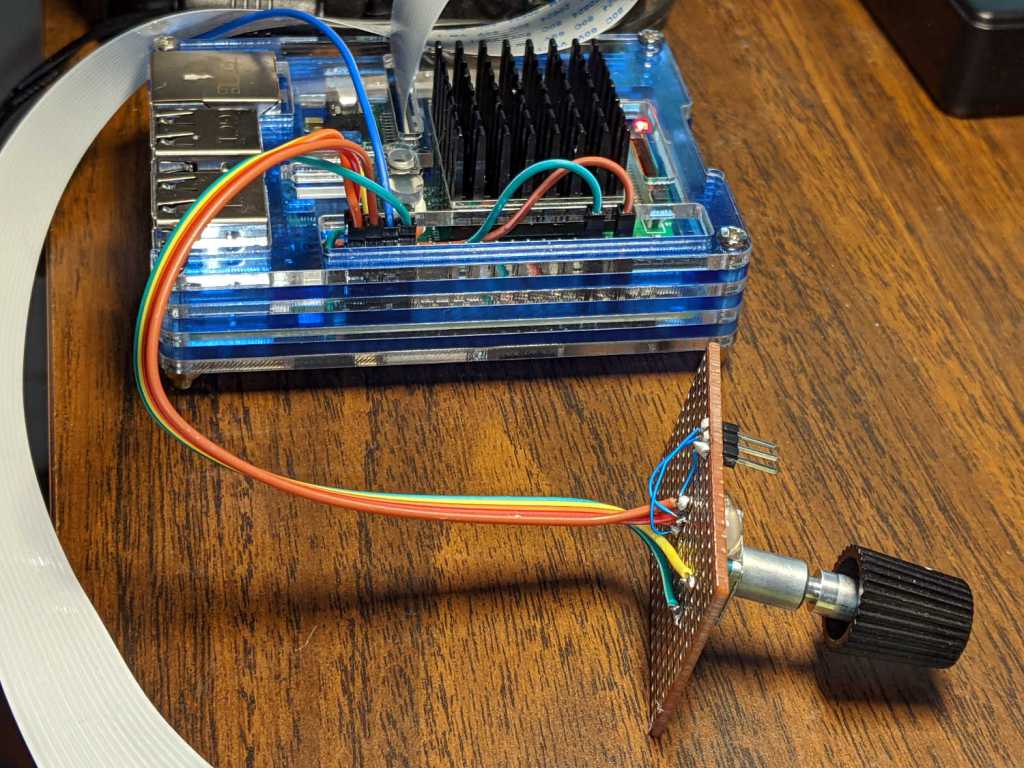

The rotary encoder knob I’m using for these tests has a pushbutton switch in its shaft:

Now that I know where to look, it turns out there’s a Raspberry Pi overlay for that:

Name: gpio-key

Info: This is a generic overlay for activating GPIO keypresses using

the gpio-keys library and this dtoverlay. Multiple keys can be

set up using multiple calls to the overlay for configuring

additional buttons or joysticks. You can see available keycodes

at https://github.com/torvalds/linux/blob/v4.12/include/uapi/

linux/input-event-codes.h#L64

Load: dtoverlay=gpio-key,<param>=<val>

Params: gpio GPIO pin to trigger on (default 3)

active_low When this is 1 (active low), a falling

edge generates a key down event and a

rising edge generates a key up event.

When this is 0 (active high), this is

reversed. The default is 1 (active low)

gpio_pull Desired pull-up/down state (off, down, up)

Default is "up". Note that the default pin

(GPIO3) has an external pullup

label Set a label for the key

keycode Set the key code for the button

Snuggle the button configuration next to the encoder in /boot/config.txt:

dtoverlay=rotary-encoder,pin_a=20,pin_b=21,relative_axis=1,steps-per-period=2<br>dtoverlay=gpio-key,gpio=26,keycode=83,label="KNOB"

I haven’t yet discovered where the label text appears, because I picked a keycode defining the button as the decimal point key on a numeric keypad. Perhaps one could create a unique key from whole cloth, but that’s in the nature of fine tuning. In any event, pressing / releasing the button produces key-down / key-up events just like you’d get from a real keyboard.

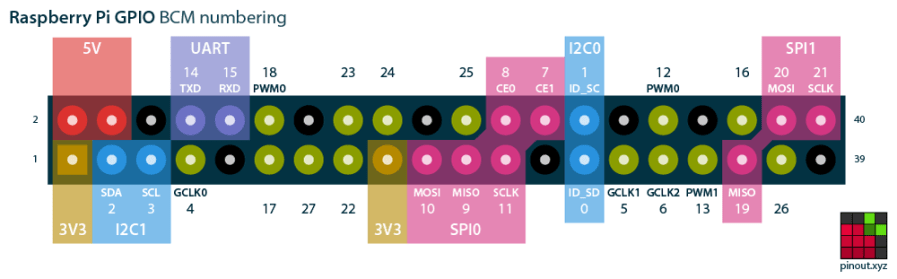

The four pins required for the encoder + switch make a tidy block at the right (in this view, left as shown above) end of the RPi’s header:

If you needed the SPI1 hardware, you’d pick different pins.

Reboot that sucker and another input device appears:

ll /dev/input/by-path/

total 0

lrwxrwxrwx 1 root root 9 Oct 18 10:00 platform-button@1a-event -> ../event0

lrwxrwxrwx 1 root root 9 Oct 18 10:00 platform-rotary@14-event -> ../event2

lrwxrwxrwx 1 root root 9 Oct 18 10:00 platform-soc:shutdown_button-event -> ../event1As with the encoder device, the button device name includes the hex equivalent of the pin number: 26 decimal = 0x1a.

Run some code:

# Keypress from Raspberry Pi GPIO pin using evdev

# Add to /boot/config.txt

# dtoverlay=gpio-key,gpio=26,keycode=83,label="KNOB"

import evdev

b = evdev.InputDevice('/dev/input/by-path/platform-button@1a-event')

print('Button device: {}'.format(b.name))

print(' caps: {}'.format(b.capabilities(verbose=True)))

print(' fd: {}'.format(b.fd))

for e in b.read_loop():

print('Event: {}'.format(e))

if e.type == evdev.ecodes.EV_KEY:

print('Key {}: {}'.format(e.code,e.value))

Which produces this output:

Button device: button@1a

caps: {('EV_SYN', 0): [('SYN_REPORT', 0), ('SYN_CONFIG', 1)], ('EV_KEY', 1): [('KEY_KPDOT', 83)]}

fd: 3

Event: event at 1603036309.683348, code 83, type 01, val 01

Key 83: 1

Event: event at 1603036309.683348, code 00, type 00, val 00

Event: event at 1603036310.003329, code 83, type 01, val 00

Key 83: 0

Event: event at 1603036310.003329, code 00, type 00, val 00

All in all, that was easy …