One of Mary’s gardening compadres teaches a kid’s class which involves starting seedlings in “pots” made from the cardboard tubes found in paper towels and toilet paper. Cutting four slits in the bottom of the tube and folding the flaps inward puts a bottom on the pot, but what’s the fun in that?

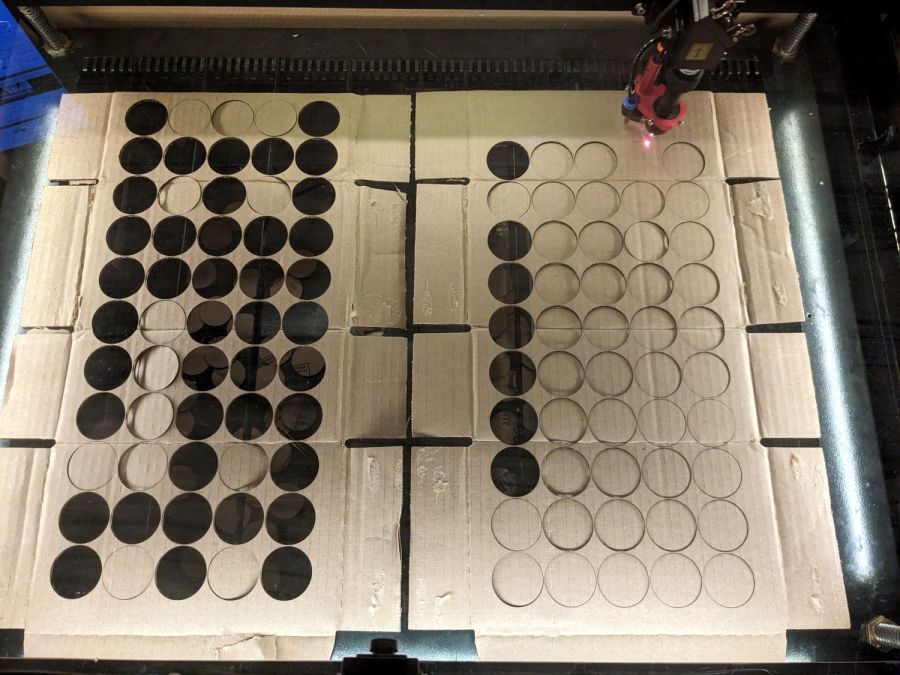

Draw a 42 mm circle, set the layer to cut corrugated cardboard, turn the circle into suitable arrays, flatten some boxes from the heap, and Fire the Laser:

Collect the fallen disks from the chip tray and jam one in place as a serving suggestion, where it fits like it was custom-made:

You’d still want to fold some flaps over the disk to keep it in place, but now your pot has a real bottom.

I have no idea if 42 mm is a Galactic Constant, but it worked for the pile of tubes we had on hand.

That was easy …

Comments

2 responses to “Seedling Starter Pot Bottoms”

Never occurred to me that a consumer level Chinese laser can cut useful parts out of packaging grade corrugated cardboard.

So all the things people cut out of plywood and acrylic, drawer dividers, custom enclosures, air, ducts, etc., a consumer grade laser can cut the same out of waste cardboard? With larger tabs and accounting for structural differences but still? Is there a tutorial you could link to that specifically addresses this?

By and large, a CO₂ laser can cut a sheet of pretty nearly any mostly-organic (in the carbon-based lifeform sense, rather than the wholesome veggie sense) stuff, modulo quibbles about health / safety / flammability.

I treat corrugated cardboard like any other material: run a few tests to find the right speed / power settings, then have at it.

One quirk: the corrugations fill up with smoke, so let the parts air out for a couple of days before using it in a critical (i.e. spouse-adjacent) application.