|

// Illuminated Tile Grid |

|

// Ed Nisley – KE4ZNU |

|

// 2020-05 |

|

|

|

/* [Configuration] */ |

|

|

|

Layout = "Build"; // [Cell,CellArray,MCU,Base,Show,Build] |

|

|

|

Shape = "Square"; // [Square, Pyramid, Cone] |

|

|

|

Cells = [2,2]; |

|

|

|

CellDepth = 15.0; |

|

|

|

Inserts = true; |

|

|

|

SupportInserts = true; |

|

|

|

/* [Hidden] */ |

|

|

|

ThreadThick = 0.25; |

|

ThreadWidth = 0.40; |

|

|

|

HoleWindage = 0.2; |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

|

|

Protrusion = 0.1; // make holes end cleanly |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

Tile = [25.0 + 0.1,25.0 + 0.1,4.0]; |

|

|

|

WallThick = 4*ThreadWidth; |

|

FloorThick = 3.0; |

|

|

|

Flange = [2*ThreadWidth,2*ThreadWidth,0]; // ridge supporting tile |

|

|

|

Separator = [3*ThreadWidth,3*ThreadWidth,Tile.z – 1]; // between tiles |

|

|

|

Screw = [3.0,6.0,3.5]; // M3 SHCS, OD=head, LENGTH=head |

|

Insert = [3.0,4.2,8.0]; // threaded brass insert |

|

|

|

ScrewRecess = Screw[LENGTH] + 4*ThreadThick; |

|

|

|

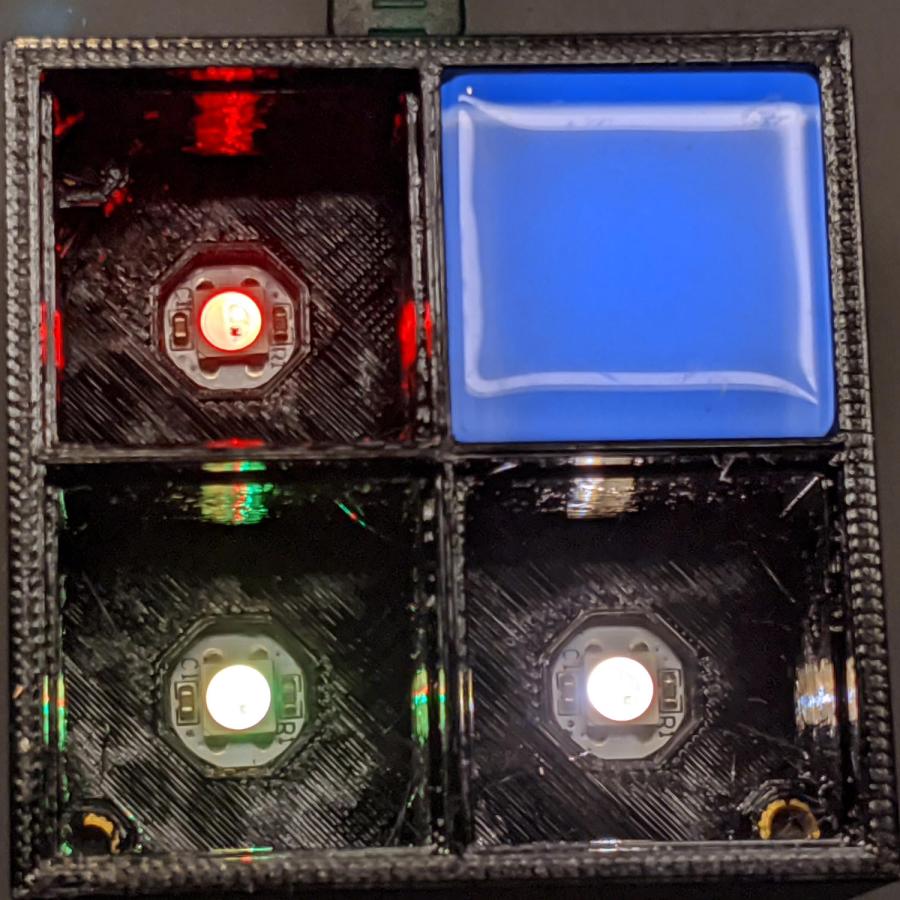

LEDPCB = [9.6,9.6,2.9]; // round SK6812, squared-off sides |

|

|

|

LED = [5.0 + 2*HoleWindage,5.0 + 2*HoleWindage,1.3]; |

|

|

|

LEDOffset = [0.0,0.0,0.0]; // if offset from PCB center |

|

|

|

CellOAL = [Tile.x,Tile.y,0] + Separator + [0,0,CellDepth] + [0,0,FloorThick]; |

|

|

|

ArrayOAL = [Cells.x*CellOAL.x,Cells.y*CellOAL.y,CellOAL.z]; // just the LED cells |

|

|

|

BlockOAL = ArrayOAL + [2*WallThick,2*WallThick,0]; // LED cells + exterior wall |

|

echo(str("Block OAL: ",BlockOAL)); |

|

|

|

InsertOC = ArrayOAL – [Insert[OD],Insert[OD],0] – [WallThick,WallThick,0]; |

|

echo(str("Insert OC: ",InsertOC)); |

|

|

|

TapeThick = 1.0; |

|

|

|

Arduino = [44.0,18.0,8.0 + TapeThick]; // Arduino Nano to top of USB Mini-B plug |

|

USBPlug = [15.0,11.0,9.0]; // USB Mini-B plug insulator |

|

USBOffset = [0,0,5.0]; // offset from PCB base |

|

|

|

WiringSpace = 3.5; |

|

WiringBay = [(Cells.x – 1)*CellOAL.x + LEDPCB.x,(Cells.y – 1)*CellOAL.y + LEDPCB.x,WiringSpace]; |

|

|

|

PlateOAL = [BlockOAL.x,BlockOAL.y,FloorThick + Arduino.z + WiringSpace]; // allow wiring above Arduino |

|

echo(str("Base Plate: ",PlateOAL)); |

|

|

|

echo(str("Screw length: ",(PlateOAL.z – ScrewRecess) + Insert.z/2," to ",(PlateOAL.z – ScrewRecess) + Insert.z)); |

|

|

|

LegendRecess = 1*ThreadThick; |

|

|

|

//———————— |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

FixDia = Dia / cos(180/Sides); |

|

cylinder(d=(FixDia + HoleWindage),h=Height,$fn=Sides); |

|

} |

|

|

|

|

|

//———————– |

|

// Base and optics in single tile |

|

|

|

module LEDCone() { |

|

|

|

hull() { |

|

translate([0,0,CellDepth + Tile.z/2]) |

|

cube(Tile – 2*[Flange.x,Flange.y,0],center=true); |

|

|

|

if (Shape == "Square") { |

|

translate([0,0,LEDPCB.z/2]) |

|

cube([Tile.x,Tile.y,LEDPCB.z] – 2*[Flange.x,Flange.y,0],center=true); |

|

} |

|

else if (Shape == "Pyramid") { |

|

translate([0,0,LEDPCB.z/2]) |

|

cube(LEDPCB,center=true); |

|

} |

|

else if (Shape == "Cone") { |

|

translate([0,0,LEDPCB.z/2]) |

|

cylinder(d=1.0*LEDPCB.x,h=LED.z,center=true); |

|

} |

|

else { |

|

echo(str("Whoopsie! Invalid Shape: ",Shape)); |

|

cube(5); |

|

} |

|

} |

|

} |

|

|

|

// One complete LED cell |

|

|

|

module LEDCell() { |

|

|

|

difference() { |

|

|

|

translate([0,0,CellOAL.z/2]) |

|

cube(CellOAL + [Protrusion,Protrusion,0],center=true); // force overlapping adjacent sides! |

|

|

|

translate([0,0,CellOAL.z – Separator.z + Tile.z/2]) |

|

cube(Tile,center=true); |

|

|

|

translate([0,0,LEDPCB.z]) |

|

LEDCone(); |

|

|

|

// cube([LED.x,LED.y,CellOAL.z],center=true); |

|

|

|

translate(-LEDOffset + [0,0,-CellOAL.z/2]) |

|

rotate(180/8) |

|

PolyCyl(LEDPCB.x,CellOAL.z,8); |

|

} |

|

|

|

} |

|

|

|

// The whole array of cells |

|

|

|

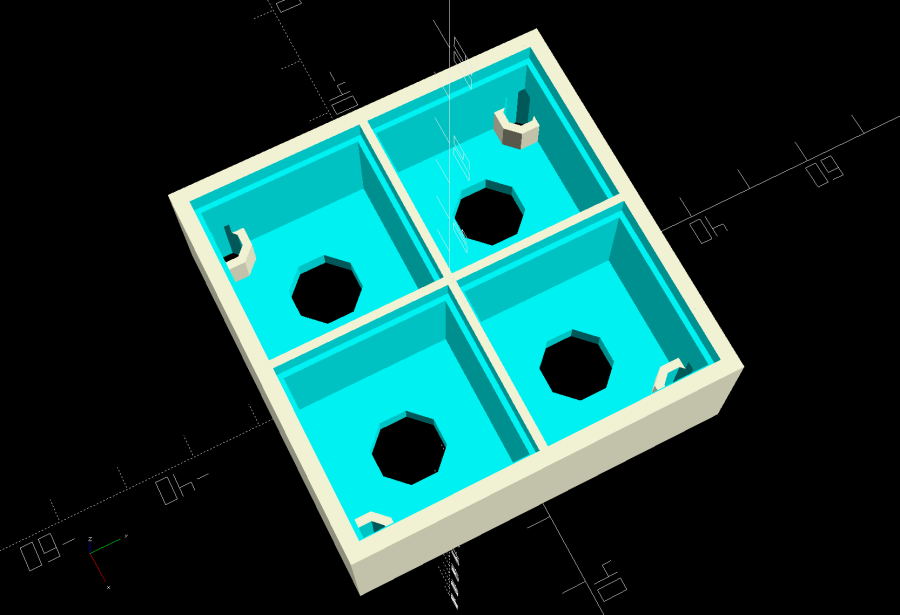

module CellArray() { |

|

difference() { |

|

union() { |

|

translate([CellOAL.x/2 – Cells.x*CellOAL.x/2,CellOAL.y/2 – Cells.y*CellOAL.y/2,0]) |

|

for (i=[0:Cells.x – 1], j=[0:Cells.y – 1]) |

|

translate([i*CellOAL.x,j*CellOAL.y,0]) |

|

LEDCell(); |

|

if (Inserts) // bosses |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*InsertOC.x/2,j*InsertOC.y/2,0]) |

|

rotate(180/8) |

|

cylinder(d=Insert[OD] + 2*WallThick,h=Insert[LENGTH],$fn=8); |

|

} |

|

if (Inserts) // holes |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*InsertOC.x/2,j*InsertOC.y/2,-Protrusion]) |

|

rotate(180/8) |

|

PolyCyl(Insert[OD],Insert[LENGTH] + FloorThick + Protrusion,8); |

|

|

|

} |

|

|

|

difference() { |

|

translate([0,0,CellOAL.z/2]) |

|

cube(BlockOAL,center=true); |

|

translate([0,0,CellOAL.z]) |

|

cube(ArrayOAL + [0,0,2*CellOAL.z],center=true); |

|

|

|

} |

|

} |

|

|

|

// Arduino bounding box |

|

// Origin at center bottom of PCB |

|

|

|

module Controller() { |

|

union() { |

|

translate([0,0,Arduino.z/2]) |

|

cube(Arduino,center=true); |

|

translate([Arduino.x/2 – Protrusion,-USBPlug.y/2,USBOffset.z + TapeThick – USBPlug.z/2]) |

|

cube(USBPlug + [Protrusion,0,0],center=false); |

|

} |

|

} |

|

|

|

// Baseplate |

|

|

|

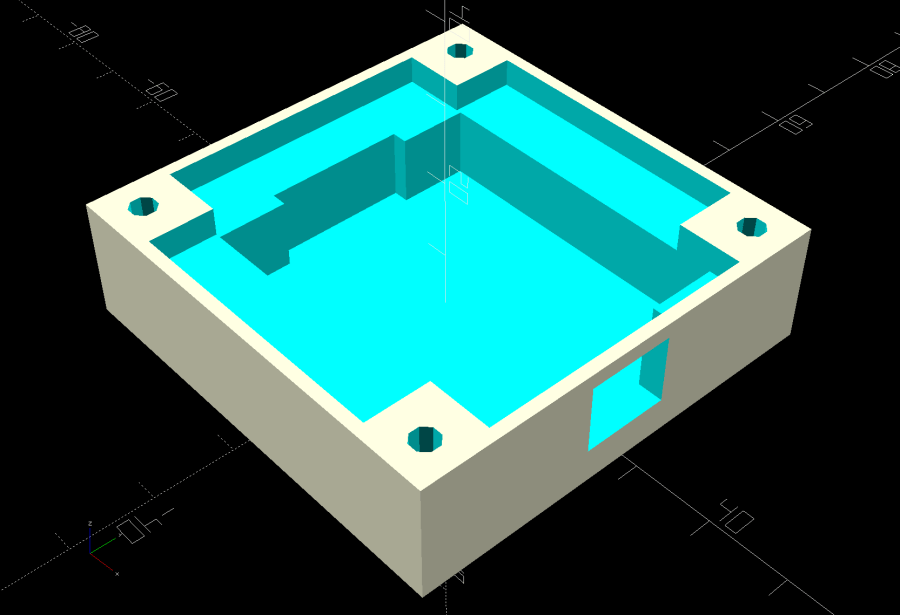

module BasePlate() { |

|

|

|

difference() { |

|

translate([0,0,PlateOAL.z/2]) |

|

cube(PlateOAL,center=true); |

|

|

|

translate([PlateOAL.x/2 – Arduino.x/2 – 2*WallThick,0,FloorThick]) |

|

Controller(); |

|

|

|

translate([PlateOAL.x/2 – Arduino.x/2 – 2*WallThick,0,FloorThick + PlateOAL.z/2]) |

|

cube([Arduino.x – 2*2.0,WiringBay.y,PlateOAL.z],center=true); // cutouts beside MCU |

|

|

|

translate([0,0,PlateOAL.z – WiringBay.z + PlateOAL.z/2 – Protrusion]) |

|

cube([PlateOAL.x – 2*WallThick,WiringBay.y,PlateOAL.z],center=true); // cutout above MCU |

|

translate([0,0,PlateOAL.z – WiringBay.z + PlateOAL.z/2 – Protrusion]) |

|

cube([WiringBay.x,PlateOAL.y – 2*WallThick,PlateOAL.z],center=true); // cutout above MCU |

|

|

|

|

|

if (Inserts) |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*InsertOC.x/2,j*InsertOC.y/2,-Protrusion]) |

|

rotate(180/8) { |

|

PolyCyl(Screw[ID],2*PlateOAL.z,8); |

|

PolyCyl(Screw[OD],ScrewRecess + Protrusion,8); |

|

} |

|

|

|

cube([45,17.0,2*LegendRecess],center=true); |

|

} |

|

|

|

linear_extrude(height=2*LegendRecess) { |

|

translate([0,1]) |

|

rotate(-0*90) mirror([1,0,0]) |

|

text(text="Ed Nisley",size=6,font="Arial:style:Bold",halign="center"); |

|

translate([0,-6.5]) |

|

rotate(-0*90) mirror([1,0,0]) |

|

text(text="softsolder.com",size=4.5,font="Arial:style:Bold",halign="center"); |

|

} |

|

|

|

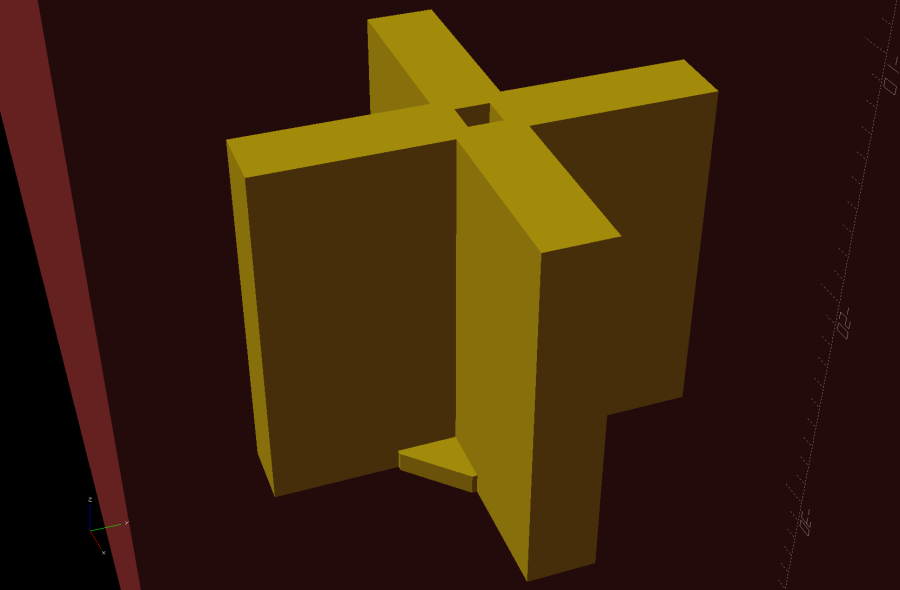

Fin = [Screw[OD]/2 – 1.5*ThreadWidth,2*ThreadWidth,ScrewRecess – ThreadThick]; |

|

if (Inserts && SupportInserts) |

|

color("Yellow") |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*InsertOC.x/2,j*InsertOC.y/2,0]) { |

|

rotate(180/8) |

|

cylinder(d=6*ThreadWidth,h=ThreadThick,$fn=8); |

|

for (a=[0:90:360]) |

|

rotate(a) |

|

translate([Fin.x/2 + ThreadWidth/2,0,(ScrewRecess – ThreadThick)/2]) |

|

cube(Fin,center=true); |

|

} |

|

} |

|

|

|

|

|

//———————– |

|

// Build things |

|

|

|

if (Layout == "Cell") |

|

LEDCell(); |

|

|

|

else if (Layout == "CellArray") |

|

CellArray(); |

|

|

|

else if (Layout == "MCU") |

|

Controller(); |

|

|

|

else if (Layout == "Base") |

|

BasePlate(); |

|

|

|

else if (Layout == "Show") { |

|

translate([0,0,3*PlateOAL.z]) |

|

CellArray(); |

|

BasePlate(); |

|

translate([PlateOAL.x/2 – Arduino.x/2 – 2*WallThick,0,FloorThick]) |

|

color("Orange",0.3) |

|

Controller(); |

|

} |

|

|

|

else if (Layout == "Build") union() { |

|

translate([0,0.6*BlockOAL.y,0]) |

|

CellArray(); |

|

translate([0,-0.6*BlockOAL.x,0]) |

|

rotate(90) |

|

BasePlate(); |

|

} |

|

|