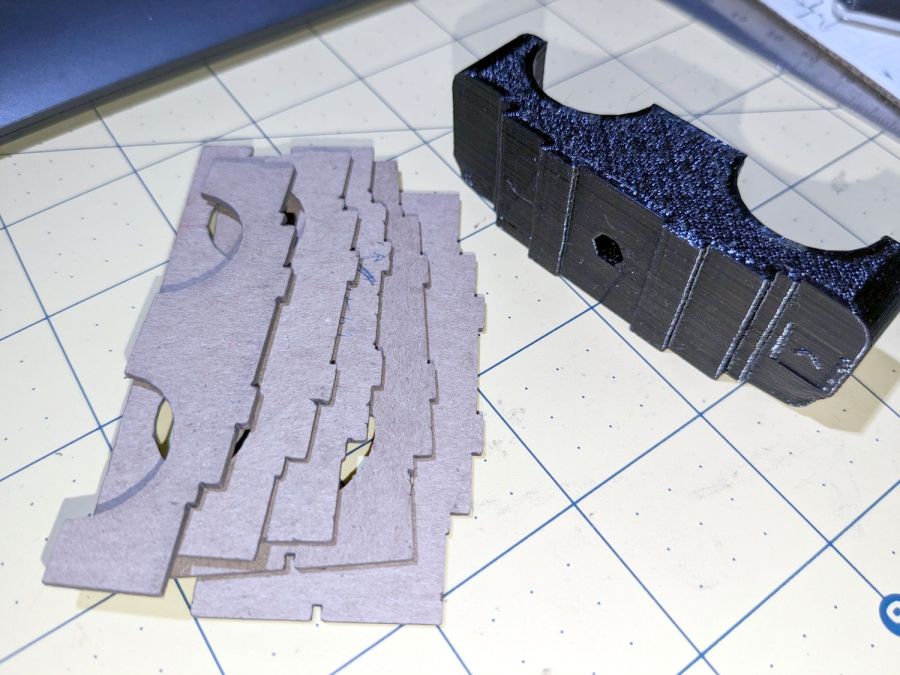

Exporting that as an SVG image and importing it into LightBurn let me cut it out of chipboard:

Obviously, it took several iterations to fit the top profile to the baseplate, particularly after finding slightly different measurements at each block position. On the other paw, laser cutting the profiles proceeded much more quickly than 3D printing just a few millimeters of the block, so it was a net win.

The new battery baseplate doesn’t have an internal space for the buck converter feeding the running lights, so there’s more construction ahead.

Comments

One response to “Laser-cut Profile Test Pieces”

[…] Their top profile matches the bottom of the new battery plate: […]