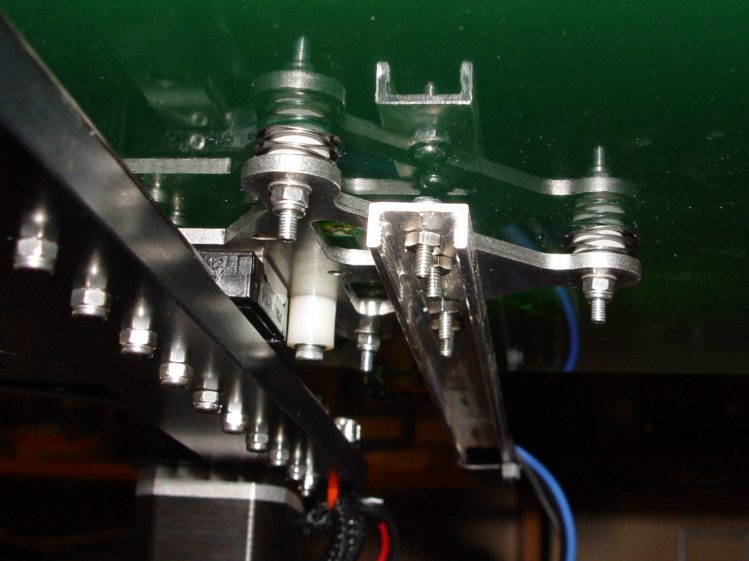

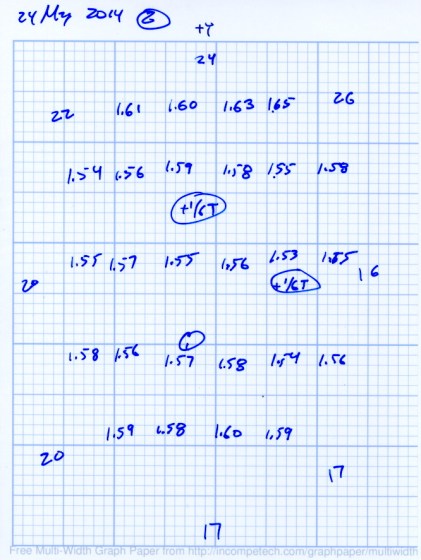

The entire Kenmore Model 158 sewing machine tilts on a pair of pivots extending from the rear of the base, just below the top surface. Mary’s slightly more recent machine has all-steel pivots:

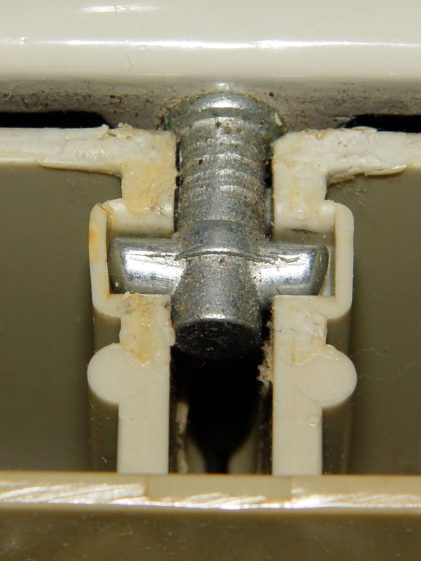

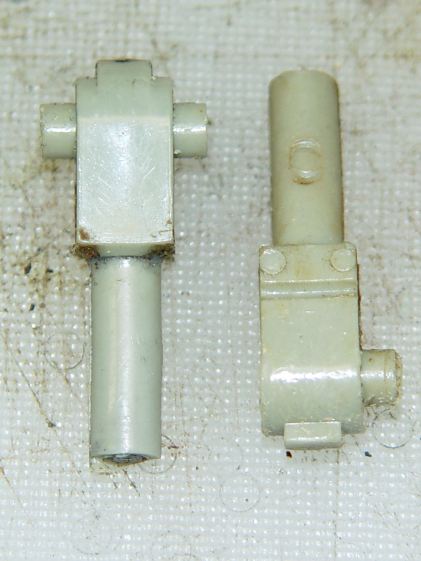

The older crash test dummy machine has two-part pivots, with a plastic housing molded around a steel pin:

Obviously, plastic was the wrong material for the cross pins that rest in the base, leading to the all-steel redesign. Sears no longer stocks replacement parts for those pins, sooo …

Both machines have a large plastic base that’s gradually disintegrating. The plan is to embed the machine frames in countertops, with those cross pins resting on plastic plugs set flush with the surface.

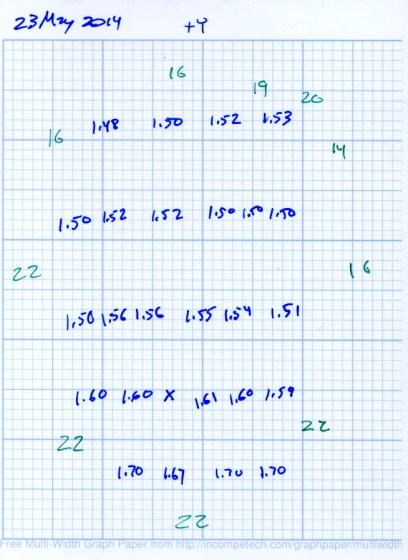

The frame sockets aren’t quite 1/4 inch in diameter; the rest of the hardware uses hard metric sizes, so they’re most likely 6 mm. A 15/64 inch (5.95 mm) drill bit fits snugly and a length of 0.228 inch (5.79 mm) drill rod fits loosely. The round pins are 18 mm long from the shoulder.

The square section is 8.5 mm wide, 9.5 mm tall, and 16 mm long. I have no idea what that mysterious tab on the end is supposed to do.

The cross pins are 5 mm diameter, a scant 15 mm end-to-end, stand 3 mm proud of the central block, and are centered 11 mm out from the edge of the block. I’d make them longer, to distribute the machine’s weight over more of the plugs in the countertop when it’s tilted back.

I can’t duplicate the newer forged steel pins and, for sure, they’re not good candidates for 3D printing. Perhaps:

- Saw off 16 mm of 3/8 inch (9.5 mm) square stock

- Blind drill 16/64 inch for the 0.228 main pin

- Cross drill #12 for a 3/16 inch pin

- Epoxy everything together

- File off the sharp edges

For the moment, the crash test dummy sits happily on the three legs that the designers thoughtfully cast into its frame.