For several decades, a succession of PCs in the basement have served files and shared printers, the former through NFS and the latter through CUPS. When the Epson R380 finally went casters-up, I got an Epson ET-3830 printer with a network interface, leaving only our venerable HP Laserjet 1200 shared through the server.

For reasons I do not profess to understand, whatever magic shared the printers rotted away over the last month (or, more likely, software updates), to the extent that we could no longer reliably print to the Laserjet. Various software tinkerings being unavailing, I dropped just under thirteen bucks to make the problem Go Away™:

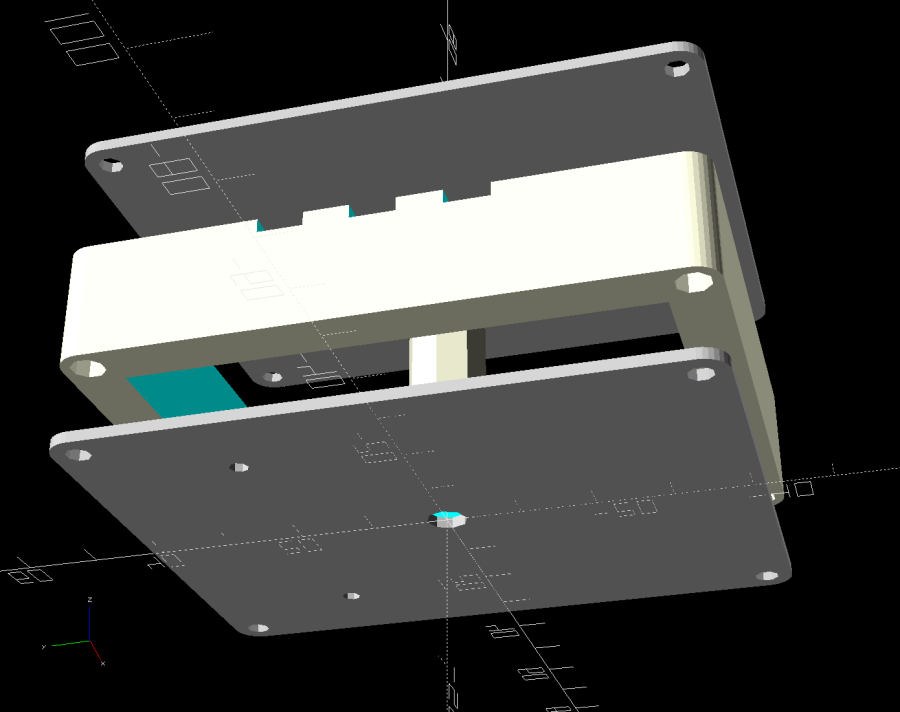

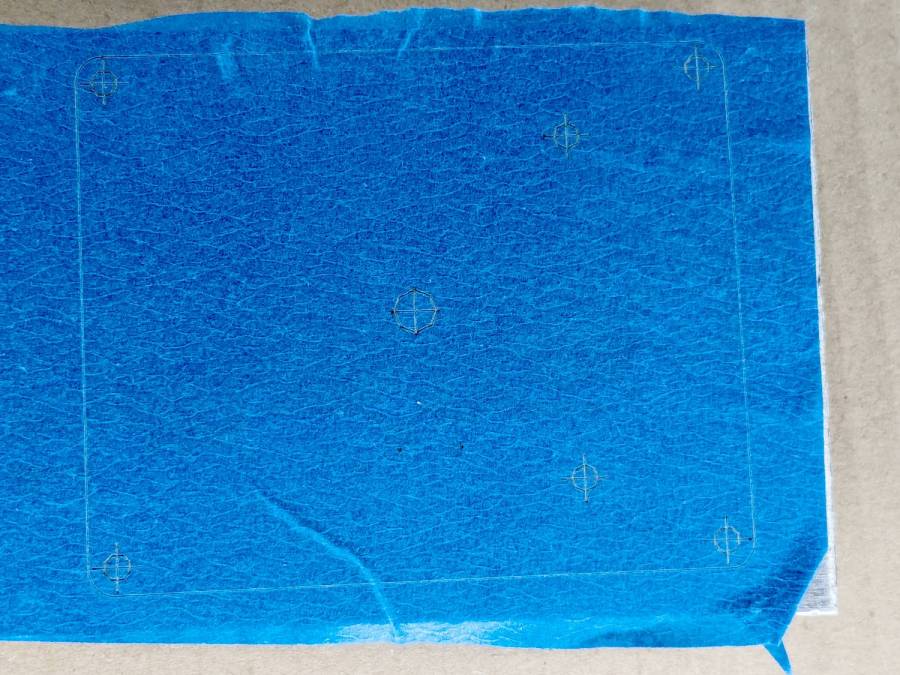

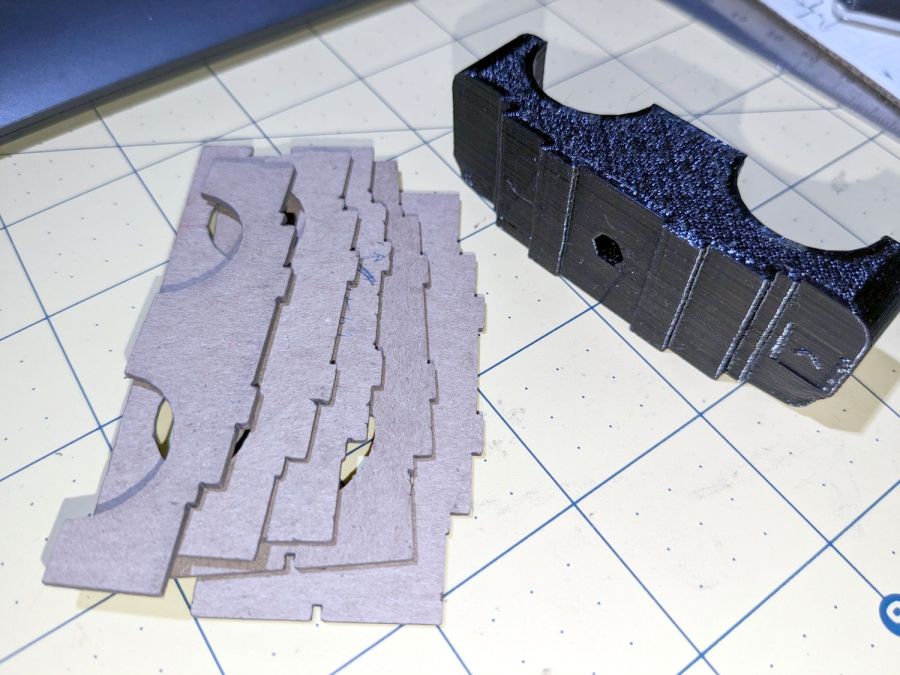

It’s a new-old-stock HP Jetdirect 175x print server from the turn of the millennium, with an Ethernet jack on the back and a USB 1.0 (yes, one-point-zero) jack on the front. It’s roughly contemporaneous with the Laserjet and designed to work with it.

The thing started up in DHCP mode, so I had to ask the router where it was on the network. Configuration then amounted to putting it in static (“Manual”) IP mode, assigning an address, and restarting it.

Aim the CUPS servers on our desktop PCs at the new address, fire off a test page, It Just Worked™, and we’re once again printing like it’s 1999.

That was surprisingly easy.