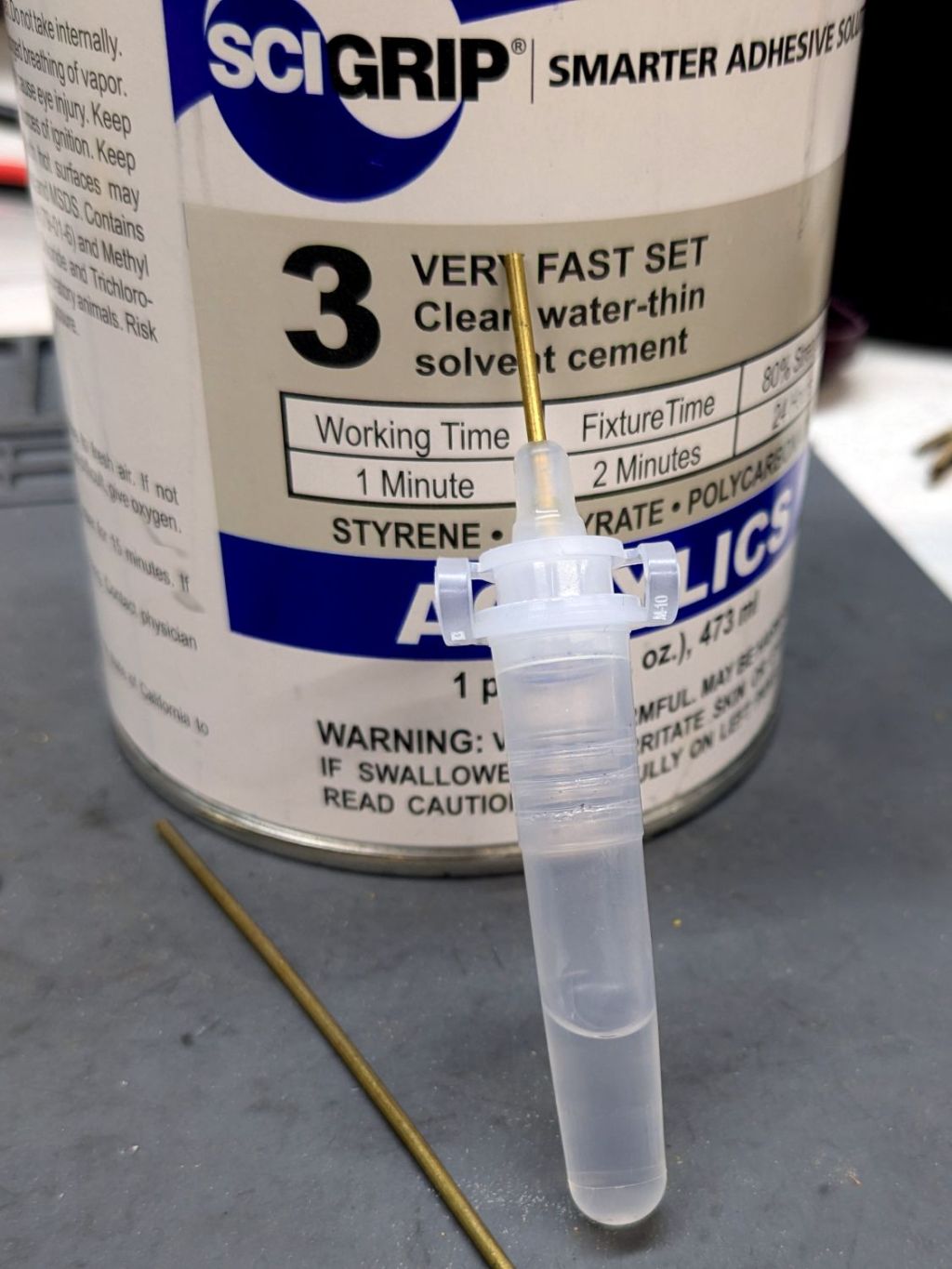

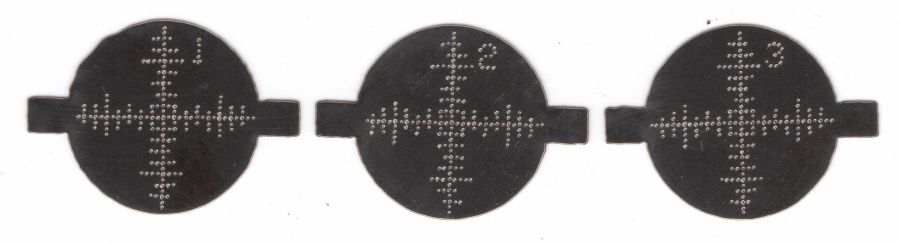

This seemed like a good idea for dispensing small drops of acrylic solvent while gluing spiders together:

It’s the Buffer Extraction Tube from a COVID-19 rapid test kit with a short brass tube jammed in its dropper tip. The longer brass tube let me suck that dose of solvent into the tube without any of the hassle required to pour the liquid from a big can into a little tube.

Tell me you didn’t save those things because you thought they didn’t look like they might come in handy for something.

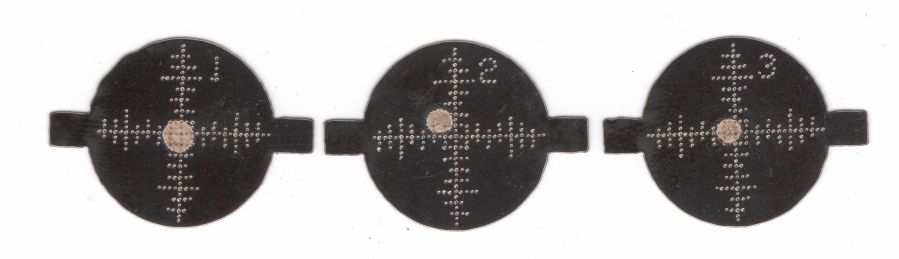

Well, that turned out to be a Bad Idea™, because whatever plastic that tube is made out of cracks when exposed to the hellish mixture in SCIGRIP #3 solvent adhesive. The tube didn’t dissolve or melt, it just cracked when you (well, I) squeezed the sides.

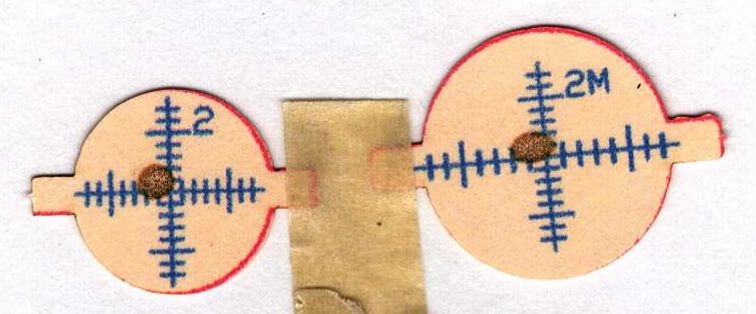

My Box o’ Test Kits has a few other types of tubes, but I used a syringe from the inkjet refilling era and that worked OK.