Going through the LightBurn lens calibration and camera alignment routine produces an orthographic view of the laser platform from a camera with an ordinary lens perched somewhere above it.

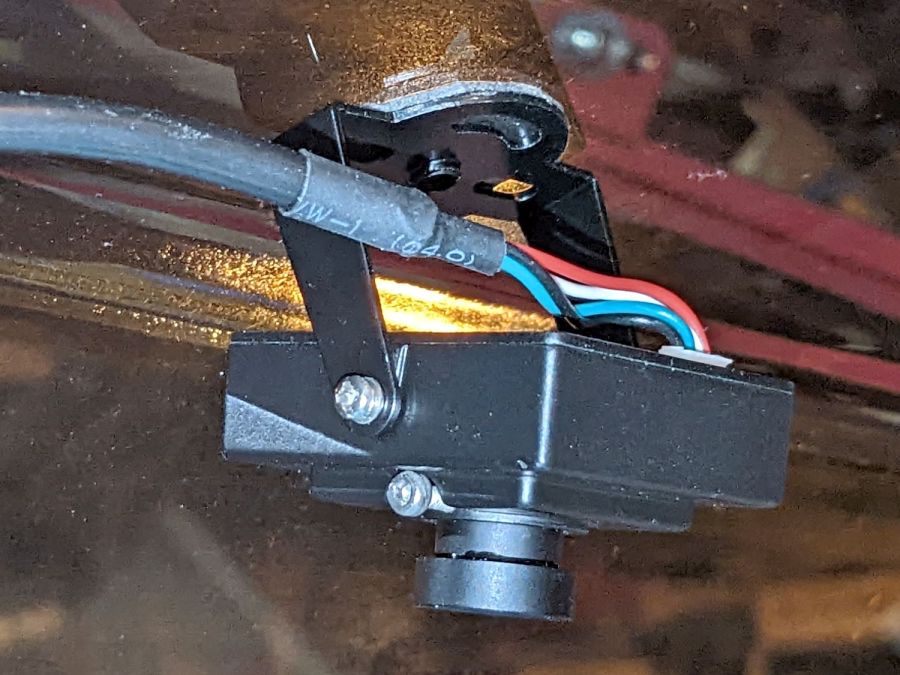

Early on, I stuck a camera to the lid of my OMTech 60 W laser:

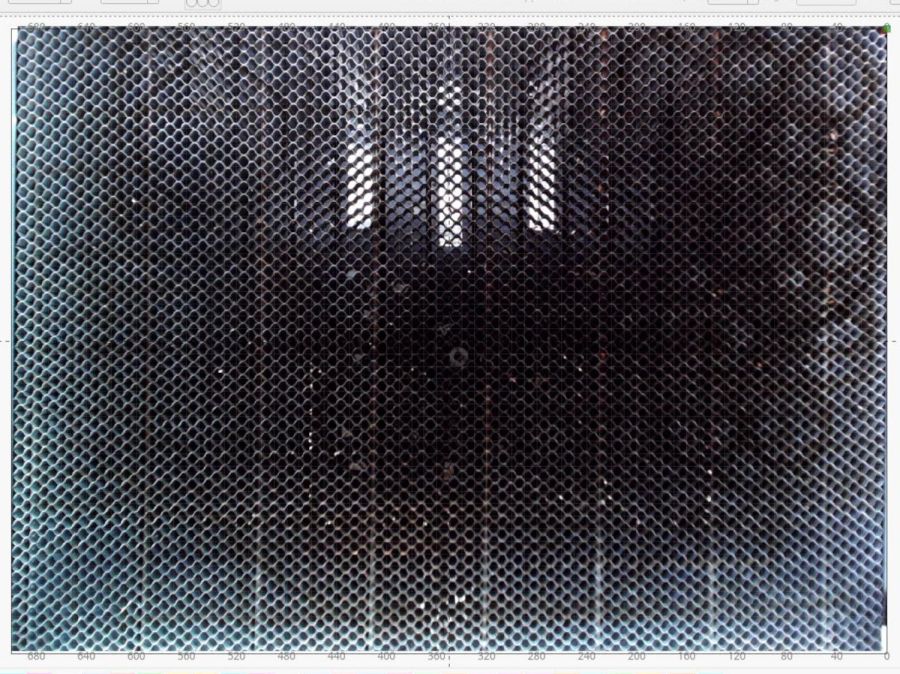

The uncorrected view from the camera (through VLC):

After calibration and alignment, LightBurn underlays this view of the platform behind the workspace:

The correction depends critically on the camera maintaining its position / orientation / focus, which turns out to be a bad assumption for the camera I’ve been using, because the (metal) focus locking screw binds directly on the (metal) lens threads. This works, until vibrations slightly loosen the screw and the lens shifts ever so slightly.

After noticing the focus had shifted again, I tucked a snippet of silicone insulation from some 30 AWG hookup wire into the screw hole to compress against the lens thread, then re-did the entire sequence with some attention to detail.

Pulsing the laser in each corner produced pinholes exactly 700×500 mm apart. One diagonal is 859.0 mm and the other is 861.5 mm, pretty close to the ideal 860.2 mm.

Next, to measure the offsets from some known positions …

Comments

One response to “Laser Cutter: LightBurn Camera Calibration”

[…] going through the LightBurn camera alignment / calibration process, I thought it would be interesting to see how well the corrected image matches the design […]