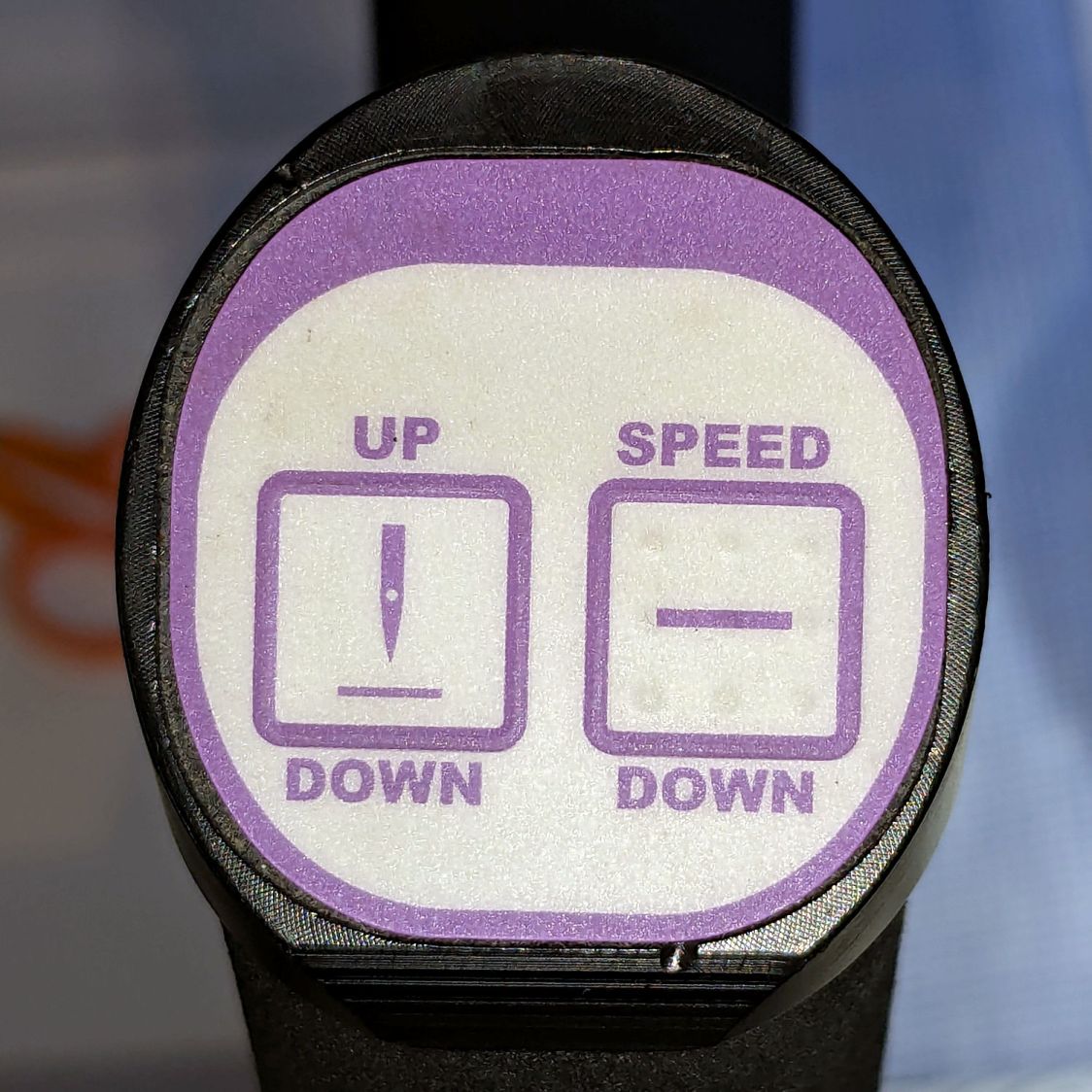

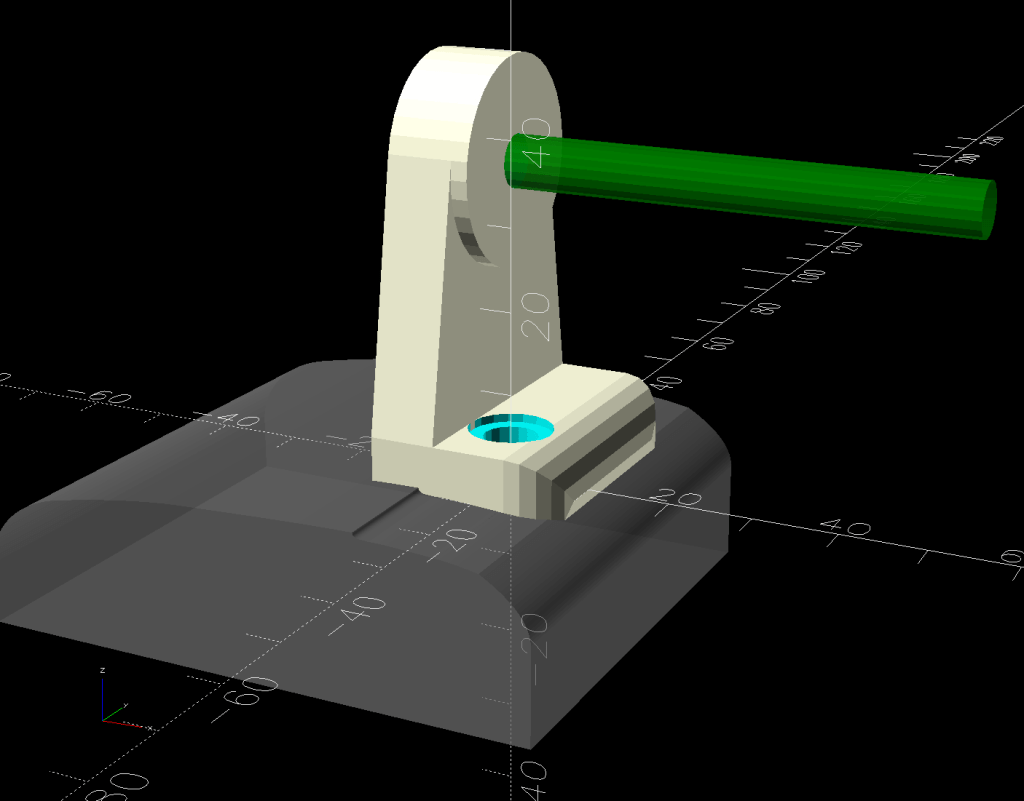

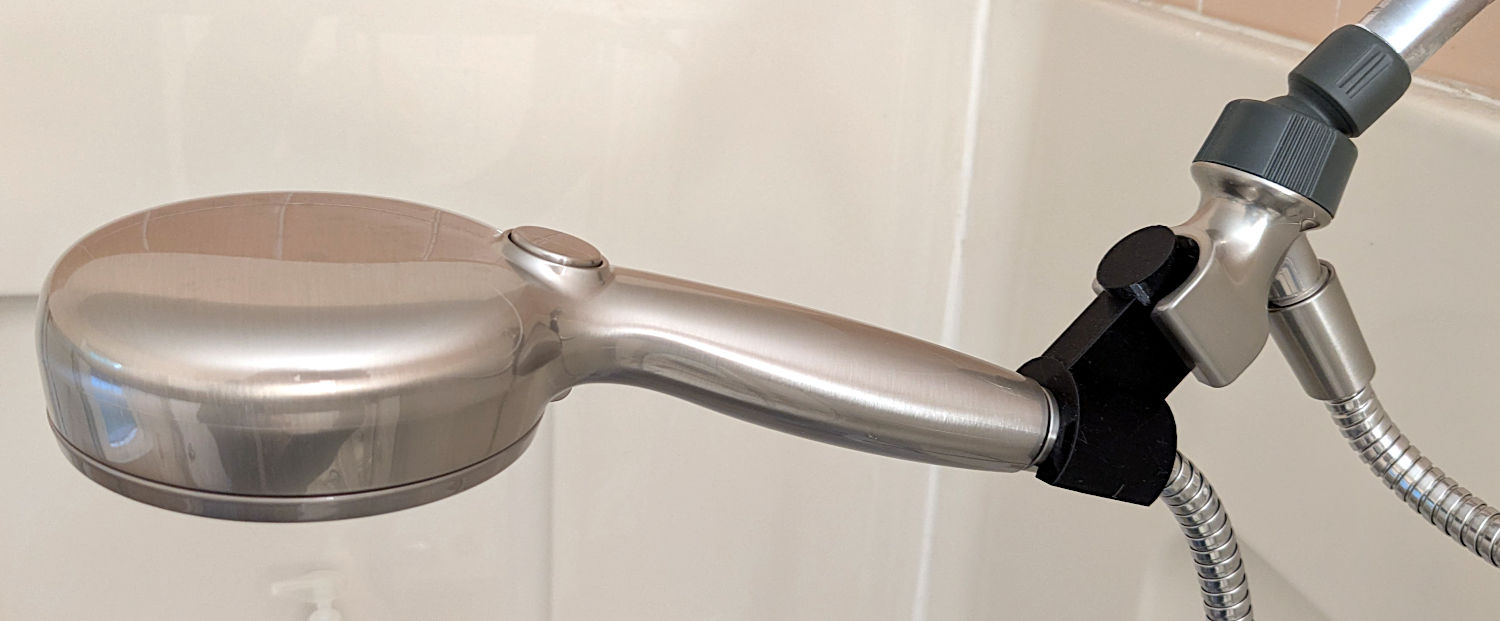

The original shower head being too far overhead for Mary’s reach, I installed a Delta ProClean Shower Head which would also be too high. It has a hose, which means I can adjust the height:

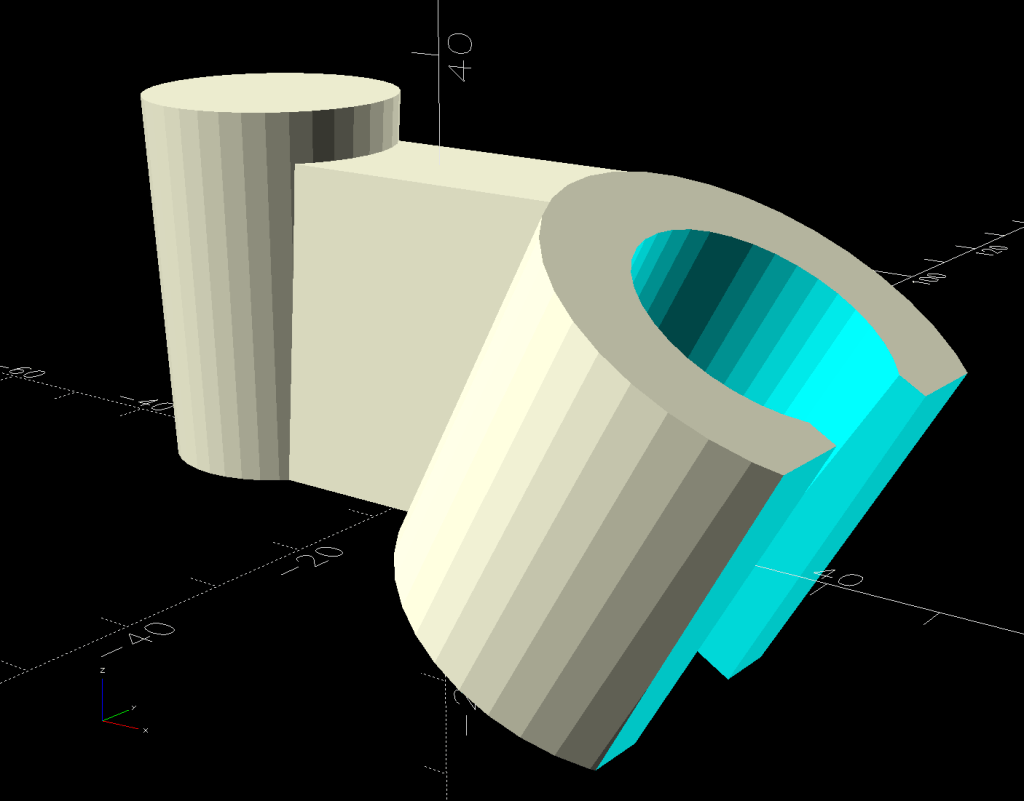

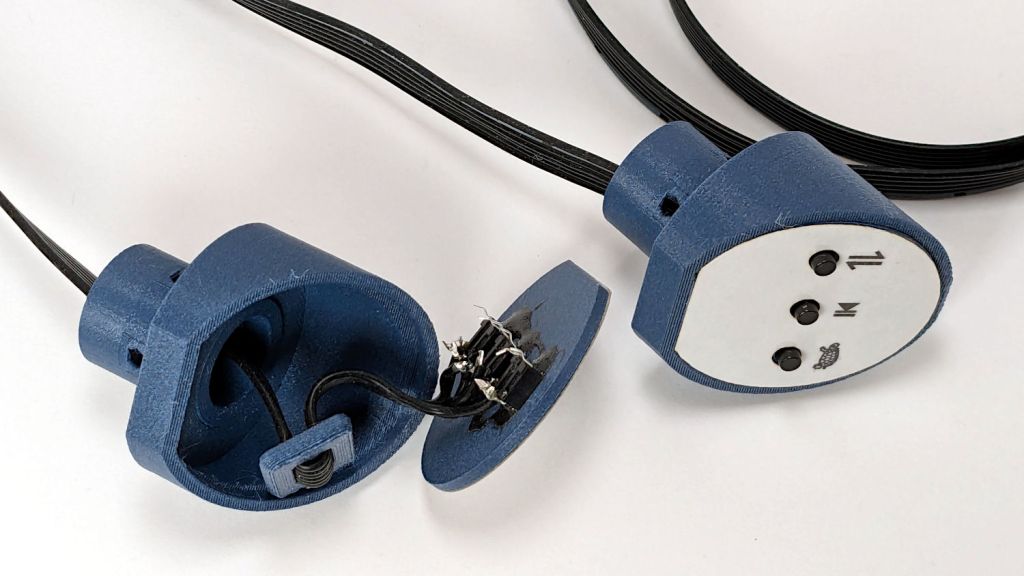

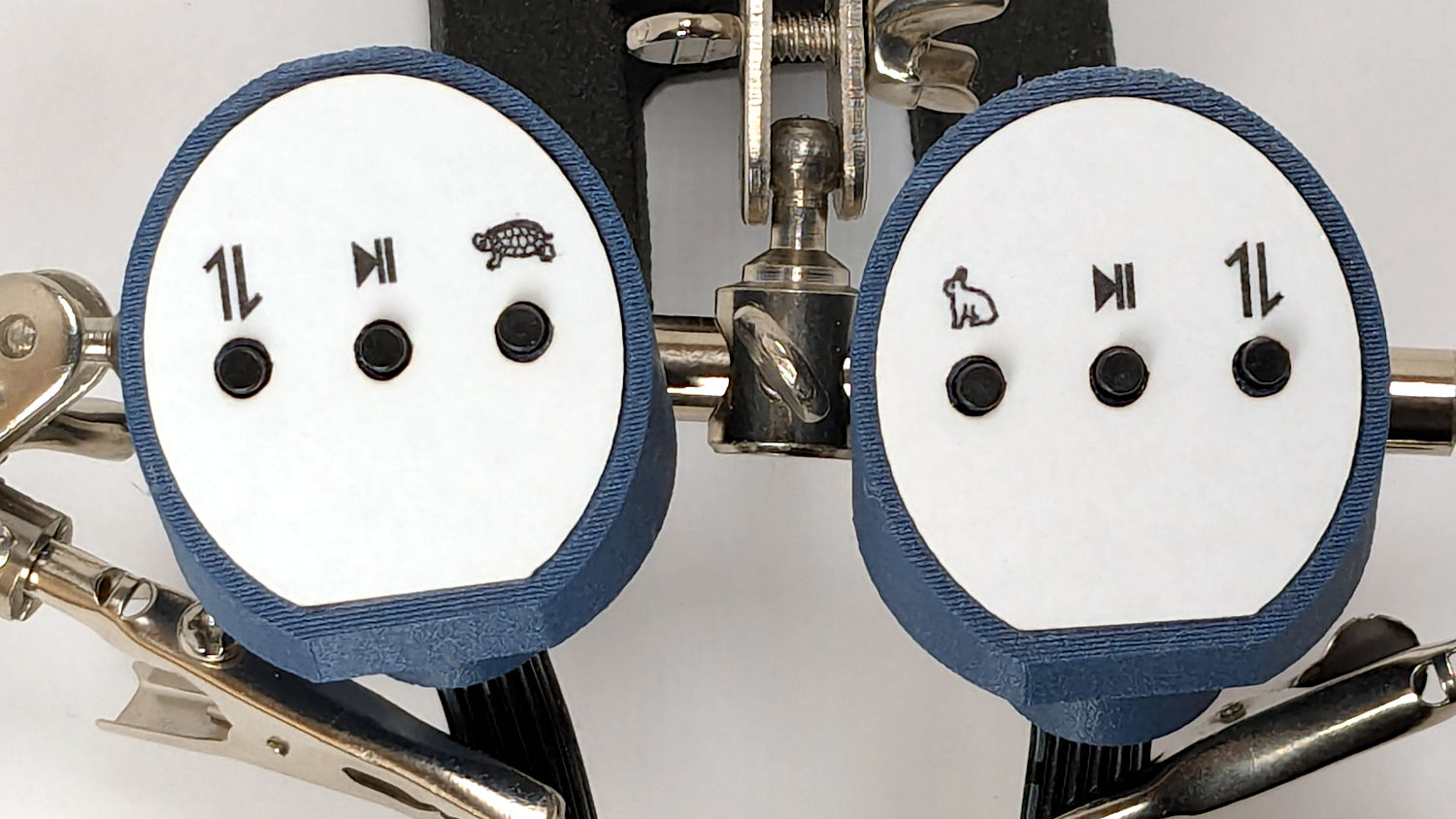

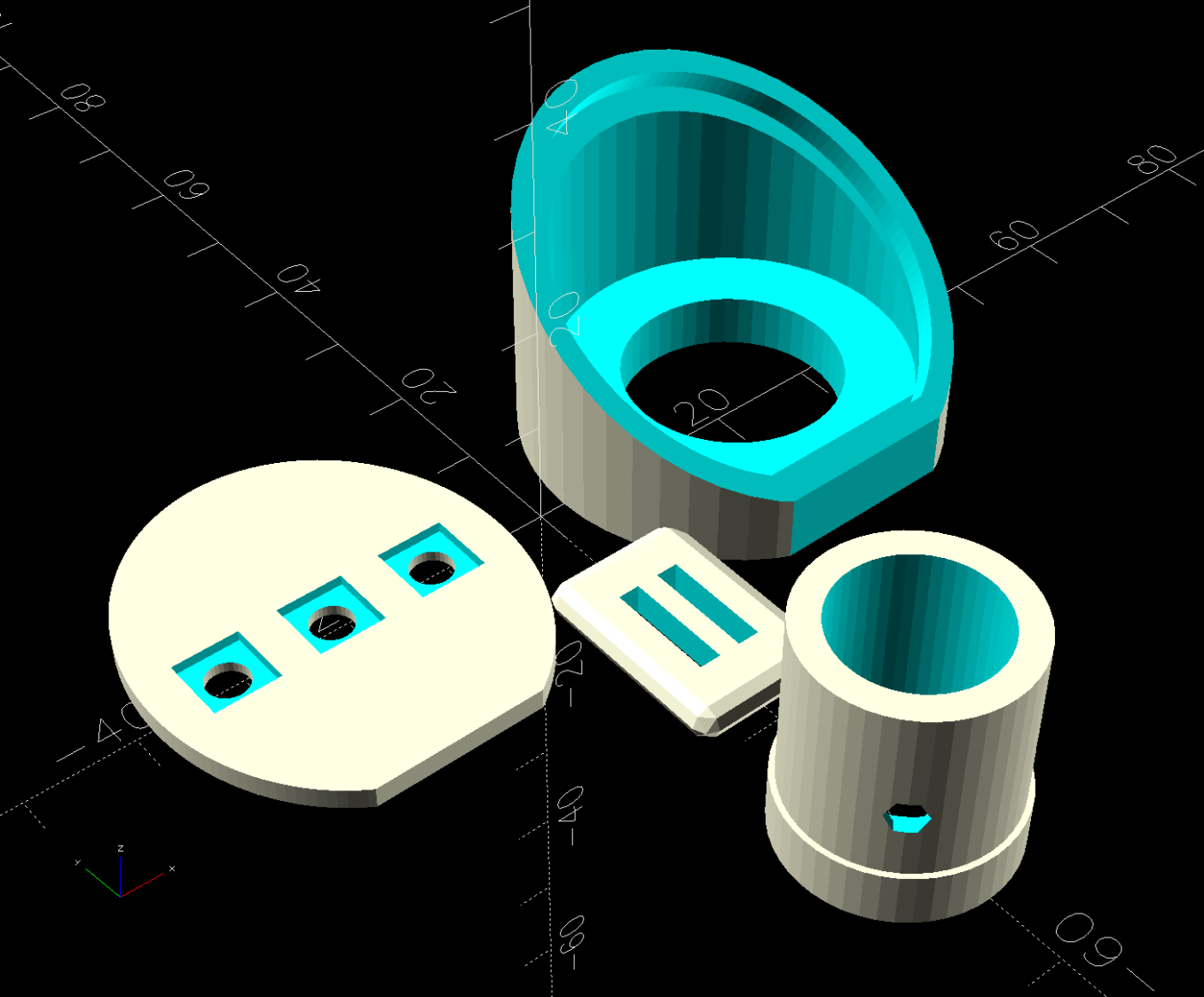

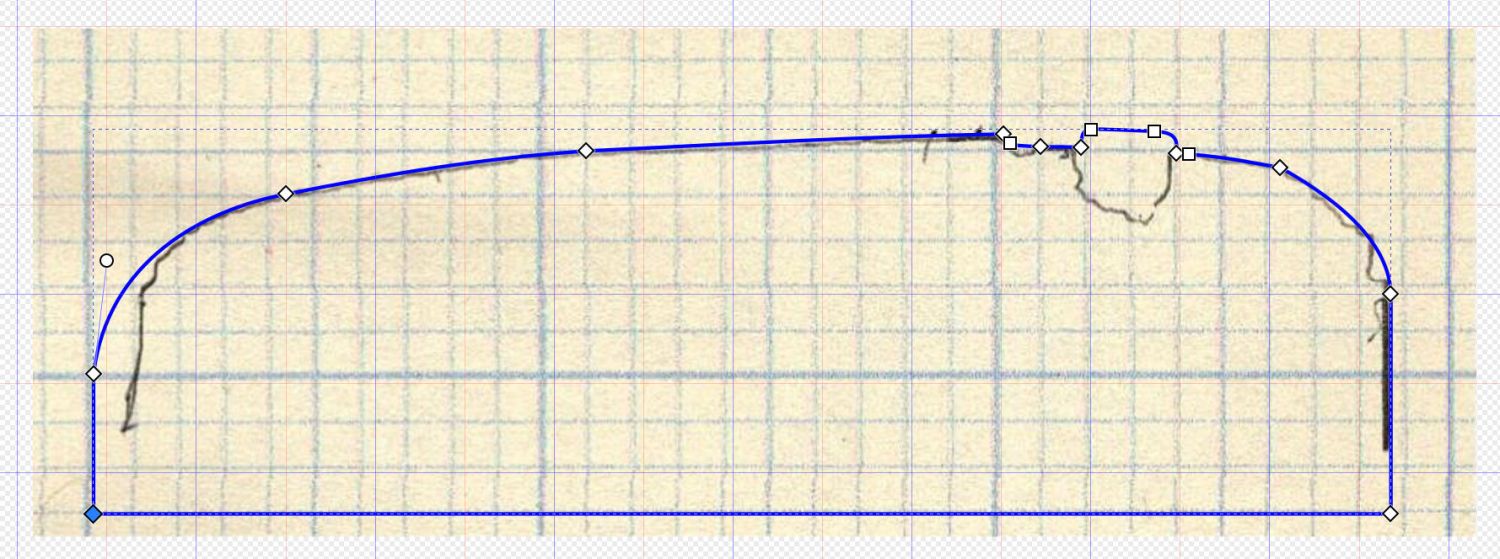

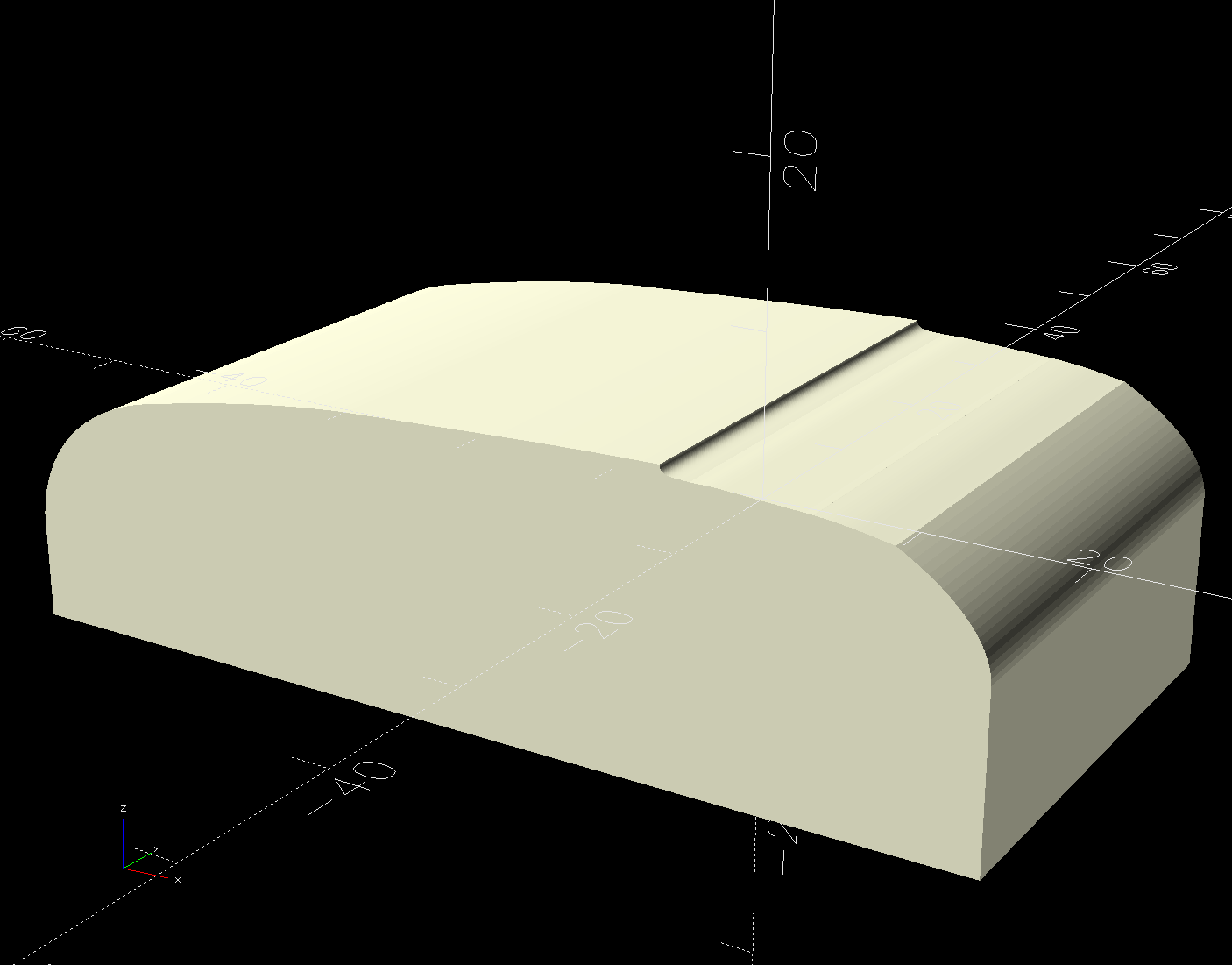

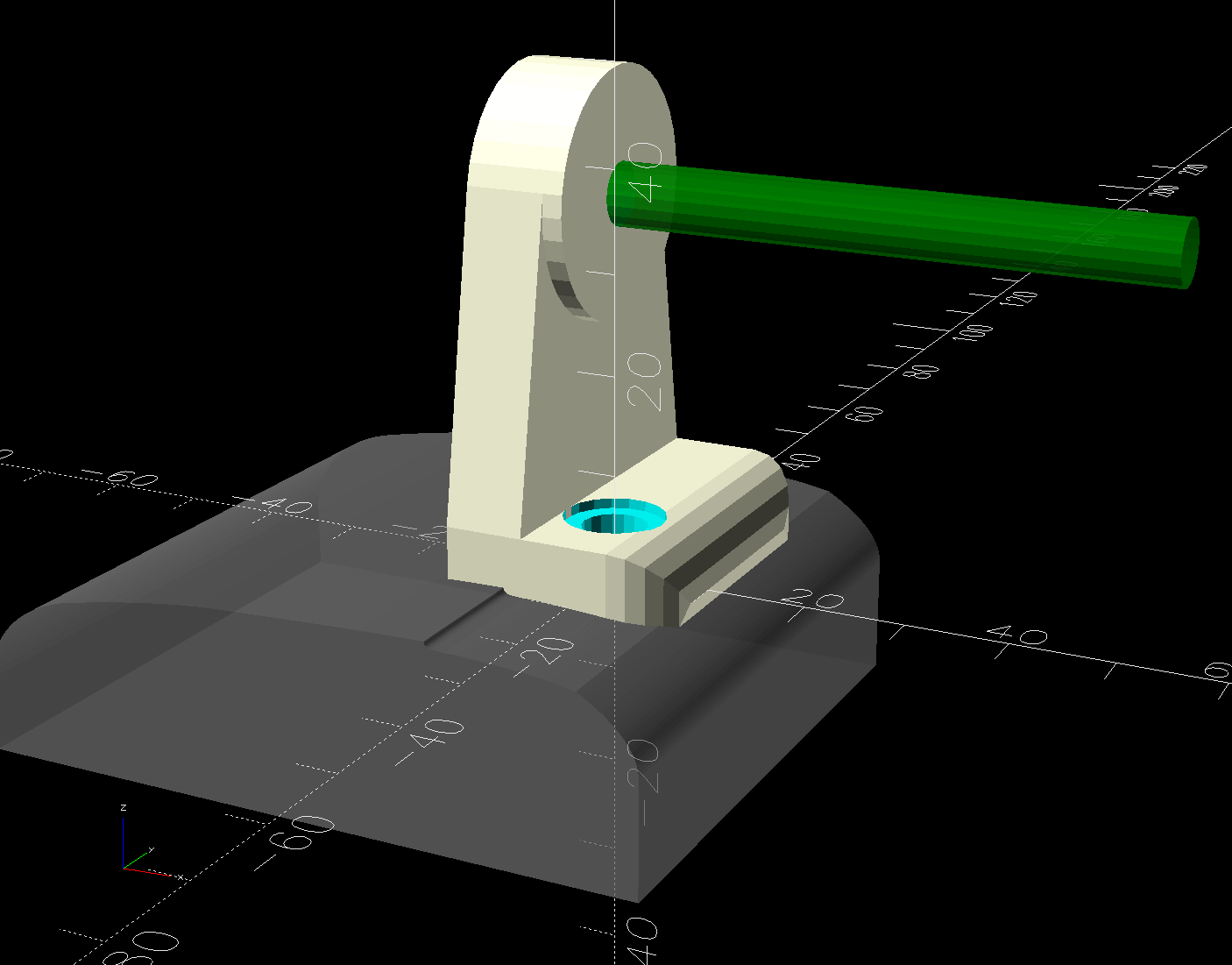

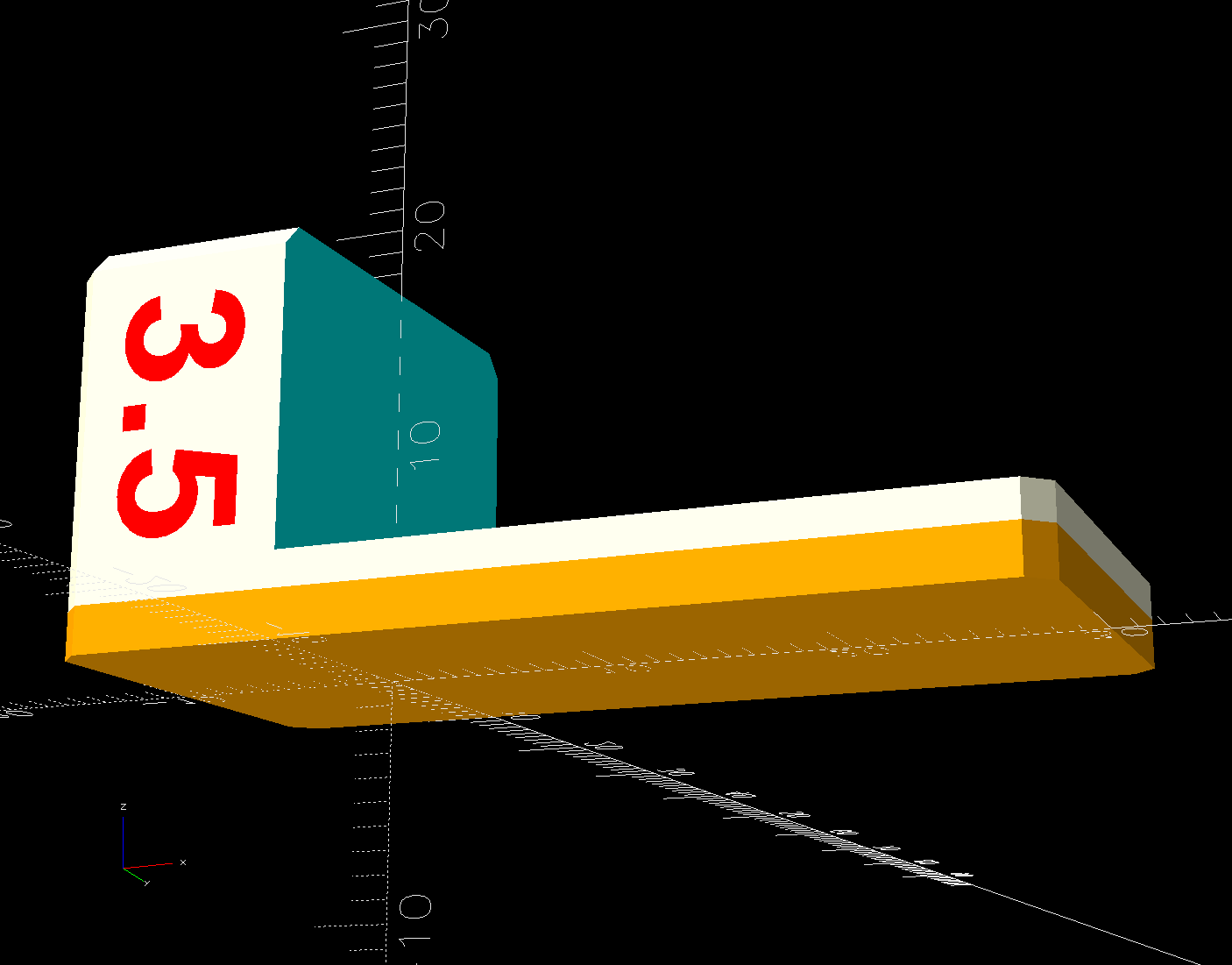

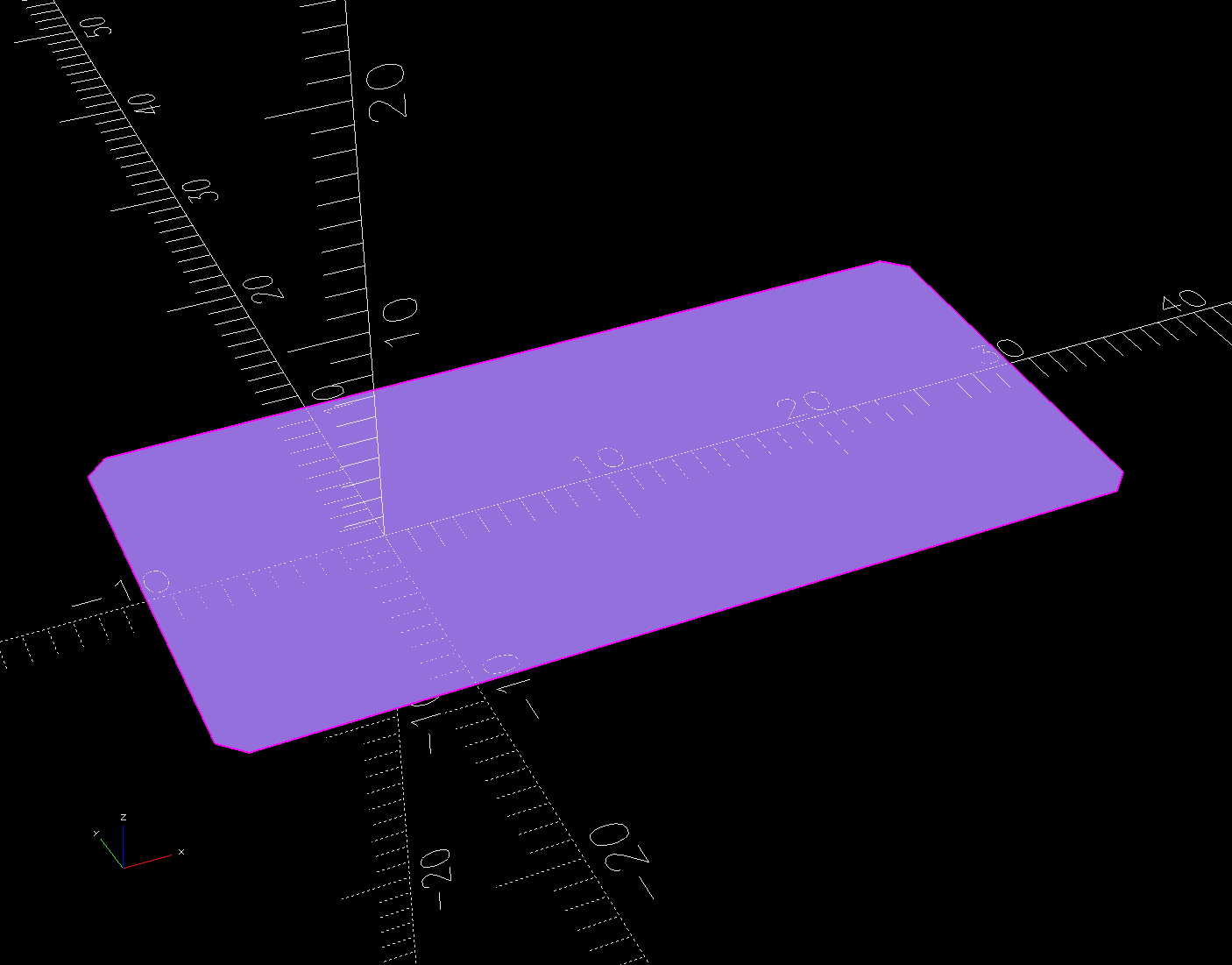

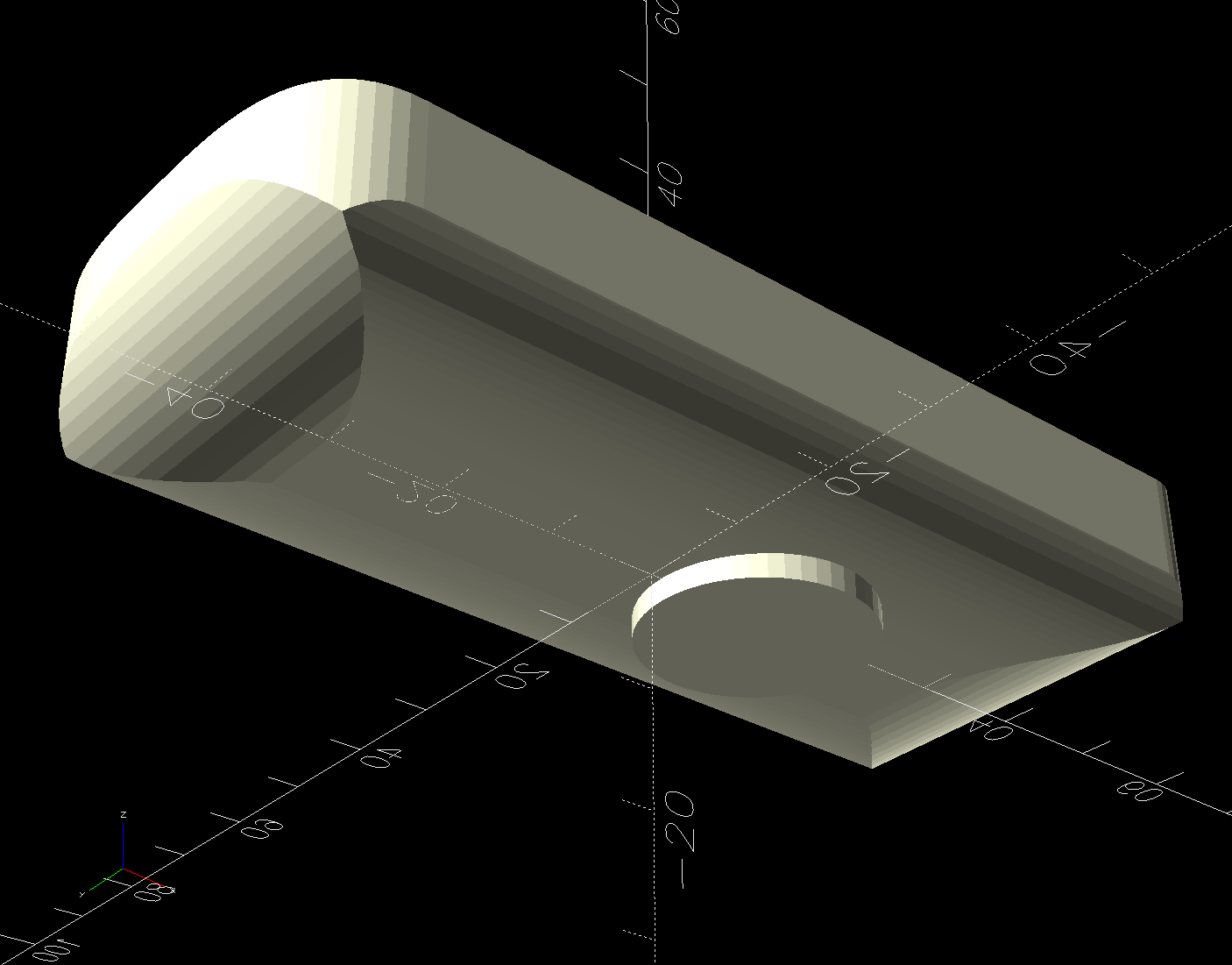

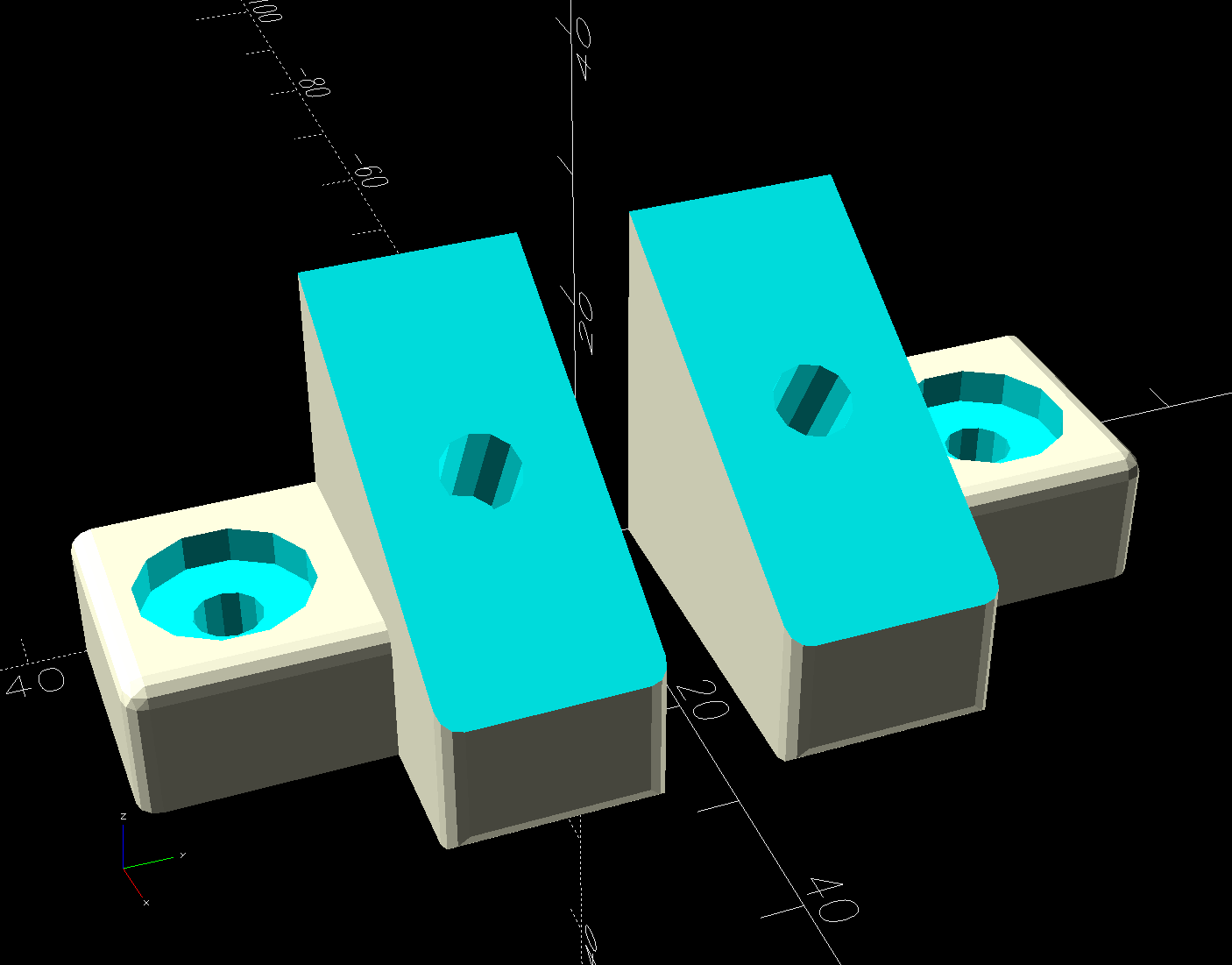

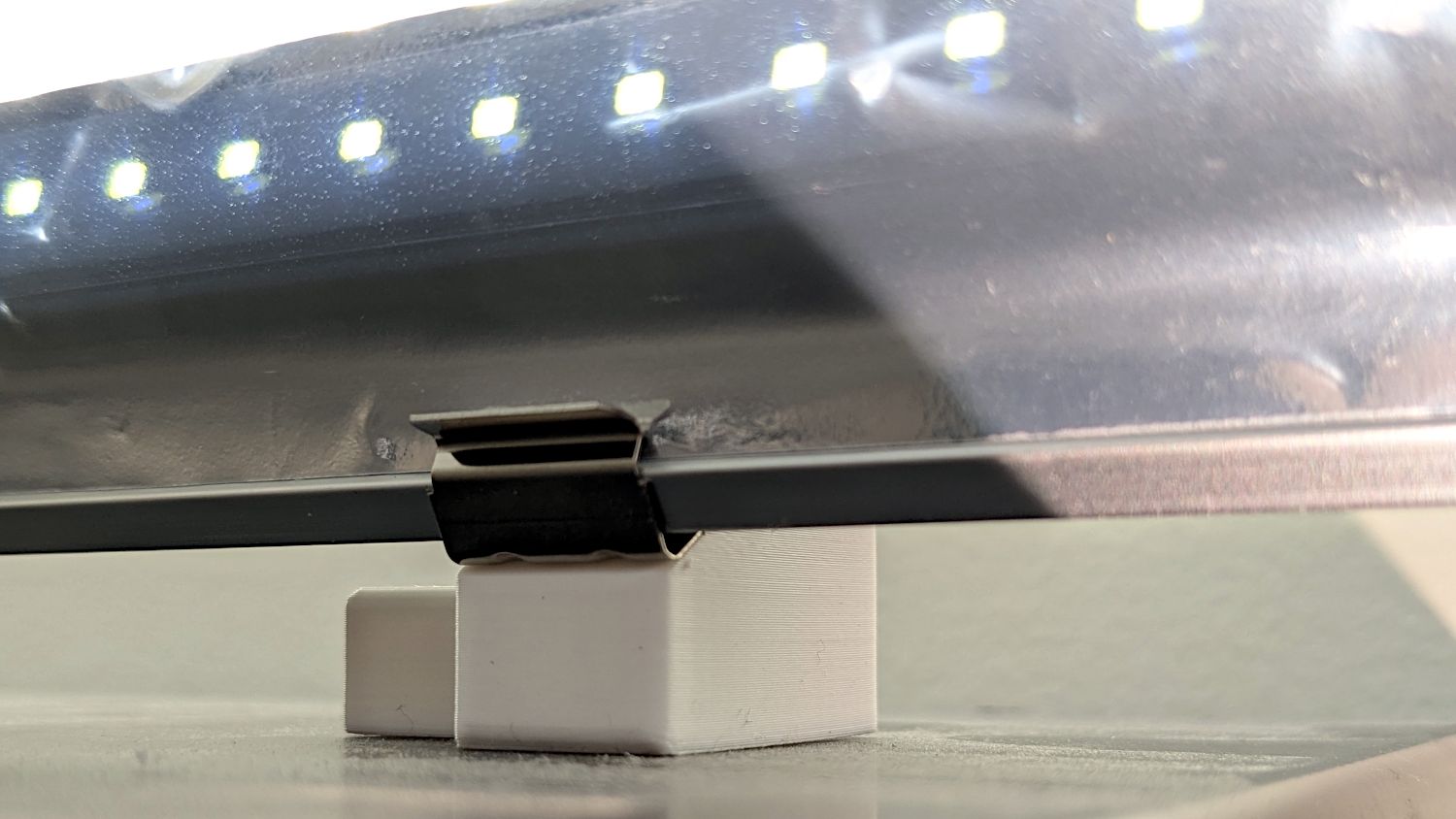

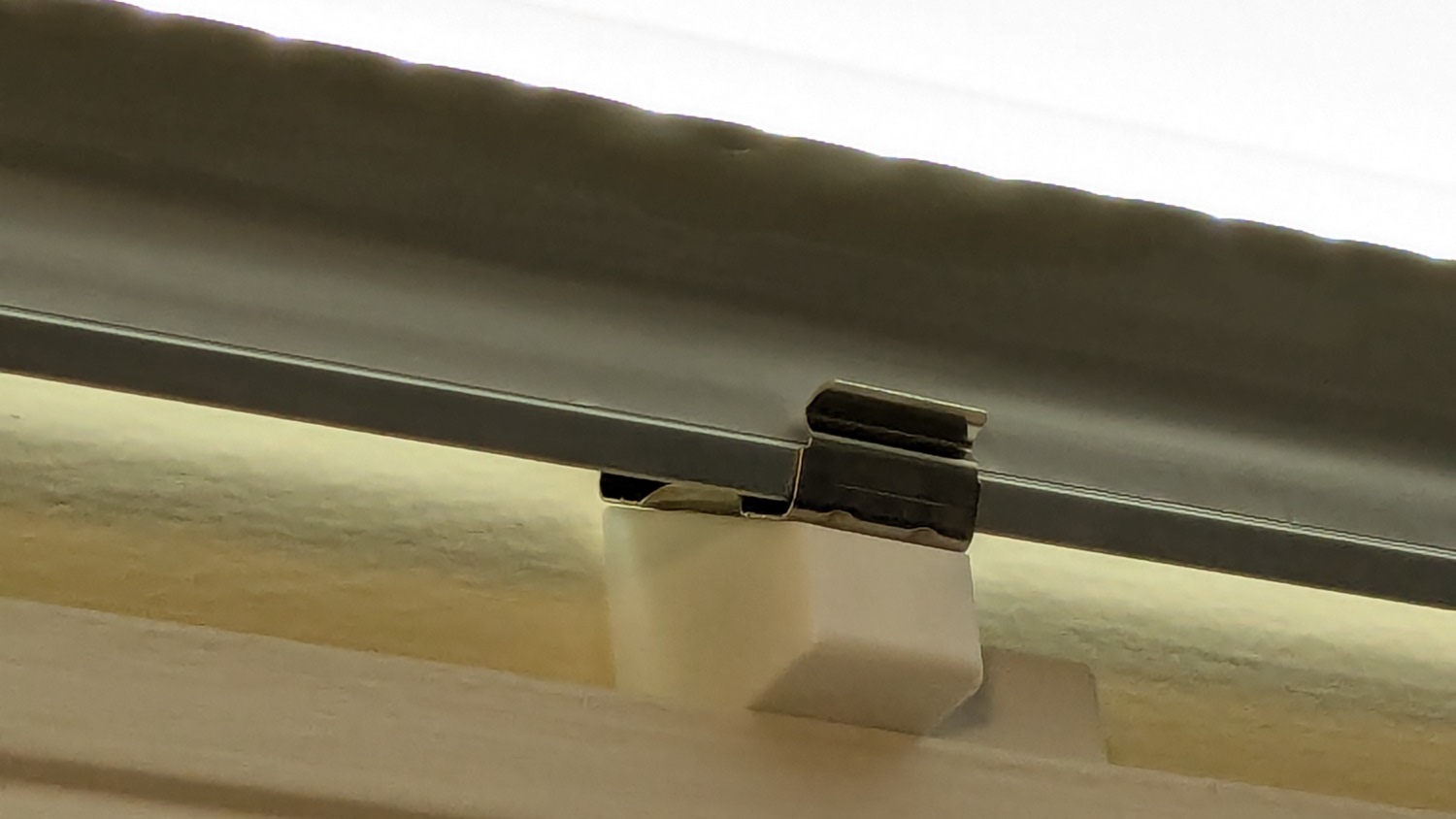

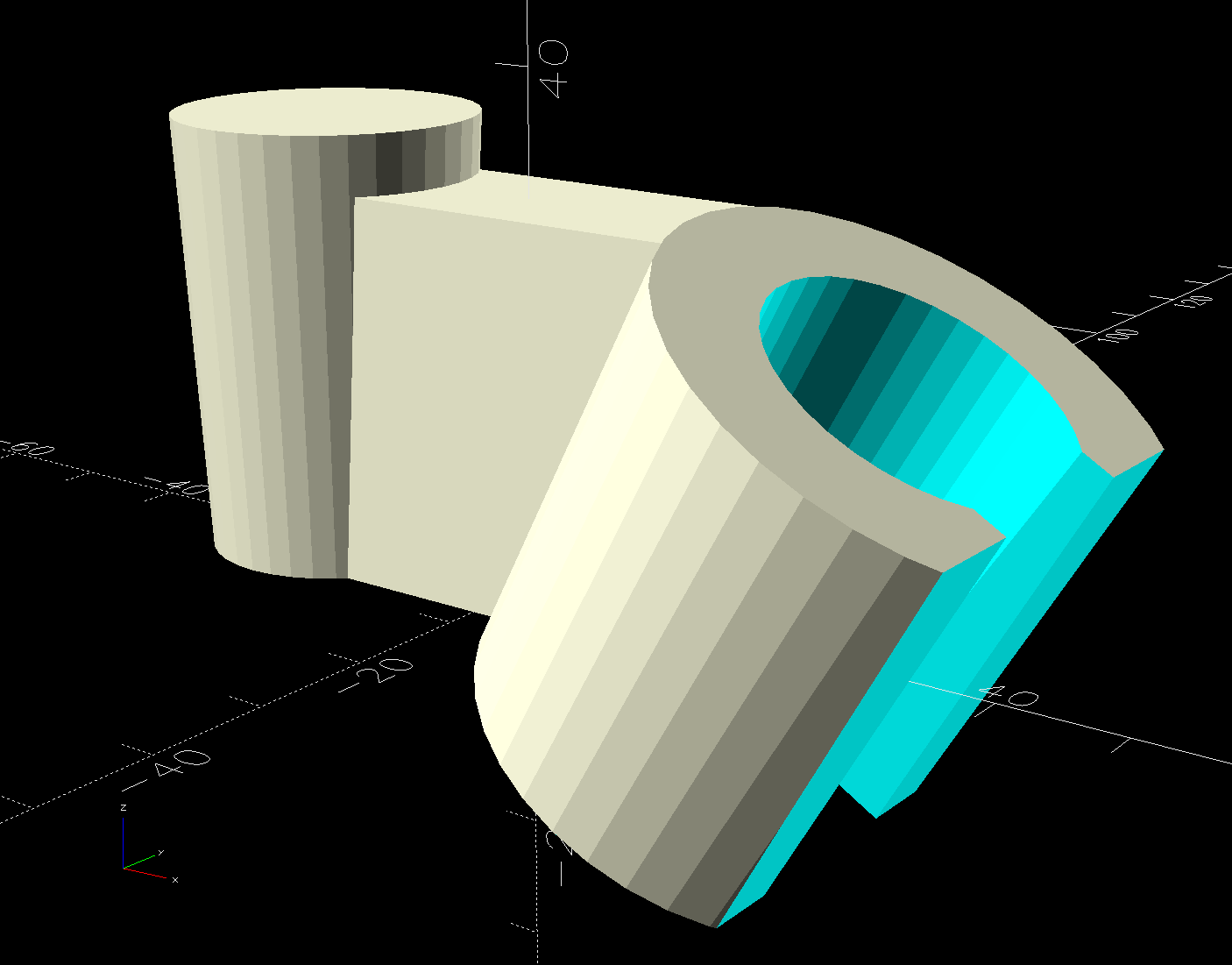

The InterWebs offer several 3D-printable versions of such a thing, but Delta offers many different shower heads, some of which are visually (to my eyes, anyway) indistinguishable from the 75740SN you see here. The model I tried did not fit the holder I have, so I conjured one from the vasty digital deep:

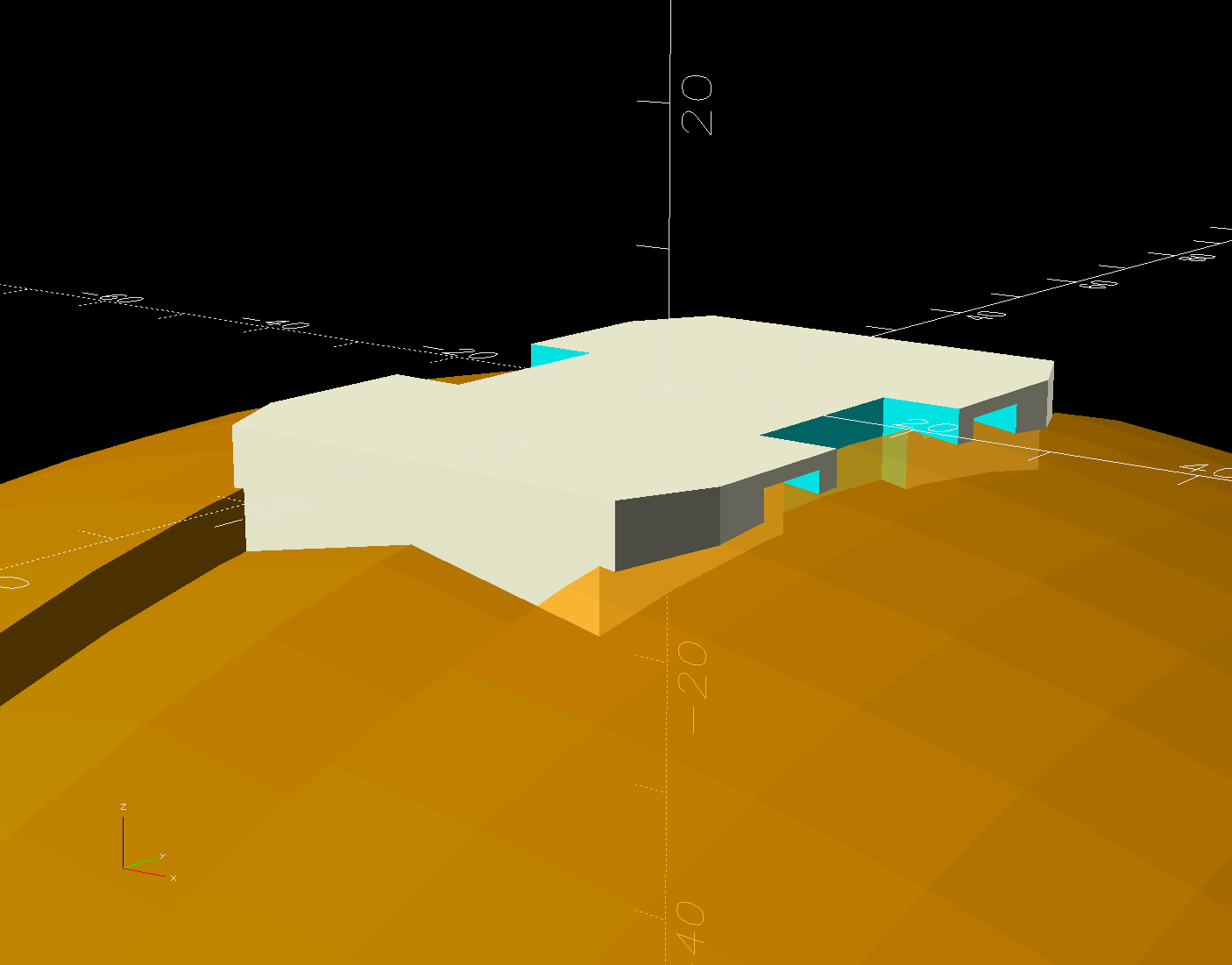

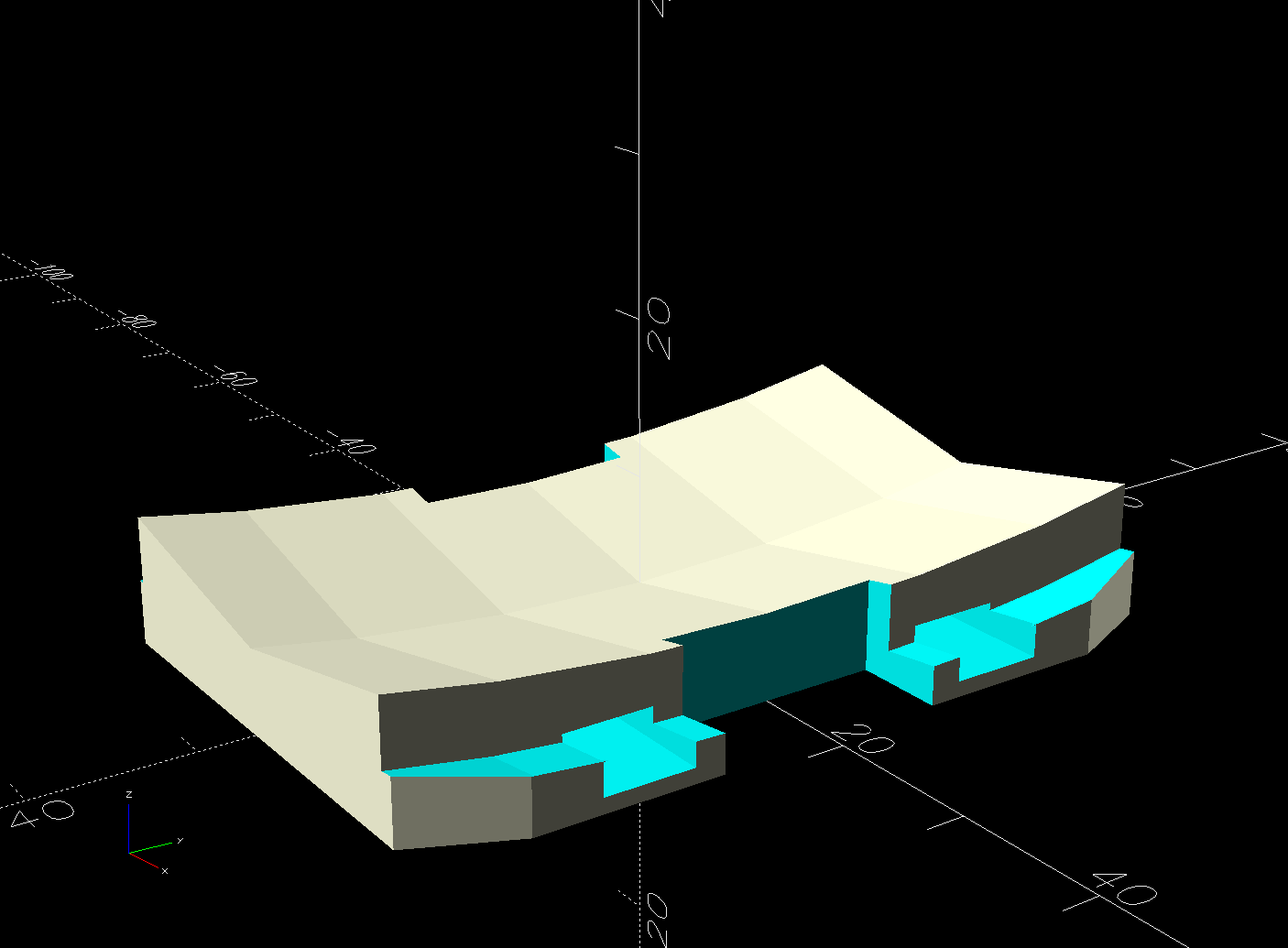

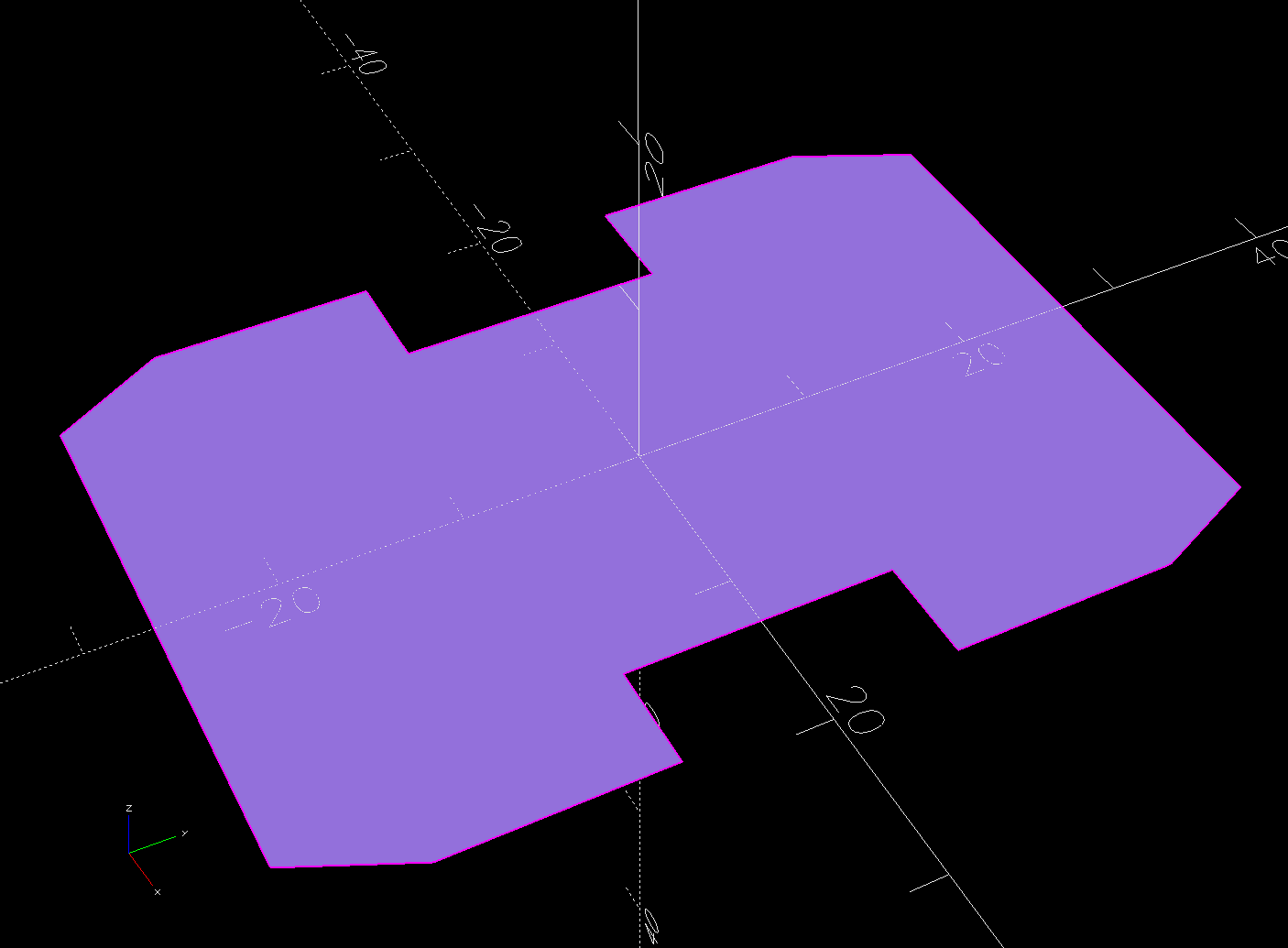

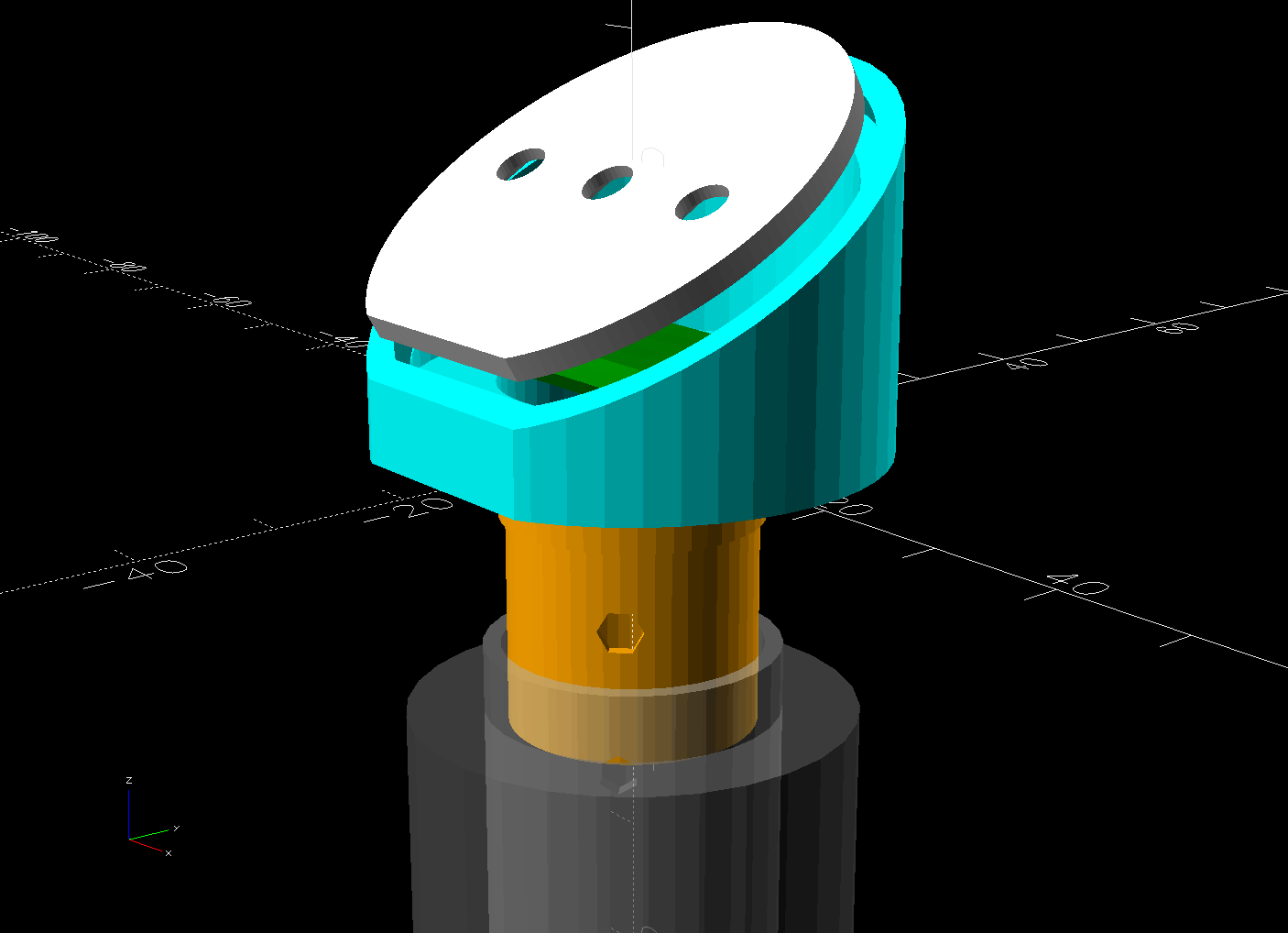

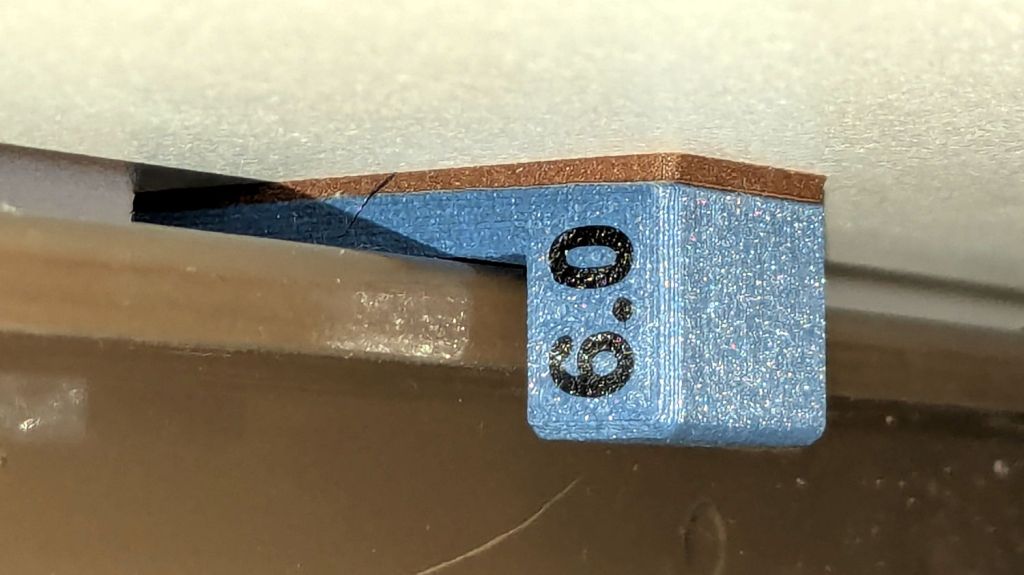

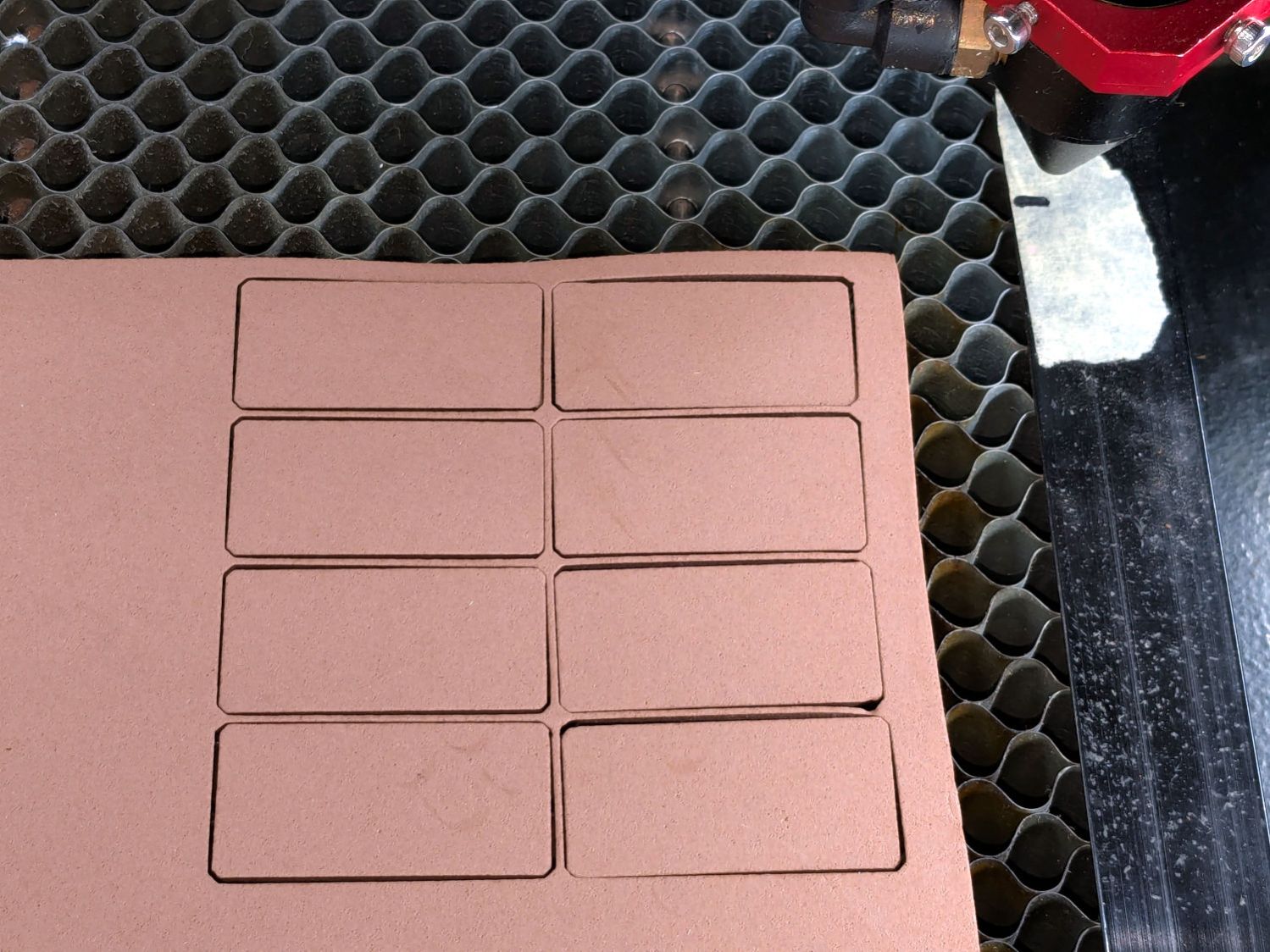

It builds standing on that tidy cutoff:

Despite PrusaSlicer’s kvetching about the “collapsing overhang” inside the socket, it came out fine.

The shower head is still slightly too high for her, but now I can print another one with a longer offset and a slightly smaller plug to fit deeper in the OEM socket.

Worst case, there’s a wall-mounted holder to put the shower head at shoulder height.

The OpenSCAD source code as a GitHub Gist:

| // Delta shower head holder extension | |

| // Ed Nisley – KE4ZNU | |

| // 2025-05-02 | |

| include <BOSL2/std.scad> | |

| Layout = "Show"; // [Show,Build,Plug,Socket,Connector] | |

| MountAngle = 30; // between OEM and new holder | |

| MountOffset = 20.0; | |

| /* [Hidden] */ | |

| HoleWindage = 0.2; | |

| Protrusion = 0.1; | |

| NumSides = 3*3*4; | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| Insert = [21.0,24.5,35.0]; // hose connector taper | |

| PlugSize = Insert + [-0.3,-0.3,0]; // … for better fit in OEM holder | |

| Slot = [Insert[OD],14.6,3*Insert[LENGTH]]; // slot on OEM holder, arbitrary length | |

| WallThick = 8.0; // holder wall thickness | |

| Radius = 3.0; // shapely rounding | |

| $fn=NumSides; | |

| //———- | |

| // Define Shapes | |

| module Plug() { | |

| cyl(l=Insert[LENGTH],d1=PlugSize[ID],d2=PlugSize[OD],anchor=BOTTOM); | |

| } | |

| module Socket() { | |

| difference() { | |

| tube(l=Insert[LENGTH],id1=Insert[ID],id2=Insert[OD],wall=WallThick,anchor=BOTTOM); | |

| cuboid(Slot + [0,1.0,0],anchor=LEFT+CENTER); | |

| right(Insert[OD]/2) | |

| cube([Insert[OD],Insert[OD] + 2*WallThick,3*Insert[LENGTH]],anchor=LEFT+CENTER); | |

| } | |

| } | |

| module Connector() { | |

| difference() { | |

| left(MountOffset) | |

| cuboid([MountOffset + Insert[LENGTH]*sin(MountAngle),Slot.y,Insert[LENGTH]*cos(MountAngle)], | |

| anchor=LEFT+BOTTOM); | |

| yrot(MountAngle) right(Insert[ID]/2 + WallThick) | |

| cyl(l=Insert[LENGTH],d1=Insert[ID] + 2*WallThick,d2=Insert[OD] + 2*WallThick,anchor=BOTTOM); | |

| } | |

| } | |

| module Adapter() { | |

| union() { | |

| left(MountOffset) | |

| Plug(); | |

| yrot(MountAngle) right((Insert[ID] + 2*WallThick)/2) | |

| Socket(); | |

| Connector(); | |

| } | |

| } | |

| //———- | |

| // Build things | |

| if (Layout == "Plug") | |

| Plug(); | |

| if (Layout == "Socket") | |

| Socket(); | |

| if (Layout == "Connector") | |

| Connector(); | |

| if (Layout == "Show") | |

| Adapter(); | |

| if (Layout == "Build") | |

| up(Insert[ID]/2 + 1*WallThick + Insert[OD]/2) | |

| yrot(90-MountAngle) | |

| Adapter(); |