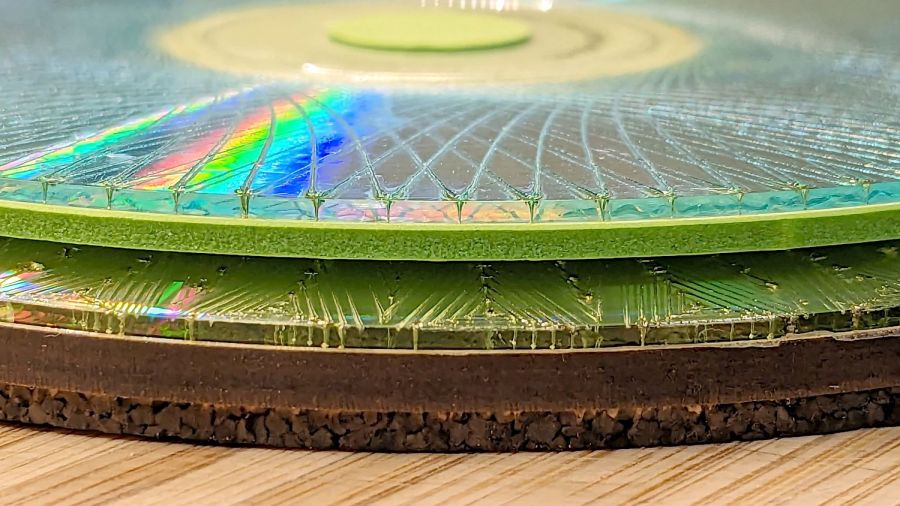

Up to this point, I’d been making coasters with a layer of cork on the bottom, held in place with wood glue (for MDF or plywood tops) or an adhesive sheet (for acrylic or glass). Doing that with a CD produced the bottom coaster:

Although the Mariner’s Compass pattern looks like it extends over the edge, you’re looking through the transparent polycarbonate at the deep pits burned nearly through the entire disc at the corners of the triangles where the laser head slows.

Although the MDF layer makes the coaster exceedingly stiff, it also makes it entirely too thick and much too fiddly to assemble.

The top coaster is a Guilloche-patterned CD stuck to an EVA foam disk with an adhesive sheet. A small foam disk fills the hub hole and, not incidentally, covers the adhesive that would otherwise be exposed:

It’s stiffer than I expected and works well unless the mug / glass / cup has a wet bottom. Alas, the small channels cut into the CD’s surface fill up with the liquid sealing the coaster to the mug, so it sticks firmly and follows the mug upward off the table.

But they’re kinda pretty, inexpensive, and easy to assemble, which counts for something.

Comments

4 responses to “CD / DVD Coasters: Foam vs. Cork Backing”

What about felt for the bottom? Can the grooves be filled with something?

Cute coasters, nice work

From what I’ve read, laser cutting a felt sheet releases the stench of a burning sheep, so that’s out.

An engraved and epoxy-filled Corian coaster might solve the stick-to-the-mug problem, but maybe, just maybe, a laser isn’t the right hammer there, either. :grin:

Thanks for the good words …

How about using scissors to cut the felt? If the felt is less than 1/16 inch thick no too bad, felt from the local sewing supply is even thinner

Ack! Manual labor! The horror!

It’ll be a while before I get back to that project … :grin: