A slide rule needs a cursor with a hairline to align numbers on its scales:

The GCMC code generating the hairline is basically a move scratching one line into the surface with the diamond bit:

feedrate(ScaleSpeed);

goto([-,-,TravelZ]);

repeat(2) {

goto([DeckTopOD/2 - 3*ScaleHeight,0,-]);

move([-,-,EngraveZ]);

move([DeckBottomOD/2 + ScaleHeight,0,-]);

goto([-,-,TravelZ]);

}

Two passes make the scratch deep enough to hold engraving crayon / lacquer / ink, without making it much wider. Laser engraving would surely work better.

In lieu of actually milling the cursor, this code scratches the perimeter:

local dr = DeckBottomOD/2;

local hr = CursorHubOD/2;

local a = atan(hr - CursorTipWidth/2,dr); // rough & ready approximation

local p0 = hr * [sin(a),cos(a),-]; // upper tangent point on hub

local c1 = [dr - CursorTipRadius,CursorTipWidth/2 - CursorTipRadius*cos(a),-];

local p1 = c1 + [CursorTipRadius*sin(a),CursorTipRadius*cos(a),-];

local p2 = c1 + [CursorTipRadius,0,-]; // around tip radius

feedrate(KnifeSpeed);

goto([-,-,TravelZ]);

goto([-hr,0,-]);

move([-,-,EngraveZ]);

repeat(3) {

arc_cw(p0,hr);

move(p1);

arc_cw(p2,CursorTipRadius);

move([p2.x,-p2.y,-]);

arc_cw([p1.x,-p1.y,-],CursorTipRadius);

move([p0.x,-p0.y,-]);

arc_cw([-hr,0,-],hr);

}Three passes makes it deep enough to snap along the line:

If you look closely, though, you’ll find a little divot over on the left along the bottom edge, so I really must machine the thing.

Were I to go into production, I’d have to figure out a fixture, but I think I can just clamp a rough-cut acrylic rectangle to the Sherline’s table, mill half the perimeter, re-clamp without moving anything, then mill the other half.

Subtractive machining is such a bother!

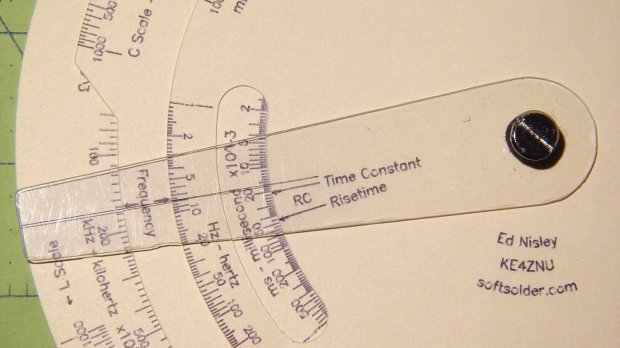

The pivot holding the cursor and decks together is a “Chicago screw“, a.k.a. a “sex bolt“. I am not making this up.

Comments

3 responses to “Tek Circuit Computer: Acrylic Cursor Hairline”

[…] made half a dozen cursors from various bits of acrylic, none of which look particularly good, demonstrates my engraving hand is too weak for a complete […]

[…] a sex bolt works as a central pivot, even the shortest one available in a cheap assortment is too long for […]

[…] tool in the (much better) CNC 3018XL LM6UU holder has engraved mostly plastic, plus a few hard drive platters, and seems only slightly […]