A month after the last desiccant change, the silica gel looks like this:

The top cup contains fresh-from-stock dry (regenerated) silica gel beads and the others, left-to-right and top-to-bottom, come from PolyDryer boxes:

| Material | %RH | Weight – g | Increase – g | Water gain – % |

| PETG White | 14 | 26.8 | 1.8 | 7.2 |

| PETG Black | 20 | 26.8 | 1.8 | 7.2 |

| PETG Orange | 13 | 26.8 | 1.8 | 7.2 |

| PETG Blue | 15 | 26.9 | 1.9 | 7.6 |

| PETG-CF Blue | 19 | 27.4 | 2.4 | 9.6 |

| PETG-CF Black | 28 | 27.3 | 2.3 | 9.2 |

| PETG-CF Gray | 27 | 27.1 | 2.1 | 8.4 |

| TPU Clear | 13 | 26.8 | 1.8 | 7.2 |

| Sum of weights | 215.9 | 8.0 | ||

| Measured weight | 216.3 | 8.1 |

I expected some correlation between the indicated humidity and the weight of adsorbed water vapor, but that’s not the case.

The bottom row suggests there’s also little-to-no correlation between bead color and humidity, at least at this low end of the scale.

The indicator cards tucked into the boxes roughly correlate with the meter reading, but they’re much easier to interpret in person.

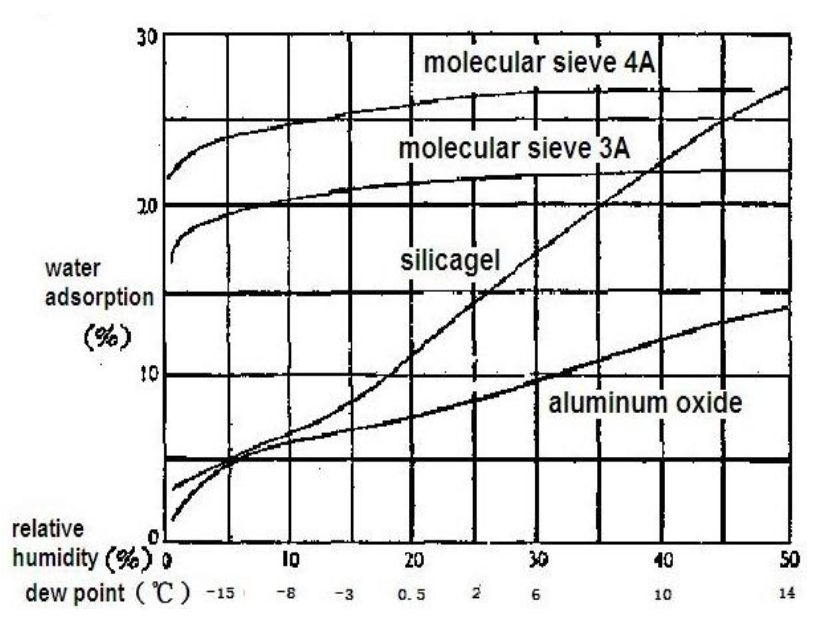

The old chart of adsorption vs. relative humidity suggests the results are plausible, with the 27-ish %RH being higher than you’d expect from 9-ish % adsorption:

So they’re all set up with 25 g of fresh silica gel, although the boxes no long have the same humidity meters they started with. This likely makes little difference, as I have no way to calibrate them.