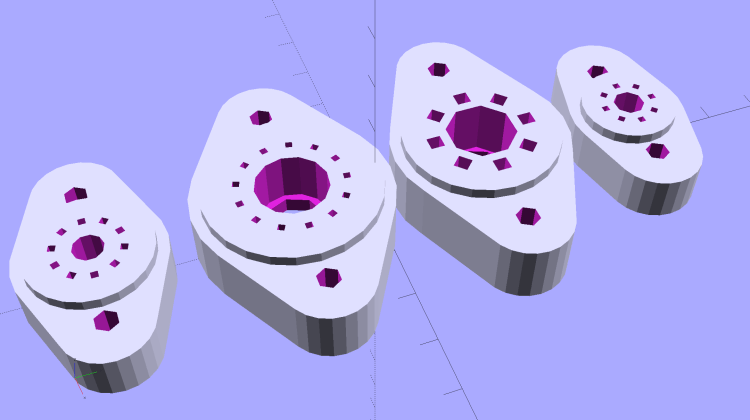

Even vacuum tubes destined to be decorations need sockets:

They’re entirely plastic, of course, but they match the dimensions of “real” tube sockets pretty closely. The bosses around the pins have hard-inch dimensions, so you (well, I) can unleash Genuine Greenlee Radio Chassis Punches on sheet metal.

All the key dimensions come from a table, so you can build whatever sockets you need. These four seem to cover the most common relics of the Hollow State Empire:

T_NAME = 0; // common name

T_NUMPINS = 1; // total, with no allowance for keying

T_PINBCD = 2; // tube pin circle diameter

T_PINOD = 3; // ... diameter

T_PINLEN = 4; // ... length (overestimate)

T_HOLEOD = 5; // nominal panel hole from various sources

T_PUNCHOD = 6; // panel hole optimized for inch-size Greenlee punches

T_TUBEOD = 7; // envelope or base diameter

T_PIPEOD = 8; // light pipe from LED to tube base

T_SCREWOC = 9; // mounting screw holes

// Name pins BCD dia length hole punch env pipe screw

TubeData = [

["Mini7", 8, 9.53, 1.016, 7.0, 16.0, 11/16 * inch, 18.0, 5.0, 22.5],

["Octal", 8, 17.45, 2.36, 10.0, 36.2, (8 + 1)/8 * inch, 32.0, 11.5, 39.0],

["Noval", 10, 11.89, 1.1016, 7.0, 22.0, 7/8 * inch, 21.0, 5.0, 28.0],

["Duodecar", 13, 19.10, 1.05, 9.0, 32.0, 1.25 * inch, 38.0, 12.5, 39.0],

];

Given that the tubes lack electrical connections, I omitted the base keying: plug them in for best visual effect.

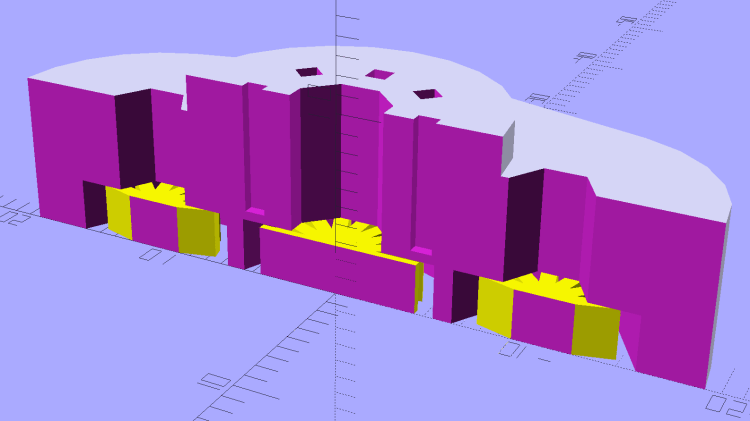

The hole through the middle passes light from a knockoff Neopixel on a 10 mm OD PCB:

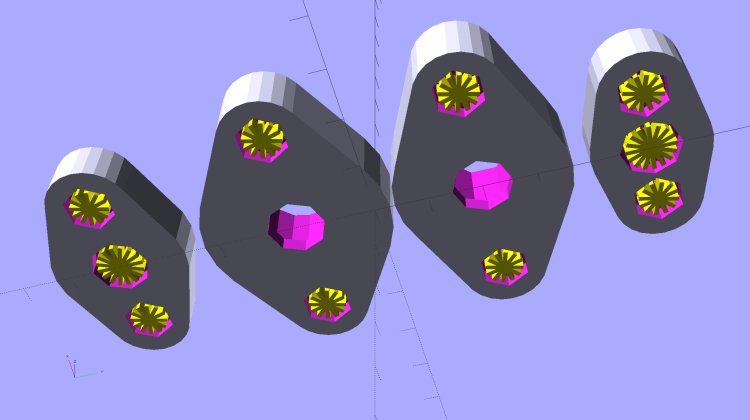

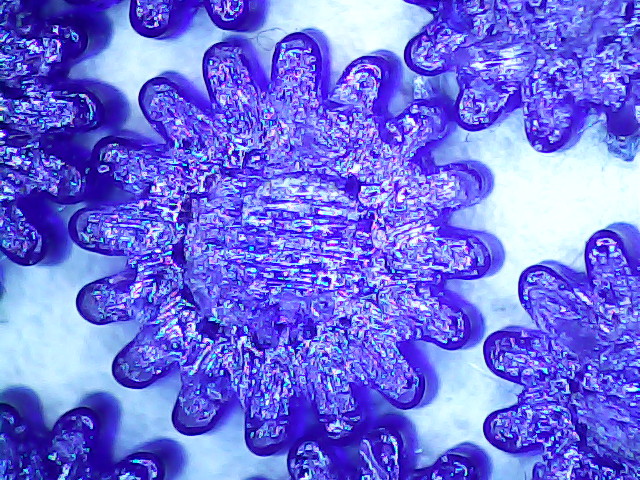

Seen from the bottom, each base traps a pair of 6-32 nuts for chassis mounting and has a Neopixel press-fit in the middle:

Those recesses require support structures:

The Miniature 7-pin socket has the least space for the 10 mm OD Neopixel PCB and shows the thin layer between the bottom of the pin holes and the top of the openings.

You see half of the eight holes in the “7 pin” socket, because it has the eighth hole where a standard socket has a gap between pins 1 and 7.

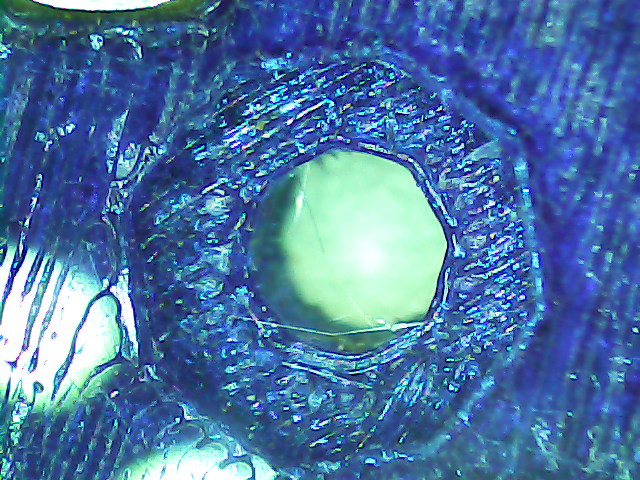

Somewhat to my surprise, punching the support spiders out with a 6-32 stud (grabbed in the drill press) worked perfectly:

They look like I intended to build tiny decorations:

The cookies held on tenuously, then released with a loud bang! as I gradually increased the pressure. A PETG support structure in a blind recess wouldn’t pop out nearly so well.

The OpenSCAD source code as a GitHub gist:

| // Vacuum Tube LED Lights | |

| // Ed Nisley KE4ZNU January 2016 | |

| Layout = "Sockets"; // Cap LampBase USBPort Socket(s) | |

| Section = true; // cross-section the object | |

| Support = true; | |

| //– Extrusion parameters must match reality! | |

| ThreadThick = 0.25; | |

| ThreadWidth = 0.40; | |

| HoleWindage = 0.2; | |

| Protrusion = 0.1; // make holes end cleanly | |

| inch = 25.4; | |

| function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); | |

| //———————- | |

| // Dimensions | |

| // https://en.wikipedia.org/wiki/Tube_socket#Summary_of_Base_Details | |

| T_NAME = 0; // common name | |

| T_NUMPINS = 1; // total, with no allowance for keying | |

| T_PINBCD = 2; // tube pin circle diameter | |

| T_PINOD = 3; // … diameter | |

| T_PINLEN = 4; // … length (overestimate) | |

| T_HOLEOD = 5; // nominal panel hole from various sources | |

| T_PUNCHOD = 6; // panel hole optimized for inch-size Greenlee punches | |

| T_TUBEOD = 7; // envelope or base diameter | |

| T_PIPEOD = 8; // light pipe from LED to tube base | |

| T_SCREWOC = 9; // mounting screw holes | |

| // Name pins BCD dia length hole punch env pipe screw | |

| TubeData = [ | |

| ["Mini7", 8, 9.53, 1.016, 7.0, 16.0, 11/16 * inch, 18.0, 5.0, 22.5], | |

| ["Octal", 8, 17.45, 2.36, 10.0, 36.2, (8 + 1)/8 * inch, 32.0, 11.5, 39.0], | |

| ["Noval", 10, 11.89, 1.1016, 7.0, 22.0, 7/8 * inch, 21.0, 5.0, 28.0], | |

| ["Duodecar", 13, 19.10, 1.05, 9.0, 32.0, 1.25 * inch, 38.0, 12.5, 39.0], | |

| ]; | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| Pixel = [7.0,10.0,3.0]; // ID = contact patch, OD = PCB dia, LENGTH = overall thickness | |

| Nut = [3.5,8.0,3.0]; // socket mounting nut recess | |

| BaseShim = 2*ThreadThick; // between pin holes and pixel top | |

| SocketFlange = 2.0; // rim around socket below punchout | |

| PanelThick = 2.0; // socket extension through punchout | |

| //———————- | |

| // Useful routines | |

| module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes | |

| Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); | |

| FixDia = Dia / cos(180/Sides); | |

| cylinder(r=(FixDia + HoleWindage)/2,h=Height,$fn=Sides); | |

| } | |

| //———————- | |

| // Tube cap | |

| CapTube = [4.0,3/16 * inch,10.0]; // brass tube for flying lead to cap LED | |

| CapSize = [Pixel[ID],(Pixel[OD] + 3.0),(CapTube[OD] + 2*Pixel[LENGTH])]; | |

| CapSides = 6*4; | |

| module Cap() { | |

| difference() { | |

| union() { | |

| cylinder(d=CapSize[OD],h=(CapSize[LENGTH]),$fn=CapSides); // main cap body | |

| translate([0,0,CapSize[LENGTH]]) // rounded top | |

| scale([1.0,1.0,0.65]) | |

| sphere(d=CapSize[OD]/cos(180/CapSides),$fn=CapSides); // cos() fixes slight undersize vs cylinder | |

| cylinder(d1=(CapSize[OD] + 2*3*ThreadWidth),d2=CapSize[OD],h=1.5*Pixel[LENGTH],$fn=CapSides); // skirt | |

| } | |

| translate([0,0,–Protrusion]) // bore for wiring to LED | |

| PolyCyl(CapSize[ID],(CapSize[LENGTH] + 3*ThreadThick + Protrusion),CapSides); | |

| translate([0,0,–Protrusion]) // PCB recess with clearance for tube dome | |

| PolyCyl(Pixel[OD],(1.5*Pixel[LENGTH] + Protrusion),CapSides); | |

| translate([0,0,(1.5*Pixel[LENGTH] – Protrusion)]) // small step + cone to retain PCB | |

| cylinder(d1=(Pixel[OD]/cos(180/CapSides)),d2=Pixel[ID],h=(Pixel[LENGTH] + Protrusion),$fn=CapSides); | |

| translate([0,0,(CapSize[LENGTH] – CapTube[OD]/(2*cos(180/8)))]) // hole for brass tube holding wire loom | |

| rotate([90,0,0]) rotate(180/8) | |

| PolyCyl(CapTube[OD],CapSize[OD],8); | |

| } | |

| } | |

| //———————- | |

| // Aperture for USB-to-serial adapter snout | |

| // These are all magic numbers, of course | |

| module USBPort() { | |

| translate([0,28.0]) | |

| rotate([90,0,0]) | |

| linear_extrude(height=28.0) | |

| polygon(points=[ | |

| [0,0], | |

| [8.0,0], | |

| [8.0,4.0], | |

| // [4.0,4.0], | |

| [4.0,6.5], | |

| [–4.0,6.5], | |

| // [-4.0,4.0], | |

| [–8.0,4.0], | |

| [–8.0,0], | |

| ]); | |

| } | |

| //———————- | |

| // Box for Leviton ceramic lamp base | |

| module LampBase() { | |

| Bottom = 3.0; | |

| Base = [4.0*inch,4.5*inch,20.0 + Bottom]; | |

| Sides = 12*4; | |

| Retainer = [3.5,11.0,1.0]; // flat fiber washer holding lamp base screws in place | |

| StudSides = 8; | |

| StudOC = 3.5 * inch; | |

| Stud = [0.107 * inch, // 6-32 mounting screws | |

| min(15.0,1.5*(Base[ID] – StudOC)/cos(180/StudSides)), // OD = big enough to merge with walls | |

| (Base[LENGTH] – Retainer[LENGTH])]; // leave room for retainer | |

| union() { | |

| difference() { | |

| rotate(180/Sides) | |

| cylinder(d=Base[OD],h=Base[LENGTH],$fn=Sides); | |

| rotate(180/Sides) | |

| translate([0,0,Bottom]) | |

| cylinder(d=Base[ID],h=Base[LENGTH],$fn=Sides); | |

| translate([0,–Base[OD]/2,Bottom + 1.2]) // mount on double-sided foam tape | |

| rotate(0) | |

| USBPort(); | |

| } | |

| for (i = [–1,1]) | |

| translate([i*StudOC/2,0,0]) | |

| rotate(180/StudSides) | |

| difference() { | |

| # cylinder(d=Stud[OD],h=Stud[LENGTH],$fn=StudSides); | |

| translate([0,0,Bottom]) | |

| PolyCyl(Stud[ID],(Stud[LENGTH] – (Bottom – Protrusion)),6); | |

| } | |

| } | |

| } | |

| //———————- | |

| // Tube Socket | |

| module Socket(Name = "Mini7") { | |

| NumSides = 6*4; | |

| Tube = search([Name],TubeData,1,0)[0]; | |

| echo(str("Building ",TubeData[Tube][0]," socket")); | |

| echo(str(" Punch: ",TubeData[ID][T_PUNCHOD]," mm = ",TubeData[ID][T_PUNCHOD]/inch," inch")); | |

| echo(str(" Screws: ",TubeData[ID][T_SCREWOC]," mm =",TubeData[ID][T_SCREWOC]/inch," inch OC")); | |

| OAH = Pixel[LENGTH] + BaseShim + TubeData[Tube][T_PINLEN]; | |

| BaseHeight = OAH – PanelThick; | |

| difference() { | |

| union() { | |

| linear_extrude(height=BaseHeight) | |

| hull() { | |

| circle(d=(TubeData[Tube][T_PUNCHOD] + 2*SocketFlange),$fn=NumSides); | |

| for (i=[–1,1]) | |

| translate([i*TubeData[Tube][T_SCREWOC]/2,0]) | |

| circle(d=2*Nut[OD],$fn=NumSides); | |

| } | |

| cylinder(d=TubeData[Tube][T_PUNCHOD],h=OAH,$fn=NumSides); | |

| } | |

| for (i=[0:(TubeData[Tube][T_NUMPINS] – 1)]) // tube pins | |

| rotate(i*360/TubeData[Tube][T_NUMPINS]) | |

| translate([TubeData[Tube][T_PINBCD]/2,0,(OAH – TubeData[Tube][T_PINLEN])]) | |

| rotate(180/4) | |

| PolyCyl(TubeData[Tube][T_PINOD],(TubeData[Tube][T_PINLEN] + Protrusion),4); | |

| for (i=[–1,1]) // mounting screw holes & nut traps | |

| translate([i*TubeData[Tube][T_SCREWOC]/2,0,–Protrusion]) { | |

| PolyCyl(Nut[OD],(Nut[LENGTH] + Protrusion),6); | |

| PolyCyl(Nut[ID],(OAH + 2*Protrusion),6); | |

| } | |

| translate([0,0,–Protrusion]) { // LED recess | |

| PolyCyl(Pixel[OD],(Pixel[LENGTH] + Protrusion),8); | |

| } | |

| translate([0,0,(Pixel[LENGTH] – Protrusion)]) { // light pipe | |

| rotate(180/TubeData[Tube][T_NUMPINS]) | |

| PolyCyl(TubeData[Tube][T_PIPEOD],(OAH + 2*Protrusion),TubeData[Tube][T_NUMPINS]); | |

| } | |

| } | |

| // Totally ad-hoc support structures … | |

| if (Support) { | |

| color("Yellow") { | |

| for (i=[–1,1]) // nut traps | |

| translate([i*TubeData[Tube][T_SCREWOC]/2,0,(Nut[LENGTH] – ThreadThick)/2]) | |

| for (a=[0:5]) | |

| rotate(a*30 + 15) | |

| cube([2*ThreadWidth,0.9*Nut[OD],(Nut[LENGTH] – ThreadThick)],center=true); | |

| if (Pixel[OD] > TubeData[Tube][T_PIPEOD]) // support pipe only if needed | |

| translate([0,0,(Pixel[LENGTH] – ThreadThick)/2]) | |

| for (a=[0:7]) | |

| rotate(a*22.5) | |

| cube([2*ThreadWidth,0.9*Pixel[OD],(Pixel[LENGTH] – ThreadThick)],center=true); | |

| } | |

| } | |

| } | |

| //———————- | |

| // Build it | |

| if (Layout == "Cap") { | |

| if (Section) | |

| difference() { | |

| Cap(); | |

| translate([–CapSize[OD],0,CapSize[LENGTH]]) | |

| cube([2*CapSize[OD],2*CapSize[OD],3*CapSize[LENGTH]],center=true); | |

| } | |

| else | |

| Cap(); | |

| } | |

| if (Layout == "LampBase") | |

| LampBase(); | |

| if (Layout == "USBPort") | |

| USBPort(); | |

| if (Layout == "Socket") | |

| if (Section) { | |

| difference() { | |

| Socket(); | |

| translate([–100/2,0,–Protrusion]) | |

| cube([100,50,50],center=false); | |

| } | |

| } | |

| else | |

| Socket(); | |

| if (Layout == "Sockets") { | |

| translate([0,50,0]) | |

| Socket("Mini7"); | |

| translate([0,20,0]) | |

| Socket("Octal"); | |

| translate([0,–15,0]) | |

| Socket("Duodecar"); | |

| translate([0,–50,0]) | |

| Socket("Noval"); | |

| } |

Comments

4 responses to “Vacuum Tube LEDs: Ersatz Tube Sockets”

I’ve actually 3D printed obscure sockets (then used Molex pins for contacts) for actual electronics use. There are several on Thingiverse. I like the idea of adding the extra pin and making them non-keyed, so you can orient the tube for best visual effect. The octal base tubes are opaque, but I guess you could break off the spigot to let the light shine on the seal (just be careful you don’t snap off the seal too, because that would let the air in, and spoil the shiny getter).

Some deft Dremel work seems in order for octal tubes, but I found one in the bottom of the box with a conveniently pre-broken base. Shining the light along the length of the seal diffuses it quite a bit, which works perfectly well in a dark room.

An LED lighting the tube from above perks it up quite nicely!

[…] that Greenlee chassis punches fit the ersatz vacuum tube sockets, this makes a certain perverse […]

[…] Via Softsolder […]